What is the Total Cost of Ownership (TCO) for Brass CNC Machining Parts?

Understanding the Total Cost of Ownership (TCO) for brass CNC machining parts is crucial for businesses to make informed purchasing and operational decisions. TCO encompasses all costs associated with the procurement, operation, maintenance, and eventual disposal or recycling of CNC machined parts.

Elements of TCO:

- Procurement Costs: This includes the cost of raw materials, transportation, and any initial processing fees.

- Operational Costs: Costs incurred during the life of the parts such as energy consumption, labor for operation, and other overheads.

- Maintenance and Replacement Costs: Regular maintenance costs and costs for replacing parts or the whole system when they fail or reach the end of their lifespan.

- End-of-Life Costs: Costs associated with disposing of or recycling the parts at the end of their useful life.

Example: Calculating TCO for a Brass CNC Machined Part

Suppose a company is manufacturing a brass gear used in automotive transmissions. To calculate the Total Cost of Ownership for this brass CNC machined part, we’ll consider several cost factors over a projected lifespan of 5 years.

- Procurement Costs:

- Material Costs: The gear requires 0.5 pounds of brass, costing $3.00 per pound, totaling $1.50.

- Transportation: Shipping and handling costs amount to $0.50 per part.

- Operational Costs:

- Machining: Each gear takes 30 minutes to machine, with machine operating costs at $50 per hour, amounting to $25.00 per gear.

- Labor: Labor costs for machining are $20 per hour, so labor cost per gear is $10.00.

- Maintenance and Replacement Costs:

- Tool Wear: The specific CNC tools used for brass need replacement after producing 1,000 gears, with each tool costing $200, adding $0.20 per gear.

- Maintenance of the Machine: Annual maintenance of the CNC machine is estimated at $1,000, allocated across the production of 2,000 gears annually, contributing $0.50 per gear.

- End-of-Life Costs:

- Recycling: At the end of its life, the brass gear can be recycled, with a net end-of-life recovery value of $0.10 per gear.

- Total Cost Calculation:

- Initial Procurement Costs: $1.50 (materials) + $0.50 (transport) = $2.00

- Operational Costs: $25.00 (machining) + $10.00 (labor) = $35.00

- Maintenance and Replacement Costs: $0.20 (tool wear) + $0.50 (machine maintenance) = $0.70

- Net End-of-Life Recovery: -$0.10 (recycling benefit)

- Total Cost of Ownership per Gear over 5 Years: $2.00 + $35.00 + $0.70 – $0.10 = $37.60

In this example, the total cost of ownership for one brass gear, considering all direct and indirect costs plus end-of-life recovery, is $37.60. This calculation helps the company understand not just the upfront costs but all contributing factors over the gear’s useful life, allowing for more informed financial planning and pricing strategies

How Does Raw Material Cost Impact the TCO of Brass CNC Parts?

The cost of raw materials is a fundamental component of the total cost of ownership for brass CNC machining parts. Given the volatility in metal markets, fluctuations in brass prices can significantly impact the initial cost and, consequently, the entire lifecycle cost of CNC machined parts.

Understanding Brass Market Dynamics:

- Global Supply and Demand: The price of brass is influenced by global copper and zinc markets, as brass is primarily an alloy of these two metals.

- Economic Factors: Economic downturns, trade policies, and geopolitical events can all affect brass prices by altering supply chain dynamics.

- Recycling Rates: The availability of recycled brass can also impact raw material costs, as higher availability can reduce the need for virgin materials.

Data Table: Historical Brass Price Trends

| Year | Average Price per Pound | Major Influencing Event |

|---|---|---|

| 2018 | $2.20 | Stable global demand |

| 2019 | $2.35 | Increased industrial demand |

| 2020 | $1.95 | Economic impact of COVID-19 |

| 2021 | $2.50 | Recovery and increased demand |

| 2022 | $2.40 | Stabilizing market conditions |

Case Study: Impact of Price Volatility

An automotive parts manufacturer that relies heavily on brass for components faced significant challenges in 2020 due to soaring brass prices amid pandemic-related disruptions. To mitigate these challenges, the company diversified its supply chain and increased its use of recycled brass, reducing its material costs by 15% in 2021.

Strategies to Mitigate Material Cost Impact:

- Long-term Supply Contracts: Locking in prices with long-term contracts can protect against short-term price volatility.

- Alternative Material Sources: Exploring alternative suppliers or recycled materials can reduce dependence on fluctuating markets.

