Introduction

I’ve been fascinated by the way Urethane shapes modern manufacturing ever since I first encountered this material in a small prototyping workshop. It was early in my career, and I remember wondering if it could be machined as easily as metals or more common plastics. Back then, I was juggling multiple projects, and I needed something that was durable, shock-absorbent, and easy to work with on standard CNC machines.

The more I explored the properties of Urethane, the more I realized it wasn’t just another polymer. It offered a unique combination of elasticity, toughness, and chemical resistance. I believe that’s why so many people in engineering, product design, and manufacturing circles are talking about Urethane today. Can it be milled, turned, or shaped without causing trouble for the machinist? Yes. Absolutely. But it requires specific approaches to get the best results.

In this article, I’m going to share everything I’ve learned over the years about machining Urethane. We’ll explore the reasons Urethane is popular in modern manufacturing, look at different machining methods(such as CNC machining), dive into recommended tools, and examine real-world use cases. If you’re curious about handling Urethane in your own facility or just want to understand how it’s used across industries, you’re in the right place.

Understanding Urethane in Modern Manufacturing

When I first heard about Urethane, I assumed it was just another plastic. But I quickly discovered that calling Urethane “just plastic” oversimplifies a material that offers a surprising range of mechanical and chemical properties. Some folks in industry even call Urethane a “miracle polymer” because it can handle so many demanding conditions. Let’s explore why Urethane has secured such a strong place in modern manufacturing.

2.1 What is Urethane?

Urethane, often referred to as polyurethane or simply “PU,” is a polymer composed of organic units joined by carbamate (urethane) links. It can be formulated in many ways to achieve a wide range of properties—this includes everything from soft, flexible foams to rigid, highly durable solids. In modern manufacturing, the term “Urethane” usually denotes a solid formulation that exhibits high tensile strength, abrasion resistance, and elasticity.

I once visited a facility that specialized in producing Urethane rollers for conveyor belts. The product manager there showed me how Urethane rollers outperformed traditional rubber rollers because they could withstand extreme abrasion and repeated impacts without breaking down. That was my first real experience seeing how Urethane’s properties make it stand out.

2.2 Key Properties of Urethane

When we talk about Urethane in manufacturing, we usually focus on attributes like elasticity, tensile strength, tear resistance, and chemical compatibility. Let me break down some of the most critical properties:

- Elasticity: Urethane can bounce back to its original shape after deformation. This elasticity is crucial for applications like shock absorbers, gaskets, and vibration dampers.

- Abrasion Resistance: In environments where parts face constant friction—like conveyor belts, wheels, or drive rollers—Urethane’s abrasion resistance is a game-changer. It can last significantly longer than rubber or certain plastics.

- Chemical Resistance: Urethane exhibits good resistance to oil, grease, and many solvents. I’ve personally tested Urethane components in a workshop environment filled with cutting fluids, lubricants, and degreasers, and they held up well.

- Wide Hardness Range: Urethane hardness can vary from soft, flexible formulations to rigid, structural types. Manufacturers often use Shore A scale for softer blends and Shore D scale for harder ones.

- Low Compression Set: Many Urethane blends can compress under load and return close to original dimensions, reducing permanent deformation. This makes them valuable in sealing applications.

2.3 Why Urethane Matters for Modern Manufacturing

In my experience, the reason so many manufacturers choose Urethane is that it fills a sweet spot between rigid plastics (like polycarbonate or nylon) and softer elastomers (like natural rubber). Traditional plastics can be too brittle or too rigid for certain dynamic applications. Meanwhile, softer elastomers often lack the strength needed for heavy industrial usage. Urethane stands in the middle, providing flexibility plus robust mechanical performance.

Additionally, Urethane can be formulated in dozens of ways to handle specific industrial challenges. Need a material that’s oil-resistant and can handle repeated impacts without wearing out? You can select a custom Urethane blend. Need a part that’s flame-retardant or meets specific FDA food-grade requirements? You can find a specialized Urethane formulation for that, too.

2.4 Typical Manufacturing Uses of Urethane

Let’s look at where Urethane shines in modern manufacturing:

