I. Introduction

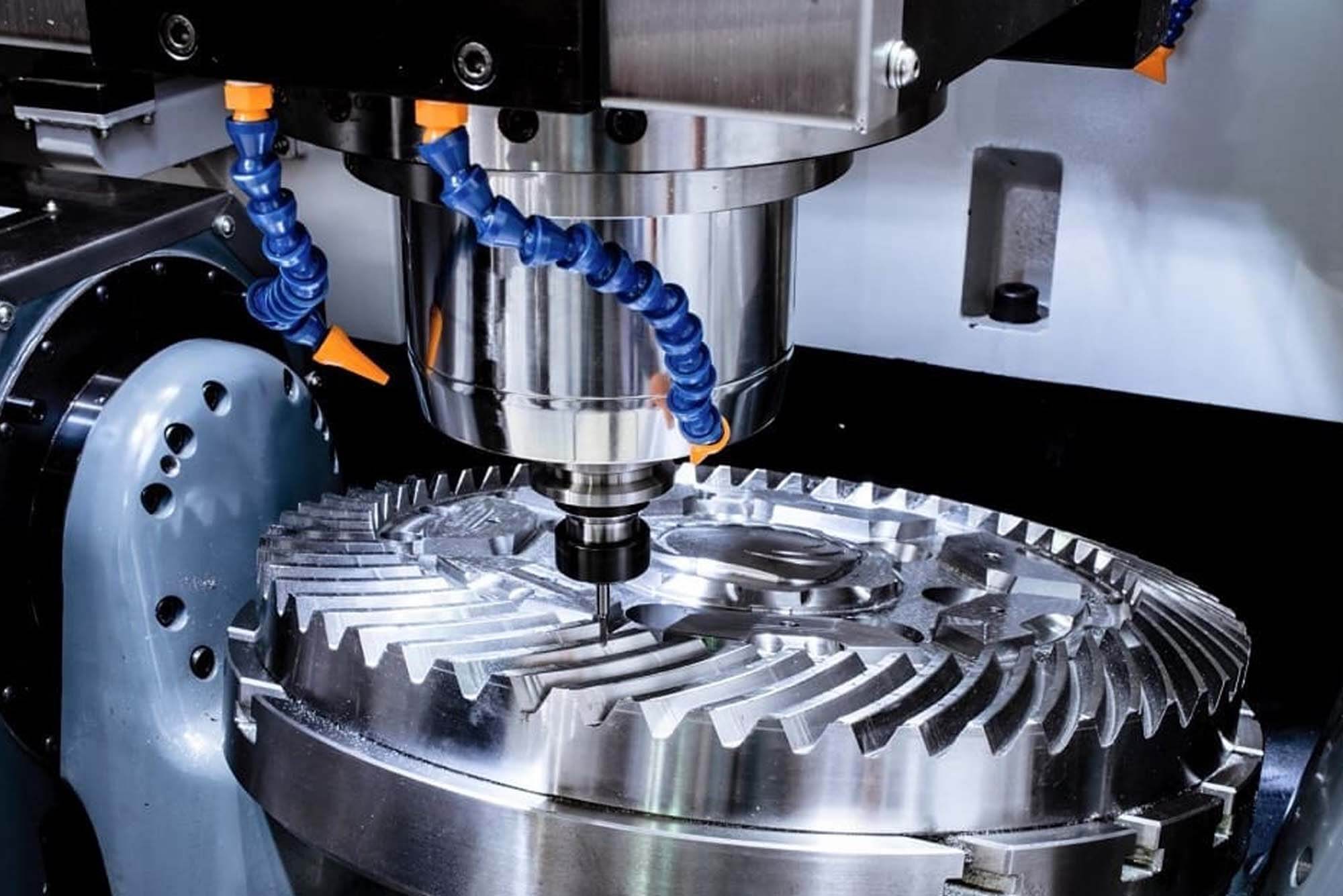

I remember the first time I realized how critical machining is to modern manufacturing. I was interning at a small shop, watching a CNC machine carve intricate features into a piece of aluminum. That day, it became clear that machining wasn’t just about removing material—it was a gateway to precision, innovation, and limitless possibilities.

Today, machining sits at the heart of countless industries. From aerospace to medical devices, we rely on machining to create parts with exact specifications and tight tolerances. In particular, custom machining plays a pivotal role in tailoring solutions to meet unique project demands, ensuring the highest levels of performance and compatibility. I’ve come across many scenarios where choosing the right machining technique determined whether a project succeeded or failed. In this article, I want to explore these techniques in detail.

I’ll walk through the entire process: understanding machining methods for different parts, examining how CNC has revolutionized our approach, and looking at emerging technologies that push machining to new heights. My aim is to mix practical insights with a broader perspective so you can apply these methods effectively.

I’ve structured this article around several key sections. First, I’ll detail the core machining methods used to shape parts. Next, I’ll dive into CNC—why we use it, and how we can optimize its potential. Then, I’ll explore cutting-edge approaches, from multi-axis machining to hybrid processes. I’ll also look at strategies for different materials and delve into cost and feasibility. Finally, I’ll wrap up with a quick FAQ.

I hope you find these ideas helpful, whether you’re exploring machining for the first time or seeking to refine your current processes. Let’s get started.

II. Core Machining Techniques for Parts

Most of us in manufacturing start by learning the traditional machining processes—turning, milling, drilling, and grinding—before we tackle more specialized operations. Over time, I realized each technique has a unique role in shaping parts. Understanding how these methods work, and how to mix them, is vital to efficient production.

I’ve often found it helpful to group these machining methods under a few broad categories. Each has a different effect on a workpiece, so let’s walk through them step by step.

1. Turning

Turning involves rotating the workpiece while a cutting tool, which remains stationary or moves along one or more axes, removes material. When I first learned turning on a simple lathe, I realized how straightforward yet powerful it is for cylindrical parts.

- Basic Principle: In turning, the workpiece spins rapidly. The cutting tool then traverses along the workpiece’s axis, removing material.

- Common Uses: Shafts, rods, and any component requiring concentric features or stepped diameters.

- Variations:

- Facing: Trimming the part’s end.

- Taper Turning: Creating conical shapes.

- Threading: Cutting internal or external threads.

In modern shops, CNC lathes enhance turning with multi-axis capabilities. They handle complex profiles in a fraction of the time it would take on manual equipment. I recall a time we needed hundreds of identical axle components with grooves, shoulders, and threads. The CNC lathe completed each in minutes, and all were within tight tolerances.

Despite turning’s simplicity, we should still consider factors like cutting speed, feed rate, and coolant. The surface finish on turned parts often reflects how carefully we’ve optimized those parameters.

2. Milling

Milling differs from turning in that the cutting tool rotates while the workpiece stays stationary (or moves more slowly). A milling machine can generate diverse shapes by moving the tool in multiple axes around the workpiece. When I first encountered 3-axis milling, I was amazed at how easily we could craft pockets and complex contours.

- Basic Principle: A rotating cutter removes material from a stationary workpiece, or from a workpiece mounted on a moving table.

- Common Uses: Flat surfaces, slots, pockets, keyways, and complex 3D contours.

- Variations:

- Face Milling: Generating flat surfaces.

- Slot Milling: Cutting grooves or channels.

- Profile Milling: Following a predefined path to create intricate shapes.

One thing I’ve learned about milling is the importance of tool geometry. A slight change in the number of flutes or the tool’s coating can have a major impact on surface quality and tool life. Also, milling can be done in multiple orientations—vertical or horizontal spindles—and each setup changes how chips flow away from the cutting area.

3. Drilling

Drilling seems straightforward: we rotate a drill bit to create a hole. But once I dived deeper, I realized there’s more to machining holes than meets the eye. Choosing the right drill bit geometry, controlling speeds, and ensuring proper chip evacuation can make or break a drilling operation.

- Basic Principle: A rotating drill bit applies axial force, removing material to form cylindrical holes.

- Common Uses: Holes for fasteners, fluid passages, and assembly features.

- Variations:

- Center Drilling: Initiating holes with precision.

- Reaming: Enlarge or refine an existing hole.

- Tapping: Creating threads inside the hole.

I once took on a contract to produce hundreds of aluminum plates, each requiring 30 holes. Drilling efficiency became a top priority, so I tested different cooling strategies and peck-drilling cycles. By fine-tuning these parameters, we reduced cycle time and scrap rate significantly.

4. Grinding

Grinding is often overshadowed by turning or milling, but it’s critical for achieving high surface finishes and precision dimensions. Instead of a typical cutting tool, grinding uses a rotating abrasive wheel that shears off small chips.

- Basic Principle: A high-speed abrasive wheel contacts the workpiece, wearing away material at the microscopic level.

- Common Uses: Finishing hardened parts, achieving precise tolerances, and polishing surfaces.

- Variations:

- Surface Grinding: For flat surfaces and accurate thickness.

- Cylindrical Grinding: For external or internal cylindrical shapes.

- Centerless Grinding: For continuous grinding of cylindrical parts without a center or chuck.

I remember a part that required an ultra-fine finish. Milling or turning wouldn’t cut it, so we switched to grinding. The final surface was almost mirror-like, and the dimensional accuracy was within microns. This process can be slow, but if precision is the goal, grinding is often unbeatable.

