Introduction to Yield Stress and Its Importance in CNC Machining

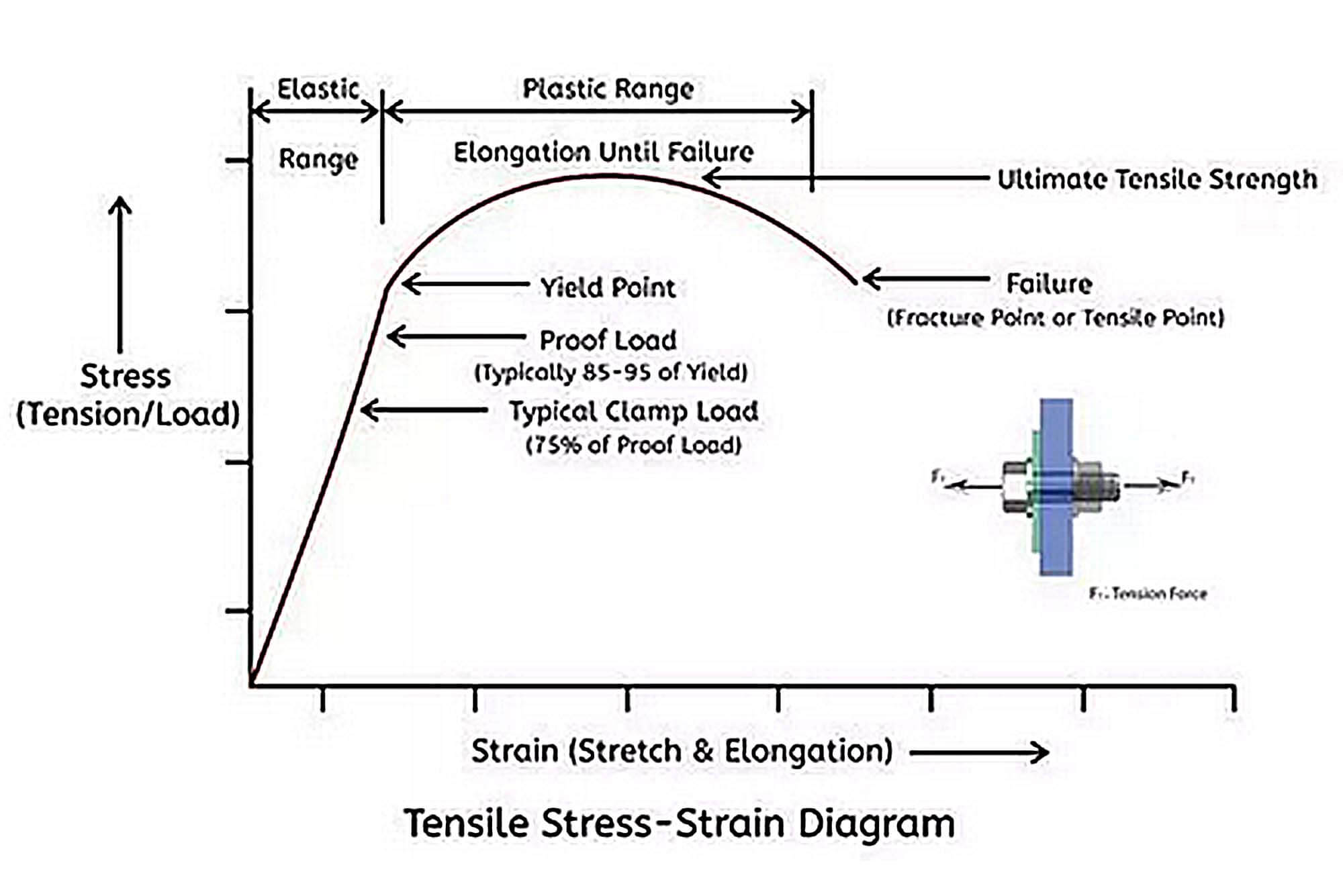

When we think about machining and materials, yield stress is one of the most crucial properties to understand. Yield stress is defined as the stress level at which a material begins to deform plastically. Below this stress, a material will return to its original shape if the applied stress is removed. However, once yield stress is surpassed, permanent deformation begins, making yield stress a defining point in the behavior of materials under force. In CNC machining, knowing a material’s yield stress is essential, as it affects everything from tool selection and machining parameters to final product durability.

