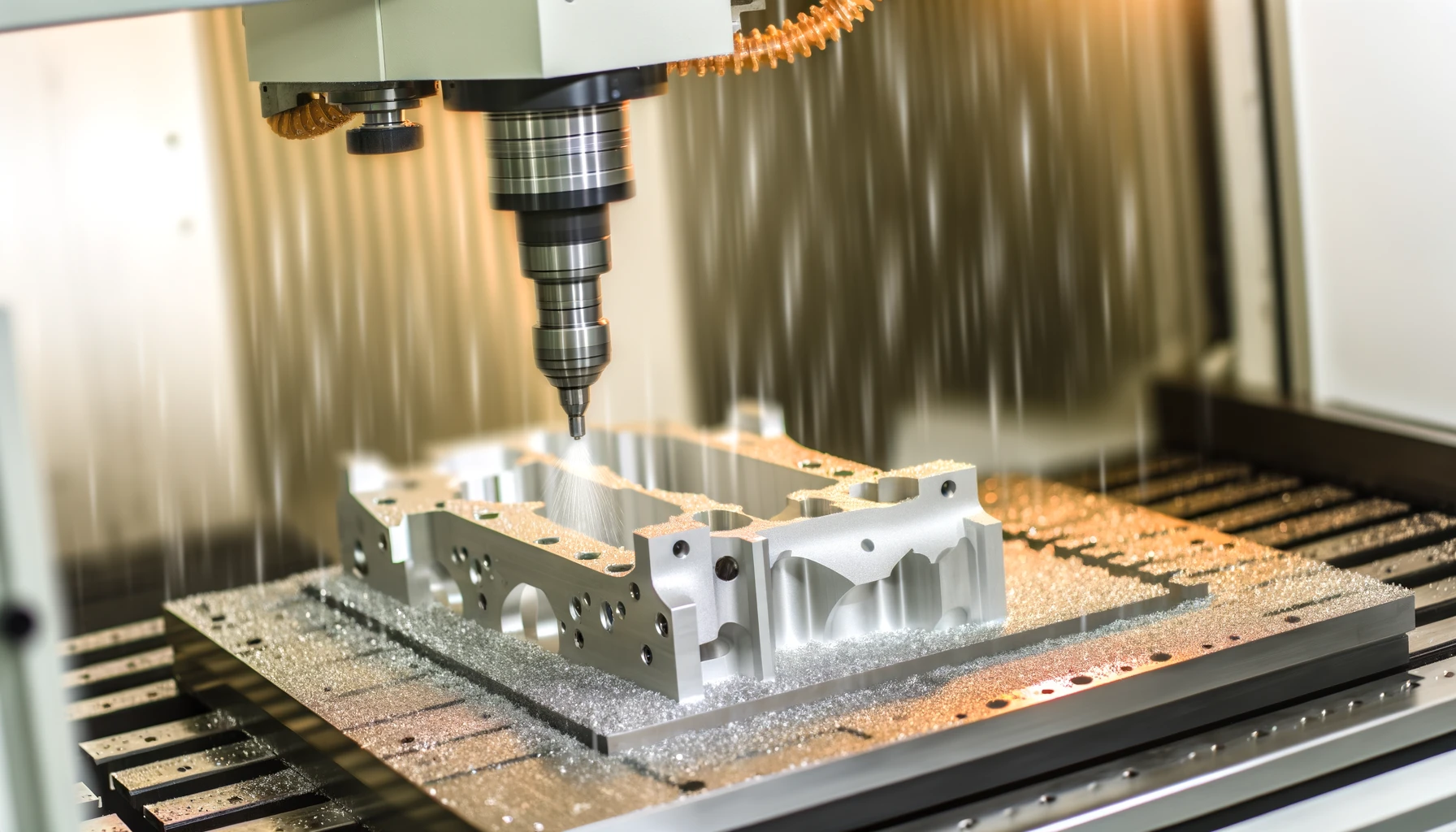

Introduction to Aluminum in Precision CNC Machining

Aluminum is renowned for its lightweight yet strong properties, making it a preferred material in industries ranging from aerospace to electronics. Its adaptability and excellent thermal and electrical conductivity also contribute to its widespread use. However, aluminum presents unique challenges when subjected to precision CNC machining processes. These challenges stem from its inherent physical properties such as its softness and susceptibility to heat. Understanding how to effectively manage these challenges is crucial for any CNC technician or engineer looking to optimize their machining processes.

