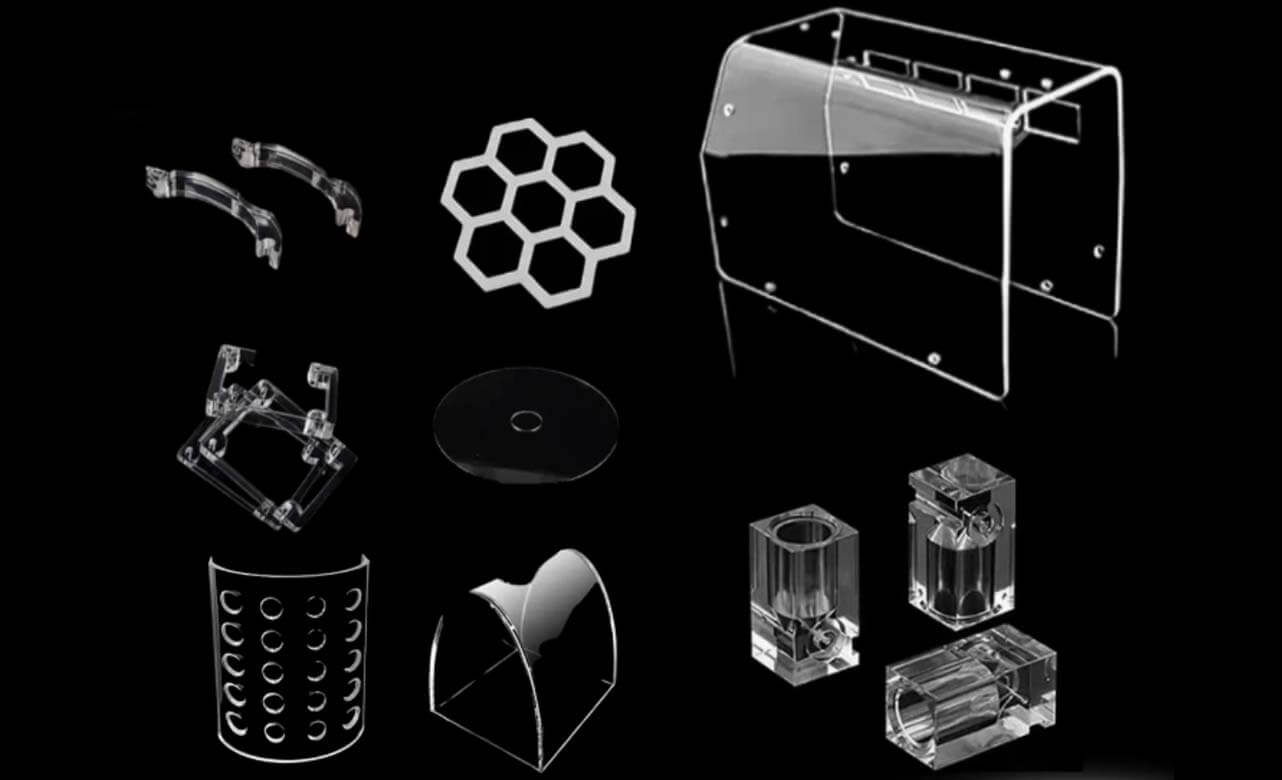

Polycarbonate Glass has become increasingly valuable in industrial and architectural applications due to its high impact resistance, clarity, and durability. Unlike standard glass, polycarbonate is lightweight and can withstand extreme conditions without cracking, making it ideal for applications ranging from safety shields to high-impact equipment. With CNC (Computer Numerical Control) custom machining, we can further enhance these benefits by precisely shaping, cutting, and treating polycarbonate glass for specific industry needs.

From my experience, polycarbonate glass holds an important place in applications where both transparency and strength are essential. The combination of polycarbonate’s natural properties and CNC’s precise customization capabilities makes it possible to produce tailor-made solutions that meet stringent industry standards. This article will explore the various applications of polycarbonate glass, delve into CNC machining processes, and offer guidance on selecting a reliable CNC supplier for polycarbonate projects.