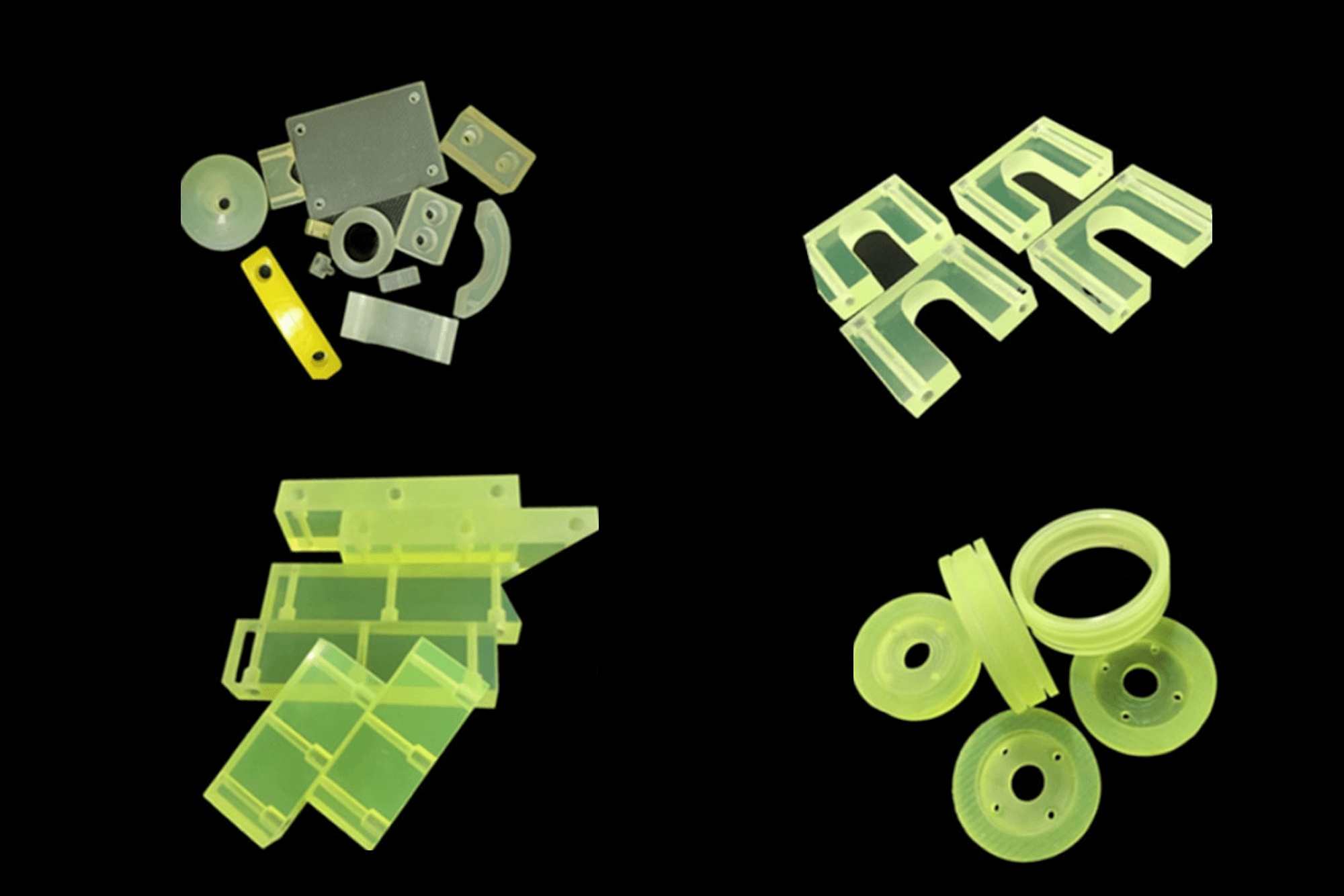

- Rollers and Wheels: You’ll often see Urethane wheels in forklifts, skateboards, or assembly lines. This is due to Urethane’s high abrasion resistance and capacity to absorb shock.

- Seals and Gaskets: The elasticity and chemical resistance of Urethane make it a go-to choice for sealing systems in automotive and heavy machinery.

- Bushings and Mounts: These are used in vehicles to reduce vibration and noise. I’ve replaced rubber bushings with Urethane bushings in a custom motorcycle project, and the difference in performance was noticeable right away.

- Protective Coatings: Urethane coatings can protect metal parts from corrosion, scratches, or chemical damage.

- Custom Molded Parts: For short-run production where injection molding might be too expensive, Urethane casting can be a quick, cost-effective way to produce prototypes or final parts.

2.5 The Rise of Machining Urethane

Traditionally, people viewed Urethane as something you cast or mold, not something you’d put on a CNC mill or lathe. But in the last decade, I’ve seen more machine shops experimenting with cutting and shaping Urethane. This shift is driven partly by better tooling technology, partly by advanced formulations of Urethane that are more stable under machining conditions, and partly by the demand for custom or short-run parts that molding alone can’t accommodate cost-effectively.

Machining Urethane comes with unique challenges. Soft materials like Urethane can tear, gum up tools, or melt if machined incorrectly. That’s why I often recommend focusing on best practices—proper speeds, feeds, and tool selection—to avoid these pitfalls. We’ll dive into these details in the coming chapters.

2.6 Looking Ahead

I like to compare Urethane to a Swiss Army knife. It’s versatile, it’s reliable, and it adapts to various tasks if you know how to wield it. As we move deeper into the era of on-demand manufacturing, we’ll continue to see rising demand for flexible, high-performance materials like Urethane. Whether you’re prototyping new components, upgrading existing systems, or simply curious about advanced materials, Urethane is worth exploring.

In the next chapters, we’ll cover how to machine Urethane effectively. I’ll walk you through the common machining methods, highlight the best tools and feeds, and share some real-world examples that underscore why Urethane remains a standout choice in modern manufacturing.

Machining Methods and Techniques

Before I started working with Urethane, I wondered if conventional CNC milling techniques would even work on such a soft material. The good news is that you can machine Urethane, but it requires certain adjustments. In this chapter, I’m going to share the core methods I’ve encountered, along with the pros and cons of each. It’s important to remember that Urethane’s unique physical properties mean you can’t just apply typical plastic or metal machining parameters.

3.1 Overview of Machining Approaches

In modern manufacturing, the most common machining operations for Urethane include:

- CNC Milling: Using a CNC milling machine (often with specialized end mills) to cut shapes, pockets, or complex 3D contours in Urethane blocks or sheets.

- Turning (Lathe Operations): Mounting Urethane on a lathe to shape cylindrical parts, bushings, and rollers.

- Saw Cutting: For rough cutting or simple shapes, bandsaws or circular saws with the right blade type can handle Urethane.

- Waterjet Cutting: Jet streams of highly pressurized water (sometimes with abrasive) can make precise cuts in Urethane.

- Die Cutting / Punching: Suitable for thinner Urethane sheets or parts requiring high-volume production of repeated shapes.

Personally, I rely on CNC milling and turning the most. I find these two methods give me the precision I need, especially for custom parts. But I’ve also worked with waterjet service providers who can cut thick Urethane sheets quickly and accurately. Let’s explore each method in more detail.

3.2 CNC Milling

CNC milling is my go-to approach when I need tight tolerances or complex geometries in Urethane. Here’s what I’ve learned:

- Tool Selection: You want a sharp tool with high rake angles that can slice rather than push through the material. Dull or incorrect geometry can cause tearing or melting.

- Speeds and Feeds: Generally, I reduce feed rates compared to metal milling. Urethane can’t dissipate heat as effectively, so going too fast can generate friction, which leads to melting or smearing.

- Chip Evacuation: Chips or slivers of Urethane can clump together, forming a gooey mess that sticks to the cutter. Keeping a steady stream of air or coolant can help.

- Workholding: Urethane is soft, so you need to clamp it without deforming it. Sometimes I use sacrificial fixtures or special soft jaws.

One challenge with CNC milling is balancing the speed. If you run the spindle too fast, the cutter heats up. If the feed is too high, the cutter can yank or tear the Urethane. With the right adjustments, though, CNC milling yields clean finishes and consistent part geometry.

3.3 Turning (Lathe Work)

Lathe operations are common for making Urethane rollers, bushings, and cylindrical parts. If you’ve ever replaced the wheels on a piece of equipment with bright-colored rollers, there’s a decent chance they were turned from Urethane rods.

- Cutting Tools: Similar to milling, sharp tools with positive rake angles work best.

- Surface Finish: I’ve noticed that turning can produce a smooth finish on Urethane if you dial in the correct RPM and feed. Occasionally, I polish the surface with a fine abrasive to refine it further.

- Buildup: Again, Urethane can build up on the tool if there’s excessive friction. A small amount of coolant or a gentle stream of compressed air can reduce the chance of material melting.

3.4 Bandsaw and Circular Saw Cutting

For rough cuts or to create blanks for milling or turning, you can use a saw. My personal tip is to pick a blade with fewer teeth per inch and ensure those teeth are sharp. Urethane can melt or smear if the blade friction is too high. I also like to use a saw lubricant or coolant sparingly.

