Polyoxymethylene (POM), is widely utilized in CNC machining due to its excellent properties and versatility.

Derived from formaldehyde, POM belongs to the family of thermoplastic polymers and stands out for its high mechanical strength and rigidity. This material’s primary attribute is its high stiffness and hardness, making it ideal for applications requiring dimensional stability and mechanical precision. Additionally, POM exhibits outstanding resistance to wear and abrasion, rendering it suitable for environments where components undergo significant mechanical stress.

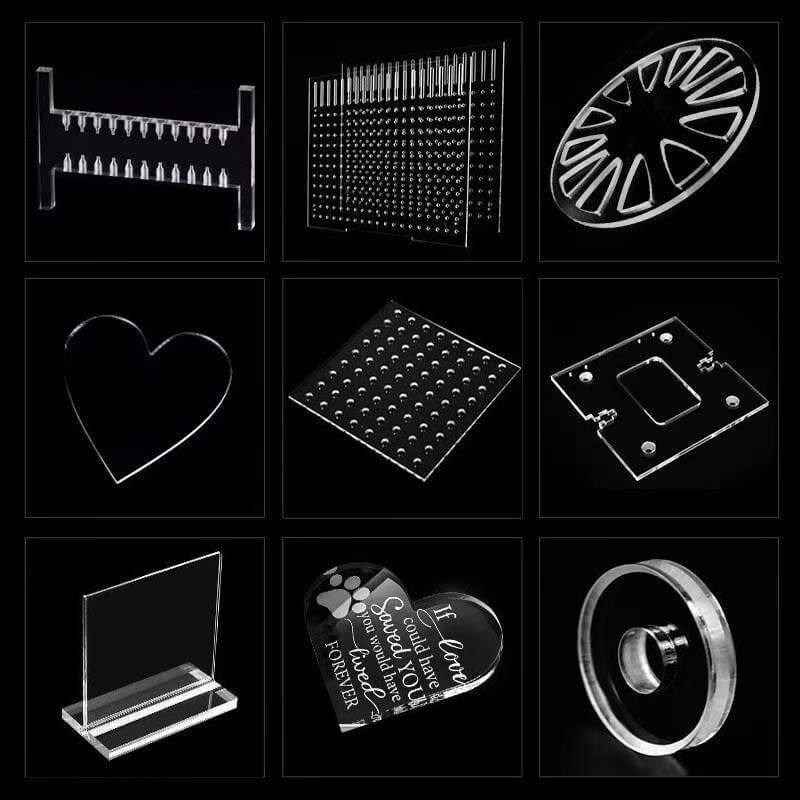

A defining feature of POM is its low coefficient of friction, enabling smooth, wear-resistant sliding between parts. This characteristic is highly advantageous in applications like gears, bushings, and bearings, where friction reduction is essential. POM also possesses low moisture absorption, enhancing its durability and performance in humid or variable environmental conditions.

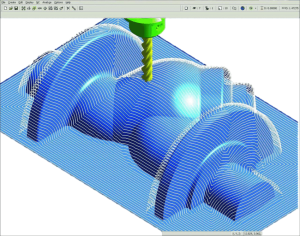

In CNC machining, POM is valued for its ease of machinability, allowing it to be fabricated into complex parts with precision. Components like precision gears, structural fittings, and sliding parts can be easily produced from POM, making it a popular choice for applications that demand dimensional accuracy and wear resistance. Its combination of strength, stiffness, and low friction has made POM a staple plastic material in various industries.

POM (Delrin) stands out in CNC machining for its impressive strength, low friction, and high dimensional stability, solidifying its reputation as a dependable material across numerous applications.