In mechanical manufacturing, selecting and forming blanks are critical factors that influence product quality, cost, and performance. Choosing the right blank can improve production efficiency and significantly reduce manufacturing costs. This article will provide a detailed introduction to the principles of blank selection and the comparison of common forming methods.

Principles of Blank Selection

Processability Principle

The processability principle for selecting blanks is based on the usage requirements of the parts to determine their shape characteristics. Different parts have different external and internal quality requirements, such as shape, size, machining accuracy, surface roughness, chemical composition, metal structure, mechanical properties, etc.

When selecting the blank forming method, the process characteristics of the part material must be considered. For example, gray cast iron parts should not use forging methods, and thin-walled blanks with poor fluidity should not use casting methods. It is also essential to consider the machinability of the blank for subsequent machining processes.

Adaptability Principle

The adaptability principle requires selecting blanks based on the structural shape, size, and working conditions of the parts. For example, stepped shaft parts with similar diameters can be manufactured using bar stock, while complex-shaped thin-walled blanks should avoid metal casting. Critical parts like spindles require high-quality materials and processing through forging and heat treatment, while simple parts like machine handles can be made from gray cast iron with minimal machining.

Principle of Production Conditions

The forming scheme for blanks should consider production conditions, including process level, equipment status, and the feasibility of outsourcing. If current conditions cannot meet the requirements, changing the material or forming method, or outsourcing the process, can be considered.

Economic Principle

The economic principle aims to select the lowest overall production cost scheme by comparing different forming methods. Generally, the blank’s size and shape should closely match the finished part to reduce machining allowances and workload.

Sustainability Principle

The sustainability principle emphasizes considering environmental protection and energy-saving issues during the blank selection and forming process. Choosing low-energy and environmentally friendly forming methods and materials can help achieve sustainable industrial development.

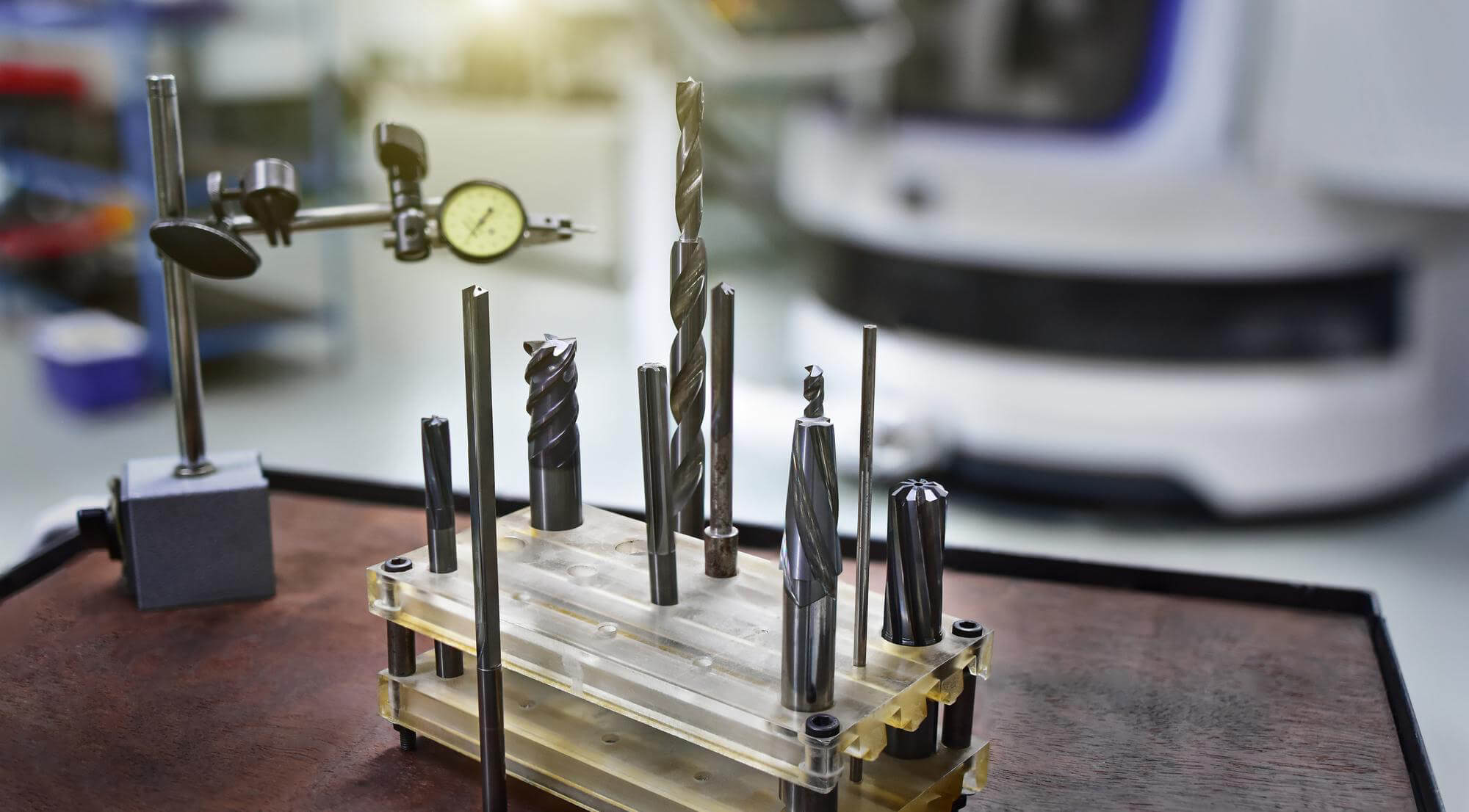

Comparison of Common Blank Forming Methods

Common blank forming methods include casting, forging, powder metallurgy, stamping, welding, plastic forming, ceramic forming, composite forming, and rapid prototyping.