3.5 Waterjet Cutting

Some shops use waterjet cutting on thicker or more complex 2D profiles. Waterjet is excellent because it doesn’t rely on a blade or cutter that can become clogged. It slices through Urethane with high-pressure water (and sometimes an abrasive grit). The downside is that certain Urethane blends can absorb water if the cut is slow, potentially causing minor swelling. However, for many shapes and thicknesses, waterjet is a go-to solution.

3.6 Die Cutting / Punching

If you need a large volume of identical parts—like gaskets or seals from thinner Urethane sheets—die cutting or punching might be the most cost-effective approach. The main limitation is that this method is mostly for 2D shapes with uniform thickness. I recall a project in a packaging company that required thousands of tiny Urethane pads for friction on assembly lines. Die cutting was their solution.

3.7 Table: Comparison of Machining Methods

Below is a table summarizing common Urethane machining methods I’ve used or observed. This table provides a clear overview:

| Method | Pros | Cons | Typical Thickness | Precision Level | Setup Complexity | Comments |

|---|---|---|---|---|---|---|

| CNC Milling | High precision, complex shapes | Potential tool gumming, requires careful speeds/feeds | Up to several inches | High (±0.005″ possible) | Moderate to High | Ideal for prototypes and small runs |

| CNC Turning | Excellent for cylindrical parts (rollers, bushings) | Similar issues with heat buildup and melting | Rods up to many feet | High for round geometry | Moderate | Common for wheels, bushings, custom rollers |

| Bandsaw / Circular Saw | Good for rough cuts and creating blanks | Limited precision, can produce rough edges | Typically up to a few inches thickness | Low to Medium | Low | Great for preparing material for further machining |

| Waterjet Cutting | Clean edges, no tool clogging | Potential water absorption, higher cost | Thick plates (6″+) | High (2D) | Medium to High | Good for complex 2D shapes, especially thick stock |

| Die Cutting / Punching | Fast for repetitive 2D shapes | Limited to sheet format, tooling cost for dies | Thin sheets (<1″) | Medium (depends on die) | Medium | Best for volume runs of seals, gaskets, pads |

| Laser Cutting | Possible on some Urethane blends | Risk of scorching or melting edges, thickness limitations | Thin sheets (<0.5″) | Medium | Medium | Not as common, must confirm material compatibility |

| EDM (rare) | Very uncommon for Urethane | Costly and slow for soft materials | – | – | High | Usually not recommended for Urethane |

(In the table above, “Precision Level” is a general guideline; actual results may vary based on machine calibration and Urethane hardness.)

3.8 My Personal Insights

When I first tried machining Urethane on a CNC mill, I learned that controlling heat was key. The caretaker at my local machine shop suggested applying compressed air to cool the workpiece. That alone made a huge difference. The surface finish was drastically improved, and the tool life increased. In fact, I got so comfortable with milling Urethane that I started experimenting with different hardness levels to see which gave the best results for automotive components I was prototyping.

One highlight: The first time I turned Urethane bushings on a lathe, I discovered that finishing them with a light pass and a minimal feed rate gave me the best results. I used to push the tool too hard, causing unsightly tear-outs. Slowing everything down was the simple trick that solved those issues.

3.9 Summary of Machining Urethane

Machining Urethane requires balancing speed, feed rate, tool geometry, and temperature control. You can definitely approach it with conventional machinery, as long as you adapt your process to account for Urethane’s softness and low melting point. In the next chapter, we’ll explore the specific tools and equipment I recommend, plus best practices for ensuring clean cuts and minimal tool wear.

Tools, Speeds, and Best Practices for Machining Urethane

I still recall the first time I tried machining Urethane using my standard set of carbide end mills. I was treating it the same way I’d handle a block of ABS plastic. That naive approach lasted about five minutes. The tool got hot, the Urethane melted along the edges, and I ended up with a gummy mess. It was a major wake-up call that Urethane isn’t like other plastics.

This chapter focuses on the tools and best practices I’ve found essential for successful Urethane machining. I’ll walk you through everything from tool materials to recommended speeds and feeds. I’ll also share some personal stories along the way, because I’ve definitely had my share of trial and error.

4.1 Understanding the Challenges

Before we dive in, let’s be clear about why Urethane is tricky in the first place. Unlike metals or stiff thermoplastics, Urethane is relatively soft and has a low melting temperature (compared to many engineering plastics). This combination means that frictional heat builds up quickly, and the material can deform or melt if you don’t control the process.

- Gumming: Urethane tends to gum up on tools if the surface temperature rises even slightly above a certain threshold.

- Tearing or Stringing: If you push the feeds or speeds too aggressively, Urethane can tear or produce stringy swarf that gets wrapped around the cutting tool.

- Workpiece Deformation: Because it’s elastic, Urethane can bend away from a cutting force, resulting in inaccurate dimensions.

4.2 Tool Materials and Geometry

I’ve experimented with various tool materials when milling or turning Urethane. Below are my insights:

- Carbide: In my experience, carbide tools with a razor-sharp cutting edge work best. I prefer uncoated carbide for Urethane because coatings designed for metal (like TiN or TiAlN) can sometimes create extra friction or heat. A sharp edge slices through Urethane cleanly, reducing melting or tearing.

- High-Speed Steel (HSS): Some machinists favor HSS for its sharper edge potential. However, it wears down faster than carbide, especially if you’re running longer production cycles. That said, for prototyping or small batches, HSS can be an economical choice.

- Tool Geometry: High rake angles help lift and slice the material. I remember switching from a standard flat end mill to one with a higher helix angle and noticing an immediate difference. The Urethane chips flew off cleaner, and I saw fewer issues with tool buildup.

If possible, keep a dedicated set of end mills or lathe inserts specifically for Urethane. Once an edge dulls, it’s more prone to generating heat, which leads to clogging or melting. I personally have a small toolbox labeled “For Urethane Only,” so I don’t mix these tools with those used on tough metals.

4.3 Optimal Speeds and Feeds

There’s no one-size-fits-all formula for machining Urethane because the hardness can vary significantly. However, I’ll share general rules of thumb that have worked in my shop:

- Spindle Speed: For milling, I typically run the spindle at lower RPMs compared to metals or rigid plastics. If the Urethane is very soft (around Shore A 70–90), I might start around 2,000–3,000 RPM. Harder Urethane (Shore D 50–70) might let me push up to 5,000–6,000 RPM, but I keep a close eye on heat.

- Feed Rate: I like to keep a moderate to low feed rate, often around 25–50% of what I’d use for a comparable dimension in ABS. This prevents the cutter from ripping or tearing at the material.

- Depth of Cut: Shallow depth passes usually help maintain better control. Sometimes I’ll do multiple shallow passes rather than one deep pass, especially on thick blocks of Urethane.

A big trick I rely on is continuous air blast or coolant if my machine setup allows. It keeps the Urethane cool and clears away chips. But I avoid heavy flooding with coolant, since some Urethane grades can absorb fluid and swell. A light mist or steady air blast often strikes the right balance.