Let’s dive into how polycarbonate glass is enhanced through CNC custom machining.

Key Industrial Applications of Polycarbonate Glass

Architecture and Interior Design

In architecture and interior design, polycarbonate glass offers a lightweight and durable alternative to traditional glass. I’ve seen its use in skylights, facades, and decorative partitions where CNC machining enables custom shapes and sizes that blend aesthetics with function. Architects and designers prefer polycarbonate glass because it maintains high transparency while offering impact resistance—a quality that’s crucial in high-traffic public spaces.

In skylight applications, CNC custom machining allows precise shaping of polycarbonate glass panels to fit unique roof structures. This level of customization ensures seamless integration with architectural designs, achieving both style and safety. CNC machining also offers edge finishing options, which create polished edges and improve the overall look of installations in high-visibility areas.

Safety and Protective Equipment

Polycarbonate glass is a popular choice for protective equipment due to its impact resistance. When processed through CNC machining, polycarbonate glass can be cut, drilled, and shaped into safety shields, face protectors, and machine guards. Personally, I’ve found that CNC customization significantly improves the fit and durability of these products, ensuring they meet safety standards in various industries.

In machine guards, for example, CNC machining allows for precise cutouts and mounting holes, enabling easy installation and a snug fit around machinery. This custom fit not only protects equipment operators but also reduces wear on the machinery itself by minimizing gaps where debris or foreign objects might enter.

Industrial and Manufacturing Equipment

CNC-machined polycarbonate glass is widely used in industrial equipment screens, control panels, and protective shields for manufacturing environments. The resilience of polycarbonate makes it ideal for use in high-impact and high-wear settings. CNC machining allows polycarbonate to be shaped and installed precisely within these devices, enhancing the longevity and usability of the equipment.

In my experience, CNC machining allows for drilling, cutting, and surface finishing that align polycarbonate glass precisely with the equipment it protects. This is particularly useful in environments where visibility is essential, as polycarbonate’s clarity ensures operators can monitor machine activity without compromising their safety.

Transportation Industry

Polycarbonate glass is increasingly used in transportation applications, including automotive windows, windshields, and dashboard protectors. CNC machining allows for the creation of complex shapes that fit precisely into vehicle frameworks. For instance, polycarbonate windshields can be custom-shaped and drilled to fit the exact specifications of a vehicle, providing both durability and clear visibility.

In public transportation and heavy equipment, where durability is paramount, CNC machining allows manufacturers to create strong, shatter-resistant components with exact fit and finish. The precision provided by CNC machining ensures that each component functions reliably, improving safety and visibility for vehicle operators.

Steps in CNC Machining for Polycarbonate Glass

CNC machining plays an essential role in customizing polycarbonate glass for various applications, allowing manufacturers to produce parts that meet specific dimensions, shapes, and surface finishes. Here’s a detailed look at the key stages in CNC machining for polycarbonate glass:

Precision Cutting and Shaping

One of the most valuable aspects of CNC machining is the precision it provides. With CNC, polycarbonate glass can be cut and shaped into complex contours with high accuracy, meeting the requirements of unique projects. From my experience, using sharp carbide tools at moderate cutting speeds is crucial to avoid cracking or melting the material during cutting. Additionally, the CNC process ensures that the edges are clean and smooth, which improves both aesthetics and safety.

In architectural installations, for example, precision cutting enables the creation of polycarbonate panels that fit seamlessly into custom-designed spaces. This precision is not only visually appealing but also provides functional benefits, such as improved fit and stability in installations.

Drilling and Installation Hole Processing

Drilling holes for installation is another essential step in CNC machining, particularly for products like machine guards, shields, and architectural installations where mounting holes are required. CNC machines can drill holes with exact diameters and spacing, ensuring an exact fit for screws or other fasteners. In my experience, controlling the feed rate and using cooling systems during drilling are essential for polycarbonate to avoid cracks or heat deformation around the drilled area.

In protective shields, for example, precise drilling ensures that the shield can be securely mounted with minimal risk of loosening over time. This is particularly important in high-vibration environments, where secure mounting is critical for safety and longevity.