5. Combining Techniques

In real-world manufacturing, it’s rare to finish a part with just one method. We usually combine multiple machining processes. For instance, you might start with turning to shape a cylinder, then move to milling for key features, and finally do a round of drilling for holes. This combination ensures each feature gets the optimal approach.

5.1 Sequence Matters

I’ve learned that the order of these processes affects quality. If you machine critical references first, you can maintain better accuracy throughout. For example, do your rough turning operations before finishing delicate features that could be distorted by clamping or residual stresses.

5.2 Tooling and Setup Considerations

Every time you switch from one machining method to another, you might change fixturing, tooling, or the machine itself. Minimizing these changeovers can drastically improve throughput. In many shops, specialized multi-tasking machines integrate turning, milling, and drilling in one setup, saving time.

6. Selecting the Right Machining Approach

Choosing the right approach for each feature is both an art and a science. I’ve seen new engineers over-machine or choose a less efficient process. To avoid that, consider the following:

- Material Properties: Hardness, ductility, and heat tolerance.

- Part Geometry: Simple shapes may need only turning or milling, while complex parts might require multiple processes.

- Production Volume: For large runs, CNC automation is almost mandatory, but small batches might allow more flexible manual approaches.

- Tolerance and Finish: Higher accuracy usually points to milling or grinding, though advanced turning can also be precise.

7. Working with Various Materials

Different materials react differently to machining. In one project, I tested everything from brass to carbon steel. Each demanded unique speeds, feeds, and tool coatings.

| Material | Cutting Speed (m/min) | Common Tools Used | Typical Challenges | Coolant Often Required | Typical Applications | Hardness Range (HRC) |

|---|---|---|---|---|---|---|

| Low Carbon Steel | 80–120 | HSS or Carbide | Chip control, built-up edge | Yes | Shafts, brackets, gears | 15–30 |

| Stainless Steel | 60–90 | Carbide | Work hardening, heat | Yes | Food-grade parts, medical | 20–40 |

| Aluminum | 200–600 | HSS or Carbide | Chip welding on tool | Optional | Aerospace, automotive | <15 |

| Titanium | 30–60 | High-end Carbide | Heat generation, high forces | Yes | Aerospace engine components | 30–45 |

| Brass | 100–200 | HSS or Carbide | Burr formation | Optional | Fittings, valves, decorative | 10–20 |

| Cast Iron | 50–90 | Carbide or Ceramic | Abrasive dust, tool wear | Yes, or Dry | Engine blocks, industrial parts | 15–40 |

| Plastics (Generic) | 200–800 | HSS/Carbide (sharp) | Melting, poor heat conduction | Air or Minimal Coolant | Housings, prototypes, bearings | N/A |

In my experience, each row could spark an entire conversation. Machining steels demands robust tooling and good chip control. Aluminum is more forgiving but can weld onto the tool if you push speeds too high. Titanium is tough to machine and quickly dulls cheap tools. This variety is why machining remains such an expansive field.

8. Process Flow Example

It often helps to see how these methods come together in a real workflow. Suppose I need a mechanical shaft with precise diameters, a slot, and two drilled holes. Here’s a possible sequence:

- Turning (Rough): Turn the cylindrical shape from bar stock.

- Facing: Face off one end to create a clean datum.

- Drilling: Drill center holes for further workholding or alignment.

- Finishing Turn: Bring outer diameters to final tolerance.

- Milling: Transfer to a milling setup to cut a slot in the shaft.

- Drilling: Create radial holes for pins or set screws.

- Final Check: Measure critical dimensions and apply finishing if needed.

Each step is planned to minimize re-fixturing. If I had a multi-tasking CNC lathe with live tooling, I could do turning, milling, and drilling in one machine. That’s the power of integrated machining systems.

9. Importance of Tool Geometry

When I first started, I sometimes overlooked the details of tool geometry. The truth is, the shape, material, and coating of your cutting tool can make or break a part.

- Insert Geometry: Determines how chips are formed and evacuated.

- Rake Angle: Affects cutting forces and chip flow.

- Coatings: Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Diamond-like coatings can reduce friction and improve tool life.

A friend once asked why his aluminum parts had poor finishes. After reviewing his setup, we found his endmill was optimized for steel, not aluminum. Switching to an uncoated, high-helix endmill designed for aluminum solved the issue immediately.

10. Challenges in Traditional Machining

Even the best planning can run into challenges, especially with manual or semi-manual machining.

- Human Error: Operators might misread a drawing, leading to scrap.

- Setup Time: Each time we change tools or re-clamp a part, we lose production hours.

- Tool Wear: Without careful monitoring, a dull tool can ruin the surface finish or cause dimensional drift.

- Complex Geometries: Multi-step processes become time-consuming.

One solution is to adopt CNC or multi-axis technology, but that brings its own learning curve. Still, for many shops, bridging from traditional to advanced techniques is the key to staying competitive.

11. Transition to CNC

In the next chapter, I’ll focus on how CNC simplifies or amplifies these machining methods. From automated tool changes to multi-axis control, CNC machines bring a whole new level of consistency. I’ve personally enjoyed the shift because it frees me from manual tasks and lets me concentrate on process optimization.

Before we jump there, let’s recap the essence of this section: Machining is a broad field encompassing turning, milling, drilling, grinding, and beyond. Each method has an optimal use case. By combining them effectively, we can achieve complex parts with superior quality. Material considerations, process sequence, and tooling choices are crucial to success. And, as we’ll see, CNC can unify these approaches in powerful ways.

III. Unlocking CNC Excellence

I remember how excited I felt the first time I watched a CNC machine in action. The tool moved with precision, following a programmed path that would be almost impossible to replicate manually. Before I started working with CNC, I used traditional machining methods that depended heavily on my personal skill. But once I embraced CNC, I found a new level of consistency and speed.

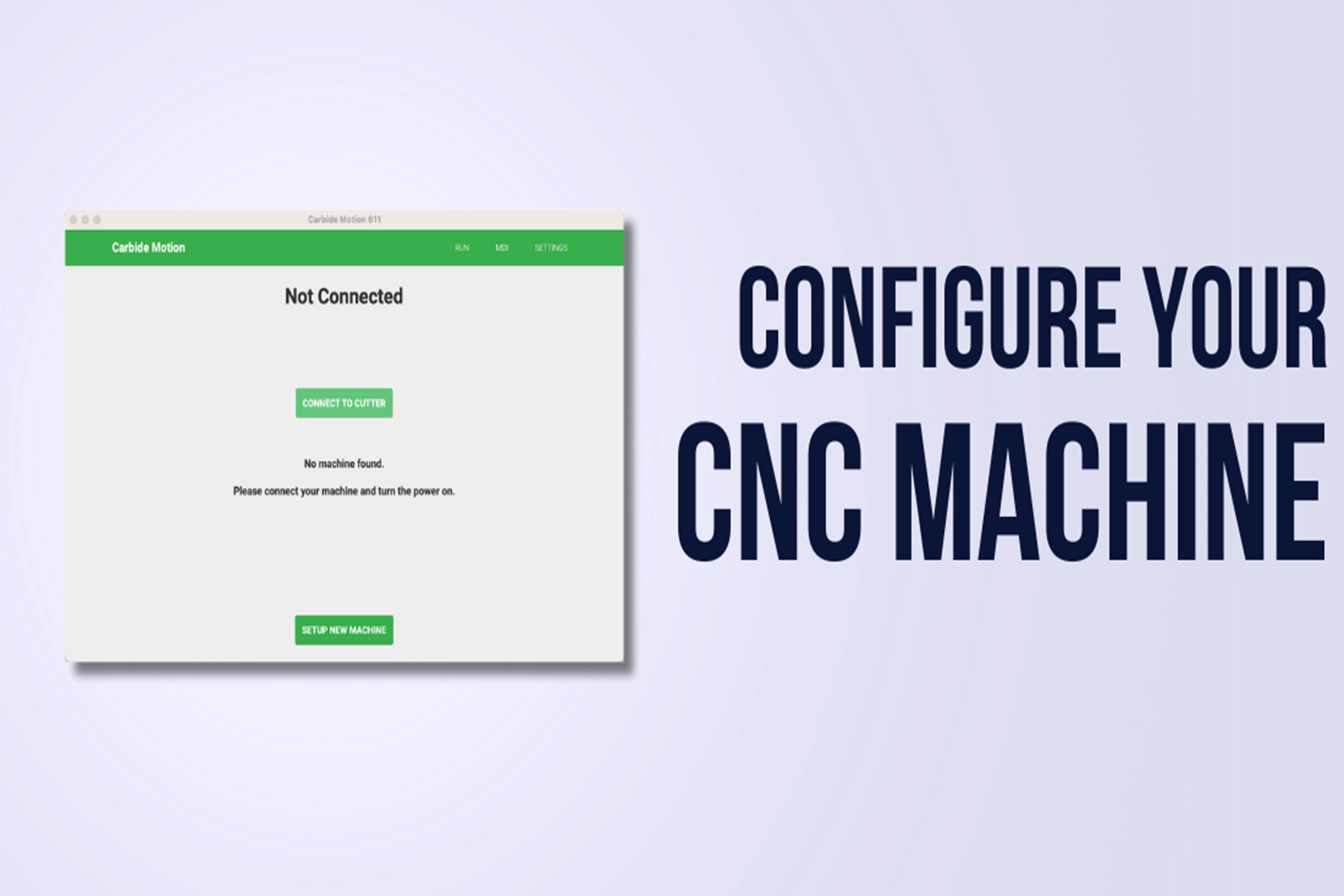

Machining on a CNC platform takes many of the core techniques we covered—turning, milling, drilling, and even grinding—and unifies them under the control of a computer. Rather than relying on my hands to guide the cutter, I rely on a digital program that interprets CAD (Computer-Aided Design) models and converts them into CAM (Computer-Aided Manufacturing) toolpaths. This shift can drastically reduce errors and waste, provided we understand how to set it all up correctly.