4.4 Table: Recommended Speeds and Feeds for Urethane by Hardness

Below is another table summarizing typical speeds and feeds I’ve found effective for different Shore hardness levels of Urethane. Please note these are general guidelines. Always run test cuts to find your optimal settings.

| Urethane Hardness (Shore) | Spindle Speed (RPM) | Feed Rate (in/min) | Depth of Cut (inches) | Tool Material | Coolant/Air | Comments |

|---|---|---|---|---|---|---|

| Shore A 70 (Soft) | 1,500 – 2,500 | 6 – 12 | 0.02 – 0.05 | Sharp Uncoated Carbide | Light air blast/mist | Very soft; avoid deep cuts that cause deformation |

| Shore A 90 (Medium-Soft) | 2,000 – 3,000 | 8 – 15 | 0.03 – 0.06 | Carbide or HSS | Mild coolant or air blast | Watch for gumming; a slower feed can help with surface finish |

| Shore D 40 (Medium-Hard) | 3,000 – 4,500 | 10 – 20 | 0.04 – 0.08 | Carbide | Air blast recommended | Good balance between softness and rigidity; less prone to tearing |

| Shore D 50 (Moderately Hard) | 4,000 – 5,500 | 12 – 25 | 0.05 – 0.10 | High Helix Carbide | Light coolant or air blast | Maintains form well; can handle slightly faster feeds without melting |

| Shore D 60 (Hard) | 5,000 – 6,000 | 15 – 30 | 0.06 – 0.12 | Carbide / Coated Carbide (if sharp) | Air blast or minimal coolant | Similar to machining rigid plastics; keep a sharp edge to avoid heat build-up |

| Shore D 70+ (Very Hard) | 5,000 – 7,000 | 20 – 35 | 0.08 – 0.15 | Carbide | Air blast/coolant optional | Approaches rigid plastic territory; measure heat carefully |

| Shore A < 70 (Ultra Soft) | 1,000 – 2,000 (max) | 4 – 8 | 0.01 – 0.03 | HSS or Carbide | Air only, avoid fluid | Extremely deformable; best for very light passes and minimal pressure |

| Multi-Durometer Blends | Varies by region (segment) | Varies by segment hardness | Varies by segment hardness | Carbide recommended | Segment-based approach | Some advanced Urethane blends have layered hardness, requiring multiple pass strategies |

I’ve tested these ranges in my personal projects and found them to be a solid starting point. You should always fine-tune based on your machine’s rigidity, tool condition, and the specific brand of Urethane.

4.5 Maintaining a Cool Cut

Thermal issues cause the most trouble when machining Urethane. If I see any sign of melting or smearing, I’ll reduce spindle speed and feed, and increase air flow. I have a small temperature gun that I occasionally use to check surface temps on the part. If it creeps too high (say, above 150°F), I pause and adjust parameters.

4.6 Workholding and Fixturing

One subtle point I learned is how critical fixturing becomes for a soft material. Traditional clamps can dent or warp Urethane. In many cases, I’ll use custom soft jaws or even 3D-printed fixtures that conform to the shape of my workpiece. For softer Shore A materials, vacuum tables can sometimes work if the surface area is large, but you risk the part shifting if your passes are too aggressive.

4.7 Tool Maintenance and Life

My standard approach is to change or sharpen tools more often when machining Urethane. Because you need a keen edge, any slight dullness leads to friction, heat, and smearing. In a production environment, consider scheduling more frequent tool replacements or regrinds than you would for typical plastics.

4.8 My Personal Lessons Learned

I’ve destroyed a few end mills by underestimating how quickly friction can build up in Urethane. Early in my career, I once tried to slot a 1-inch thick block of Shore A 80 Urethane in a single pass. That was a mistake. The cutter got packed with melted polymer, the motor started straining, and the entire block ended up a scorched mess. Since then, I do multiple step-down passes with an air blast to clear chips.

Another tip: For finishing passes, I often cut at slower speeds and shallower depths. It yields a smoother surface and helps avoid tool marks on the final part. Customers typically want that clean look, especially if the Urethane piece is visible or part of a consumer-facing product.

4.9 Final Thoughts on Tools and Speeds

Machining Urethane can be very rewarding if you approach it with patience, proper tooling, and an understanding that it’s not just another plastic. By choosing the right tool material, using conservative speeds and feeds, and cooling the cut effectively, you can get professional-grade results on standard CNC equipment. In our next chapter, I’ll delve deeper into practical tips, problem-solving tactics, and recommended best practices that have saved me time and headaches.

Tips, Tricks, and Best Practices for Urethane Machining

When I talk to other machinists about working with Urethane, the conversation inevitably turns to the “little tricks” each person has discovered. Unlike metals or some plastics, where there’s a well-defined set of parameters, Urethane can be unpredictable. It’s an elastomer, it’s heat-sensitive, and different formulations behave differently. Over the years, I’ve amassed a handful of best practices that make the job smoother. I want to share them here, along with a few personal anecdotes that shaped my perspective.

5.1 Tool Preparation and Setup

I’m a big believer in meticulous preparation. I learned this the hard way when I once rushed into milling a set of Urethane gaskets. I forgot to double-check the end mill sharpness, and halfway through the job, the tool started producing tear-outs. Now, I go through a quick checklist:

- Check Tool Sharpness: This one’s obvious, but it’s easy to overlook. I run a quick visual inspection to ensure the cutting edges show no signs of rounding.

- Clean Tool Holder: Any residual debris can disrupt the tool’s runout, causing chatter that leads to ragged edges.

- Secure Workpiece: If I’m milling or turning, I make sure the workpiece is snug but not crushed.

5.2 Controlling Heat and Friction

I can’t stress enough how crucial temperature control is. To prevent gumming or melting, I keep these pointers in mind:

- Use Compressed Air: Even a small nozzle aimed at the cutting zone helps dissipate heat and clear chips.

- Consider a Light Mist Coolant: If your Urethane grade isn’t prone to absorbing fluids, a fine mist can keep temperatures in check.

- Monitor Surface Temperature: If I suspect things are heating up, I’ll slow the spindle or feed rate. I’ve noticed that a few seconds of patience here can save a lot of grief.

5.3 Minimize Tool Contact Time

In standard milling, we often talk about “chip load” and how it relates to tool wear or surface finish. With Urethane, I focus on keeping the cutter’s contact time with the material as brief as possible. That means quick, shallow passes, or using climb milling so the cutter slices cleanly through the surface.

When the tool is engaged too long, friction accumulates, generating heat. You can reduce friction by optimizing radial engagement (stepover) so the cutter isn’t always buried in the part.

