Introduction to CNC Machining and Ceramic Composite Materials

CNC (Computer Numerical Control) machining is a pivotal manufacturing process in the aerospace industry. It’s characterized by automated control of machine tools through software inputs, ensuring precision-engineering of components that are critical for constructing aircrafts and their engines. This meticulous approach enhances accuracy, quality control and contributes significantly to safer, more efficient flight operation.

China Online CNC Machining Service

In parallel, ceramic composite materials have surfaced as an indispensable resource in this realm. A fusion of different types of ceramic particles or fibers, these materials merge properties like high thermal stability, corrosion resistance and low weight – that synergistically cater to rigorous demands of aerospace applications:

- High Thermal Stability: Aircraft components constantly face extreme temperature shifts from cryogenic cold at stratospheric altitudes to intense heat during atmospheric re-entry. Ceramics composites efficiently withstand such harsh fluctuations without degrading.

- Corrosion Resistance: Aerospace components are routinely exposed to factors leading to corrosion over time. The anti-corrosive property of ceramics allows essential prolonged component lifespan.

- Reduced Weight: Aviation efficiency largely relies on reducing total payload weight, enhancing fuel economy and operational range. Ceramic composites’ light-weight characteristics help drastically cut-down total aircraft body weight.

The intriguing symbiosis between CNC machining and ceramic composite materials continues to push boundaries of innovation in aerospace technology.

The Traditional Use of Metals in CNC Machining

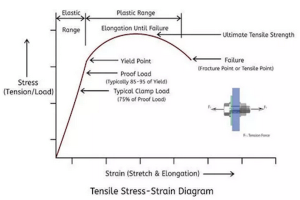

In the sphere of Computer Numerical Control (CNC) machining, metals have conventionally been the choice materials for manufacturing various components. Traditionally, typical materials used in this process include aluminum, steel, brass, copper, and titanium. Each metal carries with it a set of strengths as well as drawbacks.

For instance, Aluminum is lightweight yet durable making it suitable for high-speed machining procedures. It is resistant to corrosion which enhances the longevity of components fabricated from this metal, however, its softness can create some intricacy during machining when aiming for sharp corners or fine details.

Moreover, steel provides extreme durability and strength, but its hardness makes it slower and more energy-consuming to manufacture components from this material.

Brass and Copper spotlight excellent heat resistance and electrical conductivity but their cost-effectiveness might not always be ideal.

Titanium, despite its superb strength-to-weight ratio and impressive resistance against extreme temperatures and chemical damage, has a higher raw material cost and requires sophisticated tooling techniques due to its toughness.

Useful Features and Benefits of Ceramic Composite Materials in CNC Machining

When considering ceramic composite materials in CNC machining, it’s important to note the following features and benefits:

- Ceramic composites offer exceptional heat resistance and thermal stability, making them suitable for high-temperature applications in aerospace components.

- These materials exhibit high strength-to-weight ratios, providing lightweight yet durable solutions for aerospace machining.

- They offer excellent wear resistance and low thermal expansion, contributing to the longevity and reliability of machined components.

Current Applications of Ceramic Composites in Aerospace Components

Ceramic composite materials can be increasingly found utilized within the aerospace industry, notably providing significant contributions to improved performance and efficiency. For instance, they feature prominently in aircraft engine components such as turbines and exhaust nozzles due to their heat resistance qualities. Notably, Rolls-Royce’s Advance3 demonstrator has validated ceramic-matrix composites (CMCs) use for high-pressure turbines.

The benefits provided by these materials compared to traditional metal parts are manifold:

- Durability: Ceramic composites provide increased durability under extreme conditions. Their superior hardness, wear-resistance, and thermal stability makes them better adapted to environments with high temperatures and pressures typically seen in aerospace applications.

- Lightweight: Ceramic composites have a lower density than metals which reduces overall weight. This reduction increases fuel efficiency and decreases operational costs by decreasing energy usage during operation.

- Thermal Resistance: Unlike metallic components that may deform or degrade at high temperatures, ceramic composites ensure long-life service thanks to their excellent thermal shock resistance properties.

In conclusion, current implementation justifies that ceramic composites are not simply theoretical material alternatives; they make strong cases to become future cornerstones specific for aerospace technology.

Potential Drawbacks or Challenges with Utilising Ceramic Composites

In CNC machining, moving from metals to ceramic composites presents several logistical and technical constraints. For one, ceramics are notoriously difficult to machine due to their hardness and brittleness. Consequently, traditional methods of fabrication often lead to fractures, resulting in high wastage rates.

- Machining also requires specialised tooling, which translates into additional expenses.

- Ceramic materials generally have a lower thermal conductivity than metals, necessitating advanced cooling techniques during machining.

- The production process can be lengthy due to the need for sintering and other post-processing activities.

Furthermore, there are certain limitations regarding the use of ceramic composites in CNC machining. These include problems associated with variation in material properties such as their response to heat, their inherent brittleness, susceptibility to cracks, and difficulty in achieving precise dimensions and thin walls. In aerospace components where precision is crucial, these could potentially limit the practicality of using ceramics despite their many advantages over traditional metallics.

The Future: Are Ceramic Composite Materials a Progressive Solution for Aerospace Components?

Recent research and development endeavors have displayed an increasing trend of utilizing ceramic composite materials in Computer Numerical Control (CNC) machining, leading to predictions that they may represent the future progression within aerospace component manufacturing. Due to their lightweight properties, thermal resistance,and mechanical strength, ceramics exhibit superb performance indicators for aerospace applications. Recent studies show advancements in matrix composites, shedding light on their adaptability for diverse applications including turbine engines.

- Ceramic Matrix Composites (CMCs): Currently gaining attention due to their high-temperature resistance while maintaining structural rigidity. This makes them suitable for demanding environments such as aircraft engine systems.

- Silicon Carbide (SiC) Composites: Show stability under extreme conditions promising strong potential for higher efficiency engine designs in aerospace industries.

In conclusion, given the continual innovation surrounding ceramic composites in CNC machining and growing adoption trends, these materials appear set to significantly influence futurology of aerospace components soon.

Conclusion

In conclusion, ceramic composite materials have shown immense potential for usage in CNC machining processes. They stand out due to their excellent heat resistance, lightweight properties, and superior strength when compared to other materials such as metal alloys typically used in aerospace component manufacturing. Evidence clearly stipulates the following benefits of these composites:

- The ability to maintain structural integrity despite high-temperature environment.

- Superior weight-to-strength ratio, facilitating lighter and more efficient aerospace designs.

- An increased durability that promises longer service life of components.

Such traits not only reduce the maintenance time and cost, but also enhance overall performance of the aircraft, providing a compelling case for their adoption in future. Thus, considering the evidence presented, it could be posited that ceramic composite materials are poised to play a critical role in shaping the future of aerospace parts’ production through CNC machining methods.

Other Articles You Might Enjoy

- Guide to Selecting High-Performance Materials for CNC Machined Aerospace Components

Understanding CNC Machining in the Aerospace Industry and the Importance of High-Performance Materials Selection The aerospace industry widely utilizes Computer Numerical Control (CNC) machining for manufacturing sophisticated components. This high…

- Aerospace CNC Machining: What You Need to Know

At present, the global aerospace industry market value has increased by 278.43 billion, an increase of 6.6% compared to 2022. The ultra-high value proves that innovation in the aerospace industry…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu