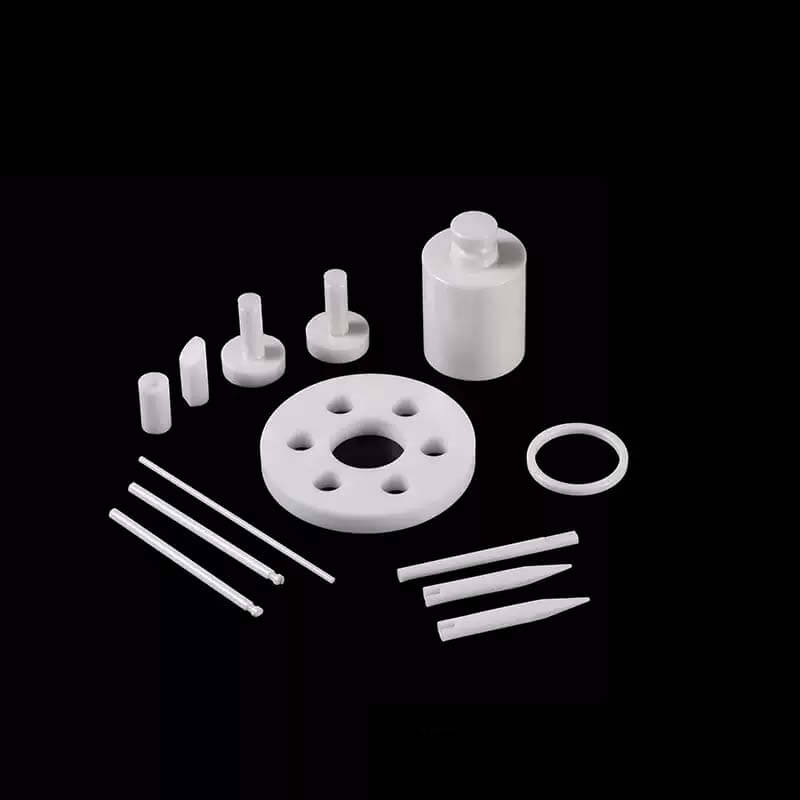

About Alumina Ceramics

Alumina ceramics, also known as aluminum oxide (Al₂O₃) ceramics, are a type of advanced ceramic material widely used in various industrial applications due to their excellent hardness, wear resistance, high melting point, and electrical insulation properties. Alumina is the most common and versatile ceramic material used in CNC machining, and it comes in multiple purity grades, typically ranging from 85% to 99.9% Al₂O₃.

Its high thermal stability makes it ideal for high-temperature applications, while its chemical stability allows it to resist most acids and alkalis. The material’s excellent mechanical strength and hardness make it suitable for parts that undergo extensive wear or high friction, such as cutting tools, valves, and seals.

Alumina ceramics are also highly valued in the electronics industry, where they are used in substrates, insulators, and circuit boards due to their good thermal conductivity and dielectric properties. In the medical field, they are applied in biocompatible implants like dental and orthopedic components. Despite alumina’s impressive advantages, its brittleness can present challenges in machining, as it can easily crack or fracture under high stress. However, CNC machining has developed techniques specifically suited for alumina, allowing for complex shapes and precise dimensions. Alumina’s versatility and durability ensure its continuous demand across sectors including aerospace, automotive, electronics, and healthcare.