5.4 Incremental Depth Passes

One of my personal rules is to avoid hogging out large volumes of Urethane in a single pass. Even if you have a powerful CNC mill, the risk of melting, smearing, or material warpage is too high. Instead, I’ll program multiple passes, each removing a manageable layer. Yes, it can add cycle time, but it also prevents catastrophic tool clogging.

5.5 Dealing with Stringy Chips and Gummy Residue

Even with the best parameters, you might see stringy swarf or gummy residue on the cutter. I keep a stiff nylon brush near the machine to clear off any material buildup between passes (with the spindle stopped, of course). If the problem persists, it’s a sign I need to tweak speeds, feeds, or temperature control.

I recall a time I was turning a Urethane cylinder for a custom roller project. Midway through, I noticed fine threads of Urethane wrapping around the part. The fix was simple: I reduced the feed rate slightly and aimed an air blast at the contact point. Those threads disappeared, and I got a nice, smooth finish.

5.6 Polishing and Finishing

Often, customers want a clean, polished look for their Urethane parts. Urethane doesn’t buff up like metal, but you can still achieve a pleasing finish:

- Fine Grit Abrasives: For lathe-turned parts, I’ll sometimes use 400–600 grit sandpaper at low speed.

- Polishing Compounds: Certain mild plastic polishing compounds can help, though I recommend testing on a small surface first.

- Avoid Excess Heat: Hand polishing can generate friction, so move lightly and frequently check the temperature.

5.7 Avoiding Common Pitfalls

Below is a short list of mistakes I’ve made or seen others make. I hope it saves you some time:

- Pushing Too Hard: High feed rates can cause tearing or dragging.

- Skipping Tool Maintenance: A dull tool is a surefire way to create friction.

- Excessive Clamping Force: Soft Urethane can deform, leading to inaccurate cuts.

- Ignoring Hardness Variation: If you switch from Shore A 70 to Shore D 60, you need to adjust parameters accordingly.

5.8 Combining Machining with Molding

One strategy I’ve used in prototyping is partially molding a part, then machining critical features. For example, if I need a complex Urethane shape with tight tolerances on just a few faces, I’ll cast the rough geometry in a simple mold. Then I’ll take that cast piece to the CNC mill for finishing. This hybrid approach can be more efficient than trying to machine everything from a solid block, or alternatively, creating a complex multi-part mold.

5.9 Personal Experience: A Case of Conveyor Rollers

There was a memorable job I did for a friend who runs a small production line. He needed custom Urethane rollers that could tolerate constant contact with oily metal parts. We chose a mid-range Shore D 50 material for durability. In the beginning, I tried turning them at too high an RPM. That created a bizarre swirl pattern, and the material started to smear.

I dropped the RPM by half, used a sharper insert, and introduced an air blast aimed directly at the tool tip. The transformation was instant. The rollers came out beautifully, with a consistent diameter and a smooth surface finish. My friend was so impressed that he asked for additional modifications, like adding a small groove for an O-ring. That experience taught me the value of carefully fine-tuning your approach.

5.10 Troubleshooting Guide

Sometimes, you’ll run into issues that aren’t solved by just slowing down. Here’s my quick troubleshooting table:

| Symptom | Possible Causes | Suggested Fixes |

|---|---|---|

| Melting or Smearing | High spindle speed, dull tool, poor chip evacuation | Reduce RPM, use sharper tool, add air blast or light coolant |

| Tear-Out or Ragged Edges | Excessive feed rate, tool geometry not ideal | Lower feed, use a higher rake angle tool, consider climb milling |

| Material Deformation | Clamping too tightly, too aggressive pass depth | Use softer clamps or vacuum fixture, reduce depth of cut |

| Gummy Buildup on Tool | Heat accumulation, insufficient chip clearance | Provide constant air, reduce friction, pause to clean tool |

| Uneven Surface Finish | Inconsistent feed or spindle speed, runout | Check machine calibration, keep speeds/feeds consistent, ensure tool holder cleanliness |

5.11 My Final Thoughts on Best Practices

Urethane machining is a dance. You have to find the rhythm between speed, feed, cooling, and tool geometry. When everything aligns, it’s a satisfying process that yields robust, flexible parts. But if something is off—like a dull tool or too much heat—you’ll immediately see (and possibly smell) the consequences.

In the next chapter, I’ll highlight some real-world use cases that illustrate these best practices in action. I’ve been fortunate to work with Urethane in automotive, industrial, and even consumer product contexts, so I’ll share some behind-the-scenes details. Stay tuned.

Real-World Use Cases for Urethane in Modern Manufacturing

Whenever someone asks me if Urethane is really worth the extra effort to machine, I point them to a few standout examples I’ve seen in the field. Over the years, I’ve encountered Urethane in everything from high-performance automotive components to specialized industrial equipment. It’s not a one-size-fits-all solution, but it does shine in certain scenarios where its unique balance of elasticity, durability, and chemical resistance provides an edge.

6.1 Urethane in the Automotive Sector

I first got introduced to Urethane bushings in an automotive workshop. A friend was restoring an old muscle car, and he swapped out the stock rubber suspension bushings for Urethane upgrades. The difference was day-and-night. The car’s suspension felt tighter, more responsive, and it held alignment better through corners.

- Performance Bushings: These bushings resist deformation, which can improve handling. They also last longer, often surviving years of punishment without splitting or tearing like rubber might.

- Engine Mounts: Some performance tuners replace rubber engine mounts with Urethane versions. It transfers torque more efficiently but can introduce a bit more vibration.

- Seals and Gaskets: Automotive fluids, like oils and coolants, tend to degrade certain plastics over time. Urethane formulations can stand up to those environments, making them a go-to choice for specialized seals.

I remember once being asked by a local car enthusiast club if I could custom machine a set of Urethane mounts for an old pickup truck that had no off-the-shelf replacements. It was a rewarding project that showed me how critical custom Urethane parts can be for older vehicles, too.

6.2 Packaging and Material Handling

In packaging facilities, I’ve seen Urethane rollers and belts that outperform traditional rubber or PVC-based solutions. The reason is simple: constant friction, impact, and exposure to cleaning chemicals wear down inferior materials. Urethane, with its abrasion resistance, stands up better.

- Conveyor Rollers: Urethane-coated rollers offer a sweet spot of friction (enough to grip packages) while maintaining resilience. If you’ve ever visited a large fulfillment center, you might have spotted bright orange or yellow Urethane rollers moving boxes around.

- Gripper Pads: Robotic arms that pick and place items sometimes incorporate Urethane pads on their grippers. The elasticity helps maintain a stable grip without marring the product.

- Protective Bumpers: Equipment guards or bumpers in packaging lines often use Urethane to absorb shocks, protecting both machinery and products.

