The advent of 5G technology is ushering in a fully connected and intelligent world, driving continuous innovation and transforming the future into a digital realm that involves everyone. Want.Net, a prominent player in the 5G technology arena, showcased their vision, intelligence, and exploration of the challenges posed by the connected smart world at the Mobile World Congress held in Barcelona, with the theme of “the Digital Village.”

Enabling 5G’s Global Reach

During the Huawei Day0 Forum, Olaf Swantee, CEO of Sunrise, Switzerland’s leading telecommunications provider, expressed his optimism about the smooth progress of Sunrise 5G, stating that Switzerland will soon launch commercial 5G services in over 150 cities across the country.

Moreover, CEO of Monaco Telecom, Martin Peronnet, signed a Memorandum of Understanding with Huawei France to enhance the planning process for building a “Smart Nation” in Monaco, aimed at establishing Monaco as a 5G-powered smart nation.

Revolutionizing Infrastructure for 5G

The need to rebuild existing facilities for 5G arises from the unprecedented download speed offered by this new technology. With 10Gbps download speeds, traditional Wi-Fi and even the current 4G networks, which typically offer speeds of 1Gbps, are inadequate. The current infrastructure falls short in meeting the demands of 5G, especially when multiple users require speeds of 10Gbps simultaneously. As a result, comprehensive infrastructure upgrades, including the expansion of machine rooms, are imperative.

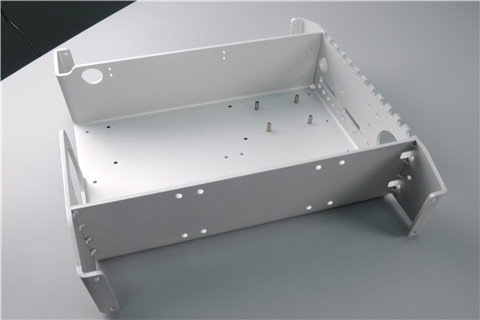

To accomplish these upgrades, a significant amount of precision machining is required. This entails redesigning and testing various industrial parts, a process that spans from the prototyping stage to mass production. Sheet metal fabrication plays a crucial role in this process, involving the creation of precision metal parts, such as steel covers and aluminum enclosures with different finishes, including powder coating.

Sheet Metal Fabrications for 5G Infrastructure

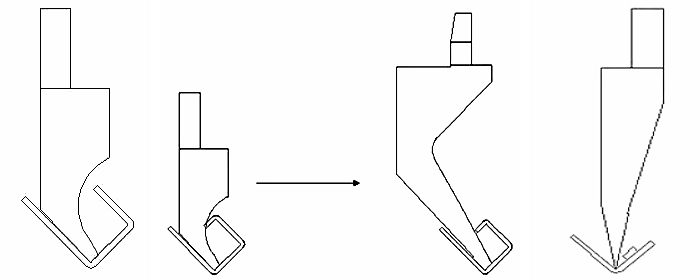

Sheet metal fabrication entails a range of techniques, including laser cutting, sheet metal bending, and wire cutting for creating intricate ribs on parts. The choice of bending tools depends on the desired part shape.

- The straight tool is suitable for machining structures without any surrounding undercuts. However, if there are nearby details, the tool selection needs careful consideration.

- In cases where undercuts are present, different bending tools, such as small and large curved tools, are utilized. Moreover, obstacles on the part can be addressed using sharp tools.

Sheet bending is a crucial technology, and with precise control, the bending process ensures the quality of the parts, preventing deformation issues and maintaining tolerances.

CNC Machining of Aluminum Cases for Smart Devices

Precision machining in CNC (Computer Numerical Control) involves two main processes: wire cutting and Electrical Discharge Machining (EDM).

- Wire cutting enables the production of various parts from conductive materials such as aluminum, copper, and graphite using an electrical spark. It offers flexibility and precision in creating complex shapes.

- EDM technology offers extreme accuracy and high cutting speeds, allowing for the production of delicate parts. It serves as an alternative to milling, turning, grinding, lathing, or broaching, offering cost-effective manufacturing options.

EDM is also employed to machine metal undercuts, as it overcomes the limitations of gluing found in plastic parts. By using a brass tool to electrically discharge the material, the EDM process effectively and gradually shapes the metal parts.

EDM resolves several challenges encountered during precision CNC machining, such as the hardness of metal workpieces. Traditionally, metal workpieces are made from special grades of hardening tool steels, machined in a soft state to facilitate cutting.

To maintain stable electrical thresholds during the EDM process, clean dielectric fluid is continuously pumped through the cutting zone. The presence of conductive particles in the fluid affects the machine’s ability to maintain stable electrical thresholds, necessitating careful management.

For metal cases used as cosmetic covers, surface quality is a primary concern. After the EDM process, the surface may appear rough and black. Manufacturers address this by sanding and smoothing the surface to ensure high-quality finishes. Furthermore, additional post-treatments such as anodizing and powder coating enhance the durability of outdoor parts, covering machining marks and providing improved aesthetics.

Embracing a Future of Precision Machining

As the world continues to evolve, innovation remains ceaseless. The machining technology employed in precision manufacturing must continually advance to meet the evolving needs and specifications of designers. A fully automated and intelligent world awaits, wherein the precision machining process will be devoid of any challenges for designers, truly realizing their ideas.

Mobile 5G technology is poised to ignite an unprecedented wave of innovation. As the next generation of mobile broadband, 5G will eventually replace or augment current 4G LTE connections. The benefits are significant, including exponentially faster download and upload speeds, as well as drastically reduced latency for seamless communication between devices and wireless networks.

With its ability to transform industries and enable groundbreaking applications such as autonomous vehicles, remote healthcare, and smart cities, 5G technology promises to revolutionize the way we live and work. The precision machining techniques discussed here play a crucial role in the development and deployment of the infrastructure required to support the immense capabilities of 5G networks.

The world is on the cusp of an era where connectivity knows no boundaries and innovation knows no limits. As precision machining techniques continue to evolve, we can look forward to a future where the fusion of 5G technology and precision manufacturing will unlock new opportunities and pave the way for a truly connected and intelligent world.

Recommended Reads

- Differences Between CNC Lathes and CNC Mills

- 10 Tips and Tricks to Master CNC Mill Operation

- Top 5 Materials Best Suited for CNC Milling

- 5 Main Types of CNC Machines: A Comprehensive Guide

- Comparing 3-Axis, 4-Axis, and 5-Axis CNC Machining Techniques

Other Articles You Might Enjoy

- Precision Crafting with ABS: Unveiling the World of ABS CNC Machining

1. Introduction: Exploring the Precision Realm of ABS CNC Machining In this opening section, we embark on a journey into the intricate world of ABS CNC machining, introducing readers to…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Precision Prowess: Unveiling the Advantages of China CNC Machining

1. Introduction: The Role of Precision in Manufacturing Excellence In this introductory section, we delve into the critical role that precision plays in manufacturing and set the stage for an…