Why 18/10 Stainless Steel and CNC Precision Engineering Are a Perfect Match

When exploring materials for precision manufacturing, 18/10 stainless steel consistently stands out as one of the most versatile and high-performing options. Its unique composition of 18% chromium and 10% nickel offers exceptional properties, such as corrosion resistance, durability, and a premium aesthetic. These characteristics make it a top choice in industries ranging from food service to aerospace.

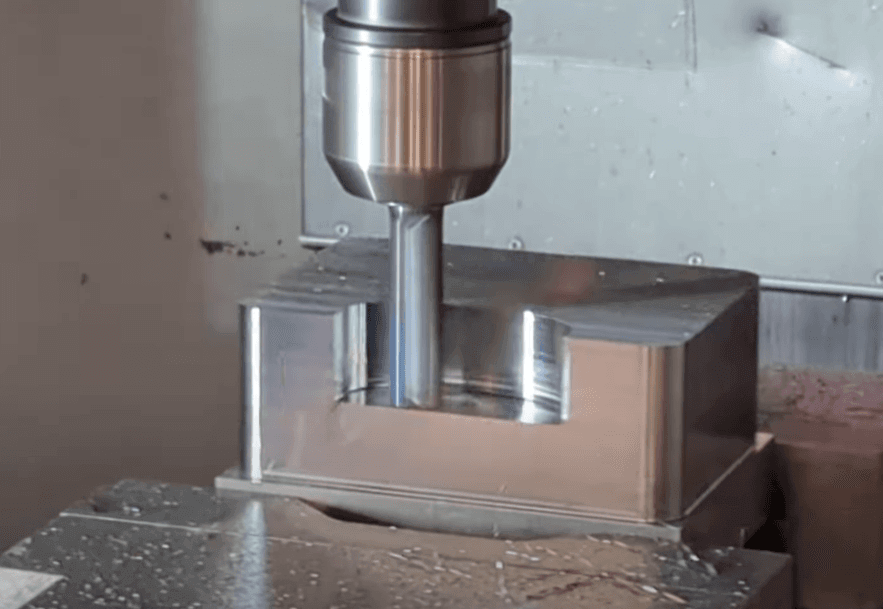

Coupled with CNC machining, which enables unparalleled precision and repeatability, 18/10 stainless steel can meet the exacting demands of modern manufacturing. This guide delves into the material’s properties, machining challenges, and wide-ranging applications.

Key Properties of 18/10 Stainless Steel for CNC Applications

18/10 stainless steel owes its popularity to its superior combination of mechanical and chemical properties.

2.1 Mechanical Properties

- High Tensile Strength: With a tensile strength exceeding 505 MPa, 18/10 stainless steel is suitable for load-bearing applications.

- Excellent Ductility: Its ability to withstand deformation makes it ideal for processes like bending, forming, and CNC machining.

- Resistance to Impact: Retains toughness even at low temperatures, making it reliable for extreme environments.

2.2 Chemical Properties

- 18% Chromium: Forms a protective oxide layer, providing excellent corrosion resistance.

- 10% Nickel: Enhances ductility, toughness, and the material’s iconic polished finish.

- Low Carbon Content: Reduces the risk of carbide precipitation during welding or high-temperature applications.

2.3 Thermal Properties

- Withstands high temperatures, making it suitable for automotive and aerospace applications where heat resistance is crucial.

| Property | Value | Impact on Machining |

|---|---|---|

| Tensile Strength | 505 MPa | Allows use in high-stress environments. |

| Melting Point | 1400-1450°C | Suitable for high-temperature operations. |

| Thermal Conductivity | ~16.3 W/m·K | Heat dissipation during machining can be challenging. |

Applications of 18/10 Stainless Steel in Different Industries

18/10 stainless steel’s combination of strength, aesthetic appeal, and corrosion resistance makes it indispensable across industries.

5.1 Food and Beverage

- Examples: Cutlery, cookware, and food processing equipment.

- Why CNC?: Precision machining ensures hygienic finishes and seamless joints.

5.2 Medical Devices

- Examples: Surgical instruments, implants, and diagnostic equipment.

- Why CNC?: Enables biocompatible and sterilizable designs.

5.3 Automotive and Aerospace

- Examples: Exhaust systems, structural brackets, and decorative trims.

- Why CNC?: Delivers the precision needed for high-stress components.

5.4 Construction and Architecture

- Examples: Railings, panels, and fixtures.

- Why CNC?: Combines aesthetics with structural integrity.

Comparing 18/10 Stainless Steel with Other Stainless Steel Grades

6.1 18/8 vs. 18/10

- 18/10 contains more nickel, enhancing corrosion resistance and giving it a shinier finish.

- 18/8 is more cost-effective but less durable in harsh conditions.

6.2 316 Stainless Steel

- Contains molybdenum for superior resistance to chloride corrosion.

- Used in marine environments, but costs more than 18/10.

| Grade | Composition | Applications |

|---|---|---|

| 18/10 Stainless Steel | 18% Cr, 10% Ni | Food, medical, architectural. |

| 18/8 Stainless Steel | 18% Cr, 8% Ni | Everyday cookware, utensils. |

| 316 Stainless Steel | 16% Cr, 10% Ni, 2% Mo | Marine, chemical processing. |

Challenges of CNC Machining 18/10 Stainless Steel

Despite its numerous benefits, machining 18/10 stainless steel presents unique challenges:

3.1 Work Hardening

- The material tends to harden at the cutting edge during machining, making subsequent operations more difficult.

