The Intersection of Polycarbonat and CNC Machining

Polycarbonat, a versatile and highly durable thermoplastic, has revolutionized modern manufacturing. Combining excellent strength, optical clarity, and processability, this material pairs perfectly with CNC machining to meet precision manufacturing needs across a wide range of industries. Over the years, I’ve had the chance to explore its potential in various projects, and I can confidently say it offers unmatched flexibility for creating both functional and aesthetic components.

This feature aims to shed light on why Polycarbonat excels in CNC machining. By delving into its properties, machining suitability, and applications, I’ll provide you with actionable insights and practical tips to leverage Polycarbonat effectively in your projects. Whether you’re a product designer, engineer, or procurement manager, this guide will help you better understand this extraordinary material.

Polycarbonat Material Properties

Polycarbonat is celebrated for its unique combination of mechanical, optical, and thermal properties. These characteristics make it a top choice for industries that demand performance and versatility. Let’s explore its key properties in more depth.

| Property | Details | Applications |

|---|---|---|

| Impact Resistance | Up to 200 times stronger than glass, even at extreme temperatures | Safety shields, automotive parts |

| Optical Transparency | Offers up to 89% light transmission, comparable to glass | Lenses, displays, lighting fixtures |

| Temperature Stability | Maintains structural integrity between -40°C to 120°C | Aerospace, medical devices |

| Lightweight | Roughly half the density of glass, making it a lightweight alternative | Portable devices, aircraft components |

| Chemical Resistance | Resistant to oils, acids, and alcohols, suitable for demanding environments | Industrial enclosures, lab equipment |

| UV Resistance (with add-ons) | Enhanced UV resistance with stabilizing coatings | Outdoor applications |

Comparative Analysis: Polycarbonat vs. Acrylic

Polycarbonat often gets compared to acrylic due to their similar uses, but they differ significantly in key areas:

| Property | Polycarbonat | Acrylic |

|---|---|---|

| Impact Strength | Very high; can absorb significant force | Moderate; tends to shatter under impact |

| Scratch Resistance | Moderate; benefits from coatings | High; natural scratch resistance |

| Machinability | Easier to machine with fewer fractures | Slightly brittle during machining |

| Temperature Range | -40°C to 120°C | 0°C to 70°C |

Polycarbonat’s robustness makes it ideal for high-stress applications, whereas acrylic’s scratch resistance suits decorative items. When choosing between the two, Polycarbonat is often favored for its durability and versatility in machining.

Suitability of Polycarbonat for CNC Machining

Why Polycarbonat and CNC Are a Perfect Match

In my experience, Polycarbonat’s machinability is one of its standout qualities. Unlike many thermoplastics, it responds well to precision CNC processes without sacrificing strength or finish. Its relatively soft yet durable nature ensures smooth cutting and drilling, while its thermal stability allows it to maintain shape and integrity during machining.

Detailed CNC Machining Techniques for Polycarbonat

Here’s an look at how Polycarbonat performs across different CNC processes:

| CNC Process | Polycarbonat Suitability | Recommendations |

|---|---|---|

| Milling | Excels at creating intricate 2D and 3D shapes | Use high-speed tools with sharp edges to reduce heat buildup |

| Turning | Perfect for crafting cylindrical components | Optimize spindle speeds to avoid deformation |

| Drilling | Delivers precise hole-making capabilities | Apply gradual feed rates to prevent cracks |

| Engraving | Achieves high precision for logos and patterns | Choose appropriate tool sizes for fine detailing |

| Laser Cutting | Effective for thin sheets but can cause discoloration | Polish edges after cutting for better aesthetics |

Polycarbonat’s flexibility makes it suitable for a range of applications, from prototypes to final products. By fine-tuning CNC parameters, you can achieve exceptional quality and repeatability.