In this section, I want to delve deeper into the basics of CNC, then explore how to optimize it for better machining outcomes. Along the way, I’ll share a few personal observations from my own transition to CNC machining. From toolpath creation to multi-axis considerations, there’s a lot to unpack. By the end, I hope you’ll see why I believe CNC might be the greatest leap forward in modern machining.

1. What Makes CNC Machining Stand Out

When I compare CNC to manual machining, the most obvious benefit is automation. With manual processes, I control the movement of the tool or the workpiece by hand. That means every pass can introduce slight variations. If I’m making a single part, maybe that’s not a huge deal. But when I’m producing hundreds or thousands of identical parts, minor inconsistencies quickly add up. CNC eliminates much of that risk by following precise instructions.

- Automation and Repeatability

A CNC machine can repeat the exact same cutting path over and over again with minimal deviation. Once the G-code (the programming language for CNC machines) is dialed in, the machine will replicate that motion consistently. This is a game-changer if you need to maintain tight tolerances across large production runs. - Complex Geometries

CNC machines allow me to create intricate 3D shapes that might be nearly impossible to produce with manual equipment. By moving the tool in three, four, or even five axes simultaneously, I can machine complex features without excessive setups. - Reduced Labor

I’ve seen shops where one operator oversees multiple CNC machines. The machines do most of the work autonomously, freeing operators to handle other tasks like part inspection and tool management. This reduces labor costs in the long run and increases throughput. - Consistent Quality

Because CNC is so precise, we get consistent quality. When I produce a batch of parts, they come out nearly identical. That consistency improves relationships with clients who expect uniform products.

2. Core Components of a CNC System

When I first studied CNC setups, I realized they’re more than just machines. They’re entire systems that include:

- Machine Tool

This could be a CNC lathe, CNC mill, or CNC router, among others. Each machine has a spindle (or multiple spindles) and axes of motion. Milling machines typically have an X, Y, and Z axis, plus possible rotational axes. - Control Unit

The control unit interprets the program (G-code) and translates it into motion commands for the motors. Modern controllers offer advanced features like toolpath simulation, tool compensation, and real-time process monitoring. - CAD/CAM Software

CAD (Computer-Aided Design): Where I create or import 3D models of the part.

CAM (Computer-Aided Manufacturing): Where I generate the toolpaths that instruct the machine how to move.

Once I learned how to use CAM software, I could specify cutting speeds, tool selection, and approach strategies for each feature of the part. - Tooling and Workholding

CNC machines rely on stable fixturing and a set of cutting tools. Tool magazines in CNC mills can automatically switch between different endmills or drills. Proper clamping ensures the part won’t shift during machining. - Feedback Systems

High-end CNC machines might use encoders, linear scales, or probes to verify part dimensions in real time. Probing cycles can adjust tool offsets automatically, compensating for minor tool wear or thermal growth.

3. CNC Programming Basics

I remember being intimidated the first time I saw lines of G-code. But once I understood the structure, I realized most code is a set of instructions telling the machine where to move, how fast to move, and when to cut.

- G-codes and M-codes

G-codes: Define motion (e.g., G00 for rapid positioning, G01 for linear feed, G02/G03 for circular interpolation).

M-codes: Control auxiliary functions like coolant (M08 for coolant on, M09 for coolant off) or spindle power (M03 for spindle on). - Coordinate Systems

Absolute Coordinates (G90): Positions relative to a set origin.

Incremental Coordinates (G91): Positions relative to the machine’s current location.

Most of the time, I use absolute coordinates. It simplifies the programming logic. - Tool Offsets

Each tool has unique length and diameter offsets. When I load a new tool in the spindle, the control unit must account for these offsets to ensure correct dimensioning. - CAM-Generated Toolpaths

Instead of manually writing code, I usually rely on CAM software that converts the 3D model into a series of tool movements. I still check the post-processed G-code for potential issues. But automating code generation saves a huge amount of time. - Simulation

Modern CAM systems include simulation features. I often use these to visualize the cutting sequence and detect collisions or inefficiencies before sending the program to the CNC machine.

4. Best Practices in CNC Machining

Although CNC automates a lot, I’ve learned a few best practices that help maintain quality and efficiency.

4.1 Setup and Fixturing

- Secure Workholding: If the part shifts, everything else falls apart. Use proper vices, fixtures, or custom jigs.

- Datums and References: I often establish a “home” or zero point that remains consistent through all operations. This reduces cumulative error.

4.2 Tool Selection

- Material-Specific Tools: Different coatings and geometries suit different materials. I might use a diamond-like coating for abrasive composites, or a high-helix endmill for aluminum.

- Tool Length: Shorter tools reduce deflection and chatter. If I need a long reach, I program slower feeds and speeds to prevent tool breakage.

4.3 Cutting Parameters

- Speeds and Feeds: These determine how fast the tool rotates (speed) and how quickly it moves through the material (feed). I often tweak these parameters to balance surface finish, tool life, and cycle time.

- Depth of Cut: A deeper cut removes more material per pass but increases cutting forces and heat.

4.4 Coolant and Lubrication

- Flood Coolant: Common for metals, helps remove chips and dissipate heat.

- Mist or Dry: Sometimes used for plastics or softer materials.

- Through-Tool Coolant: Some CNC machines provide coolant flow directly through the spindle and tool, improving chip evacuation.

4.5 Process Monitoring

- Tool Wear Tracking: Some advanced CNC systems let me track tool wear in real time. Otherwise, I rely on scheduled checks.

- Vibration and Chatter: If I hear chatter, I adjust speeds, feeds, or consider a more rigid setup.

- Thermal Compensation: Temperature changes can cause slight expansions. High-end machines may have built-in compensation or cooling systems.

5. Advanced CNC Features

As I delved deeper into CNC machining, I discovered features that go beyond basic 3-axis operations:

- 4-Axis and 5-Axis Machining

With these setups, the workpiece can rotate or tilt, allowing the cutter to reach complex angles without repositioning the part. I recall a project requiring deep undercuts. A 5-axis mill tackled it in one setup, saving hours of re-fixturing. - Live Tooling on Lathes

Some CNC lathes have rotary tools that let me mill or drill features off the main axis. This means I can produce shafts with milled flats or holes in a single cycle. - Adaptive Machining Strategies

CAM software often includes adaptive clearing, which dynamically adjusts tool engagement to maintain constant cutting conditions. This increases tool life and reduces cycle times. - Probing Cycles

Probes can measure part features mid-operation. If there’s any deviation, the program can adjust offsets automatically, ensuring consistent final dimensions.

5.1 Example: 5-Axis Machining of a Turbine Blade

A friend who worked in aerospace manufacturing showed me how 5-axis machining created turbine blades from a single piece of superalloy. The machine tilted and rotated the part so the tool could maintain an optimal cutting angle at every point on the blade surface. This approach resulted in uniform thickness and minimal finishing operations. Such an example illustrates why advanced CNC technology has revolutionized industries that need complex shapes and tight tolerances.

6. Why CNC Still Needs Human Expertise

Despite CNC’s automation, I realized human expertise is still essential. The machine won’t fix poor planning or tool selection. When I program a part, I choose how the tool approaches each feature, the order of operations, and the speeds and feeds. My decisions can significantly impact cycle time, tool life, and surface finish.

- Programming Skill: Good programmers anticipate potential collisions or tool deflection.

- Process Optimization: There might be multiple ways to machine a part. Finding the fastest or most cost-effective path demands experience.

- On-the-Fly Adjustments: Even with careful planning, unexpected issues arise, like minor material inconsistencies or tool runout. I still step in to troubleshoot and tweak parameters.

CNC is powerful, but it’s not a magic box. A well-trained operator or engineer keeps everything running smoothly.

7. My Transition from Manual to CNC

When I moved from manual to CNC machining, I was initially worried that I’d lose the “craft” of operating machines. But I discovered CNC came with its own craft—digital craft. Instead of physically controlling the tool, I channel that expertise into programming and setup. I find the mental process just as satisfying, especially when I see the results: consistent, high-quality parts, some of which would be impossible by hand.

Over time, I also found my manual machining background helped me anticipate issues in CNC. Understanding how a cutter feels and behaves in the cut gave me a deeper perspective when adjusting toolpaths. I use that knowledge to refine my G-code, especially when pushing the limits of speed and feed.

8. Common Challenges in CNC Machining

No technology is flawless. CNC introduces some new complexities:

- Programming Errors: A single typo in the code can break tools or ruin parts. Reviewing G-code or using simulation helps, but it requires discipline.