In my own experience with CNC machining, yield stress has proven to be a critical factor, especially when working with materials under high loads or demanding conditions. Misjudging yield stress can lead to product failure, tool damage, or unexpected material behavior during machining. Thus, a thorough understanding of yield stress allows engineers, machinists, and CNC operators to optimize machining processes, enhance material performance, and ensure product quality.

| Material Property | Definition | Importance in CNC Machining |

|---|---|---|

| Yield Stress | The stress at which a material begins to deform permanently | Determines material suitability, tool selection, and process parameters |

| Elastic Limit | Maximum stress a material can handle and still return to its original form | Ensures material shape integrity during machining |

| Tensile Strength | Maximum stress a material can withstand while being stretched | Guides final product strength and durability |

Yield stress is integral to CNC machining because it allows machinists to estimate how much stress the material can handle during different machining processes. This concept is especially relevant when cutting, milling, or drilling high-strength metals like steel or titanium, where maintaining material integrity is essential.

Why Yield Stress Matters for Different Materials in CNC

Different materials have vastly different yield stresses, which influence their performance and suitability in CNC machining. Let’s explore how yield stress affects some of the most commonly machined materials, including steel, aluminum, titanium, and engineering plastics.

Yield Stress and Steel

Steel, particularly in its low-carbon forms, has moderate to high yield stress, making it durable and suitable for structural and load-bearing applications. However, high-strength alloys used in aerospace or automotive parts have much higher yield stresses, requiring specific machining parameters to prevent unwanted deformation.

| Type of Steel | Yield Stress (MPa) | Applications in CNC |

|---|---|---|

| Low Carbon Steel | 250-400 | Structural parts, frames, fasteners |

| Stainless Steel | 200-600 | High-durability parts, medical devices |

| High-Strength Steel | 500+ | Automotive parts, aerospace |

Yield Stress and Aluminum

Aluminum alloys have relatively low to moderate yield stresses, making them easier to machine. Their low density and good yield properties make them suitable for applications needing lightweight and durable components.

| Type of Aluminum | Yield Stress (MPa) | Applications in CNC |

|---|---|---|

| Pure Aluminum | 30-80 | Prototypes, lightweight components |

| 6061 Alloy | 240-280 | Aircraft, automotive, consumer products |

| 7075 Alloy | 470 | High-stress parts, sports equipment |

Yield Stress and Titanium

Titanium and its alloys, prized for strength and light weight, have high yield stresses, making them a challenge to machine. Despite its benefits, machining titanium requires precision, slower speeds, and tough tooling to handle its high yield stress and prevent material fatigue.

Yield Stress and Engineering Plastics

Engineering plastics like polycarbonate (PC) and polyetheretherketone (PEEK) have lower yield stresses than metals, but their flexibility and light weight make them useful for medical devices, electronics, and lightweight enclosures. The relatively low yield stress of plastics means they can deform under higher temperatures or stresses, so precision is crucial.

Key CNC Machining Considerations Based on Material Yield Stress

Understanding a material’s yield stress plays a significant role in CNC machining, as it helps determine critical machining parameters such as cutting speed, feed rate, and tool selection.

Adjusting Cutting Speed and Feed Rate

The cutting speed and feed rate must be adjusted based on the material’s yield stress to avoid excessive forces that could push the material past its yield point. For instance:

- Low-yield materials like plastics or softer aluminum can handle higher cutting speeds, allowing for faster machining without significant risk of deformation.

