I. Introduction

If you’ve ever assembled machinery or mechanical equipment, you know how crucial small components like the lock washer can be. Despite its small size, a lock washer plays a huge role in preventing loosening caused by vibration or movement. I’ve seen lock washers used effectively in everything from car engines to aerospace systems, ensuring the reliability of critical equipment.

Lock washers might seem straightforward, but producing them with consistent precision is not an easy task. That’s where CNC machining comes in. CNC technology helps manufacturers achieve the exacting standards required for reliable lock washer performance. By incorporating fasteners like lock washers into the process, CNC machining ensures that every piece meets stringent quality demands with remarkable accuracy. In my experience, investing in precision CNC methods has significantly improved the quality and performance of lock washers produced in manufacturing facilities I’ve been involved with.

In this article, I’ll share detailed insights on lock washer manufacturing, including the techniques, materials, applications, equipment choices, and optimization processes that make CNC the ideal choice. I’ll also highlight common challenges and offer practical solutions, based on personal experience and real-world scenarios I’ve encountered.

Whether you’re an engineer, CNC programmer, or someone managing production, this guide will help you better understand and master the CNC machining processes involved in lock washer production.

II. Technical Principles and Advantages

What is a Lock Washer?

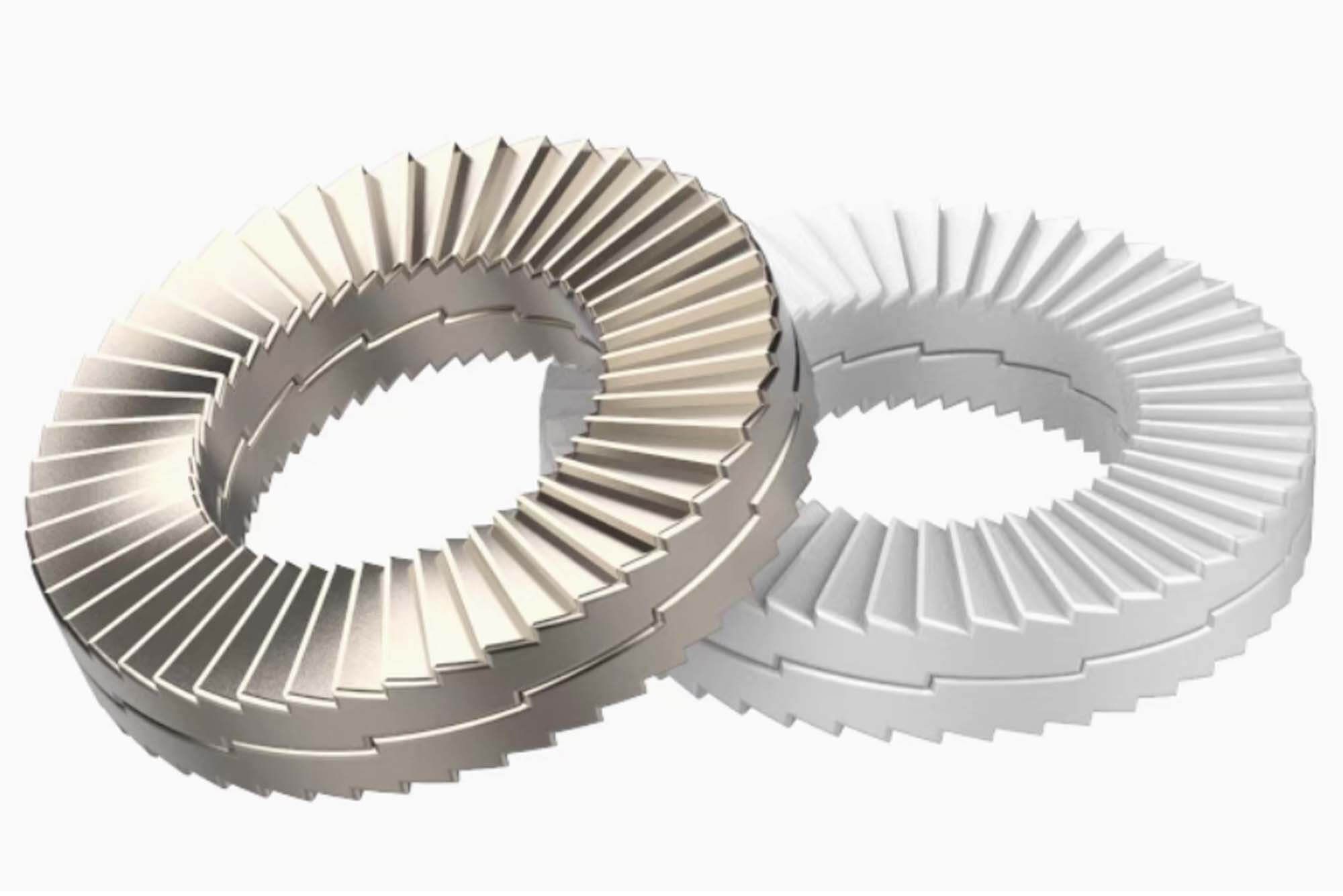

A lock washer is a small mechanical component designed specifically to prevent bolts, screws, or nuts from loosening under dynamic loads or vibrations. Different types of lock washers, such as split washers, toothed washers, and conical washers, are selected based on specific application needs.

Common materials used in lock washers include aluminum, stainless steel, carbon steel, brass, and composite materials. Selecting the right material can significantly influence the washer’s durability, corrosion resistance, and overall performance.

Here’s a quick overview table summarizing typical lock washer materials and their main characteristics:

| Material | Advantages | Typical Applications |

|---|---|---|

| Stainless Steel | Corrosion-resistant, high strength | Automotive, marine, aerospace |

| Carbon Steel | Economical, good strength | General machinery, construction |

| Brass | Corrosion-resistant, conductive | Electrical components, instruments |

| Aluminum | Lightweight, corrosion-resistant | Aerospace, automotive |

