Introduction to 3D Printing Solutions

3D printing solutions represent a transformative advancement in the field of manufacturing. Assuredly, this cutting-edge technology completely redefines traditional methodologies by facilitating seamless transition from design blueprint to physical production. The importance of bridging the gap between design and manufacturing cannot be overstated as it expedites product development while maintaining optimal quality control. In essence, 3D printing provides an efficient, precise and cost-effective solution for various industries, augmenting their capabilities in product customization and rapid prototyping. Hence, understanding its operations will equip designers with an unprecedented level of flexibility and innovation potential.

Understanding the Gap Between Design and Manufacturing

In traditional design-to-manufacturing processes, designers create prototypes using Computer-Aided Design (CAD) software. This digital model is then translated into a physical product by manufacturers through various procedures, such as molding or machining. However, this conventional approach poses certain limitations and challenges. Miscommunication often arises due to discrepancies in translating designs into tangible items, leading to errors that require time-consuming iterations for rectification and improvement. Furthermore, the process of creating molds and tools necessary for large-scale production significantly increases the overall cost. Thus, the rift between designing a product and its subsequent manufacturing stages can manifest in several ways – inaccurate outcomes due to communication gaps, delays from multiple revisions, and elevated costs associated with preparing production equipment.

Role of 3D Printing Solutions

3D printing, also known as additive manufacturing, is a technology that facilitates the creation of three-dimensional objects from digital models. This process involves layering or adding materials in precise manners to form an object, offering several advantages over traditional manufacturing techniques like machining or injection molding. Firstly, it allows designers the freedom to create complex geometries and intricate details which might be difficult or impossible with traditional methods. By incorporating this technology in design processes, companies can swiftly move from idea inception to testing physical prototypes. Moreover, rapid prototyping helps validate designs quicker, providing real-time feedback on potential design flaws – ensuring only optimized products make it to the market.

This revolutionary tool fundamentally streamlines manufacturing processes by eliminating costly and time-consuming tooling methods. Rather than managing extensive inventories, businesses can switch to demand-driven production—manufacturing parts as needed, reducing waste, and saving costs. Even more transformative, personalization opportunities are no longer restricted by mass production constraints; individual customizations can be accommodated effectively without additional time or cost burdens. In essence, 3D printing solutions seamlessly connect design and manufacturing phases boosting efficiencies across product development cycles.

Case Study: Implementation of 3D Printing in the Automotive Industry

The automotive industry has been at the forefront of adopting 3D printing technologies, leveraging them for a variety of applications that streamline the design and manufacturing process. This case study explores how 3D printing has been implemented in the automotive sector, highlighting specific uses and the benefits derived from this innovative technology.

Applications of 3D Printing in Automotive Manufacturing

- Prototyping and Design Iteration: Rapid prototyping allows for quick feedback and multiple iterations without the need for expensive tooling.

- Customization of Parts: 3D printing enables the production of customized parts and components, catering to specific vehicle customizations or aftermarket modifications.

- Production of Low-Volume or Specialty Vehicles: For limited edition models or specialized vehicles, 3D printing offers a cost-effective production method.

- Creation of Tooling and Manufacturing Aids: Jigs, fixtures, and other manufacturing aids are produced quickly and at a lower cost.

Benefits of 3D Printing in the Automotive Industry

3D printing technologies have brought about significant benefits in the automotive industry, including reduced development time, lower production costs, and the ability to produce complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. Additionally, the flexibility of 3D printing supports the automotive industry’s push towards customization and rapid innovation.

| Application | Description | Benefit |

|---|---|---|

| Prototyping | Quick production of prototypes for testing and validation | Speeds up the R&D process, reducing time to market |

| Custom Parts | Manufacturing of bespoke components for specific needs | Enables customization and personalization at lower costs |

| Specialty Vehicle Production | Efficient production method for low-volume models | Reduces waste and costs associated with small batch production |

| Tooling and Aids | Creation of tools and aids for the manufacturing process | Improves manufacturing efficiency and reduces operational costs |

In conclusion, the implementation of 3D printing in the automotive industry has not only enhanced the efficiency and flexibility of manufacturing processes but also opened up new avenues for innovation and customization. As the technology continues to evolve, its applications within the automotive sector are expected to expand further, driving the industry towards more agile and cost-effective manufacturing solutions.

Other Articles You Might Enjoy

- design for 3d printing how to reduce your cost

Relevance and Benefits of Cost Reduction in 3D Printing In an era where innovation is pivotal, 3D printing emerges as a transformative force across numerous industries, from manufacturing complex aerospace…

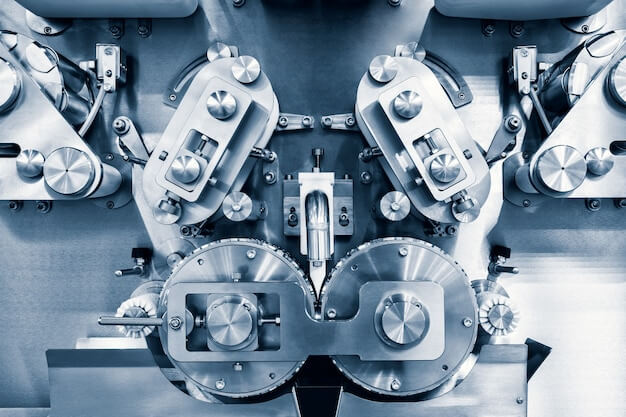

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- CNC Machining for Medical Applications: Compliance and Material Selection?

Introduction to CNC Machining in Medical Applications CNC or Computer Numerical Control machining is a manufacturing process wherein pre-programmed computer software dictates the movement of factory tools and machinery. This…