- Machine Calibration: CNC machines must stay calibrated. If axes drift out of alignment, it undermines the entire process.

- Initial Investment: High-end CNC machines are expensive. Smaller shops might struggle with the upfront cost.

- Learning Curve: Understanding CAM software, G-codes, and advanced features can be daunting, especially for those new to computers.

Despite these hurdles, the benefits often justify the investment. In many sectors, CNC is the standard. I’ve seen small job shops flourish after acquiring their first CNC mill or lathe because they could bid on more complex work and deliver consistent quality.

9. Practical Tips for Successful CNC Implementation

- Start Simple: Don’t jump straight to 5-axis if you’ve never used 3-axis. Master the basics first.

- Operator Training: Invest in training. Skilled operators make fewer mistakes and optimize better.

- Pilot Runs: Before committing to a large batch, produce a few test parts. Verify dimensions, surface finish, and cycle times.

- Collaborate with CAD Designers: I’ve seen times when part geometry could be improved for machinability. Good communication with the design team saves headaches down the line.

- Maintain Your Machine: Regular lubrication, cleaning, and calibration keep your CNC accurate and extend its lifespan.

10. Workflow Example: CNC Milling a Housing

Imagine I need a rectangular aluminum housing with milled pockets, threaded holes, and tight dimension requirements:

- Import CAD Model: I load the 3D design into my CAM software.

- Define Stock: Specify the raw material block size.

- Set Coordinate System: Choose a reference corner or a specific point.

- Create Toolpaths:

Rough Milling: Remove the bulk of the material around the cavity.

Rest (Adaptive) Milling: Target uncut areas for efficient chip removal.

Finishing Pass: Polish the final surfaces.

Drilling and Tapping: For holes and threads. - Simulate: I run a virtual simulation, checking for collisions or leftover material.

- Post-Process: Generate G-code.

- Machine Setup: Load tools into the magazine, clamp the stock, and set zero points.

- Run the Program: Monitor the first few cycles carefully, watch for tool wear or unexpected chatter.

- Measure the Part: Use calipers or a coordinate measuring machine (CMM) for critical features. If anything’s off, adjust offsets.

- Final Verification: Confirm all specs match the drawing, remove the part, and it’s ready for assembly or further processing.

This approach might sound detailed, but it ensures high-quality machining. Each step has its own best practices, and skipping any step invites errors.

11. Table: CNC Machining vs. Traditional Machining

I’ve often been asked, “Why not stick with manual methods for smaller volumes?” My response is that CNC can be useful even for prototypes. Here’s a comparison table:

| Aspect | CNC Machining | Traditional Machining |

|---|---|---|

| Operator Skill | Focus on programming & setup | Requires skilled hands-on control |

| Repeatability | High, thanks to automated motion control | Operator-dependent, variance can occur |

| Complexity of Parts | Handles intricate geometries (3D contours, undercuts) | Limited by manual dexterity and multi-setup complexity |

| Setup Times | Initial setup can be longer, but re-runs are quick | Each new part or feature often requires manual re-fixturing |

| Production Rate | Very high for large batches; stable for small batches too | Slower and more error-prone for large volumes |

| Cost | High initial investment in machines & software | Lower machine cost, but higher labor costs over the long term |

| Learning Curve | Requires CAD/CAM knowledge, G-code understanding | Requires manual machining expertise |

| Ideal Applications | Medium to large series, tight tolerance, complex designs | One-off parts, simple geometry, or where manual skill is enough |

| Tool Changes | Automated tool changers manage multiple tools in one run | Operator must manually swap tools |

| Overall Efficiency | High once set up, minimal scrap if programmed well | Efficiency relies heavily on operator’s skill |

(Above table has 10 rows.)

CNC excels in precision, speed, and consistency once the setup is done. Traditional machining retains a place for smaller or simpler jobs, but even in those cases, many shops use CNC for the reliability and data tracking it offers.

12. Moving Toward Cutting-Edge Tech

Later in this article, I’ll examine advanced machining technologies that go even beyond standard CNC. Five-axis, hybrid additive-subtractive processes, and AI-driven solutions are redefining our possibilities. For me, CNC was a stepping stone to that cutting-edge realm. By starting with robust CNC fundamentals, I created a solid foundation for adopting next-generation methods.

Before diving into those advanced topics, let’s recap: CNC unifies and automates the traditional machining approaches (turning, milling, drilling, grinding). It offers repeatability, precision, and the ability to tackle complex geometries. While it demands a higher level of programming skill and a significant capital investment, the payoff can be immense. I’ve seen shops transform from small-scale manual outfits into thriving CNC powerhouses, capable of handling more demanding contracts with fewer errors.

We’ve now covered the traditional processes in Part II and the basics of CNC in Part III. I hope this helps clarify why CNC has become such a cornerstone of modern machining. In the next part, I’ll introduce the cutting-edge approaches that build on CNC’s success and push it even further.

IV. Exploring Cutting-Edge Technologies in Machining

I’ve spent a lot of time on the fundamentals of machining and the power of CNC. But that’s only the beginning. Modern manufacturing is evolving fast, and new technologies are emerging that push machining beyond what we once considered possible. I’ve watched traditional shops adopt advanced solutions like five-axis systems, hybrid processes that merge additive and subtractive methods, and even AI-driven controls.

In this section, I want to dig into these cutting-edge innovations. Some of them might still feel futuristic, but they’re already being applied in top-tier industries like aerospace, medical, and automotive. I’ve had the privilege of seeing certain tools in action—especially advanced CNC setups—and I believe they’re reshaping the landscape of machining. I’ll explore how these methods work, why they matter, and how they can improve the parts we make.

I’ll also share experiences from colleagues who’ve implemented these high-level strategies. Whether you’re a small shop trying to stay competitive or a large enterprise aiming for the frontier of machining capabilities, these technologies could be your next step. Let’s see what they bring to the table.

1. Five-Axis Machining and Beyond

Most machining operations use three primary axes (X, Y, and Z). In many cases, that’s enough. But imagine you need to machine a complex turbine blade with undercuts and compound curves. Doing that in a three-axis setup might require multiple re-clamps and tricky tool paths. Five-axis machining allows the cutting tool (or the part) to tilt and rotate, granting more direct access to hard-to-reach surfaces.

1.1 How Five-Axis Machining Works

A five-axis machine adds two rotational axes to the usual three linear axes. These can be on the spindle head, on the table, or split between them. I saw one setup with a tilting rotary table that let the operator orient the part so the endmill could approach from any angle.

- Rotary (A, B, or C Axis): Rotates the part or the cutting head to achieve non-orthogonal angles.

- Fewer Setups: Because the machine can reach multiple faces in one go, parts that would need four or five re-fixtures on a 3-axis mill might be done in a single setup on a five-axis mill.

- Complex Geometry: Curved surfaces, intricate profiles, and pockets can be machined without manually flipping or repositioning the workpiece.

From what I’ve observed, five-axis machining is especially popular for impellers, turbine blades, and medical implants. The smooth transitions and geometry make sense only when the tool can pivot around corners. It also reduces the risk of collision because the operator can tilt the tool away from the workpiece.

1.2 Benefits and Challenges

- Improved Accuracy: Eliminating multiple re-clamps preserves datum references. That was always a concern for me when a part had to be flipped several times; each flip invited minor errors.

- Reduced Time: While initial programming might be more involved, total production time often drops because you skip intermediate setups.

- Programming Complexity: On the flip side, CAM software must handle advanced kinematics. Toolpath simulation is crucial to avoid collisions or unexpected tool orientations.

- Cost and Learning Curve: Five-axis machines aren’t cheap. They demand skilled programmers who understand tool tilt angles, advanced fixturing, and machine calibration.

I once visited a facility where they produced orthopedic implants on a five-axis milling center. The organic shapes of the implants required continuous tool movement along multiple axes. They slashed lead times by half compared to their older 3-axis process with manual repositioning. That’s the power of multi-axis machining.

1.3 Future Trends: Six-Axis and Seven-Axis?

Some manufacturers explore six-axis or even seven-axis machines, adding further rotary or tilting motions. While these systems exist, they’re often niche or custom. From what I hear, the main goal is to reduce fixturing steps even more, allowing for truly “one and done” part production. It’s an area to watch as automation and robotics integrate with machining.

2. High-Speed Machining (HSM)

High-speed machining (HSM) isn’t just about cranking up the RPMs. It’s a holistic approach that involves optimized toolpaths, higher spindle speeds, lighter cutting depths, and faster feed rates. The aim is to maintain a constant chip load while minimizing heat buildup. When done correctly, HSM can reduce cycle times substantially and often yields smoother finishes.

2.1 The Principles of HSM

- Light Cuts, High Feed: Instead of hogging out huge chunks of material in one go, I might use a smaller radial depth of cut but move the tool faster.

- Constant Chip Load: Adaptive toolpaths in CAM software keep the cutter engaged at a steady load, so we avoid spikes in cutting forces.

- Heat Control: By removing thinner chips more frequently, the material and the tool remain cooler, prolonging tool life.

I tried HSM strategies while milling an aluminum mold. The cycle times dropped 30%. More importantly, tool wear was surprisingly low, and the mold surface needed minimal polishing. HSM felt like a breakthrough, but it required a stable machine and advanced CAM algorithms.