| Plastics/Composites | Non-conductive, corrosion-resistant | Electronics, medical devices |

| Titanium Alloy | Lightweight, high strength, corrosion-resistant | Aerospace, medical implants |

From personal experience, stainless steel lock washers have proven particularly effective in automotive applications due to their corrosion resistance and durability.

CNC Machining of Lock Washers

When I first started in manufacturing, lock washers were produced primarily by stamping or manual machining methods. While stamping can produce high volumes quickly, it often lacks precision for demanding applications. CNC machining changed this dramatically.

CNC methods—including laser cutting, milling, turning, and EDM—offer a precise, repeatable way to produce lock washers. CNC laser cutting, for instance, provides unmatched accuracy and consistency for complex shapes or thin washers that are hard to manufacture using traditional stamping techniques.

The table below clearly shows the advantages of CNC machining compared to traditional methods like stamping:

| Factor | CNC Machining | Traditional Stamping |

|---|---|---|

| Precision | High, consistent | Moderate, prone to variations |

| Repeatability | Excellent | Good for simple shapes, less for complex |

| Flexibility | High (easily handles complex shapes) | Limited (simple shapes only) |

| Tooling Cost | Moderate (flexible setup) | High (initial tooling expensive) |

| Material Flexibility | Excellent | Moderate (limited to ductile metals) |

| Surface Finish | Excellent | Moderate to low |

In my experience, CNC has been essential for applications demanding tight tolerances, complex geometries, or rapid prototyping.

Advantages of CNC Machining for Lock Washers

Using CNC technology provides significant advantages in lock washer manufacturing, including:

- Consistent Precision: CNC machining produces lock washers within exacting tolerances consistently. This accuracy ensures reliable fastening performance in critical applications.

- Material Versatility: CNC machines can effectively process various materials, including hardened steels and specialty alloys, expanding design possibilities.

- Superior Surface Finish: CNC machines offer smooth surface finishes, enhancing corrosion resistance and reducing the likelihood of stress risers that cause premature failure.

- Reduced Setup and Production Time: CNC equipment minimizes setup times and enhances productivity, allowing faster transitions between batch productions.

Challenges in CNC Lock Washer Machining

However, CNC machining lock washers isn’t without its challenges. Some common issues I’ve encountered include:

- Tool Wear and Breakage: Especially common when machining harder materials like stainless steel or titanium.