Edge Finishing and Polishing

After cutting and drilling, polycarbonate glass often undergoes edge finishing to improve its appearance and ensure safety. CNC machines can be programmed to create polished, rounded edges, which not only look professional but also reduce the risk of injury from sharp edges. I’ve found that proper edge finishing also enhances the durability of the glass, as smooth edges are less likely to develop stress fractures over time.

Polished edges are especially desirable for polycarbonate used in high-end architectural and retail displays, where aesthetics are a priority. Additionally, polished edges help in maintaining the glass’s transparency, which is essential in applications requiring clear visibility.

Cooling and Heat Management

Polycarbonate glass is sensitive to heat, which can cause warping or discoloration if not managed properly. CNC machining requires an effective cooling system to maintain dimensional stability and clarity throughout the cutting and drilling processes. In my experience, air cooling or water mist cooling works well with polycarbonate, reducing the risk of damage and maintaining the material’s optical clarity.

The ability to manage heat effectively is critical in applications like optical and medical equipment, where material clarity and stability are paramount. Proper cooling prevents any discoloration or warping, ensuring that the final product meets optical and aesthetic requirements.

Table 1: Recommended CNC Machining Parameters for Polycarbonate Glass

| CNC Process | Recommended Tool Type | Cutting Speed | Cooling Type | Key Notes |

|---|---|---|---|---|

| Precision Cutting | Sharp carbide tools | Moderate speed | Air cooling | Avoid high speeds to prevent warping |

| Drilling and Hole Making | Carbide drill bits | Controlled rate | Water mist cooling | Use cooling to prevent cracking |

| Edge Finishing | Polishing wheels | Slow to moderate | Air or water cooling | Smooth edges for visual quality |

| Surface Finishing | Buffing and polishing | Low speed | None | Additional finishing for clarity |

Chip Control and Removal

During CNC machining, polycarbonate tends to produce continuous chips, which can interfere with the machining process and compromise the final product. Having effective chip-breaking or removal systems in place helps maintain a clean work environment and allows for uninterrupted machining. Automated chip removal systems are especially valuable in large production runs of polycarbonate glass, as they help maintain efficiency and improve the quality of the final products.

Surface Finishing Options for Polycarbonate Glass

Polycarbonate glass can benefit from several surface treatments to enhance its durability, clarity, and functionality in various applications. CNC machining not only enables the creation of custom shapes but also lays the foundation for applying additional surface treatments that improve the performance of polycarbonate glass. Here are some common and beneficial surface treatments:

Anti-Fog Coating

In environments where humidity and temperature fluctuations are common, polycarbonate glass may fog up, reducing visibility. An anti-fog coating helps prevent condensation from forming on the surface of the glass, which is particularly useful for applications in medical shields, industrial protective eyewear, and sports goggles. I’ve personally seen the benefits of anti-fog coatings in environments where clear visibility is essential for safety and efficiency.

Anti-Scratch Coating

Polycarbonate is known for its durability, but it can still be prone to scratching, especially in applications that involve frequent handling or exposure to abrasive conditions. An anti-scratch coating is an excellent solution to improve the surface hardness and resistance to wear. Personally, I’ve seen how anti-scratch coatings prolong the life of polycarbonate products, especially in high-contact applications such as machine guards, safety shields, and automotive windows.

UV Protection Coating

Polycarbonate glass has a tendency to yellow or degrade under prolonged exposure to UV light. Applying a UV protection coating can prevent this, ensuring that the glass remains clear and durable even in outdoor environments. This coating is particularly valuable in architectural applications like skylights or greenhouse panels, where exposure to sunlight is constant. From my perspective, UV protection coating not only maintains the material’s transparency but also adds to its aesthetic value by preventing discoloration over time.

