Introduction: Why Accurate Powder Coating Cost Estimation Matters

When I first started exploring powder coating as an option for metal finishing, I underestimated how important accurate cost estimation really was. At first glance, powder coating cost seemed straightforward—a basic price per square foot, a set price per part, and that was it.

But as soon as I dug deeper into real-world jobs, I realized how quickly those simple assumptions could break down. Differences in part size, complexity, material type, batch sizes, and even color choices rapidly affected final pricing. I soon learned how critical it was to get accurate powder coating cost estimates upfront.

If you’re a manufacturer, a procurement manager, or even running a small shop, knowing exactly how much powder coating costs can save you from unexpected surprises and help you manage budgets better.

In this guide, I’ll share insights from my own experience dealing with powder coating projects, costs, and real-world estimates. You’ll learn how to quickly calculate powder coating costs based on your project’s size, shape, and volume—no guesswork required.

Powder Coating Cost Ranges by Size and Part Type

Understanding typical powder coating cost ranges by part size and type is the first step to better estimation. After working with several suppliers, here’s a realistic breakdown I’ve compiled from industry standards and actual quotes received recently:

Average Powder Coating Cost by Part Size (Typical Ranges):

| Part Size/Type | Typical Example | Cost Per Unit (USD) |

|---|---|---|

| Small Parts | Brackets, hinges (4×4 inches) | $2 – $5 |

| Medium Parts | Bike frames, chairs (24×36 in) | $40 – $75 |

| Large Components | Gates, railings (72×40 inches+) | $100 – $250+ |

| Automotive Parts | Wheels, bumpers | $50 – $150 |

| Industrial Enclosures | Machinery covers | $150 – $350 |

| Complex Geometries | Engine parts, intricate designs | $200 – $500+ |

Powder Coating Cost per Square Foot:

For surface area-based jobs, typical pricing is:

| Complexity | Cost per Sq Ft (USD) |

|---|---|

| Simple (Flat Surfaces) | $1.50 – $2.50 |

| Moderate (Minor Bends) | $2.50 – $3.50 |

| Complex (Corners, Holes) | $3.50 – $5.00+ |

In my experience, smaller jobs and intricate shapes always land at the higher end of these ranges due to setup and labor.

How to Estimate Powder Coating Cost Based on:

A. Estimating Based on Part Size (Surface Area)

Calculating the powder coating cost by surface area is straightforward. Here’s a simple formula I regularly use:

Estimated Cost = Surface Area (Sq Ft) × Cost per Sq Ft + Setup Fee

Example from my recent project:

- Metal panel (24″ x 48″): total surface area ≈ 16 sq ft (both sides)

- Chosen complexity: Moderate ($3.00/sq ft)

- Setup fee: $50

Calculation: 16 sq ft × $3.00/sq ft + $50 = $98 total

B. Shape Complexity and How It Affects Cost

Shape complexity is often underestimated. When I first had complex brackets coated, I noticed labor and setup time quickly increased.

Here’s how I categorize complexity based on my experiences:

| Complexity Level | Typical Features | Cost Impact |

|---|---|---|

| Simple | Flat plates, smooth tubes | Lowest (Baseline rate) |

| Moderate | Mild curves, basic welded parts | Moderate (+20%-50%) |

| Complex | Deep recesses, sharp angles, holes | High (+50%-100%) |

A complex-shaped part can easily double your per-unit powder coating cost compared to simpler geometries.

C. Batch Volume: Single Job vs Production Run

Batch size dramatically affects your powder coating cost per part. I learned quickly that economies of scale are significant.

Here’s a practical table I’ve used repeatedly for quick estimations:

| Batch Volume | Cost Impact per Unit |

|---|---|

| Single Item | Highest (100%) |

| Small Batch (10-20 pcs) | Medium (70%-90%) |

| Medium Batch (50-200 pcs) | Low (50%-70%) |

| Large Batch (200+ pcs) | Lowest (30%-50%) |

For example, powder coating a single bicycle frame might cost $80, but coating 50 frames could reduce the price to around $40 each.

