The precision and reliability of custom bolts are critical in industries such as aerospace, automotive, and construction. With the increasing complexity of modern engineering, standard bolts and screws are no longer adequate for many specialized applications. The need for custom screws has grown substantially as manufacturers face demands for fasteners that meet specific design, strength, and material requirements.

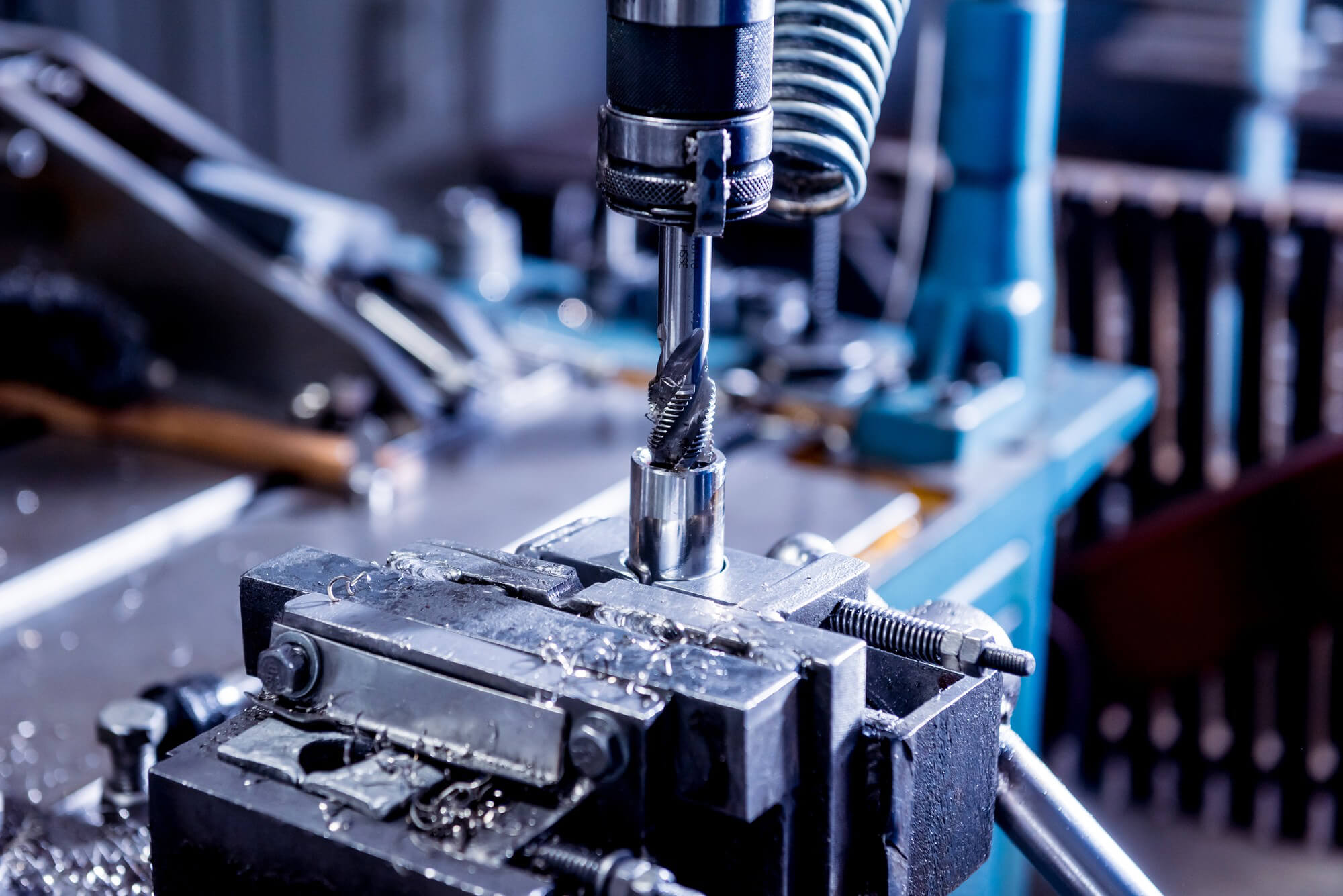

CNC machining has emerged as a vital technology in custom screw production. Its ability to create intricate, precise components while maintaining tight tolerances makes it the perfect solution for producing custom bolts. This article aims to provide an in-depth guide for procurement professionals to understand the production processes behind custom bolts, evaluate potential suppliers, and identify the key capabilities that a CNC machining partner should offer.

What Are Custom Bolts and Screws?

