Why Polycarbonate Roofing Is in High Demand

Polycarbonate roofing has become a popular choice in construction due to its durability, energy efficiency, and ability to transmit light while providing excellent protection from the elements. Whether you’re building a modern skylight, a greenhouse, or a commercial structure, polycarbonate roofing materials offer an ideal combination of practicality and aesthetics. But what makes polycarbonate roofing stand out even more is the ease with which it can be customized and manufactured using CNC machining.

In my experience, one of the key reasons polycarbonate roofing has surged in popularity across multiple industries is its unique ability to meet both aesthetic and functional requirements. From its transparent qualities that allow natural light into buildings to its impressive resistance to impact and UV radiation, polycarbonate roofing offers an unparalleled combination of durability and versatility. Moreover, CNC technology has allowed manufacturers to cut, shape, and drill polycarbonate panels with precision, enabling custom designs that were previously difficult or costly to produce.

In this guide, we will dive deep into how polycarbonate roofing is made, why CNC machining is a perfect partner for its production, and how these two elements are combined to create superior roofing solutions for various applications.

Understanding Polycarbonate as a Roofing Material

What is Polycarbonate?

Polycarbonate is a high-performance thermoplastic material with a range of physical properties that make it ideal for roofing applications. It’s lightweight, highly impact-resistant (up to 250 times stronger than glass), and offers excellent light transmission. These features make polycarbonate the material of choice for many demanding applications in both residential and commercial roofing.