Casting

Casting involves filling a mold with molten metal and allowing it to solidify, suitable for manufacturing various sizes and complex-shaped parts like housings, boxes, and machine beds. Manual sand casting is suitable for single-piece and small-batch production, while machine molding is used for mass production.

Forging

Forging is the process of shaping metal using compressive forces, suitable for making dense and strong parts like gears and crankshafts. Open die forging is used for single and large parts, while die forging is suitable for medium and large batch production.

Powder Metallurgy

Powder metallurgy involves forming and sintering metal powders to create parts, ideal for manufacturing small to medium-sized complex parts with special properties.

Stamping

Stamping uses dies to shape metal sheets, suitable for producing parts with complex shapes and high production rates, such as automotive panels and instrument boards.

Welding

Welding joins materials by heating or applying pressure, suitable for complex or large component assemblies and repairs.

Plastic Forming

Plastic forming methods include injection molding, extrusion, and compression molding, suitable for producing general structural and wear-resistant parts. Plastic forming is widely used due to its low cost and simplicity.

Ceramic Forming

Ceramic forming uses methods like slip casting and plastic forming, suitable for making high-hardness, high-temperature, and corrosion-resistant parts like tools and bearings.

Composite Forming

Composite materials are formed by combining matrix and reinforcing materials, offering high strength and stiffness, suitable for applications like ship hulls and car bodies.

Rapid Prototyping

Rapid prototyping involves creating 3D models by material accumulation, suitable for product design, prototype testing, and custom manufacturing.

Comparison of Material Forming Methods

| Forming Method | Forming Characteristics | Process Requirements | Part Features | Material Utilization | Production Rate | Main Applications |

|---|---|---|---|---|---|---|

| Casting | Molten metal fills mold | Good fluidity, centralized shrinkage | Various, complex | High | Low to high | Complex cavity parts like housings, boxes, beds, etc. |

| Open Die Forging | Plastic deformation of solid metal | Low deformation resistance, good plasticity | Various, simple | Low | Low | Transmission shafts, gear blanks, barrels, etc. |

| Die Forging | Plastic deformation of solid metal | Low deformation resistance, good plasticity | Small to medium, complex | High | High | High-stress, complex parts like gears, valves, etc. |

| Stamping | Separation or deformation by dies | Good plasticity, low deformation resistance | Various, complex | High | High | Lightweight, rigid parts, complex shapes like covers, etc. |

| Powder Metallurgy | Atomic diffusion, recrystallization of powders | Good powder flow, high compressibility | Small to medium, complex | High | High | Precision parts or special properties like bearings, tools |

| Welding | Joint by metal pool solidification or deformation | Low hardening, cracking, porosity tendency | Various, complex | High | Low to high | Complex or large component assemblies, repairs, etc. |

| Plastic Forming | Injection, extrusion, compression molding | Good fluidity, low shrinkage, low moisture sensitivity | Various, complex | High | High | General structural parts, wear-resistant components |

| Ceramic Forming | Forming by slip casting, plastic forming, etc. | Uniform, dense body structure | Small to medium, complex | High | Low to high | High-hardness, high-temperature parts like tools, bearings |

| Composite Forming | Matrix and reinforcing material combination | High fiber strength and stiffness, good plasticity of matrix | Various, complex | High | Low to high | High strength, stiffness parts like hulls, bodies, tanks |

| Rapid Prototyping | Material accumulation forming 3D models | Satisfy usage requirements | Various, complex | High | Fast | Product design, prototype testing, custom manufacturing |

Understanding the characteristics and applications of different blank forming methods can help in selecting the most suitable process, improving production efficiency, product quality, and reducing costs, while promoting sustainable development.

Other Articles You Might Enjoy

- Selection and Comparison of Blank Forming Methods for Parts

Principles of Blank Selection In mechanical manufacturing, the selection of blanks is crucial as it not only affects product quality but also influences manufacturing costs and final performance. Therefore, choosing…

- Mechanical Drawing Annotation Methods and Common Issues and Requirements

In mechanical processing, drawing annotations play a crucial role. The first key point is that the true size of the part should be based on the dimensions indicated on the…

- Typical Machining Processes for Mechanical Manufacturing

Shaft Parts Machining Function of Shaft Parts Shaft parts are primarily used to support transmission components and transmit torque. Common shaft parts include plain shafts, hollow shafts, half shafts, stepped…

- Tapping Methods in CNC Machining

Classification and Characteristics of Tapping in CNC Machining Tapping, using taps to machine threaded holes, is the most commonly used method for creating threaded holes. It is mainly suitable for…

- Why should I choose CNC multi-axis machining in China? What are the advantages?

I usually choose Chinese CNC machining factories when I need to custom manufacture parts in large quantities. These factories not only have advanced technology and equipment but also provide high-quality…

- Sustainable Manufacturing Practices for the Modern World

Sustainable Manufacturing Practices in the Modern World Sustainable manufacturing practices refer to those methods or techniques applied in production, which aim at diminishing negative environmental impacts while conserving energy and…