- Efficiency in Design and Production: Optimizing part design to use less material without compromising quality can directly reduce the material cost per unit.

What Are the Manufacturing Costs Associated with Brass CNC Machining?

The manufacturing costs for brass CNC machining parts are a significant component of the total cost of ownership. These costs are influenced by several factors including the complexity of the parts, the machining processes used, and the efficiency of the production methods.

Breakdown of Manufacturing Costs:

- Material Costs: The price of brass itself, which can vary based on market conditions.

- Machining Costs: Direct costs associated with CNC machining such as machine wear and tear, energy usage, and tooling.

- Labor Costs: Wages paid to machine operators and technicians.

- Overhead Costs: Includes factory overheads like rent, utilities, and management expenses.

Case Study: Reducing Manufacturing Costs

A CNC shop specializing in brass parts implemented lean manufacturing techniques which resulted in a 20% reduction in labor costs and a 15% reduction in waste materials, significantly lowering the per-part manufacturing cost.

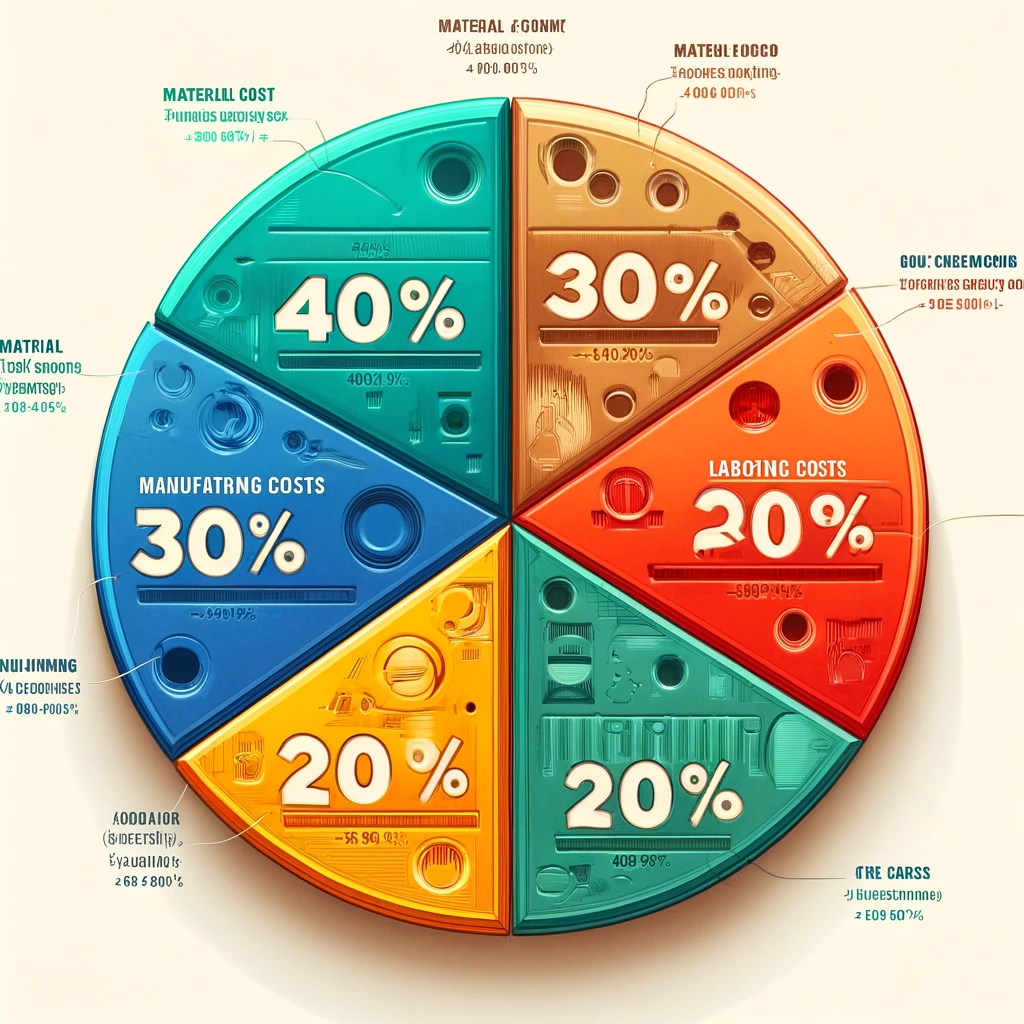

Data Table: Cost Breakdown for Manufacturing Brass CNC Parts

| Cost Type | Percentage of Total Cost | Example Values |

|---|---|---|

| Material Costs | 40% | $4.00 per part |

| Machining Costs | 30% | $3.00 per part |

| Labor Costs | 20% | $2.00 per part |

| Overhead Costs | 10% | $1.00 per part |

Graphical Representation:

The chart is divided into four major categories: Material Costs, Machining Costs, Labor Costs, and Overhead Costs, each represented by a distinct color. This visual aids in understanding how each component contributes to the total manufacturing cost. You can view the chart above.