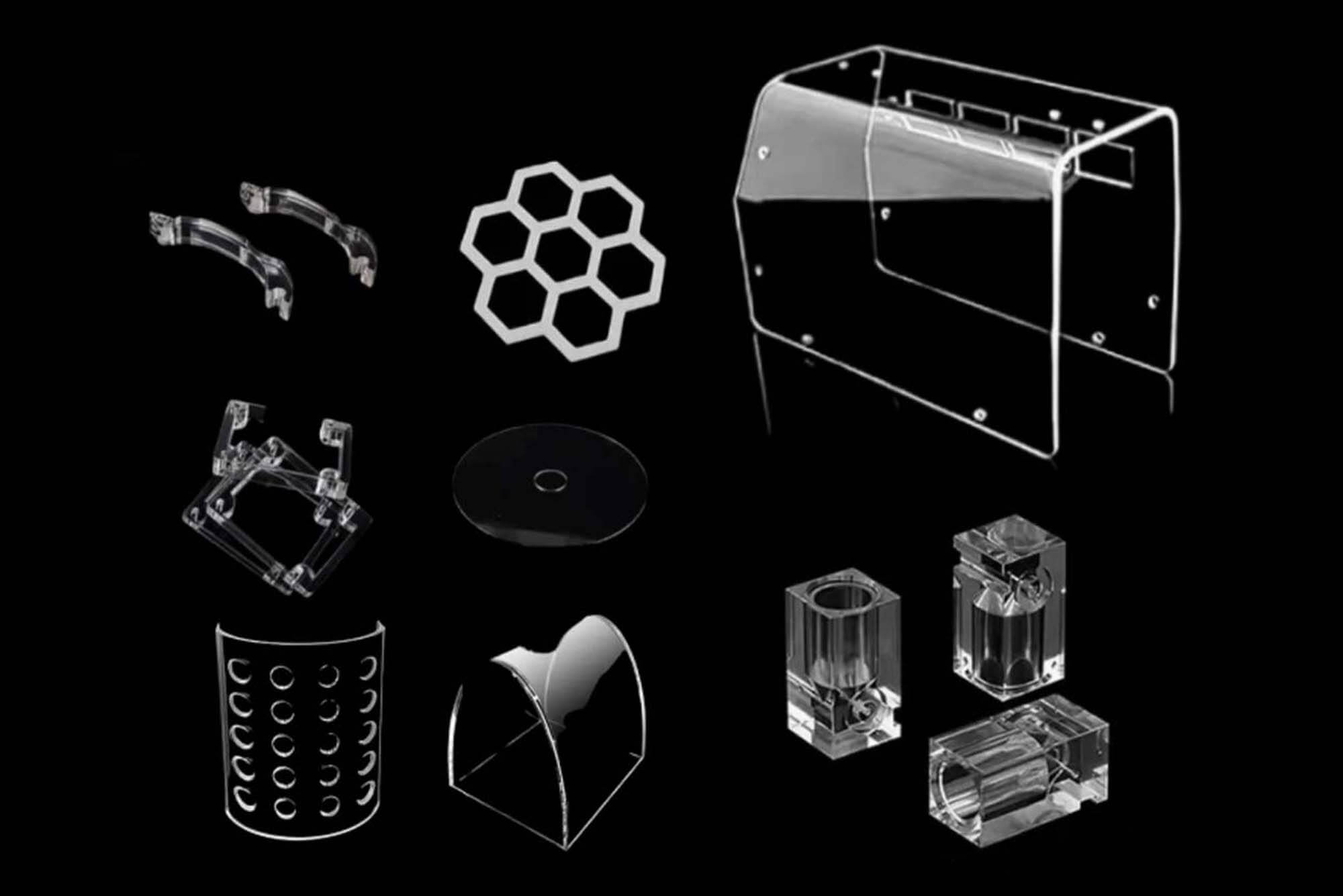

Typical Applications of Polycarbonat in CNC Machining

Polycarbonat’s versatility allows it to cater to a diverse set of industries, each requiring unique combinations of strength, transparency, and machinability.

1. Electronics Industry

- Components: Smartphone screens, protective casings, and LED lenses.

- Benefits: With excellent optical clarity and impact resistance, Polycarbonat protects delicate electronics while maintaining aesthetics.

- Example: A smartphone case made of CNC-machined Polycarbonat is not only durable but also lightweight, offering a perfect balance of protection and user comfort.

2. Automotive Sector

- Components: Headlamp lenses, dashboards, and sunroofs.

- Benefits: The material’s lightweight properties improve fuel efficiency, while its impact strength enhances safety.

- Example: Headlamp covers made from Polycarbonat are clearer than glass and can withstand harsh road conditions.

3. Medical Devices

- Components: Transparent shields, diagnostic equipment housings.

- Benefits: Polycarbonat’s biocompatibility and sterilization compatibility make it ideal for healthcare settings.

- Example: CNC-machined medical shields offer excellent optical clarity for surgical visibility.

4. Aerospace Industry

- Components: Window panels, cockpit displays.

- Benefits: Lightweight yet strong, Polycarbonat meets the high safety and efficiency standards of aerospace applications.

- Example: Polycarbonat window panels reduce aircraft weight without compromising durability.

Data Table: Polycarbonat Application Examples

| Industry | Component | Functionality |

|---|---|---|

| Electronics | Smartphone screen covers | Scratch resistance, optical clarity |

| Automotive | Headlamp covers | Impact resistance, lightweight |

| Medical | Safety shields | Transparent and biocompatible |

| Aerospace | Cockpit panels | Lightweight, high strength |

| Construction | Skylight panels | UV protection, weather resistance |

| Consumer Goods | Protective cases | Durable and shatterproof |

Optimizing CNC Machining for Polycarbonat

Best Practices for Machining Polycarbonat

Achieving optimal results with Polycarbonat requires attention to detail and careful planning. I’ve often found that small adjustments to cutting parameters can dramatically improve quality.

- Tool Selection:

- Carbide or diamond-coated tools are best for durability and precision.