Cost Impact of Coating Specifications

When estimating powder coating cost, specifications such as coating thickness, color selection, and curing requirements matter more than many people realize. Early on, I underestimated these factors and encountered budget overruns. Let’s clarify these cost variables to avoid similar mistakes.

A. Powder Coating Thickness and Material Usage

The thickness of your coating directly affects the powder coating cost because thicker coats require more powder. In typical commercial jobs, thickness usually ranges from 1.5 to 4 mils (0.0015″ – 0.004″).

From experience, here’s how coating thickness impacts powder usage and cost:

| Coating Thickness | Powder Usage (sq ft per pound) | Relative Cost Impact |

|---|---|---|

| 1-2 mil | 35-50 sq ft/lb | Low |

| 2-3 mil | 25-35 sq ft/lb | Moderate |

| 3-4 mil+ | 15-25 sq ft/lb | High |

If your job requires 4-mil coating rather than 2-mil, the amount of powder consumed nearly doubles—directly raising your total powder coating cost.

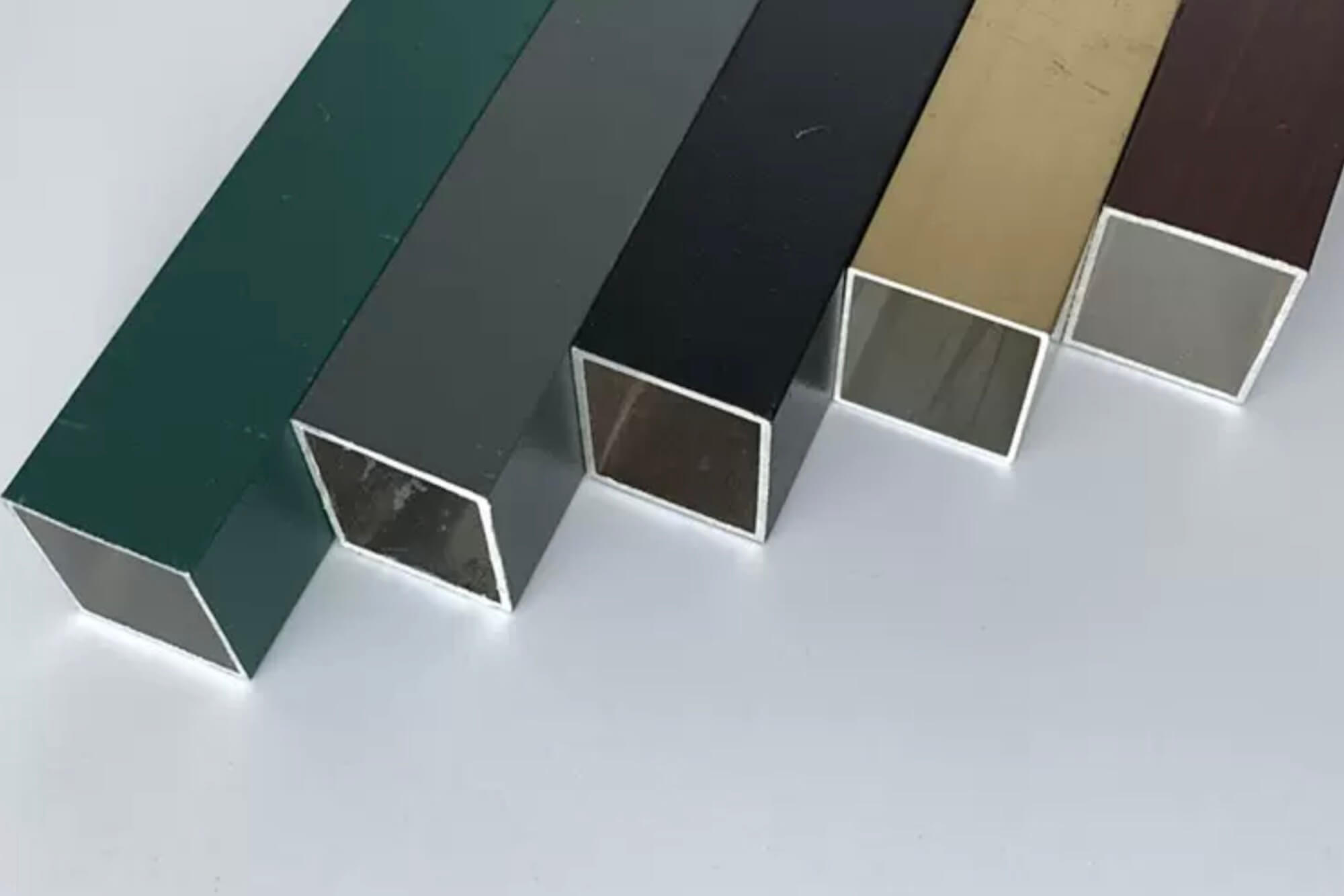

B. Color Choice and Special Finishes

Standard colors such as black, white, or gray are inexpensive and widely available. But custom colors, metallic finishes, or specialized textures can significantly increase powder coating cost.

Here’s how colors and finishes typically affect pricing:

| Color/Finish Category | Avg. Price Premium | Common Examples |

|---|---|---|

| Standard Solid Colors | Baseline pricing | Black, white, gray |

| Bright or Custom Colors | +10-20% | Reds, blues, custom blends |

| Metallic & Textured | +20-40% | Metallic silver, textures |

| Fluorescent/High-End | +50% or more | Neon colors, specialty hues |

From my own projects, I learned that special-order colors might also require minimum batch purchases, further driving up your costs.

C. Cure Time and Energy Costs

Powder coating requires curing at high temperatures (typically 350°F-400°F). Longer or higher-temperature cures consume more energy, thus adding to your overall powder coating cost.

