Introduction to Bronze and Copper: Machinability and Durability

Bronze and copper are two widely-known metals employed in various sectors, particularly in the manufacturing industry. The term ‘Bronze’ generally refers to an alloy predominantly made up of copper combined with elements such as tin or phosphorus, while copper is a pure element that brings unique flexibility and electrical conductivity. Understanding the machinability – how efficiently these materials can be cut into desired shapes and sizes, including during machining bronze – and durability – the potential to withstand wear, pressure, or damage over time – of these two materials is paramount to determining their suitability for different applications. For instance, minimal tool wear during machining translates to faster production times and lowered costs. Furthermore, great durability means products will have an extended lifespan, thereby ensuring value for money spent. Consequently, these characteristics play a fundamental part in deciding which material is more advantageous to use based on specific industrial needs.

Exploring The Machinability Of Bronze

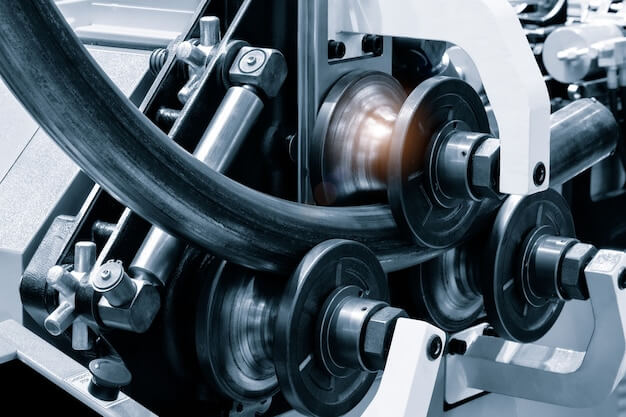

Machinability refers to the ease with which a material can be cut or shaped through machining processes including drilling, cutting, and grinding. It is influenced by factors such as tool wear rate, surface finish quality, cutting forces and power consumption.

Bronze’s machinability is largely dependent on its hardness and melting point, both of which are higher than many other common metals. This implies concentrated force and relatively high levels of heat while machining, leading to a potentially reduced lifespan for machinery tools.

- For example, in a real-world scenario, when bronze bearings used in heavy equipment undergo re-boring, the increased hardness and high melting point of the material puts more stress on the boring bar, often causing it to break down sooner compared to if softer materials were being worked with.

Understanding the Durability of Bronze

Bronze is a sturdy and strong material that is highly durable. It offers excellent resistance to wear and tear, making it suitable for various applications where durability is a key consideration. Compared to copper and brass, bronze stands out for its exceptional durability, making it a preferred choice for components subjected to high levels of stress and friction.

Overview of Copper’s Machinability

Copper, renowned for its high electrical and thermal conductivity, also possesses particular characteristics that affect its machinability. The soft and malleable nature of copper contributes to the material being challenging to machine because it tends to stick on the cutting tool during machining processes. Despite these challenges, using sharp tools with precise cutting edges, faster speeds, and higher feed rates can improve copper’s machinability.

An example demonstrating these aspects might be when milling a copper component. Incorrectly adjusting the machine could lead to smearing or burring due to copper’s inherent properties. Thus, utilizing sharp cutters at swift speeds can produce a smooth finish and enhance the product’s overall quality, showcasing how understanding and manipulating copper’s unique characteristics can improve its machinability.

Assessment of Copper’s Durability

The durability of copper is attributed to its unique characteristics. As a versatile and malleable metal, it has high thermal and electrical conductivity making it ideal for various industrial applications. Moreover, thanks to its excellent corrosion resistance; when exposed to different environmental conditions like air or water, rather than weakens, it forms a protective layer, enhancing its longevity. This particular feature makes copper exceptionally durable.

A defining instance reflecting copper’s superior durability can be seen in the construction industry. Take for example, roofing materials made from copper, which have been known to last over centuries with minimal maintenance – proof of copper’s top-notch durability.

Comparing the Machinability between Bronze and Copper

Machinability of a material includes aspects such as cutting speed, tool life, surface finish quality, power and torque requirements. When examining bronze against copper, there exist distinctive differences in their machinability characteristics. Bronze – an alloy made primarily from copper, tin, and sometimes other elements – is more abrasive due to its hardness, thereby reducing tool life but offering a remarkable surface finish. Copper, on the contrary, provides excellent thermal conductivity, reducing power and torque requirements; however, it poses challenges in controlling surface deformation due to its softness.

- Bronze: High abrasiveness leads to shorter tool life yet achieves superior surface finishes.

- Copper: Ideal thermal conductivity reduces power and torque demands but involves struggles in achieving flawless surface integrity due to inherent softness.

Research data clearly attests that understanding the unique machining traits of both bronze and copper can optimize machining strategies for each metal. One notable study underlines that while bronze tends to wear down cutting tools faster than other materials, investing in high-quality carbide tooling could counteract this effect. For copper, utilizing slower feed rates along with ample coolant proved effective to limit surface deformation during operations. This comparative analysis illuminates the path towards best practices for optimizing the machining process for both metals.

Analyzing the Durability between Bronze and Copper

When it comes to durability, there is a clear distinction between bronze and copper. According to metallurgical studies, bronze offers superior longevity and wear resistance compared to copper.

- Bronze: This alloy of copper and tin demonstrates remarkable toughness in diverse environments. It exhibits high corrosion resistance, making it less prone to rust even with regular exposure to air and moisture. Experts quote, “Bronze can last for thousands of years under various conditions, which speaks volumes about its durability.”

- Copper: Prized for its excellent heat and electric conductivity, copper tends to be softer, making it more susceptible to scratches and wear over time. Relatedly, an empirical study reveals that “Copper, due to its malleability and softness, loses out on the durability aspect when pitted against bronze.”

All these factors contribute to the enhanced durability features of bronze as opposed to copper.

Conclusion: Comparing the Durability and Machinability of Bronze and Copper

In summary, bronze and copper both exhibit distinctive characteristics in terms of their durability and machinability. Bronze, an alloy of copper and tin, surpasses copper in terms of its hardness, strength and durability making it more resistant to wear and tear thus less maintenance-intensive in long term usage scenarios. On the other hand, copper stands out in terms of its excellent thermal and electrical conductivity, malleability and ductility revealing multiple processing options for machining.

In varied scenarios, your choice between bronze and copper will largely depend upon specific application requirements. For instance, in a scenario where high temperature or electrical conductivity is required, copper might be preferred despite its lesser durability. Conversely, in applications necessitating strength, resistance to corrosion and friction such as ship propellers or heavy-duty industrial components, bronze’s superior durability would likely make it the material of choice.

Both materials have their own unique advantages but always remember that understanding the way these metals respond under different conditions will enable you to select the appropriate one for optimum performance.

Other Articles You Might Enjoy

- Choosing Between 304 and 316 Stainless Steel for CNC Machining Applications

Introduction to 304 and 316 Stainless Steel in CNC Machining Applications The selection of the right grade of stainless steel is vital in Computer Numeric Control (CNC) machining applications. Here,…

- Exploring Bead Blasting in CNC Machining(tac welding Victoria)

CNC machining stands for Computer Numeric Control, which is a manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This method can be used to…

- Exploring Bead Blasting in CNC Machining(tac welding Cora)

Bead blasting is an integral process within computer numerical control (CNC) machining that sees extensive usage across various industries because of its ability to create high-quality finishes. Fellows of the…