Metal materials are ubiquitous in our lives, playing a crucial role in various industrial fields from automobiles and construction to electronic products. Understanding the properties and applications of different metal materials can help us make better material choices. Here, we delve into several common metal materials and their specific characteristics.

1. Ferrous Metals

1.1 Industrial Pure Iron

Industrial pure iron contains more than 90% iron and is mainly used for making electrical components that require high magnetic conductivity. It boasts excellent ductility and electrical conductivity but has low hardness.

1.2 Cast Iron

Cast iron, with a carbon content between 2% and 4%, is mainly used for manufacturing machine beds, pipes, and large castings. Cast iron is known for its excellent casting properties, wear resistance, and compressive strength, but it is brittle and unsuitable for environments subject to impact.

1.3 Carbon Steel

Carbon steel, an iron-carbon alloy with a carbon content of less than 2%, is widely used in construction and mechanical manufacturing. Depending on the carbon content, carbon steel can be classified into low carbon steel (e.g., Q235 steel for construction), medium carbon steel (e.g., 45 steel for mechanical parts), and high carbon steel (e.g., T10 steel for making tools and springs).

1.4 Stainless Steel

Stainless steel contains chromium, typically above 10.5%, and offers excellent corrosion resistance. Common types include 304 stainless steel (used for cutlery and kitchen equipment) and 316 stainless steel (used for chemical equipment and marine facilities due to its superior corrosion resistance).

2. Non-Ferrous Metals

2.1 Aluminum and Aluminum Alloys

Aluminum is lightweight and corrosion-resistant, widely used in aerospace, construction, and automotive industries. Based on alloying elements, aluminum can be divided into the following categories:

| Alloy Series | Properties | Applications |

|---|---|---|

| 1000 Series | Pure aluminum, excellent ductility, high corrosion resistance | Electrical wires, foil, household items |

| 2000 Series | Copper alloys, high strength, poor corrosion resistance | Aircraft structures |

| 3000 Series | Manganese alloys, good formability, corrosion resistance | Construction, cans |

| 5000 Series | Magnesium alloys, high strength, corrosion resistance | Ships, cars |

| 6000 Series | Magnesium and silicon alloys, good mechanical properties, easy to process | Construction profiles, pipelines |

| 7000 Series | Zinc alloys, highest strength | Aerospace, high-strength structures |

2.2 Copper and Copper Alloys

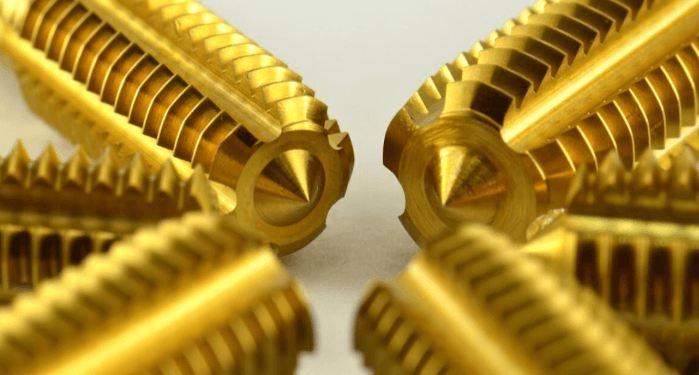

Copper has excellent electrical and thermal conductivity, making it ideal for electrical and electronic industries. Common copper alloys include brass (copper-zinc alloy) and bronze (copper-tin alloy).

- Brass: Used for valves, pipes, and decorative items.

- Bronze: Used for ship parts, mechanical bearings, and coins.

2.3 Titanium and Titanium Alloys

Titanium is known for its excellent corrosion resistance and high strength-to-weight ratio, widely used in aerospace, marine engineering, and medical devices. Titanium alloys like TC4 (titanium-6 aluminum-4 vanadium) are commonly used in aircraft engines and airframes.

3. Special Metal Materials

3.1 High-Temperature Alloys

High-temperature alloys maintain excellent mechanical properties at high temperatures, primarily used in aerospace engines and gas turbines. Common high-temperature alloys include nickel-based and cobalt-based alloys.

