Power Your Innovation with Our Custom Alloy Parts Service

As leaders in custom manufacturing, we introduce our Custom Alloy Parts Service, engineered to deliver precision and performance for industries like aerospace, automotive, and energy. Our expertise transforms your concepts into durable alloy components, tailored to excel in the toughest conditions. Here’s why we stand out:

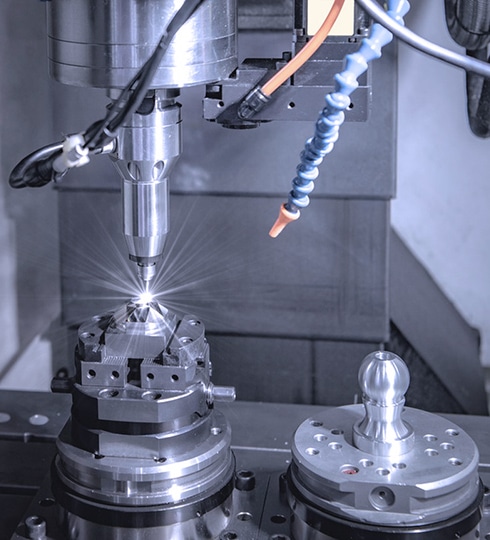

Our Custom Alloy Parts Service leverages state-of-the-art technologies to deliver precision-engineered alloy components. We excel in processes like CNC machining, forging, casting, and additive manufacturing (3D printing), tailored to the unique properties of alloys. Our multi-axis CNC machines and high-pressure forging presses handle complex geometries and tight tolerances, while our metal 3D printing capabilities enable rapid prototyping and intricate designs. We also offer heat treatment and surface finishing to enhance strength and corrosion resistance.

Alloys require deep expertise, and we deliver exceptional proficiency across a diverse range of materials. OurCustom Alloy Parts Service specializes in processing Aluminum Alloys, Copper-Based Alloys, Iron-Based Alloys, Nickel-Based Alloys, and Titanium Alloys, tailoring solutions to your specific performance needs. Whether you require lightweight components for automotive applications, conductive parts for electronics, or high-strength parts for aerospace, our team provides expert guidance to optimize material selection.

Alloy Category | Key Properties | Common Applications |

Aluminum Alloys | Lightweight, corrosion-resistant, machinable | Automotive frames, electronics housings |

Copper-Based Alloys | High conductivity, ductility | Electrical connectors, heat exchangers |

Iron-Based Alloys | Strength, durability, cost-effective | Machinery components, structural parts |

Nickel-Based Alloys | Heat/corrosion resistance, toughness | Turbine blades, chemical processing |

Titanium Alloys | High strength-to-weight ratio, biocompatibility | Aerospace structures, medical implants |

Quality is our foundation. We implement rigorous quality controls, using tools like coordinate measuring machines (CMM), spectrometry, and tensile testing to verify alloy parts’ dimensions, composition, and strength. Our ISO 9001-certified processes ensure consistency, while compliance with AS9100 (aerospace) or IATF 16949 (automotive) standards supports industry-specific needs.

We prioritize speed and adaptability. Our optimized production systems enable fast turnarounds—prototypes in days, full runs in weeks—without compromising quality. Real-time tracking keeps you updated, while our scalable infrastructure, including automated CNC lines and casting facilities, adjusts to volumes from one-off parts to thousands. Global shipping ensures timely delivery.

You’re one step from the factory-direct price of part manufacturing services.