In this article, we will explore the various strategies and innovations in precision CNC machining that are specifically tailored to overcome the difficulties associated with machining aluminum. By examining tool optimizations, cooling techniques, and the implementation of advanced machining technologies, we’ll provide a comprehensive look at how these challenges are addressed.

aluminum cnc machining service

What Makes Aluminum Difficult to Machine Precisely?

Aluminum, despite its many benefits, is notorious for its machining challenges. The softness of aluminum can lead to issues like burring and deformation during the cutting process. Additionally, the non-ferrous nature of aluminum means it does not generate sparks when machined, which while generally safer, can complicate the machining process by not providing visual feedback that is sometimes crucial for ferrous materials.

Key Challenges:

- Burring: The formation of burrs is prevalent due to the softness of aluminum, requiring additional finishing processes.

- Deformation: Aluminum’s low melting point relative to other metals means it can easily deform if improper machining techniques are used or if excessive heat builds up.

- Tool Adhesion: Aluminum’s stickiness can lead to material adhering to the cutting tools, degrading the tool’s effectiveness and requiring frequent stops to clean the tools.

Understanding these challenges is the first step towards developing effective strategies to mitigate them, ensuring the precision required in high-stakes industries is maintained.

How Are Cutting Tools Optimized for Aluminum?

Selecting the right cutting tools is paramount in precision CNC machining of aluminum. The choice of tool material, geometry, and coating determines the quality of the machining process and the longevity of the tool itself. Tools must be specifically designed to handle the unique properties of aluminum, such as its tendency to stick and deform.

Optimizations include:

- Material Selection: Polycrystalline diamond (PCD) and carbide tools are preferred for their hardness and resistance to wear.

- Geometry: Tools with sharper angles and more flutes are used to efficiently evacuate chips from the work area, preventing re-cutting and reducing heat buildup.

- Coatings: Using coatings like TiB2 (Titanium Diboride) can significantly reduce sticking and provide a smoother finish.

Data Table: Tool Comparison

| Tool Material | Wear Resistance | Cost | Effectiveness in Aluminum |

|---|---|---|---|

| Carbide | High | Moderate | Very High |

| PCD | Very High | High | High |

| High-Speed Steel | Low | Low | Moderate |

| Coated Carbide | High | High | Very High |

This table clearly demonstrates the trade-offs and benefits associated with different tool materials and their suitability for aluminum machining.

By focusing on optimizing tool selection and usage, manufacturers can improve their machining efficiency and reduce the occurrence of common machining issues. In the following sections, we will delve into advanced cooling techniques and best practices for high-speed machining, which play critical roles in further enhancing the machining of aluminum.

Can Advanced Cooling Techniques Prevent Material Deformation?

When machining aluminum, controlling the temperature is crucial to prevent material deformation and ensure the accuracy of the machined parts. Excessive heat can cause aluminum to soften and warp, which not only compromises the dimensional stability of the part but also can lead to tool failure. Advanced cooling techniques are therefore employed to maintain optimal cutting temperatures and improve the overall machining process.

Cooling Methods:

- Flood Cooling: This method involves drenching the cutting area with coolant to rapidly cool the part and flush away chips.

- Mist Cooling: A more economical and environmentally friendly option, mist cooling uses a fine spray to cool the area without the need for large quantities of coolant.

- Cryogenic Cooling: This innovative approach uses liquid nitrogen to dramatically reduce temperatures, providing excellent results in terms of finish quality and tool life.

Case Study: Implementation of Cryogenic Cooling in Automotive Parts Production

A leading automotive parts manufacturer introduced cryogenic cooling to their aluminum machining process. The use of liquid nitrogen not only prevented thermal deformation but also allowed for faster machining speeds, increasing throughput by 20%. This case study demonstrates the effectiveness of advanced cooling techniques in combating the thermal challenges of machining aluminum.

What Are the Best Practices for High-Speed Machining of Aluminum?

High-speed machining (HSM) of aluminum is a powerful technique to achieve high-quality finishes and precise dimensions, particularly in industries where time and accuracy are critical. The key to successful high-speed machining lies in the careful selection of cutting parameters and the use of appropriate equipment.

Optimal High-Speed Machining Parameters:

- Spindle Speed: Higher spindle speeds help to achieve a smoother surface finish by minimizing the contact time between the tool and the material, reducing the chances of heat build-up.

- Feed Rate: Optimizing the feed rate ensures efficient chip removal and prevents the tool from dwelling too long at any point, which can generate heat and lead to tool wear.

