Why Precision Machining Matters in Modern Manufacturing

Precision machining is a cornerstone of modern manufacturing. It enables the creation of complex, high-tolerance parts used across a wide range of industries. From aerospace to medical devices, precision machining ensures the accuracy and reliability needed to meet stringent industry standards.

Why Does It Matter?

- High Tolerance Requirements: Precision machining ensures tolerances within ±0.001 mm, critical for high-performance parts.

- Global Competitiveness: Companies utilizing precision machining are better positioned to compete in industries requiring cutting-edge technology.

- Wide Applicability: Industries like automotive, electronics, and energy rely on precision machining to meet customer demands and enhance innovation.

The Journey Ahead

This article delves into the principles, materials, challenges, and future trends in precision machining, providing actionable insights for professionals.

The Key Principles Behind Precision Machining

Precision machining revolves around three core principles: accuracy, repeatability, and efficiency. These principles are achieved through advanced machinery, skilled technicians, and modern technologies.

2.1 Understanding Accuracy in Precision Machining

- Dimensional Accuracy: Ensuring each part adheres to exact measurements as defined in CAD designs.

- Geometric Tolerances: Control over flatness, perpendicularity, and concentricity within microns.

- Surface Finish: Importance of achieving smooth finishes, measured in Ra values (average roughness).

| Requirement | Measurement Standard | Application Example |

|---|---|---|

| Dimensional Accuracy | ±0.005 mm | Aerospace components like turbine blades. |

| Geometric Tolerances | Concentricity within ±0.002 mm | Automotive crankshafts. |

| Surface Finish | Ra 0.2–1.0 µm | Medical implants requiring smooth surfaces. |

2.2 Repeatability: Manufacturing Consistency

In industries requiring mass production, consistency is paramount. Precision machining ensures every part meets the same standard, eliminating variations.

2.3 Efficiency: Time and Cost Optimization

By optimizing tool paths, material removal rates, and cooling systems, manufacturers reduce time and cost without sacrificing quality.

Case Study: Efficiency Gains with CNC

A manufacturer producing aerospace brackets reduced cycle time by 25% and tool wear by 15% after implementing multi-axis CNC machines and using adaptive control software.

Industries That Rely on Precision Machining

Precision machining touches almost every advanced industry. Below are key sectors and their specific applications.

3.1 Aerospace: Where Precision is Non-Negotiable

- Applications: Jet engines, landing gears, and navigation components.

- Challenges: Tolerances as tight as ±0.0005 mm, high-temperature material machining.

- Real-World Example: Precision machining of titanium engine blades reduced drag by 10%, improving fuel efficiency.

3.2 Automotive: Driving Innovation

- Applications: Engine parts, gear systems, brake components.

- Focus on EVs: Precision machining enables the production of lightweight battery casings and motor housings.

- Case Study: A German carmaker optimized their supply chain by partnering with a CNC precision machining company, reducing production costs by 18%.

3.3 Medical Devices: Precision That Saves Lives

- Applications: Orthopedic implants, surgical tools, diagnostic machines.

- Key Requirement: Biocompatible materials like titanium and PEEK, often machined to surface roughness below Ra 0.1 µm.

- Real-World Impact: Precision-machined titanium implants led to quicker patient recovery and reduced rejection rates.

Materials Commonly Used in Precision Machining

Precision machining is versatile, accommodating a wide range of materials to suit specific applications. The properties of each material dictate machining strategies, tool selection, and performance of the final product. Below, we explore common materials in precision machining, their advantages, applications, and machining challenges.

4.1 Metals in Precision Machining

Metals are the most widely used materials in precision machining due to their strength, durability, and conductivity.

- Aluminum

Properties: Lightweight, corrosion-resistant, and excellent machinability.

Applications: Aircraft frames, automotive components, and electronics housings.

Machining Insights:

Aluminum’s softness reduces tool wear.

Its high thermal conductivity requires efficient cooling systems to avoid overheating. - Stainless Steel

Properties: High strength, corrosion resistance, and biocompatibility.

Applications*: Medical devices, structural components, and food-grade equipment.

