In the field of mechanical design, mechanical accessories and thread modules are critical components. They are not just miscellaneous small parts, but essential elements that ensure the stability and reliable operation of the entire mechanical system. Today, we will delve into fasteners, threaded connections, single-axis drive modules, servo planetary reducers, and cam indexers.

Fasteners and Threaded Connections

What are Fasteners?

Fasteners are commonly known as standard parts in the market, used to secure two or more parts into a single unit. They mainly include threaded connections, nuts, flat washers, spring washers, circlips, and pins.

Common Threaded Connection Components

- Hex Bolts

- Studs

- Cylindrical Head Hex Screws

- Round Head, Flat Head, Hex or Phillips Screws

- Set Screws

- Various Nuts (Flange Nuts, Dome Nuts, Wing Nuts, etc.)

- Self-tapping Screws, Pins, Spring Pins, and Keys

Main Parameters of Threads

Threaded connections primarily rely on the following parameters:

- Major Diameter (d): The nominal diameter of the thread, e.g., M5 thread.

- Minor Diameter (d1): Used for strength calculations.

- Pitch (P): The axial distance between corresponding points on adjacent thread teeth.

- Thread Angle (α): The angle between the sides of the thread profile in the axial section, commonly 60°.

Common Thread Types

- 60° Metric Thread (M Series)

- Thread angle of 60°, thicker root, higher strength.

- Threads of the same nominal diameter can be coarse, fine, or extra fine.

- 55° Pipe Threads (G Series and R Series)

- Thread angle of 55°, with a rounded crest.

- G series threads are used for non-sealing connections, while R series are for sealing connections.

Common Thread Sizes and Pitches

| Size | Coarse (mm) | Fine (mm) | Extra Fine (mm) |

|---|---|---|---|

| M3 | 0.5 | 0.35 | – |

| M4 | 0.7 | 0.5 | – |

| M5 | 0.8 | 0.5 | – |

| M6 | 1 | 0.75 | – |

| M7 | 1 | 0.75 | – |

| M8 | 1.25 | 1 | 0.75 |

| M10 | 1.5 | 1.25 | 1 |

| M12 | 1.75 | 1.5 | 1.25 |

| M14 | 2 | 1.5 | 1 |

| M16 | 2 | 1.5 | 1 |

| M18 | 2.5 | 2 | 1.5 |

| M20 | 2.5 | 2 | 1.5 |

| M22 | 2.5 | 2 | 1.5 |

| M24 | 3 | 2 | 1.5 |

| M27 | 3 | 2 | 1.5 |

| M30 | 3.5 | 3 | 2 |

Operating Components

Operating components are auxiliary parts of the equipment that adhere to industry standards. They mainly include casters, leveling feet, rotating handles, door handles, hinges, locks, knobs, toggle clamps, grips, and spring clips.

Springs

A spring is a component that can produce significant elastic deformation under the action of external force and is widely used in mechanical equipment. The main purposes of springs include controlling the movement of mechanisms or parts, absorbing shocks, storing energy, measuring force, and changing the natural frequency of systems.

Types of Springs

- Helical Springs

- Cylindrical

- Rectangular

- By Load Type

- Tension Springs

- Compression Springs

- Torsion Springs

- Ring Springs

- Disc Springs

- Flat Spiral Springs

- Leaf Springs

Single-axis Drive Modules

Single-axis drive modules are mass-produced, standardized components driven by servo or stepper motors via ball screws or timing belts, causing the slide to reciprocate along linear guides. These modules are suitable for high-precision reciprocating motion applications. Leading brands include Yamaha, MISUMI, Hiwin, Silver, and TBI Motion.

Basic Structure

- Motor Flange

- Screw Bearing Seat

- Body

- Linear Guide

- Slider

- Slide Plate

- Ball Screw

Servo Planetary Reducers

Servo planetary reducers are often mounted on stepper and servo motors to reduce speed, increase torque, and match inertia. They feature high rigidity, high precision, high transmission efficiency, high torque-to-volume ratio, and maintenance-free operation. Leading brands include Alpha, Neugart, Stober, and ZF from Europe, Harmonic Drive, Shimpo, Sumitomo, and Nippon from Japan, APEX, VGM, PHT, SASAME, Dingyi, Liming, Seiko, and Thomas from Taiwan, and domestic brands like Hubei Planetary, Newstart, and Zhongda.

Cam Indexers

Cam indexers are high-precision rotary devices that rely on the gapless fit between cams and rollers (similar to worm gear transmission) to perform repetitive operations along a predetermined cam curve. They convert continuous rotary input into intermittent rotary, oscillating, or lifting motions. Commonly used in automation equipment such as rotary indexing tables. Leading brands include CDS from Italy, CAMCO from the USA, Sankyo from Japan, and TANTZU and DEX from Taiwan.

Advantages of Cam Indexers

- Simple structure

- Accurate movements

- Smooth transmission

- High output indexing accuracy

- Excellent high-speed performance

- Long service life

With the above content, we can better understand the roles and applications of various fasteners, threads, operating components, springs, single-axis drive modules, servo planetary reducers, and cam indexers in mechanical design. These components play a crucial role in ensuring the efficient and stable operation of equipment. I hope this article helps you gain a comprehensive understanding and mastery of these topics.