2.2 Machine Requirements

Not every CNC machine can handle HSM. You need high spindle speeds (some go 15,000 to 40,000 RPM or more), robust spindle bearings, and rapid servo motors. The machine must also accelerate and decelerate quickly to follow intricate toolpaths. If the axes can’t keep up, you risk chatter and poor surface quality.

2.3 Advantages of HSM

- Reduced Cycle Time: Combining faster feeds with lighter cuts can outpace traditional roughing methods.

- Better Finishes: Thinner chips often translate to cleaner surfaces.

- Less Tool Wear: Tools run cooler, especially in materials like aluminum or certain aerospace alloys.

Still, HSM requires careful planning. If you misjudge the parameters, the tool may break or you might rub the material instead of cutting it cleanly. I always use simulations to verify the tool load distribution before running an HSM toolpath.

3. Hybrid Machining: Additive + Subtractive

One of the coolest trends I’ve seen is the rise of hybrid machines that merge 3D printing (additive) with traditional machining (subtractive). Imagine a single setup where the machine can deposit material, then switch to milling or turning to refine the part. This combination unlocks design possibilities I never considered feasible.

3.1 How Hybrid Machines Work

- Additive Stage: Often uses laser deposition or wire-feed systems. The machine head builds material in layers, similar to metal 3D printing.

- Subtractive Stage: After a layer or section is deposited, the machine switches to a milling or turning head to remove excess material and achieve precise dimensions.

I spoke with a colleague who uses a hybrid system to repair high-value components, like turbine blades. They deposit material where the blade has worn down, then machine it back to the original geometry. This process saves time and money compared to forging or casting a new part from scratch.

3.2 Benefits of Hybrid Machining

- Complex Geometries: Build near-net shapes with additive, then machine critical surfaces.

- Material Efficiency: Only deposit material where needed.

- Part Repair: Restore surfaces on expensive parts without discarding the entire piece.

- Reduced Lead Times: Less waiting for castings or raw stock, especially for rare alloys.

3.3 Considerations and Challenges

- Process Control: Ensuring consistent layer deposition is tricky. Any porosity or inconsistent bonding could affect the final product.

- Machine Cost: Hybrid machines can be more expensive than separate 3D printers or CNC units.

- CAD/CAM Complexity: You need software that can handle both additive toolpaths and subtractive finishing in one environment.

Still, if a business frequently deals with custom parts, repairs, or exotic materials, hybrid machining is worth examining. It merges the best of both worlds: the flexibility of 3D printing and the precision of CNC.

4. AI and Machine Learning in Machining

Artificial Intelligence (AI) isn’t only for image recognition or chatbots—it’s making headway in machining as well. While I haven’t personally run an AI-driven CNC, I’ve seen prototypes that use machine learning to optimize cutting parameters on the fly. The idea is that the system analyzes sensor data (vibration, current draw, acoustic signals) and adjusts feeds and speeds in real time to minimize chatter or tool wear.

4.1 Potential AI Applications

- Predictive Maintenance: By monitoring spindle loads and vibrations, AI can detect early signs of tool wear or machine misalignment. It might schedule maintenance before a breakdown occurs.

- Adaptive Control: The system could automatically tweak feed rates if it senses excessive cutting force, preventing tool breakage.

- Optimized Toolpaths: Over repeated runs, AI could learn which toolpaths yield the best surface finish and shortest cycle times, then refine future programs.

4.2 Barriers to Adoption

- Data Quality: AI needs high-quality, real-time data from sensors. Installing and calibrating sensors is no small task.

- Complex Models: Machining dynamics are influenced by countless variables (material, temperature, tool geometry, etc.). Training an effective model requires extensive domain knowledge.

- Operator Trust: Many machinists (myself included) are used to controlling parameters themselves. Handing that control to an algorithm can feel unsettling.

Despite these hurdles, I believe AI has significant potential. Over time, as data collection and machine connectivity improve, more shops will experiment with AI-driven machining. It might start with monitoring and predictive analytics, then evolve into real-time control.

5. Robotics and Automation Integration

CNC machines are already automated, but we can push automation further by adding robots for part handling, assembly, or secondary operations. I remember seeing a cell where a robotic arm loaded raw stock into a CNC lathe, removed finished parts, then performed deburring—all without human intervention.

5.1 Lights-Out Machining

“Lights-out” refers to the idea of running an automated machining process after everyone goes home. The machine (and possibly a robot) handles loading and unloading. This concept can be extended with a pallet pool system. When done correctly, it raises productivity, especially for larger production runs.

5.2 Quality Control Integration

Some robotic cells include inspection stages, where a robot moves the finished part under a scanning system or a coordinate measuring machine (CMM). If the part passes, it’s packaged. If not, the system flags it for review. That kind of integrated solution ensures continuous quality checks without manual oversight.

5.3 ROI and Feasibility

- High Initial Cost: Robots, vision systems, and sensors add up quickly.

- Programming Complexity: Coordinating multiple machines and a robot requires sophisticated software.

- Throughput Gains: If your volume is high or you need 24/7 production, the payoff can be huge.

One manufacturer I visited claimed they recouped their robot investment in under two years. They specialized in medium-batch automotive components. By letting the cell run overnight, they doubled output and rarely found any rejects. It showed me how advanced automation can transform machining operations.

6. Micromachining and Nanotechnology

Micromachining is a niche but growing field, especially in electronics, medical devices, and micro-mechanical components. Tools are tiny (sometimes under 1 mm in diameter), and the tolerances are in the micron range. This demands ultra-high-speed spindles, specialized tool paths, and stable environmental conditions.

6.1 Techniques for Micromachining

- High RPM Spindles: Up to 60,000 RPM or more for extremely small endmills.

- Coolant Delivery: Minimizes tool deflection and dissipates heat. Sometimes minimal lubrication or air-blast is enough.

- Vibration Control: Even small vibrations or thermal changes can ruin a micro-part. Machines must have high rigidity and temperature control.

6.2 Materials

Micromachining is used on metals (steel, titanium, aluminum), but also on ceramics and brittle materials like glass or silicon. I recall seeing a demonstration of micro-EDM (Electrical Discharge Machining) for watch components. The parts were unbelievably small, yet perfectly formed.

6.3 Nanotechnology Connections

At the extreme end, nanotechnology intersects with machining in processes like focused ion beam (FIB) milling or atomic force microscope (AFM) cutting. These are less about conventional CNC and more about material manipulation at the atomic level. While that’s beyond traditional shop floors, it signals a future where precise material removal extends down to the nanoscale.

7. Sustainable Machining: Reducing Waste and Energy

Environmental considerations are gaining traction in manufacturing. Machining consumes energy, cutting fluids, and raw materials. I’ve seen shops adopt strategies to reduce their footprint, both for ethical reasons and to save money. Some ways to make machining more sustainable include:

- Dry Machining: Eliminates coolant usage. This requires coated tools and careful speed/feed adjustments.

- Minimum Quantity Lubrication (MQL): Uses a fine mist of lubricant instead of flooding coolant, cutting fluid consumption significantly.

- Tool Life Optimization: By fine-tuning parameters, we replace fewer tools and generate less waste.

- Energy-Efficient Machines: New CNC equipment often includes regenerative drives and efficient motors.

- Recycling and Reusing Scrap: Collecting and recycling chips or offcuts. For metals like aluminum, recycling can be quite profitable.

I once participated in a project to convert a flood-cooled milling cell to MQL. We reduced coolant consumption by more than 90%, lowered disposal costs, and found that surface finish stayed acceptable with the right tool coatings. This approach illustrates how small changes in machining processes can bring noticeable benefits to both the budget and the planet.

8. Table: Cutting-Edge Machining Technologies at a Glance

To give a concise overview, here’s a comparison table:

| Technology | Primary Benefit | Key Challenges | Typical Applications | Example Industries | Cost Level | Learning Curve |

|---|---|---|---|---|---|---|

| Five-Axis Machining | Complex geometry in one setup | High machine cost, advanced CAM | Turbine blades, medical implants | Aerospace, Medical | Very High | High |

| High-Speed Machining | Faster cycle times, better finish | Requires stable, high-speed spindle | Mold-making, aerospace structures | Automotive, Mold & Die | High | Medium |

| Hybrid Machining | Combine additive & subtractive | Process control, expensive machines | Part repair, custom geometry | Power generation, Defense | Very High | Very High |

| AI-Driven Machining | Adaptive control & predictive maintenance | Data integration, operator acceptance | Precision parts, automated lines | High-tech, Electronics | Medium to High | High |

| Robotic Automation | Lights-out production, part handling | Integration complexity, large investment | Repetitive tasks, large volumes | Automotive, Mass Production | High | Medium to High |

| Micromachining | Ultra-small parts, fine detail | Expensive tooling, vibration sensitivity | Medical devices, micro-components | Watchmaking, Electronics | High | High |

| Sustainable Approaches | Reduced waste, lower fluid usage | May need new tools or processes | General machining with green goals | Various (Eco-conscious) | Medium | Medium |

This snapshot shows the diversity of cutting-edge machining solutions. Each offers a unique advantage but demands specific resources and expertise.