*Machining Challenges*:

Susceptible to work hardening, requiring sharp tools and controlled cutting speeds. - Titanium

Properties: High strength-to-weight ratio and excellent corrosion resistance.

Applications: Aerospace parts, implants, and chemical processing equipment.

Machining Insights:

Titanium generates significant heat during cutting.

Using low speeds, high feeds, and specialized coolants minimizes heat buildup. - Tool Steel

Properties: Extremely hard, wear-resistant, and tough.

Applications: Dies, molds, and cutting tools.

Machining Challenges:

Requires coated carbide tools due to hardness.

Slow cutting speeds enhance tool life.

4.2 Plastics and Composites

Plastics and composites offer unique properties like lightweight construction, chemical resistance, and thermal insulation.

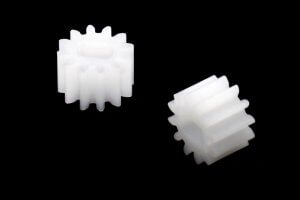

- POM (Delrin)

Properties: High stiffness, low friction, and excellent dimensional stability.

Applications: Gears, bearings, and electrical insulators.

Machining Insights:

Easy to machine at high speeds with minimal tool wear.

Requires sharp tools to prevent surface tearing. - PEEK (Polyetheretherketone)

Properties: High-temperature resistance, chemical inertness, and biocompatibility.

Applications: Medical implants, aerospace parts, and high-performance seals.

Machining Challenges:

High heat sensitivity demands careful speed and coolant management. - Carbon Fiber Composites

Properties: Lightweight, high strength, and stiffness.

Applications: Aerospace, automotive, and sports equipment.

Machining Insights:

Brittle nature requires slow feed rates and sharp tools.

Dust control measures are essential for operator safety.

4.3 Advanced Materials

Advanced materials push the boundaries of engineering performance but require specialized techniques.

- Ceramics

Properties: Extremely hard, heat-resistant, and excellent electrical insulation.

Applications: Semiconductor components, cutting tools, and medical prosthetics.

Machining Challenges:

Requires diamond-tipped tools.

Precise process controls are necessary to avoid chipping or cracking. - Superalloys (e.g., Inconel)

Properties: Withstand extreme temperatures, mechanical stress, and oxidation.

Applications: Turbine blades, heat exchangers, and jet engines.

Machining Challenges:

Highly abrasive and prone to work hardening.

Requires low cutting speeds and advanced tool coatings like TiAlN.

Material Comparison Table

| Material | Advantages | Challenges | Applications |

|---|---|---|---|

| Aluminum | Lightweight, corrosion-resistant. | Overheats without proper cooling. | Aerospace, automotive, electronics. |

| Stainless Steel | High strength, biocompatible, durable. | Work hardening, requires sharp tools. | Medical devices, food-grade equipment. |

| Titanium | High strength-to-weight ratio, corrosion-resistant. | Heat generation, tool wear. | Implants, aerospace parts. |

| POM (Delrin) | Durable, dimensionally stable, easy to machine. | Surface tearing if tools aren’t sharp. | Gears, bearings, insulators. |

| PEEK | High-temperature resistance, biocompatible. | Heat sensitivity, costly material. | Medical implants, high-performance seals. |

| Carbon Fiber | Lightweight, stiff, strong. | Brittle, requires dust control. | Aerospace, automotive, sports equipment. |

| Ceramics | Heat-resistant, wear-resistant. | Brittle, requires diamond-tipped tools. | Semiconductors, medical prosthetics. |

| Superalloys | High temperature and stress resistance. | Abrasive, work hardening. | Jet engines, heat exchangers. |

4.4 Choosing the Right Material for Precision Machining

Selecting the right material depends on several factors:

- Application Requirements: Functional demands such as strength, corrosion resistance, or biocompatibility.

- Cost Considerations: Balancing performance with material and machining costs.

- Machinability: Materials like aluminum and POM are easier to machine, while titanium and ceramics require specialized techniques.

Example:

In aerospace, titanium is preferred for its strength and lightweight properties, despite its machining difficulties. Meanwhile, for consumer electronics, aluminum’s machinability and aesthetics make it the material of choice.