Custom bolts and screws are distinct from standard fasteners in several key ways:

- Custom Design and Specifications: Unlike standard screws that adhere to predefined sizes and threads (ISO, ANSI standards), custom fasteners are designed to meet unique specifications, tailored to specific project needs. This might include specialized threading, head types, or material choices.

- Material Versatility: Custom fasteners often use specialized materials such as titanium, nickel alloys, or high-strength polymers. These materials may be necessary for extreme environments or applications that require resistance to corrosion, high temperatures, or excessive wear.

- Performance: Custom screws and bolts are typically built for higher mechanical stresses and environmental conditions. Standard fasteners might not withstand the loads or operating conditions of industries like aerospace or heavy machinery, where reliability is paramount.

- Precision Manufacturing: Custom fasteners require greater precision, which is achieved through advanced manufacturing processes like CNC machining. These fasteners can meet the exact specifications required for size, threading, and materials.

- Production Volume: Custom fasteners are often produced in smaller batches than standard fasteners, allowing for enhanced quality control and customization.

Custom Screws vs Standard Screws: Key Differences

| Factor | Custom Screws | Standard Screws |

|---|---|---|

| Dimensions | Customized to specific project needs | Standardized sizes and specifications |

| Materials | High-performance materials (e.g., titanium) | Common materials (e.g., carbon steel) |

| Production Volume | Small to medium batch production | Mass production |

| Threading and Design | Unique thread designs, specialized head types | Standardized thread and head types |

| Performance | Designed for extreme or specific conditions | General-purpose applications |

| Manufacturing Process | CNC machining for precision and complexity | Automated processes, cold heading, rolling |

The Role of CNC Machining in Custom Bolt Production

CNC machining has revolutionized the production of custom screws and bolts. By enabling a high level of precision and flexibility, CNC machining allows manufacturers to meet stringent specifications for performance-critical industries. Here’s how CNC machining contributes to custom fastener production:

- Precision: CNC machines operate with computer-generated designs that direct every cut. This ensures that each custom screw or bolt is produced with the exact dimensions and tolerances required by the engineering design.

- Consistency and Repeatability: Once programmed, CNC machines can produce large batches of fasteners with identical specifications, ensuring consistency across all products.

- Complexity: CNC machines are capable of producing intricate designs that include non-standard thread profiles, unique head shapes, and specialized finishes, which are not feasible with traditional machining methods.

- Efficiency: While initial programming may take time, CNC machines run efficiently and can handle larger production volumes, making them suitable for both small-batch and larger-scale orders.

Production Technologies for Custom Bolt

Custom fastener production involves various manufacturing techniques depending on the complexity and requirements of the design. Some common processes include:

- CNC Machining: Used for precise cuts, threading, milling, and drilling, CNC machines offer flexibility in design. CNC technology allows the production of custom fasteners with tight tolerances and complex geometries.

- Cold Heading: Cold heading is a high-speed process where metal rods are shaped into screws without material removal. This method is often used for high-volume production, but it can also be adapted for simpler custom designs.

- Thread Rolling: This process forms threads by compressing the material, creating stronger and smoother threads compared to cutting. Thread rolling is a common method for both custom and standard screws.

- Heat Treatment and Surface Finishing: Depending on the application, fasteners might require heat treatment to enhance strength or surface finishing (anodizing, plating, or powder coating) to improve corrosion resistance and aesthetics.

Custom Bolt Design Considerations

Designing custom bolts requires a detailed understanding of the application and environmental factors they will face. Here are some of the essential considerations when designing custom fasteners:

Key Design Factors:

- Material Selection: Materials must be chosen based on the environment in which the fasteners will be used. For example, stainless steel is corrosion-resistant and suitable for marine environments, while titanium is lightweight and strong, making it ideal for aerospace.

- Thread Types: The choice between coarse and fine threads depends on the application. Coarse threads are stronger and allow for faster assembly, while fine threads offer greater precision and are suited to applications requiring tighter tolerances.

- Surface Finishing: Surface treatments can improve both the aesthetics and the longevity of fasteners. Zinc plating, anodizing, and powder coating can enhance corrosion resistance and appearance.

- Head Style: The choice of head style impacts how the bolt will be installed and tightened. Hex, flat, and socket heads are common styles that cater to different installation tools and spatial constraints.

- Heat Treatment: For fasteners used in high-stress applications, heat treatments can enhance tensile strength, hardness, and durability.

- Load and Stress Requirements: Fasteners designed for high-load applications, such as automotive or aerospace, must account for tensile and shear forces. Precise engineering ensures that bolts won’t fail under stress.