- High-yield materials like titanium or high-strength steel require lower speeds and careful feed control to maintain surface integrity.

| Material | Recommended Cutting Speed (m/min) | Feed Rate (mm/rev) | Considerations |

|---|---|---|---|

| Low-Carbon Steel | 100-150 | 0.2-0.5 | Maintain moderate speeds to reduce heat |

| Aluminum | 200-400 | 0.5-1.0 | High speeds possible with minimal risk |

| Titanium | 20-50 | 0.1-0.3 | Low speeds prevent tool wear and heat buildup |

| Engineering Plastic | 150-300 | 0.5-1.0 | Avoid overheating to maintain precision |

Tool Selection and Wear Prevention

Tool wear is another consideration directly impacted by yield stress. Materials with high yield stress, such as high-carbon steel and titanium, can cause faster tool wear. In these cases, using carbide or ceramic tools can help prolong tool life and maintain accuracy.

Importance of Coolants and Lubricants

Maintaining temperature control is essential, especially for high-yield materials, which can retain heat and become more challenging to machine. Using coolants helps reduce the thermal stress on both the material and the tool, preventing issues like thermal deformation or work hardening in metals like titanium.

Yield Stress and Tool Selection: Choosing the Right Tool for High-Strength Materials

For materials with high yield stress, the choice of tool becomes critical. In my experience, using tools designed specifically for high-strength materials makes a significant difference in efficiency and product quality.

| Material Type | Recommended Tool Material | Tool Coatings | Purpose |

|---|---|---|---|

| High-Strength Steel | Carbide, HSS (High-Speed Steel) | TiN, TiAlN coatings | Minimize wear, increase tool life |

| Titanium | Ceramic, CBN (Cubic Boron Nitride) | Diamond, TiAlN | Handle high temperatures, reduce wear |

| Aluminum | Standard carbide | Uncoated or TiN | Light machining, no need for heavy-duty |

| Engineering Plastic | Carbide | None | Prevents softening, ideal for precision |

Selecting the right tool allows CNC operators to handle high-strength materials efficiently while avoiding costly tool replacements.

Practical Tips for Machining Materials with High and Low Yield Stress

Both high- and low-yield materials require specific handling to achieve optimal results in CNC machining.

Low-Yield Stress Materials

- Avoid Excessive Clamping: Materials with lower yield stress can easily deform under high clamping forces. Using soft jaws or adjusting clamping pressures can help maintain the material’s shape.

- Higher Cutting Speeds: Low-yield materials like aluminum can withstand higher cutting speeds, which can improve machining speed and efficiency.

High-Yield Stress Materials

- Use of Coolants: High-yield materials, such as titanium, require continuous cooling to avoid overheating, which can lead to deformation or hardening of the material.

- Moderate Feed Rates: High-yield materials benefit from lower feed rates, which prevent tool wear and ensure a smoother finish.

Industry-Specific Applications of Yield Stress in CNC Machining

Yield stress plays a significant role across various industries, influencing decisions in material selection, part design, and CNC machining parameters. Here’s a look at how yield stress impacts specific applications within the aerospace, automotive, and tool-making industries.

Aerospace Industry

In aerospace, where components are subject to high levels of stress, understanding yield stress is critical for ensuring safety and performance. Aerospace components, such as fuselage frames, landing gear, and turbine blades, must withstand extreme loads and temperature fluctuations. Materials like titanium alloys and high-strength steel are often selected for their high yield stresses, enabling them to resist deformation under stress.

| Aerospace Component | Typical Material | Yield Stress (MPa) | Machining Considerations |

|---|---|---|---|

| Fuselage Frame | Aluminum Alloy 7075 | 470 | Requires lightweight precision |

| Landing Gear | High-Strength Steel | 500+ | Low feed rate, high durability |

| Turbine Blade | Titanium Alloy | 800+ | High hardness, heat-resistant tools |

In my experience, aerospace machining demands the highest precision due to safety standards. Achieving reliable performance for parts under high-stress conditions is directly tied to careful management of yield stress in material selection and CNC machining processes.