- Thin Washer Deformation: Thin washers easily deform during machining, affecting final dimensions.

- Burr Formation: Precise cutting methods sometimes leave small burrs, requiring additional finishing processes.

- Maintaining Dimensional Accuracy: Consistent accuracy across high-volume production runs can be challenging without careful monitoring and process control.

Best Practices for CNC Lock Washer Machining

From my own experience and industry best practices, here are several recommendations to overcome these challenges:

- Use optimal cutting parameters (appropriate feed rates, speeds, depths of cut).

- Select appropriate tooling materials (carbide, diamond-coated, or polycrystalline diamond tools).

- Employ proper lubrication and cooling to reduce heat buildup.

- Implement stable workholding fixtures and precision collets or custom fixtures.

I remember significantly improving my team’s lock washer machining results by simply optimizing tool paths and upgrading cooling systems, which dramatically reduced tool wear and improved dimensional consistency.

III. Application Scenarios

Lock washers are everywhere—even if you haven’t noticed. Throughout my experience in manufacturing, I’ve come across numerous applications in diverse industries. CNC-machined lock washers are vital components in ensuring mechanical stability across multiple sectors. Let’s explore some real-world applications:

1. Automotive Industry

Automotive applications require high-quality lock washers due to constant vibrations, extreme temperatures, and stresses. Precision is critical here. I’ve worked on projects involving lock washers for components like:

- Engine assemblies

- Transmission housings

- Exhaust systems

- Suspension mounts

Typically, automotive lock washers are made from stainless steel or high-strength carbon steel to resist corrosion and withstand mechanical stress.

2. Aerospace Industry

Precision and reliability in aerospace are non-negotiable. Lock washers used in aerospace need to perform flawlessly under extreme conditions, including temperature fluctuations and intense vibrations.

Common aerospace applications include:

- Turbine engine assemblies

- Aircraft structural fasteners

- Landing gear systems

- Avionics and cockpit instrumentation mounts

Here, titanium alloys and stainless steel washers, precisely CNC-machined, dominate due to their strength-to-weight ratio and corrosion resistance.

3. Home Appliances

Lock washers prevent screws and bolts from loosening due to vibration and repetitive movements in household appliances.

Typical home appliance applications include:

- Washing machines (drum and motor assemblies)

- Refrigerators (compressor mounts)

- Electric fans

- Air conditioning units

I’ve seen composite or stainless steel washers frequently chosen for appliances to avoid corrosion issues in humid conditions.

4. Industrial Equipment

Heavy industrial equipment demands robust lock washers due to heavy-duty usage, frequent vibrations, and mechanical stress.

Typical applications include:

- Pumps and compressors

- Machine tools and CNC equipment

- Industrial fans

- Conveyor systems

CNC-machined carbon or alloy steel washers are common in this sector due to their strength and durability.

5. Construction Industry

In construction, lock washers are critical for structural integrity and safety, preventing bolts from loosening in high-vibration environments like bridges, steel structures, and cranes.

Typical construction applications:

- Structural steel joints

- Seismic-resistant fasteners

- Heavy machinery assemblies

- Anchoring systems

Corrosion-resistant steel lock washers, machined precisely to industry standards, are preferred.

6. Medical Devices

Precision and reliability are paramount in medical applications. Lock washers must withstand sterilization processes and maintain structural integrity in precision medical instruments and equipment.

Typical medical applications include:

- Surgical instruments

- Diagnostic imaging equipment (MRI, CT)

- Hospital beds and patient mobility equipment

- Dental equipment

Stainless steel or medical-grade composite materials, precisely CNC-machined, ensure biocompatibility and corrosion resistance.

7. Robotics and Automation

Robotics and automation demand precise, reliable lock washers to maintain operational consistency in moving parts and joint assemblies.

Common applications include:

- Robotic arms and joints

- Precision actuators

- Automated conveyor systems

- Servo motor assemblies

Precision machining of composite or lightweight alloys ensures washers provide consistent performance with minimal maintenance.