How Do Design Choices Influence the Overall Cost of Brass CNC Parts?

Design decisions play a critical role in the manufacturing cost and overall efficiency of producing brass CNC parts. The complexity of a part’s design can significantly influence both the machining time and the amount of material used, which are major components of the total cost.

Impact of Design on Production:

- Complexity: More complex designs require longer machining times and more intricate tool paths, which can increase both tool wear and the chance of errors during production.

- Tolerances: Tighter tolerances demand precision machining, which may lead to slower production rates and higher costs due to more frequent tool changes and slower feed rates.

- Material Utilization: Efficient design can reduce material waste, which is crucial given the fluctuating costs of brass.

Graph: Cost Implications of Design Choices

This graph would illustrate how different design complexities (simple, moderate, complex) affect the machining time and material usage, clearly showing the cost increase with complexity.

Example: Cost Implications of Design Complexity in Brass CNC Parts

Consider a company that produces brass fittings for plumbing applications, which comes in two design variants: a simple cylindrical fitting and a more complex, custom-shaped fitting with multiple contours and threading.

- Simple Cylindrical Fitting:

- Design Simplicity: The cylindrical design is straightforward, involving basic lathe operations with minimal tool changes.

- Machining Time: Each part takes approximately 5 minutes to machine.

- Material Usage: The design is material-efficient, with very little scrap produced.

- Cost per Part: Given the simplicity and speed of production, the cost per part is relatively low, approximately $2.00 in machining and material costs.

- Complex Custom-Shaped Fitting:

- Design Complexity: This part requires advanced 3D CNC milling with multiple tool changes to create contours and threading.

- Machining Time: Each part takes around 20 minutes to machine due to the complex shapes and precision required.

- Material Usage: The intricate design leads to higher material waste as more brass is cut away and cannot be reused.

- Cost per Part: The increased machining time and higher scrap rates raise the cost significantly, approximately $6.50 per part.

—Analysis:

- Design Efficiency: The complex fitting, while offering more functionality and customization, incurs a 225% higher production cost than the simple cylindrical fitting primarily due to increased machining time and material waste.

- Economic Decision: For the company, producing more complex parts may only be economically viable if these costs can be passed on to the customer or if the added functionality can significantly increase market demand.

What Role Does Quality Control Play in the TCO of Brass CNC Parts?

Quality control (QC) is integral to ensuring that brass CNC parts meet the required specifications and standards, which can significantly impact the total cost of ownership by minimizing the rate of defects and rework.

Quality Control Costs vs. Benefits:

- Initial Costs: Implementation of rigorous QC measures involves upfront costs such as advanced measurement instruments and training for personnel.

- Long-Term Savings: Strong QC measures reduce the occurrence of defects that can lead to costly rework or scrap. They also enhance product reliability and customer satisfaction, potentially leading to repeat business.

Case Study:

A mid-sized manufacturer implemented a new QC system that increased their upfront costs by 15% but reduced defect-related losses by 50% over the following year, demonstrating a significant return on investment.

Cost-Benefit Analysis Table:

| QC Measure | Upfront Cost | Annual Savings | Break-even Point |

|---|---|---|---|

| Enhanced Inspection | $10,000 | $20,000 | 6 months |

| Statistical Process Control | $5,000 | $15,000 | 9 months |

| Certification | $3,000 | $8,000 | 1 year |

How Can Waste Management and Recycling Reduce TCO?

Effective waste management and recycling practices are essential for minimizing the total cost of ownership for brass CNC parts. By reducing material waste and reusing scrap, companies can decrease both their material costs and environmental impact.

Waste Reduction Strategies:

- Optimized Nesting Software: This software reduces raw material usage by optimizing the layout of parts on a sheet of brass.

- Scrap Recycling: Recycling brass scrap can be cost-effective, as recycled brass is less expensive than virgin brass and retains all the desirable properties.