This chapter highlights the diverse materials used in precision machining and their specific properties, applications, and challenges. The comparison table provides a quick reference for material selection based on project needs. By understanding the nuances of each material, manufacturers can optimize processes to achieve cost-effective and high-quality results.

Challenges in Precision Machining and Solutions

Precision machining offers incredible benefits but comes with significant challenges that require thoughtful solutions.

5.1 Heat Generation

- Issue: Heat accumulation during machining leads to dimensional inaccuracies, tool wear, and poor surface finishes.

- Solution:

- Use high-pressure coolant systems.

- Opt for coated tools with high heat resistance (e.g., TiAlN coatings).

- Adjust feed rates and cutting speeds to reduce friction.

5.2 Tool Wear and Failure

- Issue: Abrasive materials such as titanium and Inconel cause rapid tool wear.

- Solution:

- Utilize advanced coated tools (e.g., diamond-like carbon, PVD coatings).

- Implement predictive maintenance to replace tools before failure.

- Use vibration-damping tool holders to minimize stress.

5.3 Complex Geometries

- Issue: Creating intricate shapes with tight tolerances is time-intensive and error-prone.

- Solution:

- Employ multi-axis CNC machines.

- Use CAD/CAM software for precise toolpath optimization.

- Conduct simulations to detect and address potential collisions or defects.

5.4 Material-Specific Challenges

- Titanium: Overheating during machining.

- Solution: Use low cutting speeds, high feed rates, and proper coolant application.

- Plastics: Melting and deformation under heat.

- Solution: Sharp tools, slow spindle speeds, and minimal heat generation.

5.5 Cost Management

- Issue: High material and tool costs increase overall production expenses.

- Solution:

- Optimize tool life through advanced coatings.

- Reduce waste using accurate simulation software and process controls.

- Consolidate machining operations to minimize setup times.

CNC Technology: Elevating Precision Machining

CNC technology is at the heart of modern precision machining, offering unmatched control, accuracy, and repeatability.

6.1 Multi-Axis CNC Machines

- Capabilities:

- 5-axis machines can produce complex components in one setup, reducing lead time.

- Simultaneous multi-axis movement ensures smooth transitions and intricate geometries.

- Applications:

- Aerospace: Jet engine components with curved surfaces.

- Medical: Implants with contoured shapes.

6.2 Automation in CNC Technology

- Advancements:

- Automation reduces labor costs and human error.

- Robotic arms for tool changes and part handling increase efficiency.

- Case Study: A manufacturer implemented automated CNC systems and reduced manual labor by 50%, increasing productivity.

6.3 Real-Time Monitoring and AI Integration

- Benefits:

- Sensors monitor vibration, tool wear, and thermal stress, preventing defects.

- AI-powered systems analyze machining data and adjust parameters in real-time.

- Example: AI integration in a CNC shop reduced scrap rates by 30% by dynamically adjusting tool paths.

6.4 Cost Efficiency

- Key Points:

- CNC minimizes material waste by optimizing tool paths.

- Shorter setup times improve operational efficiency, especially for low-volume, high-complexity parts.

Future Trends in Precision Machining

- AI-Driven Optimization: Machine learning algorithms adjust cutting parameters in real-time for maximum efficiency.

- Sustainable Practices: Recycling scrap material and using renewable energy in machining processes.

- Advanced Coatings: New tool coatings extend tool life and improve machining efficiency.

Real-World Applications

Case Study: Aerospace Fuel Efficiency

A precision-machined titanium fuel nozzle increased combustion efficiency by 15%, saving airlines millions annually.

Case Study: EV Component Innovations

CNC-machined aluminum battery enclosures reduced overall vehicle weight, improving range by 12%.

FAQ

- What is precision machining?

Precision machining is a high-accuracy manufacturing process that shapes materials to tight tolerances, ensuring consistency and quality in industries like aerospace, automotive, and medical devices. - What is the role of CNC in precision machining?

CNC technology automates machining processes, improving accuracy, repeatability, and efficiency. It allows for complex designs and reduces human error. - What materials are best for precision machining?