Application Summary Table

Here’s a quick summary table to clarify the applications and typical materials I’ve outlined:

| Industry | Typical Materials | Key CNC Requirements |

|---|---|---|

| Automotive | Stainless steel, Carbon steel | Durability, corrosion resistance |

| Aerospace | Titanium, Stainless steel | Precision, reliability, lightweight |

| Home Appliances | Stainless steel, Composites | Corrosion resistance, vibration control |

| Industrial Equipment | Alloy steel, Carbon steel | High strength, wear resistance |

| Construction | Stainless steel, Carbon steel | Strength, corrosion resistance |

| Medical Devices | Stainless steel, Composites | Biocompatibility, corrosion resistance |

| Robotics & Automation | Composite, Lightweight alloys | Precision, low maintenance |

In my own experience, carefully selecting CNC-machined lock washers based on the industry’s specific demands dramatically improves performance, reliability, and lifespan.

IV. Equipment Selection and Process Optimization

From my experience, successful lock washer manufacturing depends greatly on choosing the right CNC equipment and process optimization techniques. Proper equipment selection and careful optimization directly impact product quality, production efficiency, and overall profitability.

1. Selecting CNC Machines for Lock Washer Production

Not all CNC machines are equally suited for lock washer manufacturing. Different equipment has distinct strengths for particular washer designs and materials. Here’s a breakdown of CNC machines I’ve commonly used or recommended:

- CNC Laser Cutting Machines

Ideal for producing thin, precise lock washers from sheet metal. Laser cutting provides precise control, minimal burr formation, and low material waste. - CNC Lathes

Suitable for machining washers from bar stock, especially for thicker washers or specialty materials. Lathes offer excellent control over dimensions and concentricity. - CNC Milling Machines

Effective for washers with additional features like grooves, slots, or irregular shapes. Provides versatility for complex washer designs. - CNC Grinding Machines

Essential for achieving ultra-high precision, especially in aerospace or medical lock washers requiring tight tolerances and exceptional surface finishes. - EDM (Electrical Discharge Machining)

Useful for creating intricate shapes or working with extremely hard materials like carbide or titanium alloys.

Here’s a summary table to simplify machine selection:

| CNC Machine Type | Best Suited For | Typical Materials |

|---|---|---|

| Laser Cutting | Thin, flat washers, high precision cuts | Stainless steel, carbon steel |

| CNC Lathe | Cylindrical or thicker washers | Stainless steel, brass, aluminum |

| CNC Milling | Complex shapes or feature-rich washers | Alloy steels, aluminum, composites |

| CNC Grinding | High-precision, smooth surface finishes | Hardened steels, ceramics, stainless steel |

| EDM | Intricate designs, extremely hard materials | Titanium, carbides, hardened alloys |

2. Cutting Tools for Lock Washer Machining

Selecting the right cutting tool directly impacts product quality, tool life, and cost efficiency. Here’s a brief overview of cutting tools suited for lock washer machining based on materials:

| Tool Material | Recommended for | Advantages |

|---|---|---|

| Carbide Tools | General metals, alloys, composites | Versatile, long-lasting |

| Diamond-Coated Tools | Ceramics, abrasive composites | Exceptional tool life, surface finish |

| CBN Tools | Hardened steel, tough alloys | High heat resistance, durability |

| PCD Tools | Non-ferrous metals, composites | Extreme durability, high precision |

In my own projects, carbide tools have offered an optimal balance of durability, versatility, and cost-efficiency for general lock washer production.

3. CNC Programming Considerations

Programming CNC machines for lock washers requires careful attention. A poorly optimized CNC program can negatively impact precision, production speed, and tool lifespan. Key considerations I’ve found helpful include:

- Optimal Toolpaths: Selecting efficient paths minimizes cycle time, maximizes tool life, and ensures precise dimensions.

- Adaptive Machining Strategies: Adjust feed rates dynamically based on tool load to avoid excessive wear or breakage.

- Multiple Passes: Utilize roughing passes followed by finishing passes to achieve dimensional accuracy and excellent surface finish.

- Coolant and Lubrication Management: Program specific coolant strategies for heat-sensitive materials and intricate features.

I personally achieved significant productivity gains by implementing adaptive roughing toolpaths, which reduced cycle times and improved tool longevity.

