The Secrets of Efficient Cutting for Hard-to-Cut Materials in CNC Machining

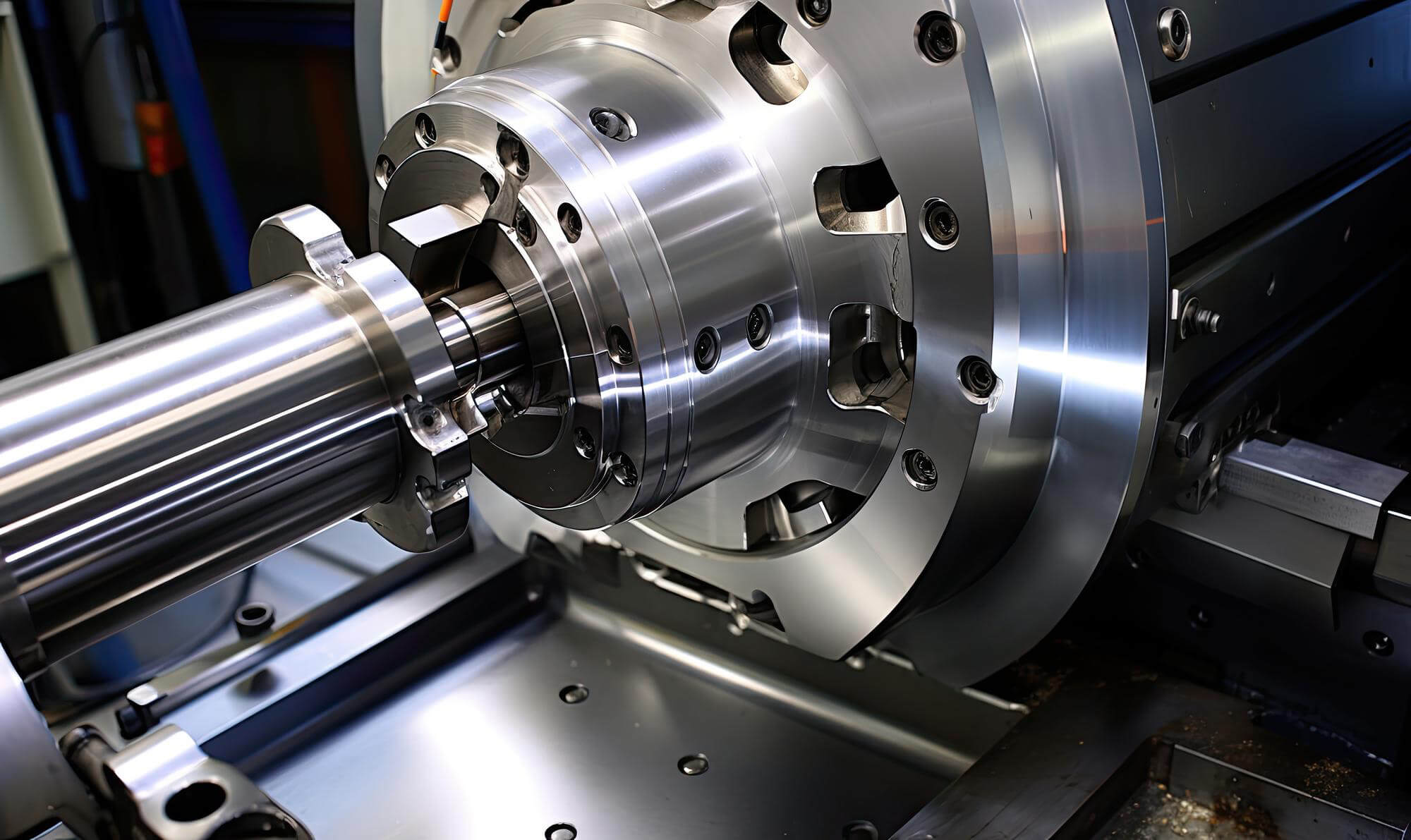

When it comes to procuring custom flanges and CNC machined parts, one critical aspect often overlooked is the residual stress left behind after machining. Residual stress can significantly impact the performance and longevity of these components, especially when they are exposed to high-pressure or high-temperature environments. This article will explore how high-speed machining (HSM) can optimize surface residual stress in CNC machined parts and flanges, ensuring you receive the highest quality products for your applications.