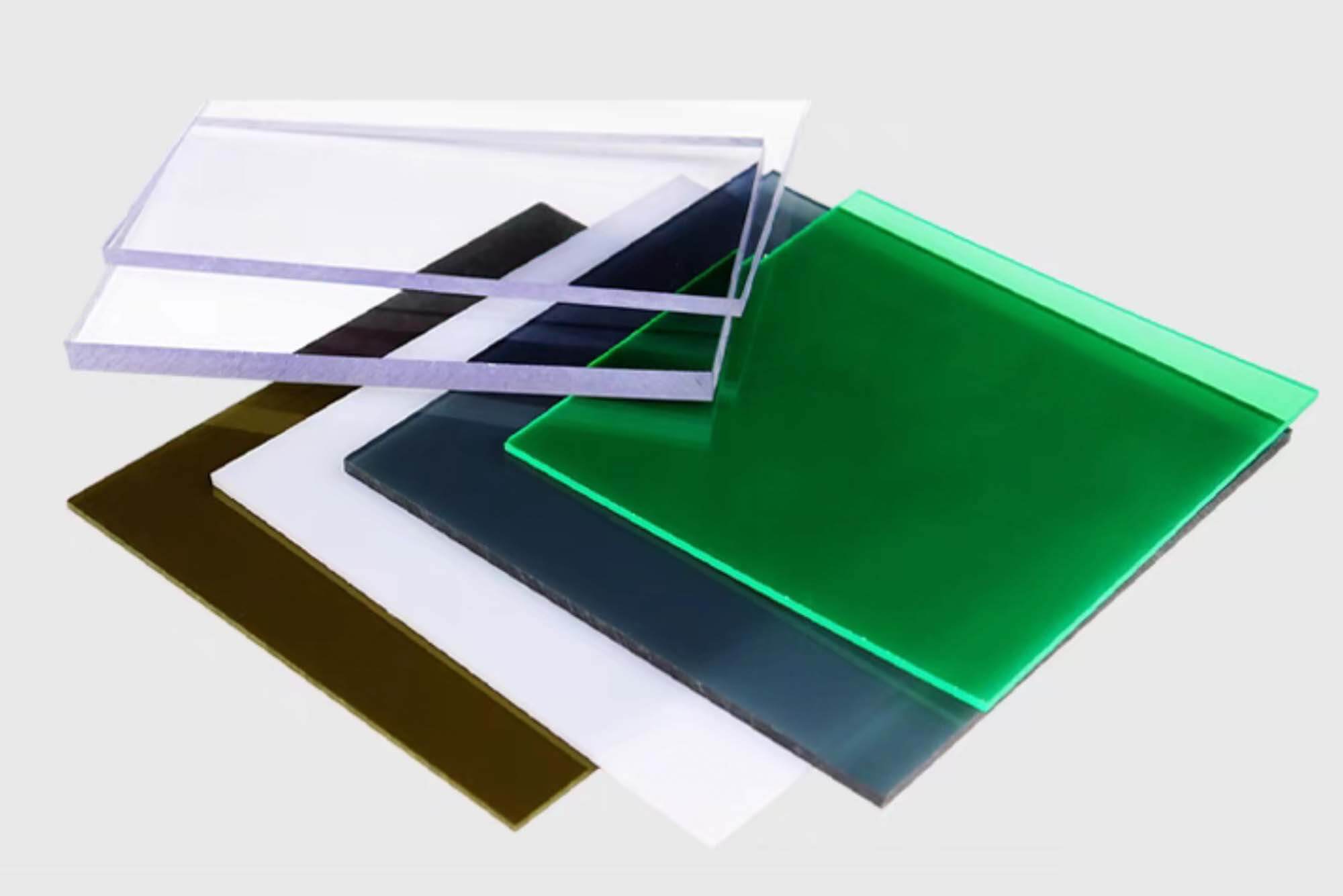

- Solid Polycarbonate: This type of polycarbonate is highly transparent, offering light diffusion while maintaining a high level of strength and UV resistance. It’s often used for skylights, domes, or as clear roofing material for outdoor structures.

- Multi-wall Polycarbonate: This polycarbonate has a layered, honeycomb structure that provides excellent thermal insulation properties. The multi-wall design reduces heat loss while still allowing a significant amount of light to penetrate, making it ideal for use in greenhouses or energy-efficient building designs.

Advantages of Polycarbonate Roofing

One of the reasons polycarbonate roofing is so sought-after is its combination of properties that offer both practicality and longevity:

- Light Transmission and Diffusion: Polycarbonate roofing allows for up to 90% light transmission, making it an ideal solution for applications like greenhouses or atriums, where natural lighting is crucial. The material also diffuses light, preventing harsh glares and creating a comfortable indoor environment.

- Energy Efficiency: Multi-wall polycarbonate offers superior insulation, helping to maintain comfortable indoor temperatures and reducing energy costs. This feature is particularly beneficial for commercial or residential buildings that seek to maximize energy efficiency.

- Weather Resistance: Polycarbonate is known for its outstanding resistance to extreme weather conditions, including UV radiation, high winds, hail, and heavy rain. Its resilience makes it an excellent option for roofing in areas prone to harsh weather.

Common Applications of Polycarbonate Roofing

Polycarbonate roofing is widely used across several industries, thanks to its unique properties. Some of the most common applications include:

- Skylights: Polycarbonate’s high light transmission and ability to withstand weather conditions make it the ideal material for skylights in both residential and commercial spaces.

- Greenhouses: The thermal insulation properties of multi-wall polycarbonate make it perfect for greenhouse roofs, providing a controlled environment while allowing sufficient light for plant growth.

- Outdoor Structures: Polycarbonate is also used in a wide range of outdoor structures, such as patios, pergolas, and walkways, where both light and weather protection are essential.

- Sports Arenas and Airports: Polycarbonate is used for roofing in large-scale public infrastructure due to its high strength and ability to maintain a bright and welcoming atmosphere indoors.

CNC Machining for Polycarbonate Roofing

CNC Machining Basics

CNC (Computer Numerical Control) machining refers to the use of computer-controlled machines to perform a variety of tasks such as cutting, drilling, and shaping materials with high precision. This technology has transformed the manufacturing industry, particularly in the production of complex and customized components.

For polycarbonate roofing, CNC machining is crucial for accurately shaping panels to meet the required specifications, whether it’s creating custom curves, precise holes for fasteners, or intricate designs.

Benefits of CNC Machining for Polycarbonate Roofing

CNC machining offers several advantages in the production of polycarbonate roofing components:

- High Precision and Consistency: CNC machines are programmed to perform cuts and shapes with a high degree of accuracy. This ensures that polycarbonate panels are cut to exact measurements, improving the overall quality and reducing the need for manual adjustments.

- Flexibility in Design: CNC technology allows for the creation of complex and intricate patterns on polycarbonate roofing materials. Manufacturers can produce panels with custom shapes, curved surfaces, and even perforated designs that would be impossible or too costly to achieve with traditional methods.

- Cost-Effectiveness for Large-Scale Production: Although the initial setup cost of CNC machines can be high, they offer significant cost savings in the long run. Once set up, CNC machines can produce large quantities of polycarbonate panels quickly and consistently, making them ideal for mass production.

Common CNC Processes for Polycarbonate Roofing

The most common CNC processes used in the production of polycarbonate roofing include:

- CNC Cutting: Cutting polycarbonate sheets to the required size is one of the primary functions of CNC machines. The precise cuts ensure that panels fit perfectly, whether they are used for standard roofs or custom-designed architectural features.

- CNC Drilling: CNC machines can also be used to drill precise holes in polycarbonate roofing panels. This is especially important when creating mounting holes for fasteners or ventilation holes in greenhouse roofing.