Common materials include aluminum, stainless steel, titanium, PEEK, and ceramics. Each material requires specific tools and techniques for optimal results. - Why is heat a problem in machining?

Heat generated during machining can distort material dimensions, degrade tool life, and affect surface quality. Coolants and heat-resistant tools mitigate these effects. - How does precision machining benefit the aerospace industry?

Precision machining produces high-tolerance components like turbine blades and navigation systems that meet strict safety and performance standards. - Can plastics be precision-machined?

Yes, materials like POM and PEEK are often used in electronics and medical devices. Machining plastics requires slow speeds and sharp tools to prevent melting or deformation. - What challenges arise with titanium machining?

Titanium generates excessive heat and causes tool wear due to its low thermal conductivity. Specialized tools and cooling techniques are essential. - What is multi-axis machining?

Multi-axis machining involves CNC systems with 3 to 5 or more axes of movement, allowing for complex part geometries to be machined in one setup. - How can costs be optimized in precision machining?

Costs can be reduced by minimizing material waste, extending tool life with advanced coatings, and automating processes. - What industries rely on precision machining?

Aerospace, automotive, medical devices, electronics, and energy sectors heavily rely on precision machining for high-performance components. - How does tool wear affect machining?

Tool wear reduces cutting efficiency, accuracy, and surface quality. Proper maintenance and advanced coatings extend tool life. - What is the future of CNC technology?

AI integration, real-time monitoring, and increased automation are driving the future of CNC technology, enhancing precision and efficiency. - What is the importance of surface finish?

Surface finish affects part functionality, reducing friction, improving aesthetics, and enhancing wear resistance. - What are the tolerances achievable with precision machining?

Precision machining can achieve tolerances as tight as ±0.001 mm, depending on the material and equipment used. - What is the difference between conventional and precision machining?

Precision machining focuses on tighter tolerances and higher surface finishes, while conventional machining prioritizes speed and bulk production. - How do ceramics perform in machining?

Ceramics are wear-resistant and heat-tolerant but brittle, requiring diamond tools and careful control during machining. - What software is used for CNC programming?

Common software includes Mastercam, Fusion 360, and SolidWorks, enabling precise toolpath creation and simulation. - What role does AI play in machining? AI optimizes machining processes by adjusting parameters in real-time, reducing defects and increasing efficiency.

- What are the advantages of automation in CNC machining?

Automation increases productivity, reduces costs, and ensures consistent quality by minimizing human intervention. - Why is precision machining critical for medical devices?

It ensures biocompatible, high-accuracy components like implants and surgical tools, meeting strict safety and regulatory standards.

Other Articles You Might Enjoy

- High-Precision CNC Machining for Military Applications

Introduction to High-Precision CNC Machining in Military Applications The technical realm of high-precision Computer Numeric Control (CNC) machining is fast becoming integral to the military sector. This process, which relies…

- Precision and Control in Machining

Machining precision is the foundation for ensuring the performance and longevity of mechanical products. During machining, various factors can cause the correct position between the tool and the workpiece to…

- Precision CNC Machining for High-End Audio Equipment

Precision CNC Machining and its Role in High-End Audio Equipment Manufacturing The production of high-end audio equipment relies heavily on precision-driven processes to ensure the best quality sound. One such…

- Precision Aluminum CNC Machining: Cost-Effective Solutions for High-Volume Production?

Precision Aluminum CNC Machining: An Overview In the realm of manufacturing, precision aluminum CNC machining stands out as a key technique sought after for high-volume production runs. The term 'CNC'…

- CNC Precision Machining High-Temperature Alloys for Heavy-Duty Vehicle Parts

1. Introduction In the automotive, aerospace, and maritime industries, high-temperature alloys have become vital materials for manufacturing components that must withstand extreme temperatures and stress. CNC precision machining has emerged…

- Machining Materials: Delrin vs. PEEK in High-Precision Applications

Machining Materials: An Introduction to Delrin and PEEK Machining materials, as the term implies, are types of substances specifically designed to be cut and fashioned into usable items by machining…