Understanding Residual Stress in CNC Machining

Residual stress refers to the stress that remains in a material after it has undergone machining processes such as cutting, milling, or grinding. These stresses can be either tensile (pulling apart) or compressive (pushing together) and are typically distributed unevenly throughout the material. While some level of residual stress is inevitable, controlling its magnitude and distribution is crucial for ensuring the structural integrity and performance of CNC machined parts and flanges.

Why Residual Stress Matters

Residual stress plays a significant role in the mechanical properties of machined parts. High tensile residual stress can lead to cracking, warping, or premature failure of components, particularly in high-stress applications like flanges used in piping systems. Conversely, compressive residual stress can enhance fatigue resistance and prolong the service life of a part.

For buyers of CNC machined parts and flanges, understanding how residual stress affects the final product can help in making informed decisions. This is where high-speed machining comes into play, offering a way to manage and optimize residual stress during the manufacturing process.

High-Speed Machining: The Game Changer

High-speed machining (HSM) is a process that operates at cutting speeds significantly higher than those used in conventional machining. By increasing the cutting speed, HSM reduces the amount of heat generated during machining, which in turn minimizes the thermal deformation of the material. This is critical for controlling residual stress in the final product.

How HSM Affects Residual Stress

- Reduced Thermal Deformation: One of the primary sources of residual stress is the thermal gradient that develops during machining. As the surface of the material heats up, it expands, while the underlying material remains cooler and less expanded. When the surface cools, it contracts, but the underlying material prevents it from contracting fully, leading to residual tensile stress. HSM reduces the amount of heat generated, thereby minimizing this effect.

- Improved Tool-Workpiece Interaction: At high speeds, the interaction between the cutting tool and the workpiece changes. The material removal rate increases, and the tool’s contact time with the material decreases, reducing the time for thermal and mechanical stresses to develop. This results in lower residual stress and a more uniform distribution of stress across the surface of the part.

- Controlled Material Hardening: Machining can cause surface hardening, where the material near the surface becomes harder due to the intense pressure and heat. While some hardening is beneficial, excessive hardening can lead to brittle surfaces prone to cracking. HSM allows for better control over the extent of surface hardening, optimizing the residual stress profile.

Tools and Techniques for Optimizing Residual Stress in Flanges

To achieve the best results in minimizing residual stress in CNC machined parts and flanges, the right combination of tools and machining techniques must be employed. Here’s how you can optimize your machining process:

Tool Selection

Using the right cutting tools is crucial in HSM. Tools made from materials like polycrystalline cubic boron nitride (PCBN) or ceramics are preferred because they can maintain their cutting edge at high speeds and temperatures. These tools also contribute to reducing residual stress by minimizing tool wear and maintaining a consistent cutting action.

Machining Parameters

Optimizing machining parameters such as cutting speed, feed rate, and depth of cut is essential for controlling residual stress. For instance, higher cutting speeds generally reduce residual stress by decreasing the thermal load on the material. However, this must be balanced against the tool’s durability and the desired surface finish.

Table 1: Recommended Machining Parameters for High-Speed Machining of Flanges

| Material | Cutting Speed (m/min) | Feed Rate (mm/tooth) | Depth of Cut (mm) | Residual Stress Reduction |

|---|---|---|---|---|

| Stainless Steel (304) | 800 | 0.1 | 0.5 | High |

| Titanium Alloy (Ti6Al4V) | 600 | 0.08 | 0.4 | Moderate |

| Inconel 718 | 500 | 0.07 | 0.3 | High |

| Aluminum 6061 | 1000 | 0.15 | 1.0 | Low |

Case Study: Optimizing Residual Stress in Stainless Steel Flanges

Let’s look at a practical example where high-speed machining was used to optimize residual stress in stainless steel flanges. Stainless steel is a popular choice for flanges due to its corrosion resistance and strength, but it is also known for being challenging to machine, especially when residual stress is a concern.