- Vibration Resistance: Fasteners in machinery or automotive applications may need to resist vibration. Features like self-locking threads or specialized coatings help keep bolts secure in high-vibration environments.

- Corrosion Resistance: Fasteners used in corrosive environments, such as marine or chemical exposure, should be made of corrosion-resistant materials like stainless steel or titanium or should have protective coatings like galvanization.

- Manufacturing Tolerances: Precision fasteners used in aerospace, medical devices, or precision machinery often require tight manufacturing tolerances, achievable through CNC machining.

- Cost Efficiency: Custom bolts often prioritize performance, but it’s essential to balance cost as well. CNC machining allows cost-efficient production by focusing machining efforts where they are most needed.

Table 1: Custom Bolt Design Options

| Design Factor | Options | Considerations |

|---|---|---|

| Material | Stainless Steel, Titanium, Brass | Application environment, strength requirements |

| Thread Type | Coarse, Fine, Extra-Fine | Load-bearing capacity, precision needed |

| Surface Finish | Anodizing, Plating, Coating | Corrosion resistance, appearance |

| Head Style | Hex, Flat, Socket | Tool compatibility, space limitations |

| Heat Treatment | Annealing, Quenching, Tempering | Strength, toughness |

| Load Resistance | High Tensile, Shear Loads | Automotive, aerospace environments |

| Vibration Protection | Self-Locking Threads, Specialized Materials | Machinery, automotive applications |

| Corrosion Protection | Galvanization, Stainless Materials | Marine or chemical environments |

| Tolerances | Tight CNC-Machined Tolerances | Precision in aerospace, medical, and automotive fields |

Evaluating Suppliers for Custom Screws and Bolts

When evaluating suppliers for custom screws and bolts, it’s essential to look beyond pricing and assess several key factors. These elements help ensure the supplier can deliver the required level of precision, performance, and quality for your specific project.

Key Considerations:

- CNC Machining Capabilities:

Ensure the supplier has multi-axis CNC machining capabilities that can accommodate the complexity of your custom designs. Some designs may require 4- or 5-axis machines for more intricate geometries, and suppliers with advanced CNC technology can better handle tight tolerances and demanding specifications.

Evaluate the types of materials the supplier can work with. You want a supplier that has experience machining the materials you need, such as titanium, stainless steel, aluminum, or specialized alloys like Inconel. The ability to work with difficult-to-machine materials often indicates a higher level of expertise. - Industry Experience:

Assess the supplier’s experience in producing custom fasteners for industries that demand high performance and compliance with stringent regulations. If your project involves aerospace, medical devices, or automotive applications, you’ll want a supplier familiar with the regulatory requirements and standards of your industry.

Consider whether the supplier has worked on similar projects or products before. A history of success in manufacturing custom screws for your sector is a strong indicator that they can meet your specific needs. - Quality Management Systems:

The supplier should adhere to internationally recognized quality management standards such as ISO 9001, AS9100 (for aerospace), or IATF 16949 (for automotive). These certifications ensure the supplier has established quality control processes to maintain consistency, traceability, and compliance throughout production.

Ask about the supplier’s inspection protocols. Do they have advanced measuring equipment like coordinate measuring machines (CMM) to verify part dimensions? Regular quality inspections ensure that each fastener meets the required specifications before shipment. - Production Capacity and Scalability:

It is important to ensure that your supplier has the capacity to meet both your current and potential future needs. Do they have the flexibility to scale production to meet growing demand while maintaining quality and lead times? Ask whether they can handle both small custom orders and larger production runs, especially if your project scales up in the future.

Additionally, inquire about their inventory management. Can they maintain stock or deliver just-in-time (JIT) to help you avoid unnecessary downtime in your production? - Lead Time and On-Time Delivery:

Evaluate the supplier’s ability to meet your deadlines. Delays in custom screw production can have significant impacts on the overall project timeline. Ask about their lead times for initial orders, prototyping, and subsequent production runs.

Ensure the supplier has a proven track record for on-time delivery. Consistent delays could signal inefficiencies or capacity limitations in their manufacturing process. - Cost and Value for Money:

While cost should not be the only deciding factor, it is still essential to ensure the supplier offers a competitive price relative to the quality and services provided. Assess whether the pricing structure reflects the complexity of the parts, the materials used, and any value-added services such as heat treatment, coating, or finishing.

Suppliers offering additional services like assembly or post-processing can save time and money by consolidating multiple production steps under one roof. - Customer Support and Communication:

Strong customer support is vital, especially in custom manufacturing. Choose a supplier who communicates well, responds promptly to inquiries, and provides updates throughout the production process.