- Sharp tools minimize surface stress, preventing cracking or chipping.

- Cutting Parameters:

- Feed Rate: Keep a steady but moderate rate to avoid overloading the material.

- Spindle Speed: Lower speeds are ideal to reduce heat buildup, especially for intricate cuts.

- Coolant Usage:

- Water-based coolants are highly effective for heat dissipation.

- Consistent application prevents material deformation.

Surface Finishing Techniques

Post-processing is essential for improving both the appearance and functionality of CNC-machined Polycarbonat components. Common finishing methods include:

- Polishing: Restores optical clarity and is essential for lenses or transparent covers.

- Buffing: Smoothens the surface, eliminating machining marks.

- Anti-scratch Coating: Adds an additional layer of durability, extending the part’s lifespan.

By implementing these best practices, you can unlock the full potential of Polycarbonat in CNC machining.

Costs and Supply Chain Considerations

Material Cost Breakdown

Polycarbonat’s cost varies based on its grade and any additional treatments. Here’s an table comparing common types:

| Material Type | Price per Kg (USD) | Application |

|---|---|---|

| Standard Polycarbonat | $3–5 | General-purpose components |

| UV-stabilized Polycarbonat | $5–7 | Outdoor panels, automotive parts |

| Optical-grade Polycarbonat | $8–10 | High-clarity lenses, precision electronics |

| Flame-retardant Polycarbonat | $6–9 | Aerospace and industrial applications |

| Reinforced Polycarbonat | $7–12 | High-stress environments, mechanical parts |

Polycarbonat remains a cost-effective choice given its durability and machinability.

FAQ

- What’s the difference between machining Polycarbonat and acrylic?

Polycarbonat offers better impact resistance and flexibility, whereas acrylic is more prone to cracking but provides better scratch resistance. - What tools work best for machining Polycarbonat?

Carbide and diamond-coated tools deliver optimal results, ensuring precision and durability. - How can I achieve a smooth surface finish on Polycarbonat?

Polishing and buffing are essential, followed by applying an anti-scratch coating if necessary. - Can Polycarbonat be laser cut?

Yes, Polycarbonat can be laser cut, but it may discolor or char if parameters are not optimized. Post-laser polishing is often required for better edge quality. - What’s the ideal spindle speed for machining Polycarbonat?

The ideal spindle speed typically ranges between 10,000 and 20,000 RPM, depending on the tool diameter and material thickness. - Does Polycarbonat require cooling during CNC machining?

Yes, using a water-based coolant helps to dissipate heat and prevent melting or deformation during machining. - Can Polycarbonat be used in high-temperature environments?

Polycarbonat is stable up to 120°C, making it suitable for applications involving moderate heat exposure. - What is the maximum thickness of Polycarbonat sheets suitable for CNC machining?

Polycarbonat sheets up to 20 mm thickness can be effectively machined, but thicker sheets may require specialized tools and parameters. - Is Polycarbonat recyclable after CNC machining?

Yes, Polycarbonat is recyclable and can be reprocessed into new products, reducing environmental impact. - What industries most commonly use CNC-machined Polycarbonat components?

Industries like electronics, automotive, aerospace, medical, and construction frequently utilize CNC-machined Polycarbonat for its versatility and durability. - How does Polycarbonat compare to other plastics for CNC machining?

Polycarbonat is tougher and more impact-resistant than many other plastics, such as ABS and acrylic, making it a preferred choice for high-strength applications.

Other Articles You Might Enjoy

- Applications and Advantages of Bronze CNC Machining

1. Introduction: The Enduring Allure of Bronze in CNC Machining In this opening section, we explore the timeless appeal of bronze as a material for CNC machining. From its rich…

- The Multifaceted Applications of Bead Blasting in CNC Machining

1. Introduction: Unveiling the Versatility of Bead Blasting In this opening section, we introduce the concept of bead blasting in CNC machining and set the stage for an in-depth exploration…

- Precision CNC Machining of Steel: High-Volume Production

Precision CNC Machining and High-Volume Production As an integral part of modern manufacturing processes, Precision Computer Numerical Control (CNC) machining brings about unmatched accuracy and consistency in the production of…

- High-Precision CNC Machining for Military Applications

Introduction to High-Precision CNC Machining in Military Applications The technical realm of high-precision Computer Numeric Control (CNC) machining is fast becoming integral to the military sector. This process, which relies…

- Zirconium vs. Titanium: Evaluating CNC Machining for Critical Applications

Introduction: Zirconium vs. Titanium in CNC Machining In recent years, we've observed an increasing trend in the use of zirconium and titanium materials in the artful domain of CNC machining.…

- Material Versatility in CNC Machining: From Titanium to Thermoplastics

Introduction to CNC Machining CNC machining stands as a cornerstone in the manufacturing sector, enabling the precise creation of parts and components. This process utilizes computer numerical control (CNC) to…