Automotive Industry

Automotive components often undergo stress in the form of vibrations, impacts, and temperature changes. Parts like engine blocks, suspension arms, and drive shafts are commonly made from materials with specific yield stress thresholds to ensure reliability and durability. High-strength steels and aluminum alloys are widely used in CNC-machined automotive parts.

| Automotive Component | Typical Material | Yield Stress (MPa) | Machining Considerations |

|---|---|---|---|

| Engine Block | Aluminum Alloy 6061 | 240 | High-speed machining, cooling system |

| Suspension Arm | High-Strength Steel | 500 | Low speed, carbide tooling |

| Drive Shaft | Alloy Steel | 400-600 | Moderate speed, heat-resistant tool |

Yield stress helps in identifying the best material for parts that will experience high loads and repetitive stress. Having worked with automotive components, I’ve seen that selecting the correct yield stress can prevent part failure under harsh conditions, extending the life of key vehicle components.

Tool and Die Industry

In tool-making, yield stress is essential for choosing materials that can withstand repetitive high-force applications, such as forming or stamping. Materials used in dies and molds, such as tool steels and carbide composites, need high yield stresses to endure without deformation or wear.

| Tool Component | Typical Material | Yield Stress (MPa) | Machining Considerations |

|---|---|---|---|

| Die for Metal Forming | Tool Steel | 600+ | High strength, low feed rate |

| Injection Mold | Hardened Steel | 500-800 | Abrasion-resistant tooling |

| Cutting Tool | Tungsten Carbide | 1000+ | Requires high precision, wear-resistant |

From my work with tool-making components, I’ve seen that understanding the yield stress of these materials ensures they can handle heavy use without deforming, keeping production processes efficient and minimizing costly downtime.

Case Studies: Improving CNC Processes Through Yield Stress Optimization

Understanding yield stress can lead to significant improvements in CNC machining processes. Here are some case studies showing how adjusting processes based on yield stress data has helped optimize CNC machining outcomes.

Case Study 1: Aerospace – Optimizing Titanium Machining

Challenge: An aerospace company needed precision turbine blades made from titanium alloy. Titanium’s high yield stress was essential for the performance of these parts, but its toughness led to rapid tool wear and overheating.

Solution: CNC parameters were adjusted to slow the feed rate and reduce cutting speed, which allowed for better control over temperature and minimized wear on the tool. Additionally, the team employed a high-efficiency coolant system to handle the heat buildup.

| Parameter | Initial Setting | Optimized Setting | Result |

|---|---|---|---|

| Cutting Speed (m/min) | 40 | 20 | Reduced tool wear |

| Feed Rate (mm/rev) | 0.3 | 0.1 | Improved surface finish |

| Coolant Usage | Standard | High-efficiency | Lowered operating temperature |

The yield stress of titanium allowed the final component to withstand operational stresses in aerospace applications, with the optimized settings leading to fewer tool changes and improved efficiency.

Case Study 2: Automotive – Enhancing Durability of Suspension Arms

Challenge: An automotive manufacturer required high-strength suspension arms capable of handling repeated stress without bending or breaking. High-strength steel was chosen, but during CNC machining, the yield stress was causing challenges in cutting accuracy and surface quality.

Solution: Switching to a titanium-coated carbide tool helped handle the high yield stress of the steel. Adjusting cutting speeds and incorporating intermediate coolant pauses also ensured surface integrity, extending the tool’s life and improving the component’s durability.

| Parameter | Initial Setting | Optimized Setting | Result |

|---|---|---|---|

| Tool Material | Standard carbide | Titanium-coated | Increased tool lifespan |

| Feed Rate (mm/rev) | 0.3 | 0.2 | Enhanced surface finish |

| Coolant Pause Frequency | None | Every 10 mins | Reduced material overheating |

This yield stress-oriented approach resulted in parts that met durability standards with lower production costs and increased efficiency.

