CNC Machining and Stainless Steel in Prototyping

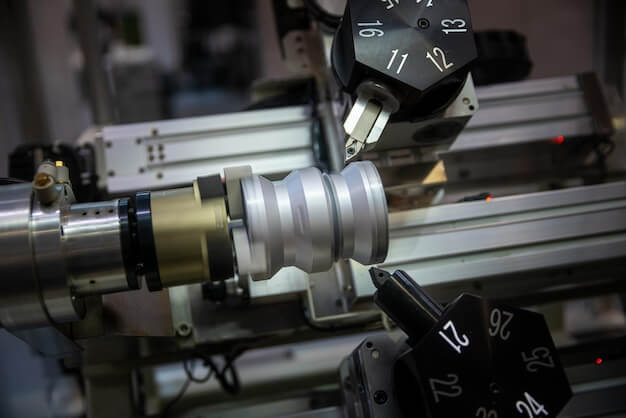

Computer Numerical Control (CNC) machining is a critical process in the manufacturing sector, particularly for prototyping projects. It’s an automated method that uses pre-programmed software to control movement of factory tools and machinery. This technology allows for precise creation and reproduction of prototype items on a large scale. CNC machining makes it possible for manufacturers to produce intricate designs that are not only accurate but also uniform.

China Online CNC Machining Services – Want.net

Stainless steel, due to its corrosion resistance properties and high strength-to-weight ratio, plays a pivotal role within these CNC machined prototyping projects. When creating prototypes, durability and resilience are key factors, hence the popularity of stainless steel. Here are some reasons why stainless steel is commonly used:

- Impressive Corrosion Resistance: Unlike ordinary steel, stainless steel does not easily rust or corrode when exposed to water – making it ideal for a wide range of applications.

- Spectacular Strength-to-Weight Advantage: Although strong and durable, stainless steel is relatively light. In terms of prototyping, this gives designers freedom without worrying about weight constraints.

Detailed overview and use of fast CNC machining services in manufacturing stainless steel prototyping involves:

- Material Properties: Understanding the properties of stainless steel, such as corrosion resistance, formability, and high tensile strength, for prototyping applications.

- Applications: Exploring the diverse applications of fast CNC machining services for stainless steel prototyping in industries such as automotive, aerospace, and healthcare.

- Advantages: Recognizing the benefits of fast CNC machining services, including efficient production, precision parts, and quick product testing and market launch.

For fast CNC machining services for stainless steel prototyping, consider utilizing a CNC Machining Service to ensure high-quality and rapid prototyping for your stainless steel components.

Importance of Using Stainless Steel for Prototyping

One crucial component in prototyping is the choice of material, with stainless steel often proving to be the gold standard. This substance offers a multitude of benefits which renders it ideal for prototyping processes. For starters, stainless steel is remarkably durable and resistant, hence it can withstand harsh environments and high stress. The glossy appearance and low maintenance make it visually appealing while remaining cost-effective. Moreover, its ability to resist corrosion advances its longevity, therefore reducing need for frequent replacements.

- The durability of stainless steel reduces wear and tear time due to constant testing, resulting in an enduring prototype model.

- An example that illustrates the effectiveness of stainless steel in prototypes is its use in automotive parts prototyping. Given its resistance to heat and rusting coupled with strength, stainless steel auto parts prototypes exhibit longevity under severe operational conditions, reflecting real-world functionality accurately.

Benefits of Fast CNC Machining Services for Stainless Steel Prototyping

The time efficiency in using fast CNC machining services is one significant benefit. This service allows for quicker production runs without the need for manual intervention, thereby reducing lead times and increasing output speed. These factors often result in substantial cost reductions, especially when dealing with large-scale projects where economies of scale come into play. The efficiencies gained from these services allow companies to bring their products from prototyping phase to market more quickly.

- CNC Machining provides high precision and complex shapes that would not be possible manually.

- With this service, multiple iterations are completed in a shorter timeframe which accelerates product development processes.

- Dramatic reduction in material waste due to advanced programming aids in cost-effectiveness.

These advantages significantly contribute to making fast CNC machining services an economical choice, highlighting its relevance in today’s highly competitive manufacturing landscape.

Potential Issues in Choosing Other Methods over Fast CNC Machining

When it comes to stainless steel prototyping, opting for more manual and slower methods instead of fast CNC machining services can lead to a variety of potential drawbacks. These issues might not be obvious initially, but they tend to surface as the project progresses towards its later stages.

- Firstly, manual methods typically require higher labor effort which may result in increased expenses and extended deadline, making them less cost-effective and timely than automated CNC machining processes.

- Secondly, manual operations are susceptible to human errors, potentially resulting in decreased accuracy and quality inconsistency.

- Lastly, while traditional prototype creation might be suitable for simple designs, they often struggle with complex geometries that CNC machines can easily handle due to their high level of precision and control.

This is why, despite seeming attractive at first glance, manual prototyping methods should be carefully evaluated against CNC machining services for their potential disadvantages before making a decision on which technique to use for creating stainless steel prototypes.

Finding the Right Fast CNC Machining Service for Stainless Steel Prototypes

Selecting a fast CNC machining service provider for stainless steel prototyping requires careful consideration in several areas. Foremost, evaluating their expertise and experience is essential. A company well-versed in quick-turnaround machining projects can deliver prototypes promptly without compromising on quality. The more experienced a firm is in handling diverse requirements and tight schedules, the higher its proficiency will be.

- Evaluating customer reviews should also factor into your decision making process. Testimonials provide insights into how previous clients rate their services – revealing aspects such as punctuality, professionalism, error management, and overall satisfaction.

- The technologies used by the potential provider should also come under scrutiny. It would help if you verified whether they are equipped with advanced facilities to perform complex tasks effectively.

- Additionally, consider the level of personalisation and flexibility offered. A provider who understands your unique project needs and offers custom-made solutions signifies an adept and accommodating fast CNC machining service.

Other Articles You Might Enjoy

- What Material Properties Need to Be Considered When CNC Machining Stainless Steel Flanges?

The CNC machining of stainless steel flanges requires a profound understanding of the material's properties to ensure high-quality, precision outcomes. This article delves into the critical material properties that impact…

- Precision CNC Machining of Stainless Steel: Innovations and Best Practices in Aerospace Machining

Introduction: Precision CNC Machining and the Use of Stainless Steel Precision Computer Numerical Control (CNC) machining, a vital technology within the manufacturing industry, uses pre-programmed software to guide machinery towards…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining: The Role of Stainless Steel and Aluminum Computer Numerical Control (CNC) machining is a groundbreaking method in manufacturing that involves precise computer commands to manipulate and control tools…

- CNC Machining Material Showdown: 304 vs. 316 Stainless Steel

CNC Machining: An Overview And Importance of Material Selection Computer Numerical Control (CNC) machining is a manufacturing process that uses pre-programmed computer software to dictate the movement of factory tools…

- Stainless Steel vs. Aluminum in CNC Machining: Pros and Cons

CNC Machining and the Importance of Material Selection CNC machining, a pivotal manufacturing process in numerous industries, uses pre-programmed computer software to dictate the movement of factory tools and machinery.…

- What Material Properties Need to Be Considered When CNC Machining Stainless Steel Flanges?

The CNC machining of stainless steel flanges requires a profound understanding of the material's properties to ensure high-quality, precision outcomes. This article delves into the critical material properties that impact…