Typical curing guidelines and their cost implications:

| Material & Powder Type | Cure Temp & Time | Relative Cost Impact |

|---|---|---|

| Standard Polyester Powder | 375°F, 10-15 min | Moderate (standard) |

| Epoxy Powders | 400°F, 15-20 min | Slightly Higher |

| High-Temp Powders (special) | 425°F+, 20 min+ | Highest |

To reduce costs, selecting standard polyester powders with short cure times usually works best, unless your application demands specialized coatings.

DIY vs. Professional Estimation: When to Use Online Calculators

Early in my career, I often tried manual calculations for powder coating cost. Over time, I discovered the value of online calculators and software tools designed for estimating powder coating projects quickly and accurately.

When DIY Calculation Makes Sense:

- Single, straightforward items (e.g., small brackets, flat sheets)

- Basic shapes and simple batch sizes

- Familiar materials and standard colors

When Professional or Online Calculators Are Essential:

- Complex shapes with multiple surfaces or deep recesses

- Large production runs or commercial projects

- Projects involving specialty coatings or custom colors

Example of Popular Online Powder Coating Cost Calculators (based on my experience):

| Tool Name | Type of Calculator | Ease of Use | Ideal for |

|---|---|---|---|

| Powder365 Calculator | Surface Area-Based | High | Small/Medium jobs |

| Reliant Calculator | Volume & Batch-Based | Moderate | Medium/Large industrial jobs |

| Coatings Comparison | Cost comparison (paint/powder) | High | Budget comparison projects |

| Custom Excel Template | Fully customizable | Low | Complex, repetitive estimates |

From personal use, Powder365 offers the simplest user experience, while Reliant suits larger industrial projects best.

Regional Pricing Benchmarks and Real Quotes

Powder coating cost varies significantly by region. After collaborating with suppliers in different locations, I’ve compiled these real-world quotes and benchmarks to help you estimate accurately.