The Challenge

A client required custom stainless steel flanges for use in a high-pressure piping system. The flanges needed to withstand both high internal pressures and external environmental conditions without deforming or cracking. The primary concern was to minimize tensile residual stress on the flange surfaces, as this could lead to premature failure.

The Solution

The machining process was optimized using high-speed machining techniques. The cutting speed was set at 800 m/min, with a feed rate of 0.1 mm/tooth and a depth of cut of 0.5 mm. PCBN cutting tools were used due to their ability to maintain a sharp edge and reduce tool wear at high speeds.

The Results

The residual stress profile of the flanges was measured using X-ray diffraction techniques. The results showed a significant reduction in tensile residual stress on the surface of the flanges, with compressive residual stress dominating. This optimized stress distribution contributed to the flanges’ improved fatigue resistance and overall durability.

Table 2: Residual Stress Measurements Before and After High-Speed Machining

| Measurement Point | Before HSM (MPa) | After HSM (MPa) |

|---|---|---|

| Surface (Tensile) | 250 | 100 |

| Subsurface (Compressive) | -200 | -300 |

| Depth 0.2 mm (Tensile) | 150 | 50 |

| Depth 0.5 mm (Compressive) | -100 | -250 |

Practical Advice for Buyers of CNC Machined Flanges

As a buyer of CNC machined parts and flanges, understanding the impact of high-speed machining on residual stress can help you make more informed decisions. Here are some practical tips:

- Specify Residual Stress Requirements: When placing an order, clearly specify your requirements for residual stress. This ensures that the supplier uses appropriate machining techniques to meet your needs.

- Inquire About Machining Techniques: Ask your supplier about the machining techniques they use. Ensure they are familiar with high-speed machining and understand how to optimize residual stress.

- Request Quality Assurance: Ensure that your supplier provides quality assurance, including residual stress measurements. This will help you verify that the flanges meet your specifications.

- Consider Material Properties: Different materials respond differently to high-speed machining. Ensure that the supplier understands the material properties and adjusts the machining parameters accordingly.

- Evaluate the Cost-Benefit Ratio: While optimizing residual stress through high-speed machining may increase the initial cost, it can significantly enhance the performance and longevity of your flanges, offering long-term savings.

High-speed machining is a powerful tool for optimizing surface residual stress in CNC machined parts and flanges. By understanding the factors that contribute to residual stress and how HSM can control them, buyers can ensure they receive high-quality, durable components that meet their specific needs. As the demand for precision and reliability in CNC machined parts continues to grow, advanced machining techniques like HSM will play an increasingly important role in delivering the best possible products.

Other Articles You Might Enjoy

- Analyzing Residual Stress in Aluminum Alloy CNC Machining Parts

Residual stress is a crucial factor affecting the performance and durability of aluminum alloy components in aerospace applications. These parts are often large, thin-walled, and complex in structure, making them…

- Can Precision CNC Machining Compensate for Material Weaknesses in High-Stress Applications?

The Role of CNC Machining in Material Enhancement In engineering applications where materials are subjected to high stress, the choice and treatment of materials are crucial for the integrity and…

- Mastering Aluminum Frame CNC Machining Parts: Overcoming Deformation from Residual Stress

Aluminum frames are essential components in aerospace, replacing traditional assembly structures with large integral structures. These frames, such as the X3280 frame for helicopters, have significantly improved the manufacturing cycle,…

- High-Speed Machining Techniques in CNC Machining Parts: Secrets to Enhanced Efficiency and Quality

High-speed machining (HSM) is an intriguing and evolving field within CNC machining. The term "high-speed" is relative and varies depending on the machining method, workpiece material, and tool material. Defining…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- High-Precision CNC Machining for Military Applications

Introduction to High-Precision CNC Machining in Military Applications The technical realm of high-precision Computer Numeric Control (CNC) machining is fast becoming integral to the military sector. This process, which relies…