- CNC Engraving: Engraving is a useful technique for adding patterns, logos, or text to polycarbonate roofing panels. This process is commonly used for decorative elements or to add functional markings, such as orientation labels for installation.

Benefits of Using CNC for Polycarbonate Roofing Production

CNC technology is integral to the production of polycarbonate roofing due to the precision, efficiency, and flexibility it offers. Here are the key benefits of using CNC machining in the production of polycarbonate roofing panels:

1. Precision

CNC machines provide an unparalleled level of precision. Whether it’s cutting panels to exact sizes or creating custom shapes, the consistency of CNC machining ensures that every panel will fit perfectly into the roofing system. This eliminates the risk of mistakes that could lead to additional costs or delays in construction.

2. Efficiency

CNC machining allows for faster production times, as the machines can work at high speeds and automate many steps in the manufacturing process. This results in cost savings, especially for large-scale projects.

3. Customization

One of the standout advantages of CNC technology is the ability to create highly customized roofing panels. Whether you need panels with unique shapes, specific drilling patterns, or special finishes, CNC machines can handle the custom requirements with ease, making it easier to meet client specifications.

4. Cost-Effectiveness

By reducing material waste and minimizing the need for manual labor, CNC machining lowers the overall cost of polycarbonate roofing production. This makes it a more affordable option for both small and large projects.

Manufacturing Process and Quality Control for Polycarbonate Roofing

Step-by-Step Manufacturing Process

The production of polycarbonate roofing involves several key stages:

- Material Selection: The first step is selecting the right type of polycarbonate (solid or multi-wall) based on the project requirements.

- CNC Cutting and Shaping: Once the material is chosen, CNC machines are used to cut the polycarbonate sheets into the desired dimensions and shapes.

- Drilling and Engraving: Holes for mounting and any necessary engravings are made to ensure the panels can be securely installed.

- Finishing and Coating: Polycarbonate roofing panels are often coated with UV-resistant layers to ensure long-lasting protection against sun damage.

Quality Control Procedures

To ensure that polycarbonate roofing panels meet the necessary standards, strict quality control procedures are implemented during the manufacturing process. These include:

- Dimensional Accuracy: Regular checks are made to ensure that the panels are cut to the correct specifications.

- Impact Testing: Polycarbonate panels are tested for their impact resistance to ensure that they can withstand harsh weather conditions.

- UV Resistance Testing: Since polycarbonate is often exposed to the sun, UV resistance is a crucial factor in its longevity. Panels are tested to ensure they can withstand prolonged UV exposure without degrading.

Challenges and Solutions in Polycarbonate Roofing Production

While polycarbonate roofing offers numerous benefits, there are some challenges in its production. This chapter explores these challenges and the solutions that CNC machining offers.

1. Handling Heat Expansion

Polycarbonate is sensitive to temperature changes, which can cause expansion and contraction. CNC manufacturers must account for these factors when designing roofing panels. Special cutting techniques and allowances are made to accommodate the material’s natural expansion.

2. Surface Scratching

Polycarbonate sheets are prone to surface scratches during handling and installation. However, with careful CNC machining and protective coatings, these issues can be minimized.

3. UV Protection

Polycarbonate is susceptible to UV degradation over time, which can affect its appearance and performance. CNC manufacturers often apply protective coatings or layer UV-resistant films to the panels during the production process.

Applications of Polycarbonate Roofing in Various Industries

Polycarbonate roofing is not limited to just one or two industries. Its combination of strength, light diffusion, insulation, and ease of installation makes it an ideal choice for a variety of sectors. In this chapter, I will explore the main industries where polycarbonate roofing has found widespread use and why it is becoming increasingly essential in each of these fields.

1. Agricultural Industry

One of the most well-known applications of polycarbonate roofing is in greenhouses and other agricultural structures. The material’s excellent light transmission properties make it an ideal choice for growing plants that need natural light to thrive. Polycarbonate is also resistant to UV radiation, which can be harmful to both plants and crops.

- Greenhouses: Polycarbonate roofing provides optimal light diffusion, ensuring that crops receive an even distribution of sunlight throughout the day. The multi-wall polycarbonate, with its insulation capabilities, helps maintain a stable temperature inside the greenhouse, thus providing a more controlled environment for plants.

- Livestock Housing: In barns and animal shelters, polycarbonate roofing can provide natural daylight, reducing the need for artificial lighting. This not only saves energy costs but also improves the wellbeing of the animals.

2. Commercial and Industrial Applications

Polycarbonate roofing is becoming a preferred material for commercial buildings, shopping centers, hospitals, and sports complexes. It is valued for its ability to allow natural light into large spaces while providing the necessary protection from the elements.