9. My Encounters with Advanced Machining

I’ve had personal exposure to five-axis machining and limited interactions with AI-driven controls. When I first encountered a five-axis mill, I was amazed by how it rotated a complex aerospace bracket to reach all sides in a single cycle. Programming it took longer than programming a 3-axis job, but the overall production time was significantly shorter.

A colleague experimented with an AI plugin that monitored tool vibration. The system suggested incremental feed-rate changes. Over a month, they documented less tool breakage and improved surface finish. They did mention it felt odd to let an algorithm make real-time decisions, but the data justified the approach.

I also recall a visit to a lab that used hybrid additive-subtractive machinery. They were manufacturing specialized heat exchangers with internal channels that couldn’t be conventionally machined. They’d 3D print each layer and then machine the surface to ensure perfect mating geometries. The results were astonishing, though the cycle times and machine costs were huge.

10. Implementation Roadmap: Taking the Leap

If you’re considering adopting any of these advanced machining technologies, you might follow a roadmap:

- Assessment: Identify which technology aligns best with your product and market needs. Is there a clear ROI for five-axis or HSM?

- Pilot Project: Start small. Run a test job to gauge feasibility, cycle times, and programming complexity.

- Training: Invest in operator and programmer training. Many failures stem from insufficient understanding of advanced features.

- Infrastructure: Check if you need power upgrades, compressed air improvements, or specialized cooling solutions.

- Integration: If going for hybrid or robotic cells, plan carefully for software handshakes and layout changes.

- Iterate and Scale: Document lessons learned, refine processes, and expand the use of advanced machining once you prove success.

11. Balancing Technology with Practicality

It’s tempting to chase every new innovation. But I learned to balance the “wow” factor with practical business needs. If you only produce basic aluminum brackets, maybe a cutting-edge hybrid system is overkill. However, if you’re in a high-competition market that values short lead times and complex designs, advanced techniques could be your ticket to differentiation.

I once worked at a mid-sized job shop. We debated whether to invest in a 5-axis machine or more 3-axis CNC mills. We ultimately chose the 5-axis, focusing on customers who needed complex parts. It was a risk, but we landed contracts that wouldn’t have been possible with conventional equipment. That move propelled the shop into a higher revenue bracket.

12. Conclusion of This Section

Cutting-edge machining technologies represent the forefront of manufacturing innovation. By embracing multi-axis systems, HSM, hybrid methods, AI-driven controls, and more, shops can tackle projects that used to be off-limits. In my view, the overarching theme is flexibility—modern machines are about doing more in fewer setups, with tighter tolerances, and often at reduced cost or time.

That said, each technology demands proper training, financial commitment, and a readiness to adapt. I’ve seen companies flourish after adopting these tools, but only when they integrated them thoughtfully. Sometimes it’s about taking measured steps rather than jumping in blindly. As these methods mature, I expect broader adoption and even newer concepts to emerge.

We’ve now covered the cutting-edge side of machining—from multi-axis to AI. Next, we’ll explore how to handle various materials in machining operations. Each material brings its own quirks, and I’ve learned that adjusting parameters to match the material is key to success. Let’s move to Part V and dive into those strategies.

V. Material-Specific Machining Strategies

I’ve worked with many types of materials during my machining journey. Each one taught me something new. The truth is, no single set of machining parameters fits every metal or plastic. I’ve seen shops try to apply the same speeds, feeds, and tool geometries to everything. That rarely ends well. Success in machining often comes from fine-tuning your approach based on the unique properties of each material.

In this part, I’ll explore how different materials respond to machining. I’ll focus on metals (like steel, aluminum, titanium) and plastics (like Acetal, Nylon), as well as briefly touch on composites. I’ve found that understanding the material’s hardness, thermal conductivity, and chemical composition can make the difference between a smooth operation and a costly scrap bin. Let’s dive into the details.

1. Machining Metals

Most of my early experience was with metals. They vary widely in their machinability depending on carbon content, alloying elements, and heat treatment. Some are a breeze to cut. Others are stubborn, quickly dulling your tools and generating intense heat.

1.1 Steel and Its Varieties

Steel remains a workhorse in countless industries. I’ve machined low-carbon steel, alloy steel, stainless steel, and tool steel. They share iron as a base but differ in hardness and machinability.

1.Low-Carbon Steel (e.g., 1018)

- Generally easy to machine.

- Tends to produce continuous chips, so chip control can be tricky.

- Coolant is almost always beneficial.

- Great for shafts, brackets, and basic mechanical components.

2.Alloy Steel (e.g., 4140, 4340)

- Added alloying elements improve strength or toughness.

- Often used in heavier-duty parts such as gears or crankshafts.

- Requires robust tooling.

- Feeds and speeds are lower than in mild steel.

3.Stainless Steel (e.g., 304, 316)

- Contains chromium and nickel, which makes it resistant to corrosion.

- Work hardening is a concern. If the tool rubs instead of cutting, the material’s surface hardens, dulling the tool faster.

- I use sharp, positive-rake carbide inserts and consistent feeds to avoid dwelling in one spot.

4.Tool Steel (e.g., D2, O1)

- High hardness, used for cutting tools or dies.

- Can be challenging to cut, especially after heat treatment.

- Grinding is often used to achieve final dimensions.

I’ve witnessed how critical it is to select the right cutting parameters for steel. If the speed is too high, the tool overheats. If it’s too low, you get built-up edge (a lump of material that welds to the cutting edge), which destroys surface finish. Balancing feed rate and depth of cut also helps control heat and chip formation.

1.2 Aluminum Alloys

Aluminum stands out for its lightweight nature and excellent machinability. I’ve machined everything from pure aluminum (soft and gummy) to aerospace-grade alloys like 6061-T6 or 7075-T6.

- High Speeds

I can run aluminum at much higher spindle speeds compared to steel, sometimes over 10,000 RPM. - Chip Welding

If parameters are off, aluminum may fuse onto the cutting edge, causing a built-up edge. Using specialized endmills with polished flutes can prevent this. - Thermal Conductivity

Aluminum dissipates heat quickly. Flood coolant may not be mandatory, but I often use some form of lubrication to improve surface finishes. - Applications

Everything from automotive parts to aircraft structures relies on aluminum for its lightness and decent strength.

In my experience, a sharp, two- or three-flute endmill with the right coating (like TiB2) can slice through aluminum effortlessly, leaving a mirror-like finish.

1.3 Titanium Alloys

I’ve heard many machinists groan at the mention of titanium. It’s strong, corrosion-resistant, and lightweight, but it’s also prone to generating a lot of heat during machining.

- Low Thermal Conductivity

Heat doesn’t dissipate well, so it stays near the cutting zone, shortening tool life. - High Strength-to-Weight Ratio

Great for aerospace or biomedical applications, but difficult to cut. - Tool Selection

Carbide tools with heat-resistant coatings are typical. - Feeds and Speeds

Generally slower than aluminum or steel. Too fast, and the tool overheats. Too slow, and you risk work hardening.

A friend of mine machines titanium surgical implants. He relies on strategic coolant delivery—often high-pressure nozzles—to flush chips away and keep the cutting edge cool. He also invests in premium tooling because cheap inserts won’t last.

1.4 Other Specialty Metals (e.g., Inconel, Hastelloy)

Superalloys like Inconel or Hastelloy push the limits even further. They’re used in turbine engines and other high-temperature environments. They tend to strain-harden quickly and can wreck poor-quality tools almost instantly. Many shops resort to advanced CNC setups with stable fixturing, optimized tool paths, and robust cooling to tackle these metals. Patience is key. Each pass must be carefully calculated to avoid catastrophes.

2. Machining Plastics

Plastics behave differently than metals. They’re typically softer and less dense, but their melting temperatures can be relatively low. I’ve seen operators who treat them like metals, only to end up with melted edges or chatter marks.

2.1 Acetal (POM)

I enjoy working with Acetal because it machines cleanly, especially on CNC mills or lathes. Acetal has low friction, high dimensional stability, and low moisture absorption. As a result, it’s commonly used for gears, bushings, and precision parts.

- Low Melting Point

This means I must avoid excessive heat. Sharp tools help. - Minimal Tool Wear

Acetal is relatively soft, so tools last a while. - Surface Finish

Acetal often yields a nice, smooth finish without heavy post-processing. - Chip Evacuation

It produces manageable chips, which can be cleared with air blasts or light coolant.

I’ve produced small gear prototypes from Acetal. The outcome was excellent. The material’s dimensional stability helped maintain tight tolerances, and we didn’t have to worry about corrosion.

2.2 Nylon

Nylon (polyamide) offers strength and wear resistance, but it absorbs moisture from the air, which can lead to dimensional changes if not dried properly.

- Machinability

Slightly more challenging than Acetal due to potential stringiness if the tool is dull. - Heat Sensitivity

High speeds can cause local melting. I reduce spindle speed or lighten the depth of cut. - Applications

Bushings, insulators, and structural components in machinery.

A colleague once tried running nylon with the same feed and speed as aluminum. The result? The part melted in spots, leaving rough edges. After tweaking the parameters and using a sharper tool, things improved substantially.

