CNC Machining and the Significance of Precision

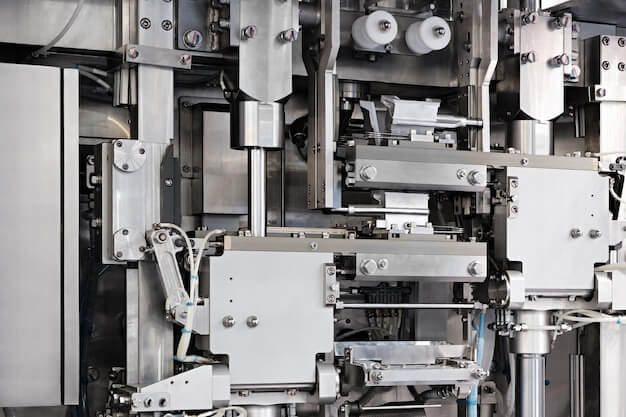

CNC machining is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process is used to control a range of complex machinery, from grinders and lathes to mills and routers. The precision of CNC machining is critical for several reasons:

1. Consistency and Repeatability

CNC machines can produce identical parts consistently, ensuring that each part meets the exact specifications required. This consistency is crucial in industries where precision is paramount, such as aerospace, medical device manufacturing, and automotive.

2. Complex Geometries

CNC machines can create parts with complex geometries that would be difficult, if not impossible, to produce with manual machining. This capability allows for more innovative and efficient designs, which can lead to better-performing products.

3. Efficiency and Productivity

The automation provided by CNC machining reduces the time needed to produce parts. Once a program is created, the machine can run unattended, allowing for continuous production and increasing overall productivity.

4. Minimized Human Error

By relying on computer programming and automation, CNC machining significantly reduces the risk of human error. This leads to fewer defects, less waste, and lower production costs.

5. High Precision and Tolerances

CNC machining can achieve very tight tolerances, which is essential for applications where even the slightest deviation can result in failure. For example, in the aerospace industry, components must fit together perfectly to ensure the safety and performance of an aircraft.

6. Flexibility in Manufacturing

CNC machines can be reprogrammed quickly to produce different parts. This flexibility allows manufacturers to respond to changes in demand and customize products without needing to invest in new machinery.

7. Quality Control

The high precision of CNC machining makes it easier to maintain strict quality control standards. Advanced CNC machines can also include in-process quality checks, further ensuring that each part meets the required specifications.

Applications of CNC Machining

- Aerospace: Production of turbine blades, engine components, and structural parts.

- Automotive: Manufacturing of engine parts, gearboxes, and custom car parts.

- Medical Devices: Creation of surgical instruments, implants, and prosthetics.

- Electronics: Fabrication of housings, connectors, and circuit boards.

- Industrial Equipment: Production of molds, dies, and tools.

Understanding Material Uniformity in CNC Machining

In the world of Computer Numeric Control (CNC) machining, material uniformity refers to the consistent condition and specifications of a material utilized to create components. This essentially means that all sections of the material have the same composition, density, hardness, and other properties. Achieving this consistency is crucial as non-uniform materials can considerably alter the outcome of the CNC machining process.

A lack of material uniformity often leads to issues such as inconsistency in tool life, unpredictability in machine behavior, inferior surface finish, dimensional inaccuracies, or even part rejection. For instance, if your component is created from metal with variable hardness levels throughout, certain areas might wear down the cutting tool faster than others, leading to inconsistent finishes across the piece. Similarly, variations in material density could lead to unpredictable distortions during the heat-treating process or uneven shrinkage in castings.

- Case Example: In aerospace applications, where precision is critical, utilizing a metal alloy with perfect uniformity for engine parts will result in high-quality products with exceptional sectional consistency and performance reliability. This not only enhances product longevity but also reduces potential failures, delivering superior-value outcomes for both businesses and consumers.

Role of Material Selection in Precision CNC Machining

Material selection plays a crucial role in achieving precision in CNC machining. Here are some key points to consider:

- Material Uniformity: Ensuring material uniformity is essential for precision CNC machining. Uniform materials have consistent properties throughout, which helps maintain dimensional accuracy and surface finish.

- Material Selection Criteria: When selecting materials for precision CNC machining, several criteria should be considered, including machinability, dimensional stability, thermal conductivity, and mechanical properties. These factors directly impact the precision and quality of the final machined parts.

- Machinability: Choosing materials with good machinability is important for precision CNC machining. Materials that are easy to machine result in smoother cutting, reduced tool wear, and improved dimensional accuracy.