Ask if the supplier provides design consultation and technical support. This can be especially useful during the early stages of development, as their expertise can help you refine your design for manufacturability.

Table 2: Key Considerations When Choosing a Custom Screw Supplier

| Evaluation Factor | Questions to Ask |

|---|---|

| CNC Machining Capabilities | Does the supplier have multi-axis CNC machining capabilities? |

| Material Expertise | Can they work with the materials required for your project? |

| Industry Experience | Have they manufactured fasteners for similar industries or projects? |

| Quality Certifications | Are they certified in ISO 9001, AS9100, or relevant standards? |

| Production Capacity | Can they handle both small custom orders and larger production runs? |

| Lead Time and Delivery | What is their track record for on-time delivery? |

| Cost and Services | Do they offer value-added services like heat treatment or coating? |

| Customer Support | Do they provide design consultation and regular production updates? |

Conclusion

Selecting the right supplier for custom bolts and screws is a multifaceted process that requires careful consideration of factors such as CNC machining capabilities, industry expertise, and adherence to quality standards. CNC machining has revolutionized custom screw production, offering unparalleled precision, consistency, and design flexibility that traditional methods cannot match.

By understanding the production processes, evaluating the necessary design considerations, and working with an experienced supplier, procurement professionals can ensure that their custom screws and bolts meet all the requirements for performance, durability, and cost-effectiveness.

As industries continue to demand higher precision and specialized fasteners, custom bolts produced via CNC machining will play a critical role in pushing the boundaries of innovation in fields such as aerospace, automotive, and construction.

FAQ

- What is the difference between custom screws and standard screws?

Custom screws are designed and manufactured to meet unique design, material, and performance specifications, while standard screws adhere to predefined industry standards for general applications. Custom screws are often used in specialized industries such as aerospace or automotive. - Why is CNC machining important for custom screw production?

CNC machining allows for high precision, repeatability, and flexibility in creating custom screws. It ensures that each screw meets exact specifications in terms of size, threading, and material, which is crucial for industries requiring tight tolerances. - How do I choose the right supplier for custom screws?

Choose a supplier with multi-axis CNC machining capabilities, industry-specific experience (e.g., aerospace, automotive), and adherence to international quality standards like ISO 9001 or AS9100. Ensure they can handle the required production capacity and offer reasonable lead times. - What materials are typically used for custom screws?

Common materials include stainless steel, titanium, brass, aluminum, and specialized alloys like Inconel for high-temperature environments. The choice of material depends on the application’s requirements for strength, corrosion resistance, and temperature tolerance. - Can custom screws handle high-stress environments?

Yes, custom screws can be designed to withstand extreme mechanical stresses, including high tensile and shear loads, making them suitable for industries like aerospace, automotive, and heavy machinery. - What is the typical lead time for custom screws?

Lead times vary depending on the complexity of the design and the supplier’s production capacity. However, CNC machining often provides faster turnaround times compared to traditional methods, especially for smaller production runs. - Are custom screws more expensive than standard screws?

Custom screws tend to be more expensive due to the specialized manufacturing processes involved and the use of high-performance materials. However, they provide superior performance, longevity, and reliability, often justifying the higher cost in critical applications. - What surface finishes are available for custom screws?

Common surface finishes include anodizing, zinc plating, powder coating, and galvanizing. These finishes enhance corrosion resistance, improve appearance, and sometimes add extra durability to the screws.

Other Articles You Might Enjoy

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Innovative CNC Machining for Custom Marine Propulsion Systems

Introduction to CNC Machining and Custom Marine Propulsion Systems CNC machining, or Computer Numerical Control machining, is a crucial technological advancement that entails the use of computers to control machine…

- Custom CNC Machining Solutions for Aerospace Instrumentation

Introduction to CNC Machining in Aerospace Instrumentation In the modern era, Custom Numerical Control (CNC) machining has emerged as a pivotal capability in the aerospace industry. Pioneering advancements in technology…

- Custom CNC Machining for Unique Applications: Exotic Material Options

Introduction to Custom CNC Machining and Exotic Material Options Custom Computer Numerical Control (CNC) machining epitomizes the pinnacle of advanced manufacturing procedures. It enables the transformation of a digital design…

- Custom Precision CNC Machining Services for Bronze Parts

Introduction to CNC machining and Bronze Parts Manufacturing Custom precision Computer Numerical Control (CNC) machining is a unique technology that employs computerized controls and machine tools to eradicate layers of…