2.3 Polycarbonate, ABS, and Other Plastics

- Polycarbonate

Tough, transparent, but can crack if it overheats. Cooling is essential. - ABS

Common in consumer products. It’s moderately easy to machine but can exhibit chatter if not well-supported. - Acrylic (PMMA)

Known for its optical clarity. Polishing edges might be necessary if cutting decorative parts. - PEEK

High-performance engineering plastic with good temperature resistance. Harder to machine and quite expensive, but often used in medical or aerospace.

Plastics usually don’t need intense lubrication, but they might need forced air to remove chips. Sometimes a light mist helps prevent heat buildup. The biggest danger with plastics is often overfeeding, which causes the tool to drag or melt the material, leaving poor finishes.

3. Composites: Carbon Fiber and Beyond

Composite materials like carbon fiber reinforced polymers (CFRP) or glass fiber reinforced polymers (GFRP) bring their own hurdles. I recall a project where we had to machine CFRP panels for an aircraft interior. The fibrous nature made it abrasive, quickly wearing out standard tools.

- Abrasive Fibers

Tools can dull fast, especially if they lack a diamond coating. - Delamination Risk

Improper feeds or dull tools can pull layers apart, damaging the material. - Dust and Safety

The dust from cutting composites can be harmful if inhaled. Good vacuum systems or enclosures are crucial. - Heat

Excessive heat can degrade the resin matrix. I keep a close eye on cutting speed and rely on minimal lubrication.

Carbon fiber is incredibly strong for its weight, but it’s unforgiving in machining. Diamond-coated endmills can help. So can specialized brad-point or “dagger drill” bits for hole-making. The key is controlling tool engagement so you don’t tear the fibers.

4. General Guidelines for Matching Material and Machining Approach

Over the years, I learned a few universal tips for any material:

- Material Hardness

A harder material means slower cutting speeds and more rigid setups. - Thermal Conductivity

Materials like aluminum dissipate heat well. Materials like titanium do not. Adjust coolant strategy accordingly. - Ductility and Brittleness

Ductile metals can form long, stringy chips. Brittle materials (like some ceramics or cast iron) produce short chips or dust. - Surface Finish Goals

If you need a mirror finish on steel, consider grinding or polishing. If you can tolerate a rougher finish, a single pass with a heavier feed might suffice. - Lubrication Requirements

Flood coolant for tough metals, minimal lubrication or air blast for many plastics. - Chip Evacuation

If chips build up, they can damage the cutting edge or re-cut, harming surface integrity.

5. Table: Common Material Machining Recommendations

Below is an extended table summarizing recommended parameters or strategies for various materials. It’s a guideline, not an absolute rule—every shop and machine differs.

| Material | Example Grades | Typical Hardness (HRC) | Preferred Tooling | Coolant Strategy | Common Feed (mm/rev) | Speed Range (m/min) | Key Considerations |

|---|---|---|---|---|---|---|---|

| Mild Steel | 1018, A36 | 15–25 | HSS or Carbide | Flood coolant recommended | 0.1–0.3 | 80–150 | Avoid built-up edge, moderate speeds |

| Stainless | 304, 316 | 20–40 | Carbide, sharp geometry | High-pressure coolant | 0.08–0.25 | 60–120 | Watch for work hardening, consistent feed |

| Aluminum | 6061, 7075 | <15 | High-helix Carbide | Mist or air blast | 0.1–0.4 | 200–600 | Prevent chip welding, high speeds possible |

| Titanium | Ti6Al4V | 30–45 | Carbide with coatings | Flood or high-pressure | 0.05–0.15 | 30–60 | Manage heat, reduce chatter |

| Acetal (POM) | Delrin, etc. | N/A | Sharp HSS/Carbide | Air blast or light mist | 0.1–0.3 | 200–800 (surface speed) | Avoid melting, excellent dimensional stability |

| Nylon | PA6, PA66 | N/A | Sharp HSS/Carbide | Minimal coolant or dry | 0.1–0.25 | 150–500 (surface speed) | Absorbs moisture, can melt if speed too high |

| CFRP | Carbon Fiber Sheet | N/A | Diamond-coated tools | Vacuum or minimal coolant | 0.02–0.1 | 50–200 (surface speed) | Abrasive, risk of delamination |

| Brass | C360, C385 | 10–20 | HSS or Carbide | Optional coolant | 0.1–0.25 | 80–200 | Chips can be sharp, easy to achieve good finish |

I often reference these sorts of data when planning a new job. Each row is a starting point, not a final prescription. I always run test cuts, measure, and tweak. Machining is partly about experimentation and refinement.

6. Material-Driven Tool Choice

One of the biggest lessons I’ve learned is that no single tool works for everything. Carbide is versatile but can still vary in grade or coating. High-speed steel (HSS) is cheaper and easier to sharpen but dulls faster in abrasive materials. Ceramics or CBN (cubic boron nitride) excel in certain high-temperature alloys or cast iron.

For plastics, I might use uncoated carbide with a high rake angle. For steel, I might choose TiN or TiAlN coatings that reduce friction and resist heat. For composites, diamond-coated tools are often essential. Matching the tool to the material can yield dramatic improvements in surface finish, tool life, and throughput.

7. Dealing with Heat and Distortion

Heat is a constant enemy in machining. If the material expands during cutting, then shrinks when it cools, you’ll see dimensional inaccuracies.

- Long, Thin Parts

I’ve seen shafts warp due to internal stress. Roughing in multiple passes, flipping the part, or stress-relieving it between operations can help. - Plastics

They may soften or melt quickly, especially near the cutting zone. Reduced spindle speeds and sharp tools are crucial. - High-Temp Alloys

They don’t dissipate heat well, so you need more aggressive coolant systems and slower speeds.

8. Specialty Coatings and Treatments

Some shops coat or treat materials to improve machinability. For instance, certain steels are available in a “free-machining” grade with added sulfur to improve chip breakup. Aluminum can be anodized to create a hard outer layer, though that’s typically post-machining.

I’ve also seen cryogenic treatments for tools, which can stabilize the metal’s microstructure. Others experiment with special cutting fluids that better suit a particular alloy or plastic. The field is continually evolving, and staying updated on new treatments can give you an edge.

9. Multi-Material Assemblies

Sometimes a single part includes inserts or multiple materials. I’ve encountered parts where a steel bushing is pressed into an aluminum component. You have to manage two sets of machining conditions or carefully plan operations so you don’t risk damaging the other material.

An example: In an automotive project, we had an aluminum housing with stainless steel threaded inserts. We machined the aluminum first, then heated the inserts to create a thermal interference fit. Post-assembly, we performed a final milling pass on some surfaces to ensure perfect alignment between materials.

10. Example Workflow: Machining a Hybrid Metal-Plastic Assembly

Let’s imagine a fixture base that’s mostly aluminum but has Acetal inserts for low friction:

- Rough the Aluminum Block: High-speed milling removes bulk material.

- Drill and Ream Holes: For the Acetal inserts.

- Press-Fit Acetal Slugs: Pre-machined to be slightly oversized.

- Final Contouring: Re-mount the assembly. Then lightly machine the entire top surface, so the Acetal inserts sit flush.

- Inspection: Check both the aluminum body and plastic areas for dimensional accuracy.

This approach integrates the properties of both materials. Aluminum offers structure, while Acetal provides a low-friction interface. But you have to carefully handle each material’s machining nuances. If you machine the Acetal too aggressively, you could melt or deform it. If you ignore the aluminum’s thermal expansion, you might throw off tolerances.

11. Troubleshooting Common Material Issues

I’ve run into all kinds of problems caused by not aligning machining parameters with the material at hand:

- Built-Up Edge on Steel

Adjust speed or add coolant. Sometimes a different coating solves it. - Chatter in Aluminum

Increase feed rate, lower depth of cut, or secure the workpiece better. - Melted Plastics

Decrease spindle speed, sharpen the tool, use air blasts. - Tool Breakage in Titanium

Slow down the feed, confirm tool rigidity, apply high-pressure coolant. - Delamination in Composites

Use specialized tools, reduce feed at entry/exit points, ensure vacuum extraction.

Every time I hit a snag, I do a systematic check: Are my speeds/feeds correct for this material? Is my tool geometry suitable? How about coolant or chip evacuation? Material-specific knowledge usually leads me to the answer.

12. Final Thoughts on Material Machining Strategies

Matching the machining approach to the material can make or break your project. I’ve seen shops that ignore these details end up with wasted tools, scrap parts, and lost time. On the other hand, those that master material-specific strategies can take on complex jobs with confidence.

I like to keep a reference sheet—similar to the tables above—for each material we commonly machine. I note recommended speeds, feeds, and any special considerations. This living document evolves with every new experience.

At this point, we’ve looked at how metals, plastics, and composites each demand tailored machining tactics. Getting these details right sets the foundation for efficient, high-quality production. In the next section, we’ll explore cost, feasibility, and how to evaluate machining projects from a business standpoint. After all, even the best technical approach must make sense financially. Let’s move on.

VI. Cost, Feasibility, and Efficiency in Machining

I’ve often found that great machining results lose their luster if the process isn’t cost-effective. The most elegant toolpath, the perfect surface finish—they mean little if they blow a project’s budget or timeline. That’s why I’ve come to believe that balancing technique with financial and logistical constraints is at the heart of successful machining. In this section, I’ll focus on how I evaluate cost, feasibility, and overall efficiency in machining projects. I’ll also share some experiences that taught me the value of strategic decision-making.

