Principles of Blank Selection

In mechanical manufacturing, the selection of blanks is crucial as it not only affects product quality but also influences manufacturing costs and final performance. Therefore, choosing the right blank is an essential step in the manufacturing process.

Processability Principle

Different parts have varying requirements for blanks, specifically in terms of shape, size, machining accuracy, and surface roughness for external quality, and chemical composition, metal structure, mechanical properties, etc., for internal quality. For example, grey cast iron parts cannot be formed by forging due to their material properties. Similarly, thin-walled blanks with poor fluidity should not be formed by casting.

Adaptability Principle

The selection of blanks must also consider adaptability. For example, for stepped shaft parts, if the diameters of each step do not vary much, bar stock can be used; if the difference is large, forged blanks should be used. Complex-shaped and thin-walled blanks should not be formed by metal casting but rather by sand casting or welding. The working conditions of different parts also require different types of blanks. For instance, the main spindle of a machine tool requires high precision and strength, thus should be made from forged blanks, while the handle can be made from simple low-carbon steel round bars.

Production Conditions Principle

When selecting blank forming schemes, production conditions must be considered, including the current technological level, equipment status, and the possibility of outsourcing. Utilize existing conditions as much as possible to complete blank manufacturing tasks. If requirements cannot be met, consider changing materials or forming methods, or solve the problem through outsourcing.

Economic Principle

The economic principle aims to minimize manufacturing costs while meeting the usage requirements of the parts. This includes material costs, energy consumption, and labor costs. For example, for mass-produced parts, high precision and high productivity forming methods such as forging and machine modeling should be used.

Sustainability Principle

In modern manufacturing, environmental protection and energy-saving are increasingly important. When designing process flows, energy consumption should be minimized by choosing low-energy forming methods and using environmentally friendly materials. Avoid using harmful materials and adopt recyclable materials and processes.

Comparison of Common Blank Forming Methods

Common blank forming methods include casting, forging, powder metallurgy, stamping, welding, non-metallic material forming, and rapid prototyping. Below is a detailed introduction to several common forming methods:

Casting

Casting involves pouring liquid metal into a mold where it solidifies into shape. It is suitable for producing parts of various sizes and complex shapes, such as bases, housings, and machine tool beds. Casting has high material utilization, but the quality of castings depends on the fluidity and shrinkage of the metal.

Forging

Forging involves the plastic deformation of solid metal under pressure. It is suitable for making parts that require high strength and dense structures, such as shafts, gears, and crankshafts. Forging methods include free forging, die forging, and semi-die forging.

Powder Metallurgy

Powder metallurgy involves forming and sintering metal and non-metal powders to create parts or blanks. It is suitable for manufacturing small to medium-sized parts with complex shapes, high material utilization, and high production efficiency.

Stamping

Stamping uses a die to separate or deform metal sheets. It is ideal for mass production of parts with complex shapes and high material utilization, such as automotive panels and instrument housings.

Welding

Welding joins materials through heating or applying pressure to create a common pool or plastic deformation. It is used for manufacturing complex or large parts and connecting dissimilar materials or repairing parts.

Plastic Forming

Plastic forming uses methods like injection molding, extrusion, compression molding, etc., at relatively low temperatures to produce parts. Plastic materials are cost-effective and widely used in various applications.

Composite Material Forming

Composite materials are made by combining matrix and reinforcing materials, providing superior performance unattainable by single materials. The forming process integrates material and structure in one step, reducing the number of parts and improving fatigue resistance and stability.

Comparison Table of Common Forming Methods

| Forming Method | Characteristics | Material Requirements | Part Features | Material Utilization | Production Efficiency | Main Applications |

|---|---|---|---|---|---|---|

| Casting | Liquid metal fills mold | Good fluidity | Complex shapes | High | Low to High | Bases, housings, beds |

| Forging | Plastic deformation of solid metal | Low deformation resistance | Simple shapes | Low | Low | Gears, crankshafts |

| Powder Metallurgy | Atomic diffusion of powders | Good powder flow | Complex shapes | High | High | Bearings, gears |

| Stamping | Die separation or deformation | Good plasticity | Complex shapes | High | High | Panels, housings |

| Welding | Heating or pressure joining | Low crack tendency | Complex shapes | High | Low to High | Large part joining |

| Plastic Forming | Injection, extrusion, etc. | Good fluidity | Complex shapes | High | High | Pipes, housings |

| Composite Forming | Material and structure integration | High strength fibers | Complex shapes | High | Low to High | Vehicle bodies, pipes |

In the mechanical manufacturing process, choosing the appropriate blank forming method can effectively improve product quality, reduce production costs, and achieve sustainable development. Hopefully, the above content helps you better understand and apply blank forming methods.