Table 2: Surface Treatment Options for Polycarbonate Glass

| Treatment Type | Purpose | Suitable Applications | Benefits |

|---|---|---|---|

| Anti-Fog Coating | Prevents condensation | Medical face shields, sports goggles | Ensures visibility in humid environments |

| Anti-Scratch Coating | Improves surface durability | Safety shields, machinery guards | Extends lifespan and maintains clarity |

| UV Protection | Blocks harmful UV light | Skylights, outdoor signage | Prevents yellowing and maintains clarity |

| Anti-Reflective | Reduces glare | Display screens, camera lenses | Enhances optical clarity and contrast |

| Mirror Coating | Reflects light for aesthetics | High-end displays, fashion eyewear | Adds aesthetic value and functionality |

| Tinted Coating | Provides shading or color | Sunglasses, architectural panels | Reduces brightness and adds aesthetic |

These surface treatments not only enhance the longevity and functionality of polycarbonate glass but also allow it to perform reliably in challenging environments. They provide customization options to meet specific needs, ensuring that polycarbonate glass can achieve maximum effectiveness in its intended applications.

Benefits and Limitations of CNC Machining Polycarbonate Glass

Benefits of CNC Machining

CNC machining offers a range of advantages when working with polycarbonate glass, including high precision, customization, and repeatability. From my experience, CNC machining is essential in achieving the exact dimensions and tolerances required for polycarbonate glass applications in safety, architecture, and industrial equipment.

- Precision and Consistency: CNC machines deliver exceptional accuracy, allowing polycarbonate glass to be shaped with high precision. This consistency is critical in applications like machine guards or architectural panels, where precise fitting is essential.

- Customization: CNC machining enables complex shapes and custom features, such as cutouts, mounting holes, and specialized edge finishes. This level of customization ensures that polycarbonate glass can meet the specific needs of each project, whether in safety shields or medical equipment.

- High Efficiency: CNC machines operate with automated controls, allowing for faster and more efficient production than manual processes. For larger-scale projects, CNC machining saves both time and labor costs.

- Repeatability: CNC machining ensures that each part is produced identically, an advantage for mass production and projects requiring consistency across multiple parts.

- Versatile Surface Finishing: CNC machining provides options for various finishing techniques, including polishing and coating application, which can enhance the appearance and durability of polycarbonate glass.

Limitations of CNC Machining Polycarbonate Glass

Despite its benefits, CNC machining of polycarbonate glass presents several challenges. Addressing these challenges is critical to maintaining product quality and maximizing material performance.

- Heat Sensitivity: Polycarbonate glass can warp or discolor if it overheats during machining. Proper cooling techniques, such as air or mist cooling, are essential to prevent heat-related issues. From my perspective, managing temperature during the cutting process is crucial to maintain transparency and dimensional accuracy.

- Surface Scratching: Polycarbonate glass is prone to scratching, especially during high-speed machining. Using anti-scratch coatings or low-friction tooling can reduce this risk. Additionally, post-machining polishing may be necessary to restore surface clarity.

- Chip Management: Polycarbonate glass produces long, continuous chips that can interfere with the machining process. An effective chip management system is necessary to avoid buildup, maintain cutting precision, and ensure a smooth finish.

- Edge Finishing Requirements: Many applications require smooth or polished edges for safety and aesthetic purposes. Achieving polished edges can add time and complexity to the machining process, but it’s essential in industries like architecture and interior design.

Choosing a CNC Machining Partner for Your Polycarbonate Glass Needs

Choosing the right CNC machining supplier for polycarbonate glass projects can significantly impact product quality, delivery times, and costs. Based on my experience, here are the key factors to consider when selecting a supplier.

Evaluating Machining Precision and Technical Capabilities

A high-quality CNC machining supplier should have the expertise and equipment necessary to achieve the precision and tolerances required for polycarbonate glass. Precision is essential to ensure that each piece fits perfectly within its designated application, whether it’s a protective shield, architectural panel, or equipment guard. Suppliers with advanced CNC machines, such as 5-axis machines, can produce more intricate and accurate shapes, which are often required in custom polycarbonate glass applications.

Requesting samples or a test run is a good way to evaluate a supplier’s precision capabilities. Samples allow you to verify the quality, accuracy, and consistency of their work before committing to a larger project.