Case Study 3: Electronics – Precision Machining of Plastic Components

Challenge: A manufacturer of electronic components needed CNC machining for polycarbonate enclosures that would withstand light impacts without warping. The low yield stress of polycarbonate meant that high clamping pressure could deform the material, affecting the product’s dimensional accuracy.

Solution: By reducing clamping force and increasing the cutting speed, the CNC operator could produce parts with high dimensional accuracy without causing deformation. Switching to a sharp, uncoated tool also helped to ensure that the polycarbonate wouldn’t melt or warp under pressure.

| Parameter | Initial Setting | Optimized Setting | Result |

|---|---|---|---|

| Clamping Pressure | High | Low | Reduced material deformation |

| Cutting Speed (m/min) | 200 | 300 | Enhanced machining speed |

| Tool Selection | Coated carbide | Sharp uncoated tool | Improved surface quality |

The adjustment based on polycarbonate’s yield stress resulted in highly accurate parts that were free from warping, with improved efficiency and reduced waste.

These case studies demonstrate the practical importance of yield stress in CNC machining. By adjusting machining parameters to align with a material’s yield stress, companies can achieve higher precision, increased tool lifespan, and better product durability. Each example underscores how knowing and applying yield stress data allows manufacturers to optimize their CNC processes and produce better quality components.

Conclusion: Leveraging Yield Stress for CNC Machining Excellence

In the world of CNC machining, yield stress serves as a fundamental guide for selecting materials, optimizing machining parameters, and ensuring product quality. Understanding the yield stress of various materials enables machinists and engineers to set machining parameters that enhance precision and prevent issues like tool wear, deformation, or part failure.

In my experience, yield stress acts as a benchmark, especially in high-performance industries like aerospace, automotive, and tool-making. By selecting materials based on yield stress and adapting machining processes to suit these properties, companies can significantly improve efficiency and reduce costs. It’s more than just a number—it’s a key factor that informs every step of the machining process, from tool selection to feed rate adjustments and even coolant use.

In closing, whether you’re working with high-yield-stress metals or softer plastics, yield stress provides invaluable insight. Armed with this knowledge, machinists can make informed decisions that ultimately lead to better-quality products and longer-lasting tools. Yield stress is, in essence, a tool of its own—a guiding parameter that helps unlock the full potential of CNC machining in diverse and demanding applications.

FAQ

Here are some common questions about yield stress and CNC machining that often come up in my experience with material selection and machining optimization.

1. What is yield stress, and why is it important in CNC machining?

Yield stress is the point at which a material begins to deform permanently under stress. In CNC machining, understanding yield stress helps to select the right materials and set appropriate machining parameters. It ensures that the material won’t deform or fail under the machining forces applied, leading to better precision and durability.

2. How does yield stress differ between materials commonly used in CNC machining?

Yield stress varies significantly among materials. For example, low-carbon steel has a moderate yield stress, making it relatively easy to machine. In contrast, titanium alloys have a high yield stress, requiring slower speeds and specialized tooling. Understanding these differences allows machinists to adapt their processes accordingly.

3. What happens if a material’s yield stress is exceeded during CNC machining?

If the yield stress is exceeded, the material undergoes plastic deformation, resulting in permanent shape changes. This can cause parts to become unusable, affect dimensional accuracy, and require costly rework. Carefully managing machining parameters based on yield stress helps prevent this.

4. Can high-yield-stress materials be machined at high speeds?

High-yield-stress materials generally cannot be machined at high speeds without risking tool wear or part deformation. They require slower cutting speeds and reduced feed rates to manage stress and heat buildup effectively.

5. How does yield stress affect tool wear during CNC machining?

High-yield-stress materials put more pressure on tools, causing them to wear out faster. In these cases, using hard, wear-resistant tools like carbide or ceramic, along with the right coatings, can help prolong tool life.