A few years ago, I worked briefly in a packaging plant to troubleshoot why their rubber rollers were failing. They switched to Urethane and immediately saw a reduction in downtime. The maintenance manager was thrilled because even a single hour of downtime cost them thousands of dollars.

6.3 Industrial Machinery and OEM Parts

Urethane has a significant presence in heavy machinery and OEM parts manufacturing. Large presses, stamping machines, and other industrial equipment often incorporate Urethane parts to absorb impact and reduce vibration.

- Press Brake Dies: Urethane dies or die films can help bend metals without scratching or marring the surface. This is especially handy for aluminum or stainless steel that needs a pristine finish.

- Vibration Dampening: Some equipment bases incorporate Urethane mounts to reduce noise and movement.

- Springs and Bumpers: In stamping operations, Urethane springs are used in certain tooling setups because they can handle repeated compression without taking a set.

I recall a visit to a large press shop where they showed me Urethane bumpers designed to cushion the final impact of a die closing. It was fascinating to see how effectively the material handled the stress, cycle after cycle.

6.4 Medical Devices and Lab Equipment

While not as common as silicone or thermoplastics in medical devices, Urethane does pop up in specialized applications. I had a chance to see this in action when I toured a small medical device prototyping lab.

- Patient Positioning Pads: Radiation therapy tables sometimes use custom-shaped Urethane pads to position patients comfortably and precisely. Urethane’s softness and shape-memory characteristics can improve patient outcomes.

- Lab Handling Equipment: Automated pipetting stations might use Urethane seals or gaskets because of chemical resistance to certain reagents.

- Orthopedic Components: In some rehabilitative equipment, Urethane handles repetitive stress and offers shock absorption.

The thing that struck me was the variety of hardness levels. They had super soft, gel-like Urethane pads for comfort, and stiffer sections for support. It was all in one piece, thanks to dual-durometer molding techniques.

6.5 Consumer Products

Urethane’s not just for heavy machinery and industrial settings. You’ll also see it in various consumer goods, often chosen for its combination of elasticity and toughness.

- Sporting Goods: Skateboard wheels are a classic example. Back when I was a kid, I remember my older brother swapping out the default wheels on his board for bright green Urethane ones that gave a smoother ride.

- Footwear Components: Certain shoe soles or inserts use Urethane foams for cushioning.

- Mobile Accessories: Cases or covers for smartphones and tablets sometimes incorporate Urethane layers for shock absorption.

I personally find it interesting that the same material I see in conveyor rollers is also used in everyday consumer products. It speaks to the adaptability of Urethane across wide-ranging industries.

6.6 Prototyping and Short-Run Production

One area where I’ve personally used Urethane extensively is rapid prototyping. Sometimes, you don’t want to commit to a full injection mold, especially if you’re only producing a handful of parts. By machining or casting Urethane, you can get functional prototypes that mimic final production materials without the massive upfront tooling costs.

- Custom Fixtures: I’ve machined small Urethane fixtures for testing mechanical assemblies. The fixtures needed to be slightly flexible to accommodate minor misalignments, which would be impossible with rigid metals or plastics.

- Product Mock-Ups: If you’re designing a consumer product that will ultimately use injection-molded TPU or TPE, you can get a feel for how a flexible polymer might behave by machining a block of comparable Urethane.

- Low-Volume Parts: Small batches (hundreds rather than thousands) can be more cost-effective to machine out of Urethane blocks than to create a steel mold.

6.7 Field Experiences and Anecdotes

I want to share two stories that highlight the real-world versatility of Urethane.

6.7.1 Custom Quarry Equipment

About a year ago, I was called to consult on a project for a small quarry. Their metal screens used to separate gravel sizes were wearing out quickly. We experimented with Urethane screen panels, which cost more initially but lasted significantly longer under abrasive conditions. The maintenance foreman reported that they recovered the cost in less than six months because they weren’t constantly shutting down to replace screens. That practical ROI story really stuck with me.

6.7.2 Personal Adventure: Off-Roading

I’m a fan of off-roading. My 4×4 truck is fitted with custom suspension parts, including coil spring spacers and bump stops made from a high-durometer Urethane. After I machined those components, I took the truck out to some rough terrain. It handled bumps much better than the stock system, and the parts have held up for over a year without any significant wear. It’s one thing to read about Urethane’s durability on a spec sheet, but experiencing it firsthand on rocky trails was awesome.

6.8 Tabular Overview: Urethane Use Cases and Benefits

Below is a concise table summarizing several industries and the key benefits of using Urethane.

| Industry | Common Urethane Applications | Key Benefits | Why Urethane? |

|---|---|---|---|

| Automotive | Bushings, mounts, gaskets, engine dampers | Durability, reduced deformation, chemical resistance | Replaces rubber for tighter handling, longer life |

| Packaging/Material Handling | Conveyor rollers, gripper pads, bumpers | Abrasion resistance, shock absorption | Lower downtime, improved part lifespan |

| Industrial Machinery | Press brake dies, shock absorbers, springs | Impact absorption, non-marring surfaces | Protects metal, withstands repeated impact |

| Medical/Lab | Positioning pads, lab seals, device components | Elasticity, chemical resistance | Comfort for patients, tolerance of chemicals |

| Consumer Goods | Skateboard wheels, shoe soles, phone cases | Shock absorption, durability | Enhanced user experience and product lifespan |

| Construction/Mining | Screen panels, wear liners, custom molded parts | Abrasion resistance, extended lifespan | Reduces maintenance, handles rough environments |

| Electronics | Protective cases, shock mounts for sensitive parts | Vibration dampening, insulation | Protects components from impact and moisture |

| Marine/Boating | Dock bumpers, fenders, flexible seals | Saltwater resistance, UV stability (with additives) | Durable alternative to rubber in harsh environments |

6.9 A Glimpse into Future Applications

I believe we’ll see Urethane carving out space in emerging technologies. Additive manufacturing might pave the way for direct 3D printing of Urethane-like materials, allowing complex geometry that can then be post-machined for precision. Additionally, with sustainability and recycling on everyone’s mind, some companies are exploring bio-based polyols in Urethane formulations to reduce environmental impact.

6.10 Conclusion for Real-World Use Cases

Every time I visit a manufacturing site, I’m surprised by the different ways Urethane is being applied. From heavy industrial machinery to consumer electronics, it manages to bridge the gap between rigid plastics and elastomers. Its unique combination of flexibility, resilience, and chemical tolerance opens the door to solutions that other materials simply can’t match.

And the best part? If you’ve read the previous chapters, you know that even though Urethane requires special attention during machining, it’s more than feasible with the right tools and parameters. That means you’re not limited to just casting methods—CNC machining can yield custom, high-quality parts tailored to unique project requirements. In the next section, I’ll wrap up with a final overview of key takeaways and then we’ll move on to our extended FAQ to address any lingering questions.