Customization Services and Added Value

Some projects may require additional customization, such as specific surface treatments or complex cutouts, that not all suppliers can offer. A versatile CNC machining supplier should provide a range of customization options, including edge finishing, anti-scratch or UV coatings, and drilling for installation. In my experience, finding a supplier who can offer end-to-end solutions—design support, prototyping, machining, and finishing—simplifies the process and helps ensure a cohesive final product.

For example, if a project requires UV-resistant polycarbonate panels for outdoor use, choosing a supplier who can apply UV coatings directly during the manufacturing process saves time and adds value by enhancing the material’s performance.

Cost and Delivery Time Management

Balancing cost with quality is essential. It’s advisable to compare pricing from multiple suppliers to ensure that you’re getting a fair rate without compromising quality. Many CNC suppliers offer cost breakdowns, covering material costs, labor, and tooling, which can help you budget effectively.

Delivery time is another critical factor, especially for projects with tight timelines. Look for suppliers with reliable lead times, and establish a clear timeline for each stage of production. In my experience, discussing milestones with suppliers early on helps manage expectations and ensures timely delivery without sacrificing quality.

Table 3: Key Criteria for Selecting a CNC Machining Supplier for Polycarbonate Glass

| Criteria | Description | Importance |

|---|---|---|

| Precision and Accuracy | Ability to meet exact specifications | Essential for applications requiring tight tolerances |

| Customization Options | Range of additional services offered | Important for projects needing specific features |

| Surface Treatment Capabilities | Availability of UV, anti-scratch coatings | Enhances product durability and performance |

| Cost Transparency | Detailed cost breakdown and competitive pricing | Helps in budgeting and cost management |

| Delivery Time and Reliability | Ability to meet deadlines | Critical for projects with tight schedules |

| Design Support and Prototyping | Assistance in design and prototype stages | Adds value and helps achieve optimal design |

Checking Certifications and Industry Experience

A reliable supplier should have relevant certifications, such as ISO 9001, which demonstrate their commitment to quality and compliance with industry standards. Industry-specific experience is also valuable, as it ensures that the supplier understands the unique requirements of polycarbonate glass applications. For instance, suppliers with experience in architectural or safety equipment manufacturing will be better prepared to meet the specific needs of these industries.

Assessing Supplier Communication and Support

Effective communication with the CNC machining supplier is crucial for a smooth production process. The supplier should provide clear and timely updates on the progress of each project stage, addressing any potential issues or modifications. In my experience, suppliers who maintain open lines of communication and are responsive to questions or changes contribute to a successful outcome.

Conclusion

Polycarbonate glass is a versatile and highly durable material that, when combined with CNC custom machining, offers unmatched precision and performance across a variety of applications. Its transparency, impact resistance, and adaptability make it an excellent choice for industries such as architecture, industrial equipment, and safety.

In my experience, selecting the right CNC machining supplier and understanding the necessary surface treatments can significantly enhance the performance and lifespan of polycarbonate glass. By using CNC technology, industries can benefit from custom-cut, polished, and treated polycarbonate that meets exacting standards for clarity, strength, and durability.

Whether you’re developing protective shields, architectural installations, or industrial components, polycarbonate glass combined with CNC machining provides a reliable and high-performance solution tailored to your specific needs.

FAQ

- What are the main advantages of using polycarbonate glass over traditional glass in industrial applications?

Polycarbonate glass is highly impact-resistant, lightweight, and flexible, making it safer and more durable than traditional glass in industrial environments. It’s also easier to machine and customize, offering advantages in settings where strength and durability are critical. - How does CNC machining enhance the performance of polycarbonate glass?

CNC machining allows polycarbonate glass to be precisely cut, drilled, and shaped to meet the exact specifications of various applications. This customization improves fit, durability, and functionality, especially in complex industrial or architectural projects. - Can polycarbonate glass be used outdoors, and what treatments are necessary for outdoor use?

Yes, polycarbonate glass is suitable for outdoor applications, but UV-protective coatings are recommended to prevent yellowing and maintain clarity over time. Anti-scratch coatings can also enhance its durability in outdoor environments. - What factors affect the cost of CNC machining polycarbonate glass?