4o

Other Articles You Might Enjoy

- Mechanical Drawing Annotation Methods and Common Issues and Requirements

In mechanical processing, drawing annotations play a crucial role. The first key point is that the true size of the part should be based on the dimensions indicated on the…

- Blank Selection and Forming Methods in Mechanical Manufacturing

In mechanical manufacturing, selecting and forming blanks are critical factors that influence product quality, cost, and performance. Choosing the right blank can improve production efficiency and significantly reduce manufacturing costs.…

- Common Materials and Processability of Mechanical Parts

Mechanical parts are indispensable components in various machines and equipment. To ensure these parts operate efficiently under different working conditions, it is essential to understand the common materials used for…

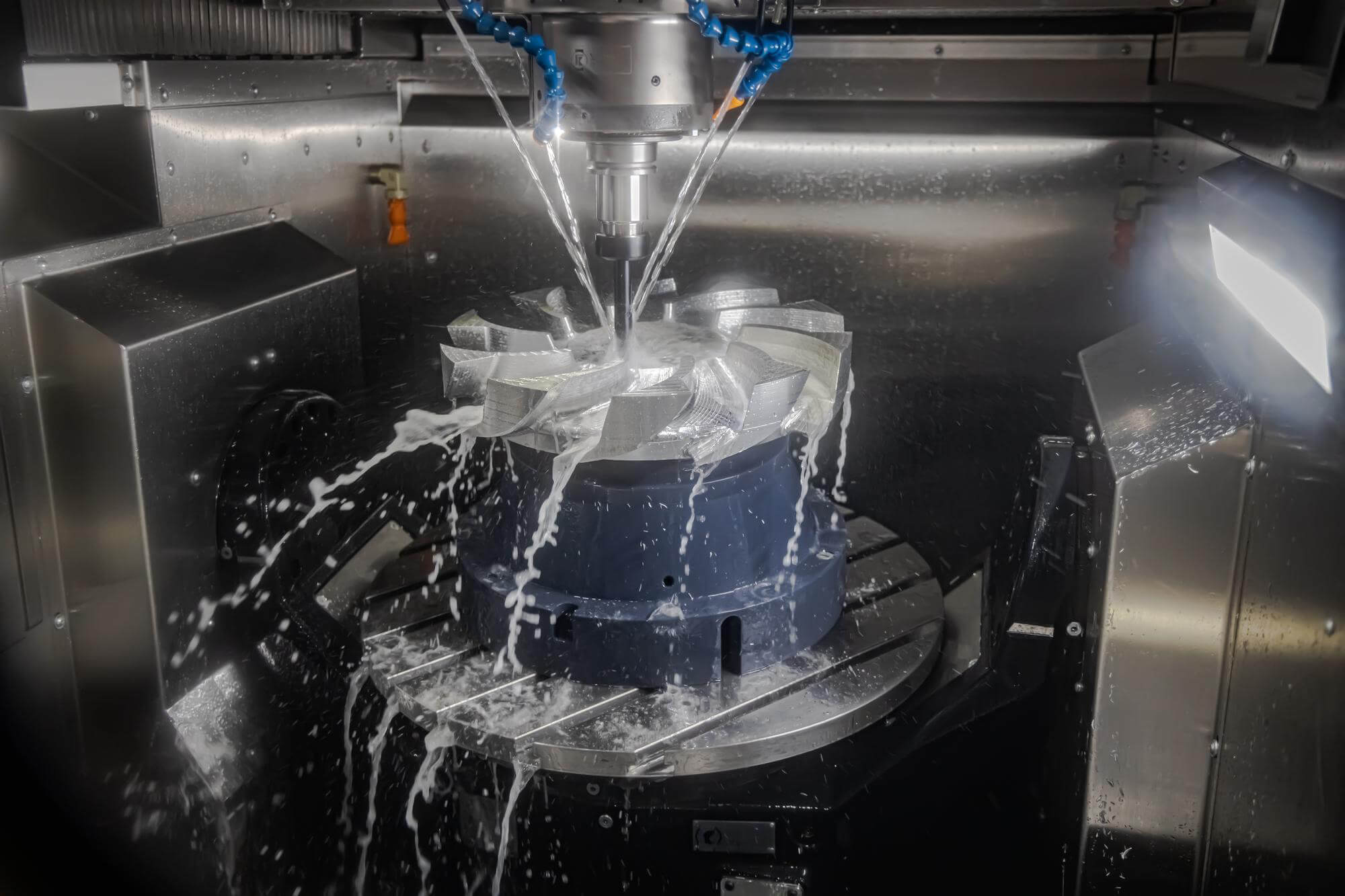

- Enhancing Surface Quality of CNC Machining Parts with Mechanical Preprocessing

Mechanical preprocessing When it comes to CNC machining, achieving a perfect surface finish is crucial. It's not just about making parts look good; it's about ensuring they function as intended,…

- Heat Treatment of Mechanical Part Materials and Their Applications

Introduction to Steel Heat Treatment Steel heat treatment involves heating, holding, and cooling the steel in solid-state to change its internal structure, thereby improving its mechanical and process properties. The…

- Mechanical Machining Surface Quality: From Principles to Practical Application

Mechanical machining surface quality is a crucial aspect of mechanical manufacturing that directly impacts the performance and longevity of parts. This article will discuss the principles, influencing factors, and practical…