Introduction to CNC Machining and its Industry Applications

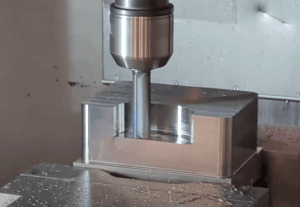

CNC machining, or Computer Numerical Control machining, is an automated manufacturing process where pre-programmed computer software dictates various types of complex machinery. The process involves precise control of tools such as lathes, mills, routers and grinders, ensuring efficient production with high accuracy and repeatability. It has become a cornerstone in the manufacturing industry, facilitating the production of both simple and intricate parts.

This versatile technology finds application across a spectrum of industries such as:

- Aerospace: Used for developing engine components, airfoils and more.

- Automotive: Essential in creating parts like pistons, transmissions etc.

- Medical: Employed in the fabrication of surgical equipment and orthotic devices.

- Jewelry: Facilitates creation of detailed, intricate designs.

In essence, affordable CNC machining services play an instrumental role in streamlining production, reducing labor costs, improving precision and enabling quick turnaround across diverse sectors.

The Importance of Quick Turnaround in the Manufacturing Industry

In the manufacturing industry, time finely correlates with both productivity levels and return on investment (ROI), placing immense importance on quick turnaround. Projects tend to be time-sensitive, framed within strict deadlines that allow very minimal slack. A fast turnaround directly impacts productivity by enabling rapid production cycles, thus generating more throughputs in less span of time. This sort of speed not only minimizes costly downtime but also enables manufacturers to meet or even exceed customer expectations early.

- As an example, consider a company that offers CNC machining services in steel. If they’re able to complete projects faster than competitors without sacrificing quality, this competitive edge could translate into increased business opportunities.

Moreover, when turnaround times are swift, the ROI is positively influenced too. Shorter completion times mean reduced labor costs and quicker realization of income from finished products, optimizing the overall profit margin. Hence, quick turnaround resonates powerfully as an operational necessity in manufacturing sectors for its exponential influence over productivity and profitability.

Understanding Affordable CNC Machining Services

Affordable Computer Numerical Control (CNC) machining services in steel implies value for money. Affordability comprehended as a balance between the cost and the quality of the machining services provided. Multiple factors contribute to this cost-effectiveness, helping manufacturing businesses maximize productivity while minimizing expenses.

- CNC Machine Efficiency:The speed, accuracy, and consistency of CNC machines directly affect their affordability. Faster turn-around times mean more production output, which inherently lowers operational costs per piece. High precision reduces material wastage, making processes even more economical.

- Competitive Pricing:Service providers typically offer varied pricing models based on volume, complexity, and lead time requirements, allowing businesses to select a model that fits their budget and needs best.

- Comprehensive Services: Full-service shops can manage everything from design to final finishing under one roof. This helps to cut costs linked with outsourcing different tasks to multiple service providers.

- Longevity and Durability: High-quality CNC-machined components last longer, reducing replacement costs over time and ensuring optimal performance of the machinery they form part of.

The affordability of CNC machining services hence is not only about an inexpensive purchase price but also an advantageous long-term investment due to higher productivity, improved efficiency, lowered waste, and reduced overall manufacturing expenses.

Steel is a widely used metal alloy with desirable properties and qualities. CNC stainless steel is a recommended grade for machining and parts manufacturing, but it is important to evaluate all available grades before making a selection.

Finding an Affordable CNC Machining Service Provider

When choosing a service provider for affordable CNC machining services in steel, several factors should be taken into account. These include costs, skills of the operators, the type of equipment used, and adherence to schedule timelines. Firstly, costs are an obvious consideration – an affordable service that doesn’t compromise on quality is ideal. Secondly, the skills of the operator matter – they should have sufficient knowledge and experience with CNC machines. Next, consider the kind of equipment being used – it should be up-to-date and able to deliver high-quality results. Lastly, timeline adherence is crucial as it affects your project’s delivery. The provider needs to work efficiently to produce quick turnaround times without compromising on the precision or quality of the work.

An example of a reputable, cost-effective CNC machining service provider offering fast turnaround times is ‘XYZ Machining Services’. They use advanced CNC technology, employ skilled technicians, provide competitive pricing, and guarantee timely deliveries thus meeting all the key considerations.

Maximizing Efficiency & Affordability in Your CNC Machining Projects

In order to maximize the efficiency of your CNC machining projects, careful planning is paramount. A well-executed plan can result in significant time and cost savings. Begin by communicating clear project specifications with your CNC machining service provider, be it dimensions, tolerances, materials or finish requirements. Clear communication aids in minimizing errors and consequently, unnecessary costs associated with reworks.

- Accurate CAD drawing: The accuracy of a Computer-Aided Design (CAD) drawing plays a crucial role in project success. Ensure all measurements are correct and details like radii and chamfers are clearly marked.

- Simultaneous Milling: Make use of milling techniques that enable multiple operations to happen simultaneously. This cuts down on time, reducing project duration and hence, optimizing costs.

Pursuing affordability without compromising quality requires judicious management of resources. For instance, ordering parts in bulk could render volume discounts from your CNC Machine vendor. Also, using material that provides optimum strength while being economical could prove useful. Moreover, consider investing in preventative maintenance for your machine tools as this could optimize its lifespan and performance, thereby cutting down on long-term costs.

- Bulk Ordering: Consider ordering larger quantities at once to enjoy discounted rates provided by many suppliers for high-volume purchases.

- Economical Material Selection: Choose materials with care. Aim for those which provide necessary functionality at cost-effective prices.

- Preventative Maintenance: Regularly checkup on your CNC machines to prevent any unexpected malfunction which may interrupt your operations and incur additional costs.

Other Articles You Might Enjoy

- Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical…

- Understanding Bead Blasting in CNC Machining(china machining Avery)

Bead blasting, a compelling term in the world of Computer Numerically Controlled (CNC) machining, is an influential process that plays a transformative role in optimizing and enhancing parts' aesthetic and…

- Understanding Bead Blasting in CNC Machining(cnc g code Jacqueline)

CNC (Computer Numerical Control) machining is a dominant method employed for multiple manufacturing systems across the globe. From healthcare to aerospace, this technology has revolutionized how we manufacture products. One…