FAQ:

FAQ 1: Can Urethane be machined with the same CNC equipment used for metals?

Absolutely. I use the same CNC mills and lathes for Urethane that I do for aluminum or steel. The key is adjusting speeds, feeds, and tooling. Urethane’s elasticity means you have to slow down and keep temperatures low. But there’s no need to buy specialized machines solely for Urethane.

I remember a time when a colleague insisted we needed a special “soft material” mill. We tried standard equipment first, made some parameter tweaks, and got great results. As long as your machine is in good shape, there’s no reason you can’t do top-notch Urethane work on it.

FAQ 2: What’s the difference between thermoplastic Urethane (TPU) and thermoset Urethane when it comes to machining?

Thermoplastic Urethane (TPU) can be softened by heat, then hardened again when cooled. Thermoset Urethane, once cured, doesn’t melt or reshape the same way. In my experience, thermoplastics can be more prone to melting or smearing if you generate too much friction. Thermosets often have slightly higher thermal stability but can still exhibit gumming if you push the speeds too far.

If I had to generalize, TPU requires extra attention to cooling and slower spindle speeds. Thermoset Urethane can sometimes handle a bit more aggressive approach, but it’s not a night-and-day difference. Always test small samples.

FAQ 3: Is Urethane machining dangerous for operators or the machine itself?

Not inherently, as long as you follow standard machining safety protocols. I always wear eye protection because stringy chips can fly around. Use gloves if you’re handling large, soft pieces that might cause pinch points. In terms of the machine, the main concern is preventing buildup on the tool or in the collet.

Also, some Urethane blends emit fumes if they overheat, so ensure proper ventilation. I haven’t found it to be significantly more hazardous than working with other plastics or soft metals, but always check the safety data sheet (SDS) for your specific formulation.

FAQ 4: How do I prevent Urethane from melting or fusing onto the cutter?

Heat is your number one enemy. Slow your spindle speed, reduce feed if necessary, and use air blasts or light mist coolant. Keep your cutter sharp. Any sign of dullness will cause friction, which leads to heat buildup and melting.

I sometimes pause the job briefly to let the material cool if I sense things are getting too hot. It might not be ideal for cycle time, but it’s better than scraping a part that’s fused into a solid blob around your tool.

FAQ 5: Which tool coatings, if any, work best for cutting Urethane?

I’ve had the most success with uncoated or lightly coated carbide tools. High friction coatings, like TiAlN, can sometimes raise temperatures, which is the opposite of what you want. A diamond-like carbon (DLC) coating might help with abrasion, but honestly, a sharp uncoated edge usually performs just fine for Urethane.

When I tested various coatings on a CNC router, I saw minimal improvement over plain carbide. If your tool is extremely sharp, that often matters more than any special coating.

FAQ 6: Can I laser cut Urethane?

Yes, but it depends on thickness and the specific grade of Urethane. Thin sheets (maybe up to 0.25 or 0.5 inch) can sometimes be laser cut, though the edges might show signs of charring or melting. I’ve personally seen this done on a CO2 laser for gaskets, but you need to test carefully.

Thicker sections tend to distort or burn. Waterjet is often safer and cleaner for thick or multi-layer Urethane. If laser is your only option, start with low power, high speed, and be prepared for edge discoloration or potential smoke/fume generation.

FAQ 7: What’s the best way to clamp or hold soft Urethane on a CNC mill?

I prefer custom soft jaws or 3D-printed fixtures designed for the part’s geometry. Vacuum tables can work for flat sheets, but the suction might deform extremely soft Urethane. Clamping pressure must be gentle. Sometimes, I’ll sandwich the part between two sacrificial plates to spread out the force.

A friend of mine once used double-sided tape for small, lightweight Urethane pieces. This can be risky for deeper cuts, but for light passes, it’s a simple solution. Test your setup to ensure no shifting occurs mid-cut.

FAQ 8: How can I achieve a polished or smooth surface finish on machined Urethane?

First, dial in your speeds and feeds to minimize tearing. Then, consider a finishing pass at a slower feed. Afterward, you can lightly sand with fine-grit abrasives (400–600 grit) or use a plastic polishing compound. Just watch for heat if you’re using power tools to polish.

I’ve even used a buffer wheel on some cylindrical Urethane parts. It wasn’t perfect, but it removed minor tool marks. Always keep an eye on temperature because friction-based polishing can create heat.

FAQ 9: Does machining Urethane require different CAD/CAM strategies?

The primary difference is how you choose step-downs, stepovers, and feed rates. In your CAM software, you might reduce the feed and step-down. You might also incorporate more finishing passes. But the geometry strategies themselves (like pocketing, contouring, or 3D surfacing) don’t drastically change.

What I do is label these toolpaths as “Urethane Ops” in my CAM so I remember to keep speeds conservative. Also, you can simulate a toolpath to watch for areas where the cutter might stay engaged too long, which could lead to extra heat buildup.

FAQ 10: Are there specific brand recommendations for Urethane rods, sheets, or blocks?

Brand preference often depends on local availability. I’ve worked with manufacturers like Argonics, Polyurethane Products, and Redwood Plastics for sheets and rods. I also source custom formulas from specialized suppliers who tailor hardness to my project.

When choosing a brand, ask about recommended machining guidelines. Some producers have detailed PDFs with speed and feed suggestions, or they might offer free samples for testing.

FAQ 11: How do I know which Shore hardness is right for my project?

It boils down to application requirements. Softer Shore A materials are great for cushioning or seals that need flexibility. Mid-range Shore D (40–60) can handle moderate wear and impact. High Shore D (70+) approaches rigid plastic behavior.

When I’m unsure, I test multiple hardness levels. For instance, I needed custom rollers for an assembly line. I ordered small test samples in Shore A 90, Shore D 50, and Shore D 60. After quick prototypes, I settled on Shore D 50 because it gave the best combo of wear resistance and slight elasticity.

FAQ 12: Is it cost-effective to machine Urethane compared to molding it?

This depends on quantity and complexity. Molding can be cheaper for high-volume runs, especially if the part is simple. However, molds can be expensive to create. If you only need a few hundred parts, machining blocks of Urethane might be more economical.

I’ve seen companies use a hybrid approach: cast the basic shape with minimal complexity, then machine the critical features. This often strikes a balance between mold cost and machining time.

FAQ 13: Will coolant or certain cutting fluids degrade the Urethane during machining?

Some Urethane formulations can swell if exposed to certain fluids for extended periods. I typically rely on minimal lubrication—like an air blast or a small mist of water-soluble coolant. If in doubt, consult the supplier’s chemical compatibility chart.