- Shopping Malls and Airports: Large commercial structures, such as malls and airports, benefit from polycarbonate roofs due to their ability to withstand harsh weather conditions. The material allows ample natural light to penetrate, helping reduce energy consumption.

- Sports Stadiums: Polycarbonate roofing is often used in sports arenas and stadiums where natural light is needed to illuminate seating areas, courts, or fields. The durability of polycarbonate ensures the roofing can withstand extreme weather conditions, from heavy snow to intense sunlight.

3. Residential Buildings

In residential architecture, polycarbonate roofing is commonly used for skylights, sunrooms, and patio covers. The material offers homeowners a high degree of customization, enabling architects and designers to create aesthetically pleasing spaces while maximizing the amount of natural light in the home.

- Skylights and Conservatories: Polycarbonate’s transparency and insulation properties make it a popular choice for skylights and conservatories, where maintaining a comfortable indoor temperature and having ample light is essential.

- Decks and Patio Covers: Polycarbonate roofing is often used as a covering for outdoor spaces. It provides protection from rain and UV rays while allowing homeowners to enjoy natural sunlight during the day.

4. Infrastructure and Public Works

Public infrastructure projects such as bus shelters, train stations, and airport terminals have increasingly adopted polycarbonate roofing solutions. The ability to withstand heavy environmental stress—whether from extreme temperatures, wind, or rain—makes polycarbonate a reliable material for public transportation infrastructure.

- Public Transportation: Polycarbonate roofing on bus and train stations ensures that passengers are protected from weather elements while still benefiting from natural light. The material’s low-maintenance nature is also a significant advantage for public sector projects where long-term durability is key.

- Stadiums and Arenas: Sports venues often use polycarbonate roofing for its lightness and durability, which helps support large roof spans without requiring heavy structural support. This application benefits from the material’s energy efficiency, reducing the need for artificial lighting.

Conclusion

Polycarbonate roofing is a versatile and efficient roofing material that continues to gain popularity across various industries. When paired with CNC machining, the possibilities for customization and precision are virtually limitless. From its exceptional strength and energy efficiency to its ability to be easily shaped into custom profiles, polycarbonate roofing is an ideal choice for both residential and commercial applications.

By understanding the unique properties of polycarbonate and the role of CNC technology in its production, you can make more informed decisions about your roofing needs, ensuring you choose the best solution for your project.

FAQ

1. What is Polycarbonate Roofing?

Polycarbonate roofing refers to roofing materials made from polycarbonate, a durable, lightweight thermoplastic material. Polycarbonate roofing systems are known for their exceptional light transmission, high impact resistance, and UV protection, making them suitable for various applications, such as skylights, greenhouses, and commercial buildings.

2. Why is Polycarbonate Roofing a Popular Choice?

Polycarbonate roofing is popular because of its combination of strength, energy efficiency, and natural light diffusion. It is also highly durable and can withstand extreme weather conditions like hail, high winds, and heavy snow. Additionally, polycarbonate roofs provide excellent thermal insulation, helping to reduce energy costs in both residential and commercial buildings.

3. How Does CNC Machining Benefit Polycarbonate Roofing Production?

CNC machining offers unparalleled precision when cutting, drilling, and shaping polycarbonate panels. With CNC technology, manufacturers can create complex shapes, precise cuts, and customized roofing solutions quickly and efficiently, ensuring the production of high-quality polycarbonate roofing components for various applications.

4. What Are the Advantages of Polycarbonate Roofing Over Other Materials?

- Light Transmission: Polycarbonate allows up to 90% light transmission, reducing the need for artificial lighting.

- Durability: It is up to 250 times stronger than glass and highly resistant to impacts.

- Weather Resistance: Polycarbonate can withstand extreme temperatures, UV radiation, and weathering.

- Energy Efficiency: Multi-wall polycarbonate provides excellent insulation, reducing energy consumption for heating or cooling.

5. Can Polycarbonate Roofing Be Used for Residential Projects?

Yes, polycarbonate roofing is widely used in residential applications such as patios, sunrooms, and skylights. It provides homeowners with energy-efficient, durable, and aesthetically pleasing roofing options. The material’s transparency allows natural light into living spaces, reducing the need for artificial lighting during the day.

6. How Long Does Polycarbonate Roofing Last?

Polycarbonate roofing has a lifespan of 20 to 30 years, depending on the type of polycarbonate and the environmental conditions it is exposed to. The material’s resistance to UV degradation, impact, and extreme temperatures makes it a long-lasting choice for both residential and commercial roofing projects.