6. What role do coolants play when machining high-yield-stress materials?

Coolants help manage the heat generated by machining high-yield-stress materials. By reducing the temperature, they prevent thermal expansion and stress, allowing for more accurate machining and preventing the workpiece from deforming.

7. Are there yield stress limits I should consider when choosing materials for CNC machining?

Yes, choosing materials within an appropriate yield stress range for the application is crucial. For example, for lightweight parts with low stress, materials with lower yield stress (like aluminum) are suitable. For high-load applications, high-yield-stress materials (like titanium or high-strength steel) are preferred.

8. How do I calculate yield stress for a specific application?

Yield stress can be measured through tensile testing, which involves applying force until the material begins to plastically deform. Most suppliers provide yield stress data for common materials, so you can select materials based on those values.

9. Is yield stress the same as tensile strength?

No, yield stress is the stress at which permanent deformation begins, while tensile strength is the maximum stress a material can withstand before breaking. Yield stress helps predict material performance under normal loads, while tensile strength indicates maximum load capacity.

10. Can yield stress influence the choice of CNC machine itself?

Yes, high-yield-stress materials require CNC machines with greater stability, strength, and rigidity to handle the forces involved. A sturdy machine reduces vibrations and maintains precision when machining tougher materials.

11. Why is yield stress particularly relevant for aerospace and automotive parts?

In industries like aerospace and automotive, components face extreme stresses during use. Yield stress data ensures materials can withstand these stresses without permanent deformation, leading to safer, longer-lasting parts.

12. Do machining strategies change with the yield stress of plastic materials?

Yes, plastics with low yield stress require different clamping and machining strategies. Lower clamping forces and sharp, uncoated tools are often used to avoid deformation or softening of the plastic under machining forces.

13. How does yield stress impact the design of load-bearing parts?

For load-bearing parts, yield stress determines the maximum force the material can withstand before deforming. Choosing materials with sufficient yield stress prevents part failure and extends the life of the structure or component.

14. Can yield stress data help reduce waste in CNC machining?

Absolutely. By understanding yield stress, machinists can prevent over-stressing materials, reducing errors and rework. This leads to higher material efficiency, cost savings, and minimized waste.

15. What are the main machining challenges when working with low-yield-stress materials?

Low-yield-stress materials are prone to deformation, especially under high clamping forces or excessive speeds. Adjusting these factors and using proper support reduces the risk of deformation and improves machining accuracy.

Other Articles You Might Enjoy

- Understanding the Stress Strain Curve for CNC Material Selection

The Importance of the Stress-Strain Curve in CNC Machining In the world of CNC machining, understanding the stress-strain curve isn't just a technical necessity—it's a strategic advantage. When I first…

- How Does Tensile Stress Affect CNC Machining Processes

Tensile stress is a fundamental concept in material science that has far-reaching implications in CNC machining processes. Understanding how tensile stress interacts with various materials can greatly impact the effectiveness…

- SFM Meaning and Its Importance in CNC Machining for Different Materials

Introduction: What Is SFM and Why Does It Matter in CNC? When I first heard the phrase “sfm meaning” in the context of CNC machining, I remember feeling a bit…

- Can Precision CNC Machining Compensate for Material Weaknesses in High-Stress Applications?

The Role of CNC Machining in Material Enhancement In engineering applications where materials are subjected to high stress, the choice and treatment of materials are crucial for the integrity and…

- Analyzing Residual Stress in Aluminum Alloy CNC Machining Parts

Residual stress is a crucial factor affecting the performance and durability of aluminum alloy components in aerospace applications. These parts are often large, thin-walled, and complex in structure, making them…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Optimizing CNC Machining with Hybrid Materials: Benefits and Challenges

Introduction: CNC Machining and the Role of Hybrid Materials CNC machining, short for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory…

- What should be noted about materials when machining parts with CNC?

When machining parts with CNC, not all materials can be precisely processed. Some materials are too hard and may damage the CNC machining tools, making them unsuitable for precision machining…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…