I once used a heavy oil-based coolant that discolored the Urethane slightly. It didn’t ruin the part’s function, but the client wanted a uniform appearance. After that, I stuck to lighter or water-based coolants unless I had verified compatibility.

FAQ 14: What should I do if the Urethane part warps or deforms after machining?

Warping can happen if there’s internal stress or if the material experiences uneven heating. One approach is to “stress-relieve” the block by letting it rest at a stable temperature before machining. Another is taking lighter cuts so you don’t overheat any section.

I’ve occasionally let freshly machined parts rest overnight to see if they return to a slightly different shape. If they do, I’ll perform a final finishing pass to refine the dimensions. Slowing down and reducing heat usually prevents major warping.

FAQ 15: Can I 3D-print Urethane and then machine it afterward?

Yes, if you’re using a 3D printer capable of working with flexible filaments that mimic Urethane-like properties. After printing, you can lightly machine or sand to achieve certain dimensions or surface finishes. Be warned that 3D-printed Urethane parts might have layer lines or internal voids that affect machining.

I once tried post-machining a TPU print to add threaded holes. It worked, but the layered structure meant it wasn’t as smooth as a molded or solid Urethane block. For functional prototypes, though, it can be a viable approach.

FAQ 16: Are there environmental or disposal concerns with Urethane waste?

Urethane, like many polymers, is not biodegradable in its typical industrial formulations. Machining chips or scrap usually end up in landfill unless you find a recycling service that specifically handles polyurethane. Some specialized programs can regrind or repurpose certain forms of Urethane waste.

I’m personally interested in the emerging field of bio-based polyols that might make Urethane more eco-friendly. For now, check local regulations. If your area has facilities for plastic recycling, they might accept certain Urethane scraps, but it’s not always guaranteed.

FAQ 17: Do I need special dust collection for Urethane chips?

Urethane chips aren’t as hazardous as glass-filled materials or carbon fiber. Still, fine Urethane dust can get sticky if it melts slightly. A general dust collector or vacuum system is often enough. I personally keep a shop vac nearby and use it between passes if needed.

Always confirm that your dust collection setup can handle soft, fibrous chips. A clogged filter can reduce suction. If you’re generating large chips from milling or turning, they’re usually manageable with typical chip evacuation methods.

FAQ 18: Any final words of wisdom for someone new to machining Urethane?

Take it slow. Test small pieces. Keep the material cool. Use sharp tools with the right geometry. Embrace incremental depth passes. And don’t be discouraged if you get melting or gumming on your first attempt. Every Urethane grade reacts a bit differently. Once you find the sweet spot, you’ll discover that Urethane can solve a lot of engineering challenges.

Also, ask suppliers for advice. They often have data sheets or recommended machining parameters. Staying curious and open-minded makes a world of difference.

References & Further Reading

- Wikipedia: “Polyurethane.”

https://en.wikipedia.org/wiki/Polyurethane

Offers a broad overview of Urethane’s chemical structure, manufacturing methods, and main applications. - Wikipedia: “Elastomer.”

https://en.wikipedia.org/wiki/Elastomer

Explains the broader category of elastomers and how Urethane fits into this family of flexible polymers. - Wikipedia: “Machining.”

https://en.wikipedia.org/wiki/Machining

Covers general machining principles, relevant to how we adapt speeds, feeds, and tools for Urethane. - Encyclopedia Britannica: “Polyurethane.”

https://www.britannica.com/science/polyurethane

Delves into the history and development of polyurethanes, plus key chemical properties and industrial uses. - Engineering Toolbox: “Polyurethane – Mechanical Properties.”

https://www.engineeringtoolbox.com/polyurethane-mechanical-properties-d_796.html

Lists data on tensile strength, hardness ranges, and other details that help inform machining strategies. - PubChem: “Polyurethane.”

https://pubchem.ncbi.nlm.nih.gov/compound/Polyurethane

Provides molecular structure information, safety data, and chemical property details from a reputable scientific database. - ScienceDirect Topics: “Polyurethane.”

https://www.sciencedirect.com/topics/engineering/polyurethane

Contains academic and technical articles discussing polyurethane formulations, properties, and processing methods. - Wikipedia: “Elastomeric Polyurethane Foam.”

https://en.wikipedia.org/wiki/Polyurethane_foam

Useful if you’re specifically interested in foam applications, though many machining considerations overlap with solid Urethane forms.

Other Articles You Might Enjoy

- How to Cut, Drill, and Modify ABS Pipe Using CNC Machines

Introduction ABS pipe is everywhere—from plumbing systems to DIY projects, from prototypes to structural parts in lightweight assemblies. But recently, I’ve noticed a growing trend: people want to take their…

- Polyester Resin in Industry: How It’s Used in Manufacturing, 3D Printing, and Composites

Chapter 1: Introduction – What is Polyester Resin? Polyester resin is a widely used synthetic material composed primarily of unsaturated polyester dissolved in styrene monomer. It’s well-known for its versatility,…

- Polyester Material in Modern Manufacturing: Applications, 3D Printing And Machining

Introduction: The Role of Polyester Material in Modern Manufacturing I still remember the first time I stumbled upon polyester material in a manufacturing setting. I had this preconceived notion that…

- How to Machine Polypropylene Material: A Complete Guide for CNC & Fabrication

I chose this title because I want to give a comprehensive yet approachable look at Polypropylene Material and how it’s best machined using CNC methods and other fabrication techniques. Over…

- Hemiacetal vs Acetal: Understanding Chemistry, Key Properties, and Best Machining Practices

Why "Hemiacetal vs Acetal" Matters in CNC Machining In my years of experience in the field of materials science and CNC machining, I've had the opportunity to work with a…

- Nylon Material Properties and Applications in CNC and Other Machining Methods

I chose this title because I believe it captures the essence of what we’ll explore: the fundamental properties of nylon material, its applications, and especially its role in CNC and…

- In-Depth Analysis of Nylon 66: Machining Properties and Applications

Introduction I want to share my personal experiences and observations regarding the remarkable material called Nylon 66. I’ve seen plenty of engineering plastics throughout my career, and each has its…

- Hard Plastic Sheets Explained For Makers And Machinists: Which One Is Right for Your Project?

Chapter 1: Introduction I've worked in manufacturing and DIY fabrication for years, frequently handling all types of materials. Among these, hard plastic sheets consistently proved versatile and reliable for various…

- Master CNC Machining with ABS Plastic Sheet: Tools, Tips, and Techniques

Introduction: Mastering CNC Machining with ABS Plastic Sheet When it comes to CNC machining, the choice of material can make or break a project. ABS plastic sheet is one of the most…

- Nylon CNC Machining Service for Custom Parts

Nylon is an engineering plastic known for its high strength, wear resistance, and chemical inertness. It possesses excellent mechanical properties and durability, making it widely used in various fields including…