Introduction to Custom Part Manufacturing and the Importance of Quality Control

Custom part manufacturing is a specialized branch of industrial production where components are designed, produced and tested according to unique client specifications. Consistency, accuracy, and adherence to standards are vital for successful outcomes in this type of engineering process. Quality control, hence, becomes critical in custom part manufacturing to ensure that each manufactured piece meets stringent quality parameters before it reaches the customer. This not only ensures product reliability but also significantly minimizes wastage caused by defects or variances from defined specifications. For instance, in automotive custom part manufacturing, quality control could involve electronic testing of sensors to verify their precision, thereby preventing potential vehicle malfunctions.

The Role of Quality Control Before Production

Quality control is an integral aspect at the pre-production stage in custom part manufacturing. Initially, it involves a meticulous analysis and evaluation of customer requirements, for example understanding specific design specifications. This process ensures that any produced parts align seamlessly with what customers need. A wrong interpretation could lead to costly errors or complications later in production. Additionally, selection of suitable materials is pivotal in quality control; for instance, choosing the correct type of metal based on its function in a part can significantly impact overall performance. All these elements are examined meticulously before production begins to assure top-notch output while eliminating chances for potential product recalls or losses due to poor quality.

The Role of Quality Control During the Production Process in Custom Part Manufacturing

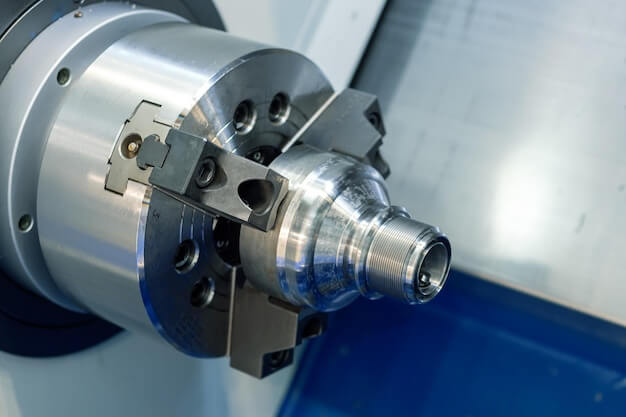

Quality control (QC) plays a pivotal role in the production process of custom part manufacturing, ensuring that each component meets the predefined standards and specifications. This rigorous process involves a series of steps and methodologies designed to maintain the integrity of the manufacturing process and the quality of the output.

Key Aspects of Quality Control in Custom Part Manufacturing

- Early Detection of Defects: QC methodologies are implemented at various stages of the production process to identify and rectify defects early, preventing them from advancing to later stages where they become more costly to address.

- Adherence to Specifications: Through precise measurement and testing, QC ensures that each custom part strictly adheres to the client’s specifications, maintaining the functionality and performance of the part.

- Use of Advanced Technologies: Automation and advanced technologies play a significant role in QC by providing accurate and consistent results, reducing human error, and improving the efficiency of the QC process.

Methods Utilized in Quality Control

| Method | Description | Application |

|---|---|---|

| Quality Control Charts | Track variances in product attributes to identify trends and outliers. | Used for monitoring and controlling the production process to ensure consistency. |

| The Taguchi Method | Focuses on design and development phases to minimize variance in production. | Applied in the early stages of custom part manufacturing to enhance product quality. |

| 100% Inspection | Assessing all parts to identify and eliminate defects. | Crucial for high-precision components where defects cannot be tolerated. |

Implementing effective QC measures during the production process of custom parts not only ensures the quality and reliability of the manufactured components but also reinforces the manufacturer’s commitment to excellence. By employing a combination of traditional and innovative QC methods, manufacturers can achieve superior product quality, thereby contributing to the overall success of the business.

The Role of Quality Control After Production

In custom part manufacturing, quality control plays a vital post-production role involving inspection and testing of finished parts. For example, checking the surface finish is an integral step, which requires specialized equipment to ensure precision and accuracy consistently. Beyond mere physical examination, quality control also encompasses documentation and record-keeping. These systematic records serve as a concrete reference for all quality control measures taken during the production process. One such form of documentation could involve maintaining traceability records. Traceability records are particularly invaluable when any issues arise with the finished product or if specific data about the component’s manufacture is needed later on. Hence, they provide evidence of due diligence in adhering to set standards and can even be presented during audits. In essence, quality control retains its importance from start to finish — ensuring every manufactured part meets the highest possible standard.

The Benefits of Effective Quality Control in Custom Part Manufacturing

Quality control plays a pivotal role in custom part manufacturing, owing to its broad range of benefits. Firstly, an efficient QC mechanism can significantly reduce wastage and cut down production costs because it pre-empts defect creation during the manufacturing phase, thus saving resources. Secondly, quality control also enhances customer satisfaction and trust. A product that consistently meets the desired specifications will invariably boost customer confidence, thereby building strong relationships with them. Moreover, by ensuring that all manufactured parts meet strict quality standards, the overall product quality and reliability are enhanced. For instance, if one is manufacturing customized vehicle components, rigorous testing for tolerance, strength, etc., could ensure the longevity of the end product, boosting the credibility of the manufacturer ultimately.

Other Articles You Might Enjoy

- The Dependable Quality Assurance in China CNC Machining

1. Introduction: Setting the Stage for Quality Excellence In this introductory section, we lay the groundwork for an exploration into the world of quality assurance in China CNC machining. We…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- Transforming Architecture with CNC Machined Aluminum Facades

Transforming Architecture with CNC Machined Aluminum Facades CNC machined aluminum facades are a significant innovation in the architectural industry due to their innovative design, structure, and aesthetics. Through a process…