- Depth of Cut: A shallower depth of cut can be used effectively in high-speed settings to minimize the load on the tool and improve the surface quality.

Data Table: High-Speed Machining Parameters for Aluminum

| Parameter | Recommended Setting | Impact on Machining |

|---|---|---|

| Spindle Speed | 10,000 – 20,000 RPM | Enhances surface finish |

| Feed Rate | 0.01 – 0.05 inches | Optimizes chip removal |

| Depth of Cut | 0.1 – 0.3 inches | Reduces tool wear |

By adhering to these parameters, manufacturers can significantly improve the efficiency and outcome of their aluminum machining processes.

How Do Precision CNC Machining Centers Adapt to Aluminum’s Challenges?

The performance of CNC machining centers is critical in addressing the specific challenges posed by aluminum. Innovations in machine design and adaptive technologies have enabled more precise control over the machining process, leading to better quality and less waste.

Adaptive Features Include:

- Enhanced Spindle Control: This allows for adjustments in real-time to maintain optimal cutting conditions despite variations in material properties or tool wear.

- Vibration Damping: Advanced damping systems reduce vibrations during machining, which is crucial for maintaining accuracy and achieving a high-quality finish.

Case Study: Upgrading CNC Centers for Better Aluminum Machining

An aerospace components manufacturer upgraded their CNC centers with enhanced spindle control and vibration damping capabilities. These upgrades resulted in a 25% reduction in machining errors and a 30% improvement in the surface quality of aluminum parts.

What Role Does Surface Treatment Play in Machining Aluminum?

Surface treatment of CNC machined aluminum parts is not merely about aesthetics; it significantly enhances the mechanical properties and durability of the parts. These treatments can improve resistance to corrosion, increase surface hardness, and even provide better electrical and thermal conductivity, which are crucial for certain applications.

Common Surface Treatments:

- Anodizing: This electrochemical process thickens the natural oxide layer on the surface of aluminum parts, improving their corrosion resistance and wear properties. It also allows for color dyeing, which is beneficial for parts that application of oxide layers that further enhance the durability and performance of aluminum parts under extreme conditions.

- Powder Coating: This surface treatment provides a protective and decorative finish. It’s particularly useful for improving wear and tear resistance and adding vibrant colors to the parts.

Data Table: Effects of Various Surface Treatments on Aluminum

| Surface Treatment | Corrosion Resistance | Wear Resistance | Aesthetic Impact | Application Example |

|---|---|---|---|---|

| Anodizing | High | Medium | High (colorable) | Automotive trim |

| Hard Coating | Very High | High | Low | Industrial machinery |

| Powder Coating | Medium | High | High | Consumer electronics |

By selecting appropriate surface treatments, manufacturers can significantly extend the life of their products and tailor the properties of aluminum parts to specific operational requirements.

How Are Tolerances Achieved and Maintained in CNC Machining of Aluminum?

Achieving and maintaining precise tolerances is one of the key challenges in the CNC machining of aluminum, given its propensity to deform under machining stresses. Precision in CNC machining is critical, especially in industries where even minute deviations can lead to significant operational failures.

Key Strategies:

- Use of Precision Tooling: Employing high-quality tools that can maintain sharpness over extended periods is crucial.

- Real-time Monitoring Systems: These systems provide continuous feedback during the machining process, allowing for immediate adjustments to maintain accuracy.

- Automated Feedback Mechanisms: Integrating these mechanisms helps compensate for tool wear and material inconsistencies, ensuring consistent quality throughout production runs.

Case Study: Aerospace Component Manufacturing

In aerospace manufacturing, where tolerances are critical, a company implemented real-time monitoring and automated feedback mechanisms to maintain tight tolerances. The introduction of these systems reduced scrap rates by 40% and increased the reliability of the aerospace components produced.

Conclusion

Throughout this article, we’ve explored the various challenges associated with precision CNC machining of aluminum and the innovative strategies and technologies that have been developed to overcome these issues. From advanced tooling and cooling techniques to adaptive machinery and sophisticated surface treatments, the field of CNC machining continues to evolve. As we advance further into the era of smart manufacturing, these developments promise to enhance not only the capabilities of CNC machines but also the overall productivity and quality of the manufacturing industry.

Other Articles You Might Enjoy

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…

- Revolutionizing CNC Machining for Complex Aerospace Assemblies

Introduction to CNC Machining in Aerospace Assemblies Computer Numerical Control (CNC) machining represents a significant technological development playing a notable role in the creation of complex aerospace assemblies. CNC machining…