Powder Coating Cost Comparison by Region (2024 data):

| Region | Avg. Cost per Sq Ft (USD) | Notes |

|---|---|---|

| United States | $2.50 – $5.00 | Labor & environmental standards |

| Canada | $2.75 – $5.50 | Similar to US, slightly higher |

| Europe (Germany/UK) | $3.00 – $6.50 | Stricter environmental regulations |

| Asia (China/India) | $1.50 – $3.00 | Lower labor cost |

| Latin America | $2.00 – $4.50 | Moderate labor/environmental costs |

| Australia | $3.00 – $6.00 | Higher energy costs, regulation |

Real-World Example Quotes (recent project):

- USA: 50 metal chair frames (medium size): quoted $65/unit

- China: 200 small brackets: quoted $1.20 each

- Germany: 10 industrial cabinets (large): quoted $320/unit

Clearly, sourcing region affects your powder coating cost considerably, which I learned firsthand managing global supply chains.

Smart Cost-Saving Tactics During Estimation

When I first started estimating powder coating costs, budgets frequently ran higher than expected. Over time, I’ve developed practical, proven strategies to significantly reduce powder coating costs without sacrificing quality. Here’s what I’ve learned works best:

A. Optimize Part Design for Powder Coating

From personal experience, the single most effective way to reduce your powder coating cost is thoughtful part design. If your product is still in the design phase, here’s my practical advice:

- Minimize Complex Shapes:

Simple designs mean quicker spraying and lower cost. Avoid unnecessary bends, holes, and recesses. - Reduce Sharp Edges and Corners:

Sharp edges waste powder and require more touch-ups, which increase costs. - Standardize Parts:

Reusing standardized shapes across your product line can dramatically lower batch pricing.

I’ve personally witnessed cost reductions of up to 25% simply by revising designs for easier coating.

B. Plan Efficient Batch Sizes and Scheduling

Small batches cost more per piece due to setup fees. My experience taught me to group similar parts into larger batches whenever possible. Here’s the typical batch pricing structure:

| Batch Size | Avg. Cost Saving per Unit |

|---|---|

| Single Item | Baseline (no saving) |

| Small Batch (10-20) | ~15%-25% saving |

| Medium Batch (20-50) | ~25%-40% saving |

| Large Batch (50+) | 40%-60% saving |

Whenever I’ve grouped similar items or colors, I’ve significantly reduced per-unit costs.

C. Limit Color and Finish Variety

Every color change costs time and money. Early on, I underestimated this factor. Now, I try to standardize powder coating colors for larger production runs or limit color changes within batches. Here’s a simple comparison:

| Color Changes per Batch | Avg. Additional Cost |

|---|---|

| Single Color | None |

| 2 Colors | +10%-15% |

| 3+ Colors | +25% or more |

Sticking to fewer colors or standard colors has consistently cut my costs.

D. Negotiate with Powder Coating Suppliers

One powerful yet often overlooked cost-saving tactic is negotiation. I’ve found most powder coating suppliers are willing to negotiate if you:

- Offer regular, predictable volume.

- Bundle multiple jobs or parts together.

- Provide longer lead times.

Simply asking my suppliers, “What if we committed to this volume monthly?” has saved me 10%-20% per job.

FAQ

1. How do I calculate powder coating cost per square foot?

Multiply surface area by the quoted rate per square foot, adding setup fees.

2. What’s the average powder coating cost for metal parts in 2024?

Typically $2.50-$5.00 per square foot in the US, varying by complexity and volume.

3. How much does it cost to powder coat car wheels or bike frames?

Usually $50-$100 per wheel, $40-$75 per bike frame.

4. Is powder coating cheaper than painting?

For mid-to-large batches, powder coating generally costs less due to efficiency and durability.

5. What affects powder coating cost the most?

Complex shapes, custom colors, small batch sizes, and extensive prep work increase costs significantly.

6. Why do small jobs cost more per unit?

Due to fixed setup and overhead costs spread over fewer parts.

7. How much does powder material cost per pound?

Typically $5-$12 per pound, varying with color and quality.

8. Can I powder coat at home to save money?

Yes, but initial equipment costs and learning curves usually outweigh short-term savings.