- Solution: Use sharp tools, maintain constant feed rates, and avoid tool dwell.

3.2 Heat Generation

- Low thermal conductivity causes localized heat buildup, accelerating tool wear.

- Solution: Employ flood cooling or high-pressure coolant systems.

3.3 Tool Wear

- Its toughness and abrasive properties can quickly wear down cutting tools.

- Solution: Use carbide tools with advanced coatings like TiAlN for extended tool life.

CNC Techniques for Optimizing 18/10 Stainless Steel Machining

To overcome these challenges, manufacturers can adopt specialized CNC techniques:

4.1 Tool Selection

- Carbide Tools: Provide superior hardness and resistance to wear.

- Coated Tools: TiAlN or TiCN coatings reduce friction and heat generation.

- Sharp Geometry: Tools with positive rake angles minimize cutting forces.

4.2 Machining Parameters

| Parameter | Recommended Value | Impact |

|---|---|---|

| Cutting Speed | 20-30 m/min | Avoids overheating and reduces work hardening. |

| Feed Rate | 0.1-0.2 mm/rev | Ensures smooth cuts without tool chatter. |

| Depth of Cut | 1-3 mm | Reduces stress on both the tool and material. |

4.3 Advanced Techniques

- Trochoidal Milling: Reduces tool engagement time and distributes cutting forces.

- High-Speed Machining (HSM): Allows for lower depths of cut with increased productivity.

- Peck Drilling: Prevents chip buildup in deep holes, improving tool life.

CNC Best Practices for Cost and Efficiency Optimization

7.1 Tool Maintenance

- Regularly inspect and replace tools to maintain consistent machining performance.

7.2 Cooling Optimization

- Use high-pressure cooling to dissipate heat effectively.

7.3 Process Automation

- Incorporate smart CNC systems for real-time adjustments to parameters, ensuring efficient machining.

7.4 Case Study:

A CNC machining shop producing 18/10 stainless steel cookware reduced tool wear by 30% and improved surface finishes by optimizing feed rates and using coated carbide tools.

Future Trends in CNC and 18/10 Stainless Steel Manufacturing

8.1 AI Integration

- Smart algorithms optimize machining parameters in real time, improving efficiency and reducing waste.

8.2 Sustainability

- Increased focus on recycling and eco-friendly machining practices.

8.3 Advanced Coatings

- Nano-composite coatings are improving tool performance, making machining faster and more cost-effective.

Conclusion: Unlocking the Potential of 18/10 Stainless Steel

18/10 stainless steel, combined with CNC precision engineering, represents the pinnacle of modern manufacturing. Its properties make it ideal for demanding applications, and CNC machining ensures it meets the highest standards of quality and precision. From food-grade utensils to aerospace components, the potential of 18/10 stainless steel is virtually limitless.

FAQ

- What is 18/10 stainless steel?

It’s an alloy with 18% chromium and 10% nickel, known for its durability and corrosion resistance. - Why is CNC machining ideal for 18/10 stainless steel?

CNC machining ensures precise shaping and finishing, even for complex designs. - What challenges arise in machining 18/10 stainless steel?

Work hardening, heat generation, and tool wear are common issues. - Which industries use 18/10 stainless steel most?

Food and beverage, medical devices, automotive, aerospace, and architecture. - What are the best tools for machining 18/10 stainless steel?

Coated carbide tools with TiAlN or TiCN coatings are preferred. - Can CNC achieve mirror finishes on 18/10 stainless steel?

Yes, CNC polishing processes can create mirror-like surfaces. - Is 18/10 stainless steel recyclable?

Yes, it’s 100% recyclable, making it environmentally friendly. - How does 18/10 compare to 18/8 stainless steel?

18/10 has more nickel, offering better corrosion resistance and a shinier finish. - What cooling methods are best for machining 18/10 stainless steel?

Flood cooling with water-soluble coolants is highly effective. - Can CNC machining handle custom designs with 18/10 stainless steel?

Absolutely, CNC is ideal for intricate and precise custom designs.

Other Articles You Might Enjoy

- How Does CNC Machining Achieve Precision Tolerances in Stainless Steel Parts?

The Importance of Precision Tolerances in Stainless Steel Parts Precision tolerances are the allowable limits of variation in a physical dimension. In CNC machining, particularly for stainless steel parts, achieving…

- Stainless Steel Machining for Aerospace: Precision and Challenges in CNC Operations?

Introduction: Brief Overview of CNC Machining and Its Importance in the Aerospace Industry Computer Numerical Control (CNC) machining is a modern manufacturing process using pre-programmed computer software to control movement…

- How to Choose a CNC Company for Precision Stainless Steel Flange Machining?

Selecting the right CNC machining company is crucial for achieving high-quality, precision stainless steel flanges. This detailed guide explores the essential factors to consider in this decision-making process, ensuring that…

- Precision CNC Machining of Stainless Steel: Innovations and Best Practices in Aerospace Machining

Introduction: Precision CNC Machining and the Use of Stainless Steel Precision Computer Numerical Control (CNC) machining, a vital technology within the manufacturing industry, uses pre-programmed software to guide machinery towards…

- Comprehensive Guide to CNC Machining: Carbon Steel vs Stainless Steel

Choosing the right material for CNC machining is a crucial decision for any manufacturer or engineer. Two of the most commonly used materials in various industries are carbon steel and…

- What Factors Affect the Precision of CNC Machined Stainless Steel Flanges?

What Role Does Material Selection Play in the Precision of CNC Machined Stainless Steel Flanges? The choice of stainless steel grade significantly affects the machining process and the quality of…