Statistical Data:

| Year | Waste Generated | Waste Recycled | Cost Savings | Environmental Impact |

|---|---|---|---|---|

| 2020 | 500 kg | 300 kg | $5,000 | Reduced carbon footprint |

| 2021 | 450 kg | 350 kg | $5,500 | Further reduced emissions |

What Are the Long-Term Costs Associated with Brass CNC Parts?

Assessing the long-term costs involved with brass CNC parts requires consideration of not only the initial manufacturing costs but also ongoing maintenance, potential downtime, and the lifespan of the parts.

Lifecycle Cost Analysis:

- Maintenance: Regular maintenance ensures optimal functionality but incurs costs.

- Replacement: Some parts are subject to wear and need to be replaced periodically, which adds to the TCO.

- Downtime: Unscheduled maintenance can result in costly downtime, affecting overall productivity.

Lifecycle Cost Table:

| Component | Initial Cost | Maintenance Cost/year | Replacement Cost | Total Cost Over 5 Years |

|---|---|---|---|---|

| Brass Gear | $100 | $20 | $100 | $200 |

| Brass Bushing | $30 | $5 | $30 | $65 |

Example: Long-Term Cost Analysis of Brass Gears in Industrial Machinery

Consider a manufacturing scenario where a company uses brass gears in their high-speed industrial machinery. These gears are critical components that influence the efficiency and longevity of the machinery.

- Initial Costs:

- Purchase Price: Each brass gear costs $150.

- Installation Costs: Installation and initial calibration of each gear cost $50.

- Maintenance Costs:

- Regular Maintenance: The brass gears require lubrication and inspection every six months, costing $30 per maintenance session.

- Unexpected Repairs: On average, unexpected repairs due to wear or malfunction occur once every two years, costing $100 per incident.

- Replacement Costs:

- Lifespan: Each gear has an expected operational lifespan of 5 years under normal usage conditions.

- Replacement: Replacing a worn-out gear costs $150 for the gear and an additional $50 for installation.

- Downtime Costs:

- Production Impact: Each time a gear fails or requires maintenance, the machinery is down for 4 hours. Assuming the production value lost during downtime is $500 per hour, the cost associated with downtime for each maintenance or repair session amounts to $2,000.

Total Cost Calculation Over 5 Years:

- Initial Costs: $200 (purchase and installation).

- Maintenance Costs: $30 x 10 (biannual for 5 years) + $100 x 2.5 (average of 2-year interval over 5 years) = $300 + $250 = $550.

- Replacement Costs at End of Lifespan: $200.

- Downtime Costs: $2,000 x 12.5 (10 maintenance + 2.5 repair sessions) = $25,000.

- Total Cost: $200 (initial) + $550 (maintenance) + $200 (replacement) + $25,000 (downtime) = $25,950.

Discussion:

This example illustrates how a single brass gear, while only costing $150 initially, can accumulate significant costs over its operational lifespan, primarily driven by the indirect costs associated with downtime during maintenance and repairs. The example underscores the importance of considering not just the direct purchase and maintenance costs, but also the broader impact on production and operational efficiency.

Other Articles You Might Enjoy

- What Are the Latest Trends in Sourcing Brass CNC Machining Parts?

How Are Global Market Dynamics Shaping the Sourcing of Brass CNC Machining Parts? The global landscape for sourcing brass CNC machining parts is heavily influenced by international trade dynamics, including…

- CNC Machining Aluminum vs. Brass: A Detailed Comparison for Precision Parts Manufacturing

Introduction to CNC Machining and Material Choices CNC (Computer Numerical Control) machining is a critical process in precision parts manufacturing. Its importance lies in its ability to create intricate and…

- CNC Machining Aluminum vs. Brass: A Detailed Comparison for Precision Parts Manufacturing

CNC Machining: Aluminum vs. Brass in Precision Parts Manufacturing The continuous quest for efficiency and precision has made CNC (Computer Numerical Control) machining a vital process in the manufacturing of…

- Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining in High-End Audio Equipment Manufacturing Precision Computer Numerical Control (CNC) machining refers to a highly-advanced technology where computer-generated codes are used to operate factory machinery and tools.…

- How Do Import Regulations Affect the Procurement of Brass CNC Machining Parts?

What Are the Global Import Regulations for Brass CNC Machining Parts? The global landscape for importing brass CNC machining parts is complex and varies significantly by country. Key players such…

- Precision CNC Machining: Aluminum vs. Brass for Your Custom Parts

Introduction to Precision CNC Machining and Custom Parts Precision CNC (Computer Numeric Control) machining is a cutting-edge manufacturing process that utilizes computer-controlled machinery to produce intricately designed custom parts, adhering…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu