CNC Lathe Machining Services for Brass Parts

CNC, or Computer Numerical Control, lathe machining service is a modern manufacturing process that utilizes computerized controls to manage and manipulate machine tools such as lathes. This approach offers superior precision and proficiency in creating complex designs and dimensions with optimal efficiency. In the context of brass parts, CNC services play a crucial role due to the unique attributes of this metal.

Brass, known for its durability, resilience and excellent conductivity, lends itself well to diverse industries ranging from electronics to automotive applications. Moreover, brass’s malleability facilitates easy manipulation into detailed forms without compromising material strength or integrity. Hence the demand for accurate and specialized CNC lathe machining services to cater to precise design requirements.

- CNC lathe machining service: Utilizes computer-controlled actions along multiple axes leading to high precision manufacturing.

- Role of brass parts: Favoured for their superior qualities like toughness, machinability and electrical conductivity, they necessitate expertise offered by CNC processes for intricate component crafting.

Understanding CNC Lathe Machining Services: What is it?

CNC Lathe Machining services involve the use of Computer Numeric Control (CNC), a technique that uses computer-aided designs to control machine tools, minimizing manual intervention and enhancing precision. Essentially, a lathe is an age-old tool dating back to ancient Egypt that rotates a workpiece around a specific axis.

- Explanation of Computer Numeric Control (CNC) Technique: This involves feeding a predefined set of instructions or programs in alphanumeric format into the CNC machine’s controller. The CNC software converts your CAD design files into a code called G-code, which guides the movement of the cutting tool across the chosen material – brass, in this case – accurately forming the desired shape with high precision.

- Working Mechanism of the Lathe Machine: A traditional lathe machine operates by firmly securing the brass part between two points, then spinning or rotating it. As the piece spins, a stationary cutting instrument gradually shaves off excess metal to form the part as per the stipulated dimensions. In terms of a CNC lathe, these operations are automated whereby the CPU instructs the motorised mechanism on how much to cut, thus ensuring greater accuracy and consistency.

Importance of CNC Lathe Machines for Brass Parts Production

CNC lathe machines play an integral role in the production of brass parts. Brass, a versatile and durable material known for its high performance under different conditions, is commonly used in the making of machined parts. It offers properties like corrosion resistance, heat resistance and excellent electrical conductivity which makes it a preferred choice for various industries such as electronics, plumbing and automotive.

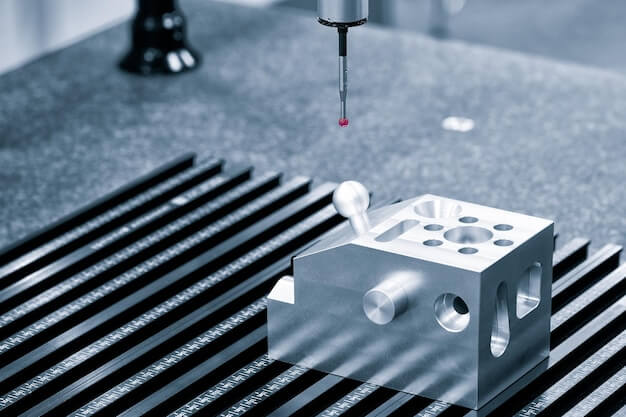

The role of CNC machines in creating precise brass components cannot be underestimated. These machines provide accuracy, repeatability, and speed that goes unmatched by manual processes, thus ensuring the manufacture of high quality, uniform and accurate components. They allow complex geometries to be manufactured with ease.

- Accuracy: Computer numerical control (CNC) offers far greater precision than manual machining.

- Repeatability: With programmed instructions, CNC lathes can produce identical parts over long runs.

- Speed: Efficient and automated CNC operations enable faster turnaround times.

In conclusion, CNC lathe machines are indispensable tools in the production of precise, reliable and highly functional brass components.

Producing brass components using a CNC lathe machine involves a precise manufacturing process that utilizes computerized machine tools to create custom-designed parts. The CNC lathe machine is specifically used for manufacturing cylindrical, conical, or flat surface shapes with brass material. This process requires careful consideration of factors such as composition, properties, and specific application requirements to ensure optimal results. To achieve high-quality brass components, it is essential to work with a online CNC service that specializes in precision machining and has expertise in CNC lathe machining for brass parts.

Advantages of Using CNC Lathe Machining for Brass Parts

CNC lathe machining offers a wide range of advantages when working specifically with brass parts. Firstly, the precision offered by this process is second to none. This machine-operated process eliminates human error and ensures an incredibly high level of accuracy in comparison to manual techniques. For instance, complex shapes and components can be crafted in one continuous cutting operation ensuring every piece matches another perfectly.

The time efficiency associated with CNC is a major bonus. With automated capabilities, positing 3D designs for direct replication allows for mass production of identical parts in significantly shorter timescales than traditional methods. Besides saving on labour hours, it also reduces the likelihood of costly mistakes due to less manual intervention.

Additionally, flexibility and versatility are inherent qualities of CNC lathe machining. Machines can effortlessly switch between tasks, making adaptability an attractive characteristic of these systems. Essentially, as long as the desired design fits within the size constraints of the particular lathe used, virtually any scheme imaginable can be brought to life – whether manufacturing simple or extremely sophisticated items out of brass.

Real-World Examples of CNC Lathe Machining of Brass Parts

In the manufacturing industry, computer numerical control (CNC) lathe machining is a vital service for crafting specific brass parts with precision. Let’s consider the creation of automotive components as an example. Car factories regularly use CNC lathes to produce complex parts like gears, which require exceptional accuracy in their dimensions and fit. The high-speed cutting and shaping ability of CNC machines significantly increases production speed whilst ensuring flawless quality.

In the plumbing sector, manufacturers use this technology to create fittings and valves made from brass because it needs detailed attention to achieve water-tight seals. CNC lathe machining seamlessly creates these intricate shapes, speeding up the delivery process and upholding product standards. Moreover, in industries such as aerospace and medical device construction, where safety and specificity are paramount, CNC lathe machining proves beneficial for crafting unique, tight tolerance brass parts suitable for mission-critical applications.

- Automotive: Accurate constructing gears.

- Plumbing: Producing water-tight valves and fittings.

- Aerospace & Medical Device Construction: Crafting precision equipment and instruments.

In all instances, the benefits of lower costs, increased throughput, improved repeatability, superior surface finish quality, and compatibility with a wide range of materials make CNC lathe machining invaluable in the modern manufacturing landscape.

Conclusion

In conclusion, the article has emphasised the significant role of CNC lathe machining services in crafting brass parts. This technology offers a series of benefits such as precision, efficiency, and repeatability which is crucial in mass production settings. Also highlighted was the ability for intricate detail it affords manufacturers who are crafting complex part designs.

The adoption of CNC lathe machine operations not only streamlines the manufacturing process but also helps ensure consistent quality across all produced parts. To recap, we discussed:

- The versatile roles played by brass parts in different sectors due to its durability and resistance factors.

- The use of CNC lathe machines in fulfilling custom needs effectively with its automated control system.

- The reliability it brings in terms of accurate dimensions including diameter, length, and symmetrical features.

Moving forward, industries stand to benefit immensely from incorporating these advanced technologies into their operations. Evidently, CNC lathe machining provides an impeccable solution for fabricating durable, highly precise, and cost-effective brass components that prove invaluable across various applications.

Other Articles You Might Enjoy

- Comparing Machinability of Various Tool Steels: What's the Best Choice?

Understanding Tool Steels and their Machinability Tool steels are referred to as an extensive variety of carbon and alloy steels known for their distinctive hardness, abrasion resistance, and ability to…

- High-Speed Steel vs. Carbide in CNC Tooling: Life Span and Performance Showdown?

Introduction to High-Speed Steel and Carbide in CNC Tooling In the world of Computer Numerical Control (CNC) tooling, two materials have emerged as key players: high-speed steel (HSS) and carbide.…

- Unraveling Bead Blasting in CNC Machining(cnc laser cutting Geoffrey)

CNC machining continues to be a crucial player in manufacturing due to its ability to produce complex, high-quality parts on a large scale. One of the techniques applied within this…