4. Process Optimization Techniques

Optimizing the machining process can substantially boost productivity and quality. Here are key optimization techniques I’ve successfully applied:

- High-Speed Machining (HSM)

Using higher spindle speeds combined with smaller cuts reduces machining time while maintaining excellent surface finishes. - Tool Wear Monitoring

Regular inspections or sensor-based monitoring can predict and prevent tool breakage, avoiding costly downtime and scrap. - Precision Workholding

Investing in custom or hydraulic fixtures provides better stability, ensuring dimensional consistency and preventing vibration. - Thermal Management

Proper use of coolants prevents thermal deformation and ensures dimensional accuracy.

In one case, simply switching to premium coolant reduced heat-induced deformation in thin lock washers, significantly enhancing dimensional consistency.

5. Inspection and Quality Control

Ensuring quality through precise inspection is essential in lock washer production. Reliable inspection methods I’ve employed include:

| Inspection Tool | Inspection Capability | Recommended For |

|---|---|---|

| Coordinate Measuring Machine (CMM) | Highly accurate dimensional checks | Aerospace, medical washers |

| Optical Comparator | Quick visual checks for dimensional accuracy | General manufacturing |

| Profilometer | Surface roughness measurement | High-precision washers |

| Digital Micrometers | Fast diameter and thickness checks | Everyday production monitoring |

Regular use of CMM and profilometers in my production line dramatically improved quality consistency and reduced customer rejections.

Summary of Equipment and Optimization

Selecting appropriate CNC machines, cutting tools, and applying smart CNC programming and process optimization techniques significantly improves the efficiency and quality of lock washer production. From personal experience, investing in these areas consistently yields excellent returns.

V. Market Trends and Industry Analysis

Understanding market trends in lock washer manufacturing helps businesses stay competitive. I’ve personally observed several key trends influencing how lock washers are made and utilized today:

1. Rising Demand for Precision Lock Washers

Industries like automotive, aerospace, and robotics increasingly require precision components. Growing demand for electric vehicles, high-performance aircraft, and automated systems is driving precision lock washer manufacturing.

2. Technological Advances in CNC Systems

Advanced CNC systems, including multi-axis machining and laser technology, improve lock washer manufacturing capabilities. I’ve seen CNC machines increasingly integrate real-time monitoring, artificial intelligence (AI), and automated quality checks.

3. Integration of Automation and Industry 4.0

Smart factories, utilizing IoT (Internet of Things) and automation, now dominate precision component manufacturing. Lock washer production lines are moving toward fully automated systems, enhancing efficiency, accuracy, and traceability.

4. Sustainability and Eco-Friendly Manufacturing

Eco-conscious production methods are becoming a priority. CNC manufacturing of lock washers now includes using recyclable materials, eco-friendly lubricants, and optimized processes that minimize waste.

5. Competitive Landscape and Market Opportunities

Competition among lock washer manufacturers is intense. Here’s a simplified look at the competitive landscape I’ve noticed:

| Competitor Type | Strengths | Weaknesses |

|---|---|---|

| Large OEM Manufacturers | High-volume, cost-efficient production | Less flexibility, slower innovation |

| Specialized Manufacturers | Precision, custom solutions | Limited volume capacity |

| Emerging Startups | Innovation, rapid prototyping | Limited industry recognition |

Focusing on niche markets or specialty washers (like aerospace-grade or medical-grade) often gives smaller manufacturers a significant competitive advantage.

VI. Summary and Outlook

Throughout this guide, we’ve explored key aspects of precision lock washer manufacturing using CNC technology. Lock washers might seem simple, but their reliable performance is crucial in many industries. CNC machining ensures consistent precision, making it ideal for producing lock washers for demanding applications.

Choosing the correct CNC machinery, tooling, programming strategies, and optimizing the entire process significantly enhances quality and efficiency. Throughout my career, I’ve observed these factors directly influencing product reliability and customer satisfaction.

Looking ahead, lock washer manufacturing will increasingly focus on:

- Enhanced precision: Driven by automotive, aerospace, and robotics industries.

- Advanced CNC technologies: Incorporating AI and multi-axis machining for greater accuracy and efficiency.