- Dimensional Stability: Materials with high dimensional stability are less prone to warping or distortion during machining processes. This is crucial for achieving precise and consistent dimensions in the final machined parts.

- Thermal Conductivity: The thermal conductivity of the material affects heat dissipation during machining. Materials with high thermal conductivity help prevent heat buildup, reducing the risk of thermal deformation and improving precision.

- Mechanical Properties: The mechanical properties of the material, such as strength, hardness, and elasticity, impact the performance and functionality of the machined parts. Choosing materials with the right mechanical properties ensures the desired precision and functionality.

By carefully considering material selection criteria and ensuring material uniformity, manufacturers can achieve precision in CNC machining. To explore precision CNC machining services that offer expertise in material selection and precision manufacturing, you can visit our Precision Machining Service.

Consequences of Poor Material Uniformity and Wrong Material Selection

The precision in CNC machining largely depends on the uniformity of material used and its appropriate selection. Potential issues may arise due to incorrect material choice or lack of material uniformity, impacting both product quality and production efficiency. For instance, a non-uniform material can lead to irregular wear on cutting tools resulting in inconsistency in production. On the other hand, inappropriate material selection might cause complications such as inadequate strength or poor surface finish in the final product.

CNC machining industries have witnessed cases where poor precision has led to flawed production due to these reasons. To highlight an example, when a company selected a softer metal for a high-load application, the resulted components failed under pressure leading to costly downtime and rework. Furthermore, another industry experienced inconsistencies in their manufacturing process by using materials with different grain structures, ultimately causing variation in dimensions of machined parts. These real-life experiences underline the critical role played by material uniformity and correct selection in achieving precision through CNC machining.

Solutions for Achieving Precision in CNC Machining

Maintaining material uniformity and making appropriate material selection are two core techniques necessary for achieving precision during the CNC machining process. Material uniformity ensures consistent machine performance and component integrity, this can be maintained by regular inspections, adhering to standardized operating procedures, and using high-quality materials. For example, a Metal Inert Gas (MIG) welder might perform periodic tests on their equipment and workpieces to identify any irregularities early.

- Regular inspections not only assess the state of the raw material but also check the tool wear which significantly contributes to maintaining material uniformity.

- Standardized operating procedures help maintain consistency throughout the production process reducing variability caused by human error or environmental factors.

- Lastly, investing in superior quality base metals plays an instrumental role in minimizing defects that could impact machining precision.

On the flip side, appropriate material selection is determined based on the individual characteristics of each manufacturing project. Key considerations include understanding the requirements pertaining to the hardness, strength, corrosion resistance, and cost-effectiveness of prospective materials. For instance, stainless steel may be preferred for its exceptional durability and anti-corrosion properties in harsh environments, while aluminum alloys might be selected for projects requiring lightweight but strong components.

Assessing Your Needs and Choosing Wisely

Understanding your specific CNC machining needs relative to material uniformity and selection is an essential part of achieving precision in production. The type, size, complexity, and application of the desired final product all play a significant role in determining the most appropriate materials for CNC machining. For instance, if high durability or corrosion resistance is required, you might opt for materials like stainless steel or aluminum. On the other hand, wood or plastic may be suitable for lower-stress applications.

The significance of expert advice in decision making can’t be overstated when it comes to choosing materials. An experienced machinist will typically have extensive knowledge about various material properties, their impact on the machining process, and how they correlate with the final product’s performance. Here are some key considerations:

- Evaluation of design specifications: Understanding end-user requirements, operational environment, load conditions, among others

- Cost-effectiveness: Balancing the project budget while ensuring quality and performance isn’t compromised

- Machining characteristics: Selection based on machineability score that indicates how easily a material can be cut

In conclusion, both self-assessment of your machining requirements and taking expert advice into account form vital grounds for material selection leading to enhanced accuracy and efficiency in CNC machining.

Other Articles You Might Enjoy

- CNC Machining Tolerances and Material Selection: Precision Engineering Insights

Introduction to CNC Machining, Tolerances and Material Selection CNC machining is a prevalent manufacturing process that entails the use of pre-programmed computer software to dictate the movement of factory machinery…

- Elevating Precision Standards through Chamfer in CNC Machining

1. Introduction: The Pursuit of Unparalleled Precision In the realm of CNC machining, precision is paramount. This section introduces the article by exploring the significance of precision in manufacturing and…

- Choosing the Correct Material for High-Precision CNC Gear Machining

Introduction: Understanding CNC Gear Machining and The Importance of Material Selection The precision in gear manufacturing largely depends on Computer Numerical Control (CNC) technology - a systematic procedure implemented to…