Although the tool marks on metal parts made using CNC machining services can be visually appealing, there may be cases where additional processing is required. You have many options to enhance the functionality and aesthetic appeal of parts. The article can help you choose the right one for you.

Anodizing

Anodizing can be used to increase the thickness of the oxide layer on metal parts. This is most commonly used for CNC aluminum parts. Anodizing is a process that serves both cosmetic and functional purposes. It forms a protective layer on the part’s surface to prevent corrosion and scratching.

There are two types of aluminium anodizing.

Type II provides corrosion protection and is approximately 0.001 inches thick. This means that part dimensionality remains virtually unchanged. It also offers a wide range of colour options.

Type III, also called hard anodizing or hard anodizing, is thicker (up to 0.006″) and provides more protection, but it has a limited colour palette, often clear or black.

Heat Treatment

Although there are many types of heat treatment, they all involve heating metal in different ways to modify its properties at different times.

Most heat treatments used on finished parts (mostly steel) increase the hardness. This can be desirable for many reasons, such as wear resistance or long-term dimensional consistency.

Heat treatment can also leave part surfaces with a dull gray finish.

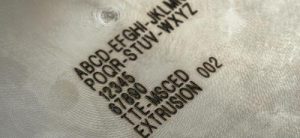

Laser Etching

Laser engraving or laser etching works by using lasers. These high-frequency lasers can mark parts with text, symbols, or other patterns. You can easily etch most metals and other materials by tuning your laser.

This process can be used to identify parts by assigning serial numbers. Laser etching can also be used on anodized parts. It will remove the protective layer and expose the metal beneath. This is great for creating high-contrast logos and patterns that stand out.

Media blasting

This cosmetic finishing technique gives metal parts a matte appearance.

Media blasting may refer to a variety of small granular materials, such as glass beads and aluminum oxide (sand). The material is fired at high speeds to create a texture on the surface. In most case, the machining manufacturer use a handheld spray nozzle so that the finish isn’t always as consistent as automated blasting during mass production runs.

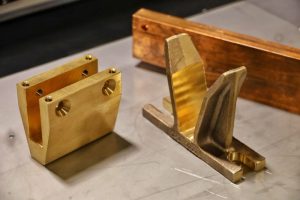

Plating

A plating process is coating a metal part with a thin layer of another metal, or an alloy, to prevent corrosion and oxidation or improve its aesthetic appearance. All common plating metals include Zinc (galvanizing), Chrome, Tin, Nickel, copper, and carbon steel.

Polishing

Next, polishing is the final step in terms of surface refinement. To give a part’s surface a mirror finish or extra fine finish, polishing uses a soft applicator or buffing wheel. This process can be used to improve the optical clarity and reflectivity of parts as well as smoothen machined grooves and other features that are useful for sealing purposes.

Although many metals can be polished with complex geometries, reaching all surfaces cannot be easy. It can also be expensive to polish harder metals like 316 and 304 stainless steel.

Parts can also be tumbled as an alternative to hand polishing or sanding. They are placed in a rotating drum with or without abrasive media. The drum rotates the parts over long periods to give them a polished surface. Although this method cannot be used for selective finishing and is not possible to achieve high levels of polish, it is often more cost-effective as parts can be tumbled in large batches without the need for operator supervision.

Powder Coating

Parts can be powder coated using different electric potentials to apply a dry polymeric powder.

The parts to be coated must first be grounded electrically. Next, powder is sprayed using an electrostatic gun or any other source that induces a positive charge. This causes it to stick to it. The coated part is then heat-cured. Protective coating is available in many colors.

Sanding

Sanding is one of the most basic metal finishing methods, but it can also be used for cosmetic finishing. You can quickly remove tool marks by sanding a metal piece with medium or heavy-grit sandpaper. Gradually working the part with finer grits will produce a smooth, uniform, and lustrous finish.

Remember that the harder the metal is, the more time it takes to sand. Steel can be expensive if you aren’t the one doing the work.

Conclusion

Many of the metal finishes can be used together. An aluminum part can be polished or bead-blasted to achieve the surface finish you need. Then it could be anodized to protect against corrosion and color. Finishing is best when there are large quantities of parts. Each finish requires attention to detail.

It may be a good idea to skip some processes during functional prototyping until your design is more refined. Although it can take some time to understand all the options for finishing, once you have prototyping with metal for a while, you will likely find that you need many of them.

Going for several testing before the final decision is always recommended. If your design requirements permit it, don’t be afraid of trying a new finish. You might discover new aesthetic and functional benefits that you didn’t know about!

Other Articles You Might Enjoy

- The Ultimate Guide to Metal Surface Finishes

Part production requires metal surface finishing. Quality metal surface finishing will make any part look better, no matter how well it is finished. There are many types of metals. Welder…

- Aluminum CNC Machining Service for Custom Parts

Aluminum CNC machining stands at the forefront of modern manufacturing, epitomizing precision, versatility, and efficiency. With its widespread applications across industries ranging from aerospace to automotive and beyond, aluminum CNC…

- CNC Milling Definition | Types | Process for Custom Metal Parts (2023)

According to a report published on 30 January 2023, CNC milling services requirement will cross US$ 110,203 millions by 2033. It is due to the increasing demand in the food,…