1. Breaking Down Machining Costs

When someone asks me how to estimate the cost of a machining job, I picture a pie chart with three big slices: materials, labor, and overhead (including machine amortization). But each slice has layers. Understanding these layers helps me quote jobs accurately and manage my shop’s profitability.

- Material Costs

- Raw Material: Whether it’s aluminum, steel, or plastics, the per-pound or per-unit price matters. Metals like titanium or superalloys can be quite expensive.

- Material Utilization: How much material is removed? If you’re hogging out a big chunk of metal just to get a small part, you’re paying for a lot of scrap. Sometimes, near-net-shape processes like forging or casting reduce scrap.

- Storage and Handling: Large or special-order materials need space and safe handling. Oversized stock can require extra cutting or specialized equipment.

2.Labor Costs

- Programming Time: CAM programming can be substantial, especially for complex parts. Senior programmers often command higher wages, but they can create optimized toolpaths that save cycle time.

- Setup and Fixturing: Each setup consumes operator hours. Multi-axis machines or pallet systems can reduce re-fixturing, thus cutting labor costs.

- Machine Operation: If the part runs on a CNC with minimal intervention, labor might be low. But manual or semi-automatic processes could demand constant attention.

3.Overhead and Machine Costs

- Machine Depreciation: High-end CNC equipment is expensive. I factor in depreciation so I know how each job contributes to paying off the machine.

- Maintenance: Tools wear out, spindles need calibration, and coolant systems require cleaning. Those expenses add up.

- Utilities: Power consumption can be large, especially for heavy-duty machining or when running multiple machines.

4.Tooling and Consumables

- Cutting Tools: Inserts, endmills, drills, and reamers all cost money. Exotic coatings or diamond-coated bits for composites can be pricey.

- Coolant or Lubricants: Flood coolant, mist coolant, or specialized fluids require periodic replacement and disposal.

- Workholding: Certain parts need custom fixtures or jigs. That initial investment can be amortized if the part is a repeat job, but for one-offs, it’s a direct cost.

- Inspection Equipment: CMMs, gauges, and measuring tools must be purchased and maintained.

- Inspection Labor: Checking tolerances can be time-consuming, especially for complex or high-precision parts.

- Scrap or Rework: Mistakes cost time and materials. Factoring in a small rejection rate can be prudent.

I once underestimated the total cost of a complex stainless-steel part. I overlooked how much material we’d waste, and I didn’t account for extended programming hours due to intricate pockets. That mistake taught me the importance of thorough cost breakdowns. By dissecting each element—materials, labor, overhead, tooling—I now produce more accurate quotes and manage expectations better.

2. Determining Feasibility

Even if a job is profitable, it might not be feasible given my equipment, skills, or time constraints. Feasibility goes beyond cost; it’s about whether I can physically machine a part to meet the specs. These are the questions I ask:

- Do I Have the Right Machines?

If a part demands five-axis milling, but I only have 3-axis mills, I can’t accept the job unless I outsource or invest in new equipment. That might push me to partner with another shop or decline the work. - Are the Tolerances Achievable?

Some clients want extremely tight tolerances—microns or better. If my best CNC can only reliably hold ±0.01 mm, I won’t promise ±0.005 mm. Reject rates would skyrocket. Occasionally, I can use grinding or lapping to tighten final accuracy, but that adds cost and complexity. - Material Constraints

If the client requests a superalloy I’ve never machined, I must factor in a learning curve. I also check if my tooling inventory and machine power can handle it.

For instance, a tough nickel-based alloy might require advanced fixturing and high-torque spindles. - Timing

Sometimes a rush order is impossible if I’m already at capacity. Or a project might require special tooling with a long lead time. I weigh whether I can meet the deadline without overloading the shop. - Regulatory or Certification Needs

Certain aerospace or medical parts require certifications (ISO, AS9100, FDA compliance, etc.). If I lack those certifications, I can’t legally produce such components. - In-House Expertise

If the job demands advanced CAM programming or specialized inspection methods that my team doesn’t know, I consider training or hiring a consultant. But that might be too costly or time-consuming for a one-off project.

A few years ago, I considered a contract for titanium aerospace brackets with tight tolerances. The job was lucrative, but I realized my machines weren’t powerful enough for the cutting forces required, and my team lacked the titanium experience. I could have tried to force it, but I likely would have lost money and tarnished my reputation with late deliveries. I turned the job down, focusing on what I did best at the time. That decision saved me from a potential fiasco and let me plan future upgrades more strategically.

3. Efficiency in Machining: Beyond Speeds and Feeds

When I think about “efficiency,” it goes beyond how quickly I can remove material. Efficiency is about process flow, setup reduction, and even how the shop floor is laid out. I’ve spent hours fine-tuning speeds and feeds, only to realize we were losing more time in manual tool changes or part transfers.

3.1 Setup Reduction

- Single-Minute Exchange of Dies (SMED): This concept, from lean manufacturing, aims to cut changeover times. I try to complete as many setup steps as possible offline so the machine isn’t idle.

- Modular Fixturing: Reusable fixture components can be reconfigured quickly, reducing the need to build custom jigs for each part.

- Pallet Systems: Some CNC machines use pallet changers, so while one part is being machined, another pallet is being loaded or unloaded in the background.

3.2 Tool Management

- Tool Libraries: I maintain a database of tool assemblies. That way, I don’t have to measure each tool from scratch for every job.

- Preset Tooling: Using offline tool presetters, I can measure tool lengths and diameters before they go into the machine.

- Tool Wear Monitoring: Automated systems can track how long each tool has been in use. When it reaches a preset limit, the machine can prompt an operator to change it.

3.3 Automation and Robotics

- Lights-Out Machining: With robust setups, I can run machines unattended during off-hours. This boosts output without adding labor cost.

- Robotic Part Handling: For high-volume parts, a robot can load blanks and unload finished pieces. That keeps the spindle turning.

3.4 Workflow Optimization

Sometimes I see shops with an inefficient layout—raw materials on one side of the building, finishing equipment on the other, forcing staff to cart parts across the floor multiple times. Arranging the workflow in logical steps reduces wasted movement and time. Some adopt lean principles like “cellular manufacturing,” grouping machines needed for similar part families. That shortens travel distance and allows one operator to manage multiple machines in proximity.

I once rearranged a milling cell so the CNC mills sat near the inspection station and tool crib. Operators could grab tools, measure finished parts, and quickly return to their machines. That simple change saved hours of walking each week and sped up feedback when parts deviated from specs.

4. Assessing Make-or-Buy Decisions

Now and then, I consider whether to machine a part in-house or outsource it. This decision often hinges on cost, capacity, and strategic value. If a part is outside my core expertise—like a complex Swiss-turned medical component—I might contract with a specialist who has the right machinery. This can free up my resources for jobs I’m better suited to handle.

- Cost Analysis: Compare the total in-house cost (machine time, labor, tooling) versus a supplier’s quote.

- Quality Control: Outsourcing can introduce communication gaps or shipping delays. On the other hand, a specialized vendor may deliver better quality.

- Lead Time: If the supplier is overseas, shipping can add weeks. But if my internal capacity is strained, outsourcing might still be faster.

- Strategic Focus: I ask whether this part aligns with my long-term capabilities. If I see a future in that part family, investing in new machinery might pay off eventually.

A colleague of mine used to machine all of his shop’s turned parts in-house on older lathes. After analyzing the cost, he realized a nearby CNC turning specialist could produce them cheaper and faster. By outsourcing, he freed up capacity on his mills for higher-margin work he excelled at. Overall profitability rose, and he reduced headaches related to lathe maintenance.

5. Calculating ROI on New Machines

Investing in advanced CNC equipment can catapult productivity. But it’s not always the right call. I’ve done ROI (return on investment) analyses when considering a new 5-axis mill or high-speed machine. The formula typically involves:

- Machine Price: Base cost plus accessories, shipping, installation.

- Financing Terms: Interest rates if leasing or taking out a loan.

- Production Gains: Estimate how much cycle time or setup time is cut. Multiply that by labor cost savings and increased throughput.

- New Business: If the new machine opens doors to complex parts, I factor in potential revenue from those jobs.

- Maintenance and Training: Advanced machines might demand specialized training, and if they break, repairs can be costly.

The tipping point often comes when you see a clear path to loading the machine with enough work to offset its costs. If I can fill the schedule with profitable jobs, the machine pays for itself. If it stands idle half the time, the ROI plummets. Sometimes it’s a calculated risk—buying the machine first, then pursuing markets that require its capabilities.

I recall a mold shop that struggled to justify a 5-axis. They rarely made parts with tricky angles. But after buying it, they proactively marketed complex mold designs that took advantage of 5-axis. Within a year, they’d secured new clients who valued their upgraded tooling. The ROI was solid in the end, but it took an intentional sales push.

6. Minimizing Scrap and Rework

Scrap and rework erode profits and chew up valuable machine hours. To keep them in check, I take these steps:

1.Robust Process Planning

- Clearly define each operation in the right order.

- Ensure consistent datums and references across processes.

2.Quality Checks at Critical Stages