- Sustainability: Prioritizing eco-friendly materials and manufacturing processes.

Manufacturers who adapt to these trends will thrive in the highly competitive landscape of precision lock washer production.

FAQ

1. What is a lock washer?

A mechanical component designed to prevent bolts and nuts from loosening due to vibration.

2. What materials are commonly used to make lock washers?

Stainless steel, carbon steel, brass, aluminum, titanium, plastics, and composites.

3. Why is CNC machining ideal for lock washer production?

CNC provides consistent precision, repeatability, complex geometries, and superior surface finishes.

4. What industries rely heavily on lock washers?

Automotive, aerospace, home appliances, industrial equipment, construction, medical, and robotics.

5. How do I choose the right CNC machine for lock washer production?

Consider washer material, complexity, precision needs, and volume. Laser cutters for thin washers, CNC lathes for thicker, CNC mills for complexity.

6. What challenges arise in CNC machining of lock washers?

Common challenges include tool wear, thin washer deformation, dimensional accuracy, and burr formation.

7. How can I improve surface finish on CNC-machined lock washers?

Optimize cutting parameters, use sharp precision tooling, ensure proper cooling, and apply finishing passes.

8. What cutting tools are best for lock washer manufacturing?

Carbide for general machining, diamond-coated for abrasive materials, CBN for hardened steel, PCD for non-ferrous and composites.

9. How important is cooling and lubrication in lock washer machining?

Vital for reducing heat, preventing deformation, and prolonging tool life.

10. What inspection tools are recommended for lock washer quality control?

Coordinate Measuring Machines (CMM), optical comparators, profilometers, digital micrometers.

11. What is Industry 4.0’s role in lock washer production?

Industry 4.0 integrates IoT, automation, and AI to enhance efficiency, quality, and traceability.

12. How do market trends affect lock washer manufacturing?

Increasing demand for precision, sustainability initiatives, and advanced CNC technologies shape manufacturing methods.

13. What sustainability practices are relevant in lock washer CNC machining?

Using recyclable materials, biodegradable lubricants, reducing waste through optimized CNC programming.

14. Can CNC milling machines produce lock washers effectively?

Yes, especially washers with complex geometries or specialized features.

15. How does CNC technology improve overall productivity in lock washer production?

Reduces setup times, improves repeatability, ensures precision, and reduces manual labor requirements.

Authoritative Resources on Lock Washers and CNC Machining

To further enhance your understanding of lock washers and CNC machining, here are several authoritative resources from reputable sources:

- “Lock Washer Categories” – Knapp Fasteners Inc.

- This article provides an overview of various lock washer types, including split, external tooth, and internal tooth lock washers, detailing their specific applications and characteristics.

- https://knappfast.com/uncategorized/lock-washer-categories/

- “Fundamentals of CNC Machining” – TITANS of CNC Academy

- This comprehensive PDF covers the basics of CNC machining, offering insights into machine setup, operation, and best practices for achieving precision in manufacturing.academy.titansofcnc.com

- https://academy.titansofcnc.com/files/Fundamentals_of_CNC_Machining.pdf

- “How to Design Parts for CNC Machining” – Hubs

- This guide outlines best practices for designing parts optimized for CNC machining, discussing factors like tool selection, material considerations, and design constraints.Protolabs Network

- https://www.hubs.com/knowledge-base/how-design-parts-cnc-machining/

- “How and When Should Lock Washers Be Used?” – Marsh Fasteners

- This article explains the function of lock washers, their importance in preventing fastener loosening due to vibration, and guidelines on proper usage.

- https://marshfasteners.com/how-and-when-should-lock-washers-be-used/

- “Manufacturing Process” – Growermetal

- This brochure details the manufacturing processes involved in producing security and flat washers, including blanking, cold working, and heat treatment procedures.Grower Metal

- https://growermetal.com/wp-content/uploads/2021/10/Growermetal_Brochure_2022_EN_271021_web.pdf

- “6 Design for Manufacturing Best Practices for CNC Machined Parts” – Summit CNC

- This article discusses critical design considerations to enhance the manufacturability and performance of CNC machined parts, emphasizing wall thickness, feature alignment, and material selection.