9. What’s the price difference between matte, gloss, and textured finishes?

Matte/gloss have little difference; textured or metallic finishes often cost 20%-40% more.

10. How much does it cost to start a powder coating business?

Basic professional setups start around $20,000, ranging up to $100,000+ for industrial equipment.

11. Is it cheaper to outsource or buy powder coating equipment?

Outsource for occasional jobs; invest in equipment if frequent and high-volume coating is needed.

12. What’s the minimum charge for custom powder coating jobs?

Most shops set minimum charges around $50-$100 per job.

13. Are there hidden costs in powder coating services?

Occasionally, extra charges appear for masking, specialty colors, or extra prep work—always ask upfront.

14. How do I estimate costs for complex shapes?

Use a higher per-square-foot rate (+50%-100%) to cover extra labor.

15. Can I reduce powder coating costs without sacrificing quality?

Absolutely—optimize part design, plan efficient batches, and minimize color changes.

16. Do powder coating costs vary by region?

Yes, significantly; North America and Europe typically charge higher rates than Asia or Latin America.

17. How do professional coaters price large industrial parts?

Usually based on surface area, complexity, special handling requirements, and batch volume discounts.

📚 References and Further Reading

For more technical insights, pricing standards, and expert tips on powder coating cost and systems, check out the following trusted resources:

- Powder Coating Institute (PCI)

Educational hub for coating cost analysis, finishing processes, and equipment selection.

https://www.powdercoating.org - Finishing.com – Powder Coating Q&A

An interactive archive of expert advice on powder coating applications, challenges, and pricing benchmarks.

https://www.finishing.com - Reliant Finishing Systems – Equipment Cost Guides

In-depth articles and ROI calculators for in-house powder coating investments.

https://www.reliantfinishingsystems.com - Nordson Industrial Coating Systems

Equipment specifications, powder savings data, and process optimization content.

https://www.nordson.com - Thomasnet – Powder Coating Suppliers Directory

Find regional suppliers and compare market pricing.

https://www.thomasnet.com

Other Articles You Might Enjoy

- How to Powder Coat: A Professional Machinist’s Guide to Perfect Results

Chapter 1: Why Machinists Need to Learn Powder Coating Powder coating is a robust, eco-friendly finishing method that I’ve seen more and more machinists adopt.When people look up “how to…

- Ceramic Coating and Machining: Unlocking Advanced Manufacturing Applications

Introduction I’ve been fascinated by the way ceramic coating can radically transform the performance of machined parts. Ceramic coating, as a concept, goes well beyond the automotive finishes many of…

- The Art of Burnished Bronze: Exploring Machining and Polishing Methods

Introduction Burnished bronze has been a material of fascination for many over the centuries. Whether you’re an artist crafting a masterpiece or an engineer designing industrial components, burnished bronze offers…

- The Complete Guide to Polishing Aluminum: Challenges and Solutions for Machinists

Introduction – Polishing Aluminum and Why It Matters I remember the first time I tried polishing aluminum. I wanted a clean, glossy finish but ended up with swirl marks and…

- Glass Bead Blasting Material and Its Impact on CNC Machining Performance

In the world of CNC machining, precision, quality, and surface finish are critical factors, especially for industries that demand high-performance components. Among the various surface finishing techniques used to improve…

- Surface Treatment After CNC Machining Applications of the Anodized Aluminum Colors Chart

In the world of manufacturing, CNC machining is a cornerstone of precision and efficiency, especially when it comes to working with aluminum. However, the journey of a part doesn’t end…

- How Wire Brushed Finish Complements CNC Machining for Superior Surface

CNC machining has revolutionized the manufacturing industry by enabling the precise production of complex parts. However, even with the advanced capabilities of CNC machines, the surface quality of the final…

- Tackling Tough High-Temperature Alloys in CNC Machining with Sand Blasting Glass Beads

High-temperature alloys, also known as superalloys, are designed to withstand extreme environments where ordinary materials would fail. These alloys are crucial in industries such as aerospace, power generation, and chemical…