Other Articles You Might Enjoy

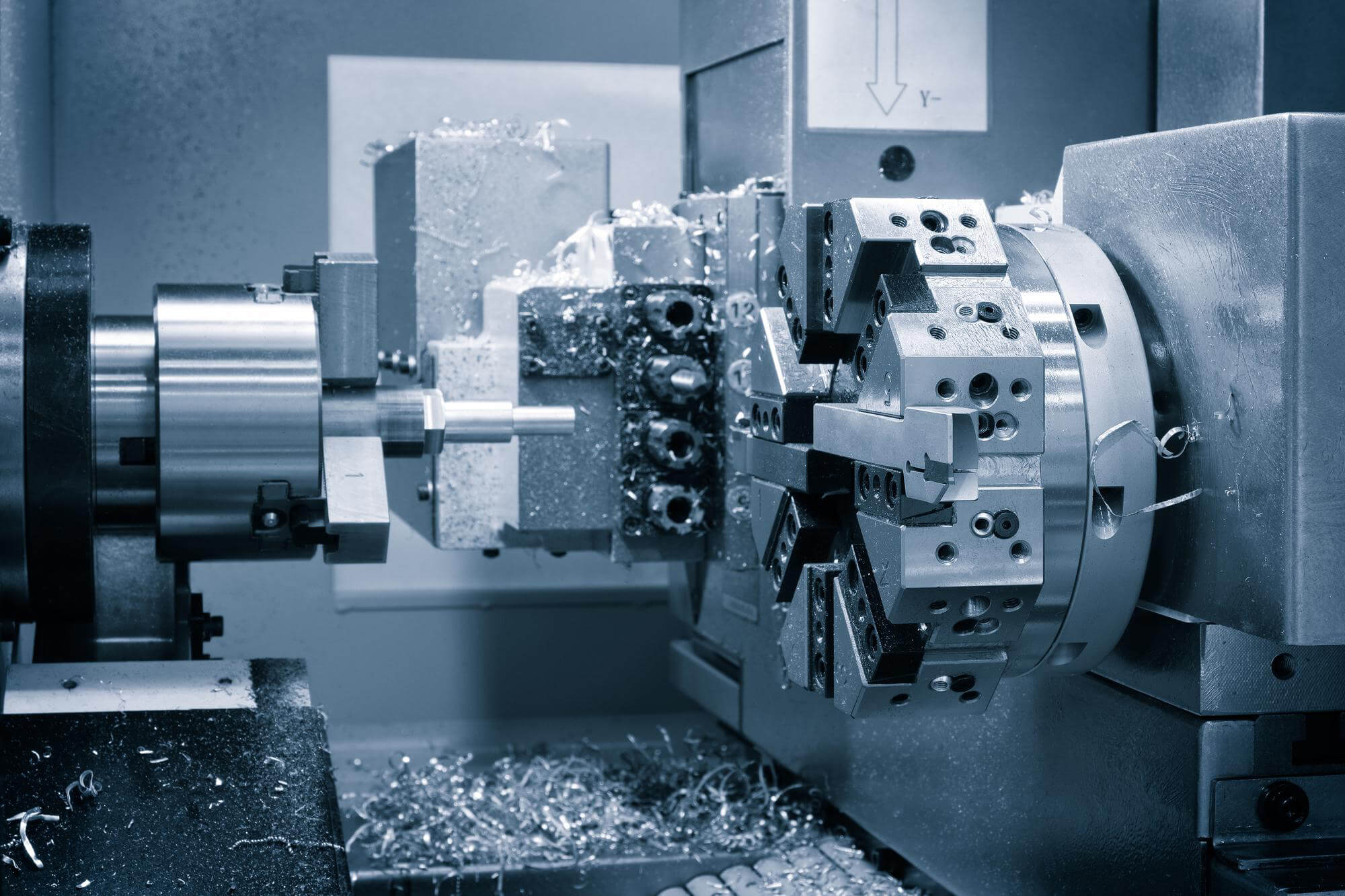

- Analysis of machining process for CNC machine tool parts, formulation of machining plans, selection of fixtures and cutting tools

CNC Lathe Processing Based on Material, Contour Shape, and Machining Precision of Workpiece: Selection of Suitable Machine Tools, Development of Processing Plan, and Determination of Processing Sequence, Tools, Fixtures, and…

- Unraveling the World of CNC Machined Plastic Parts(CNC machined plastic parts Mabel)

Modern innovations have taken traditional manufacturing methods to new heights. One such innovation that stands out is Computer Numerical Control (CNC) machining, a process used extensively in various industries from…

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…

- Reaming Process for Stainless Steel Parts

The reaming process for stainless steel parts involves the following steps: Tool Geometry Design Most reaming of stainless steel materials uses carbide reamers. The structure and geometric parameters of these…

- What are the requirements for CNC machining of bearing parts?

Bearings are common and important parts in the automotive industry, which can support transmission components and transmit torque. Generally, CNC machining centers are used to process bearing parts. So what…