Costs are influenced by factors like material thickness, complexity of the design, customization needs, and surface treatments. Each additional treatment or customization will add to the overall cost. - Is it possible to get polished edges on CNC-machined polycarbonate glass?

Yes, CNC machining can achieve polished edges through finishing processes such as buffing. Polished edges not only enhance the appearance but also reduce the risk of injury from sharp edges. - What are the limitations of CNC machining for polycarbonate glass?

CNC machining requires proper heat management to avoid warping or discoloration of polycarbonate glass. Additionally, polycarbonate glass can be prone to scratching, so careful handling and, in some cases, post-machining treatments are necessary. - What are the common surface treatments applied to polycarbonate glass, and how do they improve performance?

Common treatments include anti-scratch coatings to prevent surface wear, UV-protection coatings for outdoor durability, and anti-fog coatings for applications in humid environments. These treatments extend the life and improve the functionality of polycarbonate glass in various conditions. - How do I ensure the quality of CNC-machined polycarbonate glass from a supplier?

It’s essential to request samples or a small test run before committing to a large order. Reviewing the supplier’s certifications, such as ISO 9001, and asking about their industry experience can also help ensure quality. - Can polycarbonate glass be used for safety equipment, and is CNC machining necessary for these applications?

Yes, polycarbonate glass is ideal for safety equipment due to its impact resistance. CNC machining allows for precise customization, which is often necessary to meet the specific dimensions and fit requirements of safety equipment like shields and goggles. - How long does polycarbonate glass typically last in outdoor applications?

With proper UV-protective coatings, polycarbonate glass can last many years outdoors without significant yellowing or degradation, making it a reliable option for long-term exposure to sunlight. - Is polycarbonate glass suitable for high-temperature environments?

Polycarbonate glass has a moderate heat tolerance and can withstand temperatures up to around 125°C (257°F) before it begins to deform. It’s generally not recommended for continuous exposure to high temperatures. - What thickness options are available for polycarbonate glass in CNC machining?

Polycarbonate glass is available in a wide range of thicknesses, typically from 1 mm to over 20 mm. The optimal thickness depends on the application’s requirements for impact resistance and structural stability. - How can I manage shipping and handling of CNC-machined polycarbonate glass to avoid damage?

Polycarbonate glass should be carefully packed and transported to prevent scratching or warping. Protective film layers and foam padding are commonly used to ensure safe handling during shipping. - What industries benefit most from CNC-machined polycarbonate glass?

Industries such as architecture, automotive, medical equipment, manufacturing, and safety equipment benefit greatly from CNC-machined polycarbonate glass due to its customizable strength, transparency, and durability. - How is polycarbonate glass different from other transparent plastics, like acrylic?

Polycarbonate glass is generally more impact-resistant and flexible than acrylic, making it better suited for applications where durability is essential. However, acrylic may offer greater optical clarity in certain uses and is less prone to scratching without a coating.

Other Articles You Might Enjoy

- CNC Machining for Consumer Electronics: Glass vs. Polycarbonate Screens

Introduction to CNC Machining for Consumer Electronics: Glass vs. Polycarbonate Screens In the sphere of consumer electronics, a broad taxonomy exists ranging from personal devices such as smartphones and watches…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…

- Precision CNC Machining for High-Performance Industrial Machinery

Precision CNC Machining for High-Performance Industrial Machinery The process of Precision CNC (Computer Numerical Control) machining is at the core of manufacturing high-performance industrial machinery. This technique leverages a computer's…

- The Future of Beryllium Copper in CNC Machining: Is It Still the Go-To for Electrical Connectors?

The Significance of Beryllium Copper in CNC Machining and Electrical Connectors Beryllium Copper, commonly referred to as BeCu, is a copper alloy with 0.5-3% beryllium that exhibits superior thermal conductivity,…

- Optimizing CNC Machining with Hybrid Materials: Benefits and Challenges

Introduction: CNC Machining and the Role of Hybrid Materials CNC machining, short for Computer Numerical Control machining, is a manufacturing process where pre-programmed computer software dictates the movement of factory…