- https://summitcnc.com/blog/design-for-manufacturing-dfm-best-practices-for-cnc-machined-parts

- “Types of Lock Washers and Their Uses” – DigiKey Forum

- This forum post provides a breakdown of different lock washer types, including split lock, sealing, internal tooth, external tooth, flat, and flat retaining washers, along with their specific applications.电子元件与工程论坛

- https://forum.digikey.com/t/types-of-lock-washers-and-their-uses/930

- “Perfect Guide to Washers – Its Types, Features, Manufacturing and Applications” – Khatabook

- This guide offers an in-depth look at washers, covering their types, features, manufacturing processes, and various applications across industries.

- https://khatabook.com/blog/how-are-washers-made/

- “Best Practices: Designing for CNC Milling” – MakerVerse

- This resource outlines essential design practices for CNC milling, focusing on aspects like internal corner radii, cavity depths, and feature orientations to optimize machining efficiency.Makerverse+1Protolabs Network+1

- https://www.makerverse.com/resources/cnc-machining-guides/best-practices-designing-for-cnc-milling/

- “Lock Washers” – Huyett

- This page provides an overview of lock washers, discussing various types such as split washers, toothed washers, and wedge locking washers, along with their unique locking mechanisms and applications.

- https://www.huyett.com/all-products/washers/lock-washers

These resources offer valuable insights into the design, application, and manufacturing of lock washers, as well as best practices in CNC machining.

Other Articles You Might Enjoy

- Stainless Steel Fasteners: What Designers and CNC Machinists Must Know

Why Stainless Steel Fasteners Matter in CNC Applications As someone who has spent significant time around CNC machines and designing mechanical assemblies, I've learned one critical truth: the smallest parts…

- Choosing the Right Metal Fasteners: A Practical Guide for CNC Customization or Purchasing

Introduction: Why Metal Fasteners Matter in CNC Projects If you're involved in CNC machining or design, you've likely realized metal fasteners aren't just a small detail. They're often the deciding…

- Automotive Fasteners Manufacturing Guide: Precision, Strength & Industry Standards

I’ve spent a good part of my career exploring how Automotive Fasteners shape a vehicle’s overall safety and performance. I’ve personally toured manufacturing facilities, spoken with CNC operators, and tested…

- Custom Brass Fasteners: How CNC Machining Enhances Strength, Precision, and Durability

Hello, and welcome to this comprehensive guide on Brass Fasteners and the pivotal role that CNC machining plays in crafting custom solutions. I’ve spent years working alongside design engineers, procurement managers, and…

- The Growing Demand for Custom Fasteners: How to Manufacture and Source Specialized Components

Hello, and welcome to my comprehensive guide on fasteners. I’ve spent a significant part of my career working with manufacturers, design engineers, and machining experts who rely on fasteners in…

- Understanding Screw Head Types : Design, Standards, CNC Machining & Optimization

I. Introduction I’ve worked with many different screw head types throughout my career in manufacturing. I remember the first time I had to figure out why a certain screw head…

- Brass Screws Custom Machining Guide: Techniques, Tools, and Best Practices

Introduction Brass screws are among the most popular fasteners used across various industries due to their unique combination of aesthetics, corrosion resistance, and excellent machinability. If you're considering CNC machining…

- Nuts and Bolts Machining Explained: Methods, Standards, and CNC Tips

Introduction: Why Nuts and Bolts Are More Complex Than They Look If you’ve ever walked into a machine shop or looked at a mechanical assembly, you’ve probably noticed one thing…

- Custom Stainless Steel Screws with CNC Machining: Techniques, Tools, and Tips

Introduction I first realized how crucial Stainless Steel Screws are in CNC machining projects when I worked on a small manufacturing assignment.We needed durable, corrosion-resistant fasteners for an outdoor piece of equipment,…

- Titanium Bolts: The Ultimate Guide to High-Strength, Lightweight Fasteners

Introduction: Why Titanium Bolts and CNC Machining Matter? Welcome, and thanks for reading my in-depth guide on titanium bolts. I’ve been working around metals and machining for a good part…