3.2 Superconducting Materials

Superconducting materials exhibit zero electrical resistance and expel magnetic fields at extremely low temperatures, used in MRI machines, particle accelerators, and efficient power transmission systems. Common superconducting materials include niobium-titanium and niobium-tin alloys.

3.3 Shape Memory Alloys

Shape memory alloys can return to their original shape when heated, used in medical devices (such as dental braces and stents) and smart materials (such as self-repairing structures). Nickel-titanium alloy is the most common shape memory alloy.

4. Specific Application Cases

4.1 Metal Materials in Automobile Manufacturing

- Body Structure: Mainly uses high-strength steel to improve safety and reduce weight.

- Engine Parts: Aluminum alloys are widely used for engine blocks and pistons to reduce weight and enhance heat dissipation.

- Electrical System: Copper is used for cables and connectors due to its excellent electrical conductivity.

4.2 Metal Materials in Construction Engineering

- Structural Steel: Used for building frames and reinforcing structures.

- Aluminum Alloys: Used for window frames, doors, and curtain wall systems due to their corrosion resistance and lightweight properties.

- Stainless Steel: Used for exterior facades and decorative elements due to its aesthetic and durability.

4.3 Metal Materials in Electronic Devices

- Wires and Connectors: Copper is used for wires and electronic connectors, providing excellent electrical conductivity.

- Heat Sinks: Aluminum is commonly used in heat sinks for electronic devices to improve heat dissipation.

- Structural Components: Aluminum and magnesium alloys are used for making the casings of laptops and phones to reduce weight and enhance strength.

5. Comparison Table of Metal Materials

To more intuitively understand the properties of different metal materials, we have listed the following comparison table:

| Material Type | Main Components | Advantages | Disadvantages | Application Fields |

|---|---|---|---|---|

| Industrial Pure Iron | Iron | Good magnetic conductivity, high ductility | Low hardness | Electrical components |

| Cast Iron | Iron, Carbon | Excellent casting properties, high wear resistance | Brittle | Machine beds, pipes |

| Carbon Steel | Iron, Carbon | High strength, low cost | Prone to rust | Construction, mechanical manufacturing |

| Stainless Steel | Iron, Chromium | Corrosion-resistant, aesthetically pleasing | High cost | Cutlery, chemical equipment |

| Aluminum Alloy | Aluminum, Magnesium, Silicon, etc. | Lightweight, corrosion-resistant | Relatively low strength | Aerospace, construction |

| Copper Alloy | Copper, Zinc, Tin, etc. | Excellent electrical conductivity, easy to process | High cost | Electrical, piping |

| Titanium Alloy | Titanium, Aluminum, Vanadium | High strength, corrosion-resistant | High cost, difficult to process | Aerospace, medical |

By understanding these common metal materials in detail, we can better choose the materials that suit our needs, improving the performance and quality of products. Whether in daily life or industrial production, metal materials play an irreplaceable important role.

Other Articles You Might Enjoy

- Common Metal Materials and Their Properties

Classification and Grades of Industrial Steel Steel Classification In the steel industry, there are several ways to classify steel. The first is by carbon content: Low Carbon Steel: Carbon content…

- Common Materials and Processability of Mechanical Parts

Mechanical parts are indispensable components in various machines and equipment. To ensure these parts operate efficiently under different working conditions, it is essential to understand the common materials used for…

- Comprehensive Guide to Metal Cutting Tools

In modern mechanical manufacturing, metal cutting processes are the most widely used methods, accounting for over 50% of the total workload in mechanical manufacturing. Whether it's a conventional lathe, an…

- The Ultimate Guide to Sheet Metal Materials: Aluminum vs. Galvanized Steel

Introduction: A Brief Overview of Sheet Metal Materials in Manufacturing In the wide world of manufacturing, sheet metal materials play a pivotal role. They serve as critical components in various…

- The Ultimate Guide to Metal Surface Finishes

Part production requires metal surface finishing. Quality metal surface finishing will make any part look better, no matter how well it is finished. There are many types of metals. Welder…

- Innovations in CNC Machining: High-Temperature Alloys vs. Traditional Materials

CNC Machining: Its Techniques and Significance in Material Selection Computer Numerical Control (CNC) machining, a fabrication method extensively employed within the engineering realm, manipulates pre-programmed computer software to regulate factory…