7. What is the Difference Between Solid Polycarbonate and Multi-Wall Polycarbonate?

- Solid Polycarbonate: Offers higher transparency and clarity, commonly used for skylights and roofing where clear, bright light is desired.

- Multi-Wall Polycarbonate: Features a hollow structure that provides excellent insulation properties, making it suitable for applications like greenhouses, energy-efficient buildings, or areas requiring temperature control.

8. Is Polycarbonate Roofing Suitable for Cold Climates?

Yes, multi-wall polycarbonate is particularly well-suited for cold climates due to its insulating properties. It can help maintain the desired temperature inside buildings by reducing heat loss while allowing natural light to enter. The material is resistant to cracking or damage even in extreme temperatures, making it a reliable option for areas with harsh winters.

9. How Does Polycarbonate Roofing Perform in High-Wind Conditions?

Polycarbonate roofing is incredibly strong and impact-resistant, making it well-suited for areas that experience high winds. The material’s flexibility and strength allow it to withstand gusts and storms without cracking or breaking. This durability makes polycarbonate an ideal choice for coastal areas or regions prone to severe weather conditions.

10. Can Polycarbonate Roofing Be Custom-Made Using CNC?

Yes, CNC machining allows for the precise cutting, shaping, and drilling of polycarbonate panels. This means that polycarbonate roofing can be customized to meet the exact requirements of a building project, whether it involves creating unique shapes, custom sizes, or intricate designs. CNC technology is essential for producing complex roofing components and ensuring a perfect fit.

11. What Are the Environmental Benefits of Polycarbonate Roofing?

Polycarbonate roofing offers several environmental benefits:

- Energy Efficiency: By improving insulation and allowing natural light to enter, polycarbonate reduces the need for artificial lighting and heating, leading to lower energy consumption.

- Recyclability: Polycarbonate is a recyclable material, which makes it an environmentally friendly choice when the roofing system reaches the end of its life cycle.

- Sustainability: Polycarbonate’s long lifespan reduces the frequency of replacements, minimizing the environmental impact of manufacturing and disposal.

12. How Do I Maintain Polycarbonate Roofing?

Maintaining polycarbonate roofing is simple and requires regular cleaning to keep the panels free from dirt and debris. For best results, it’s recommended to wash polycarbonate panels using a mild detergent and water. Avoid using abrasive cleaners that could scratch the surface, as scratches can affect the material’s light transmission properties.

13. Can Polycarbonate Roofing Be Installed Over Existing Roofs?

Yes, polycarbonate roofing can often be installed over an existing roof, depending on the structural integrity of the current roof and local building codes. This makes it an ideal option for retrofitting and improving the energy efficiency of older buildings without the need for a complete roof replacement.

14. What Is the Cost of Polycarbonate Roofing?

The cost of polycarbonate roofing varies depending on the type of polycarbonate used, the thickness, and the size of the installation. Generally, multi-wall polycarbonate is more affordable than solid polycarbonate, but the exact cost can also be influenced by factors like installation complexity and the region you’re located in.

15. Can Polycarbonate Roofing Be Used in Hot Climates?

Yes, polycarbonate roofing is suitable for hot climates. Multi-wall polycarbonate, in particular, offers excellent thermal insulation, helping to keep buildings cooler in the summer. The material’s UV resistance also helps prevent degradation due to prolonged sun exposure, ensuring the roofing maintains its performance and appearance over time.

Other Articles You Might Enjoy

- Why Polycarbonat Excels in CNC Applications

The Intersection of Polycarbonat and CNC Machining Polycarbonat, a versatile and highly durable thermoplastic, has revolutionized modern manufacturing. Combining excellent strength, optical clarity, and processability, this material pairs perfectly with…

- How Polycarbonate Glass Benefits from CNC Custom Machining

Polycarbonate Glass has become increasingly valuable in industrial and architectural applications due to its high impact resistance, clarity, and durability. Unlike standard glass, polycarbonate is lightweight and can withstand extreme…

- Polycarbonate Lenses Provide Advanced Customization for Industrial Performance

Introduction In today’s world, where industrial performance and precision are critical, Polycarbonate Lenses stand out for their advanced customization potential and high impact resistance. From protective eyewear to optical instruments,…

- CNC Machining for Medical Applications: Compliance and Material Selection?

Introduction to CNC Machining in Medical Applications CNC or Computer Numerical Control machining is a manufacturing process wherein pre-programmed computer software dictates the movement of factory tools and machinery. This…

- Flange Production Mastery with China's CNC Services

Exploring the Landscape of Flange Production in China China cnc machining service is developing very rapidly and have become an important force in global CNC processing services. Especially in the…