Introduction to Prototype CNC Machining and Custom Aluminum Solutions

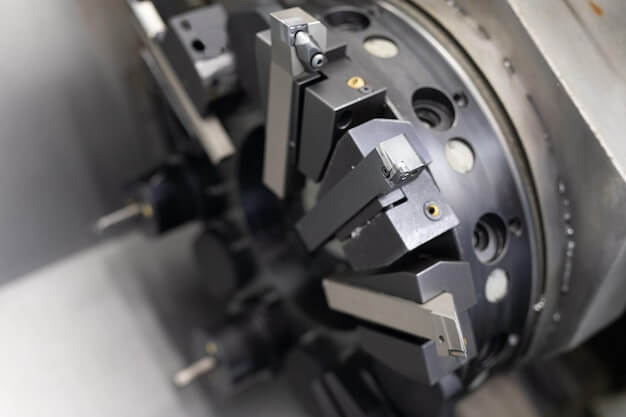

Prototype CNC (Computer Numerical Control) machining is a manufacturing technique that entails the use of pre-programmed computer software to dictate the movement of industrial machinery. This process can be used to manage an array of complex equipment, including grinders, lathes, mills, and routers. Efficient in creating intricate and precise components for various industries, prototype CNC machining eliminates the possibility of human error, as well as provides quick production turnaround times and higher output rates.

Particularly with custom aluminum solutions, this method offers tremendous benefits. Given that aluminum is lightweight yet durable, it becomes an ideal material choice especially for aviation and automotive sectors. A customized solution entails producing specific designs according to individual client requirements with focus on aspects such as accurate dimensions, optimal strength, adequate thermal conductivity, and superior corrosion resistance.

- Aluminum’s malleability: This property allows the alloy to be easily cut and shaped into complex geometrical configurations using CNC machines, enhancing design flexibility.

- Durability: Despite its light weight, aluminum exhibits good strength making it suitable for heavy-duty applications.

- Affordability: Compared to other materials like titanium or stainless steel, custom aluminum is cost-effective.

Technological Insights into CNC Machining Services:

- CNC Machining for Aerospace: The extremely high level of precision needed within the aerospace industry makes CNC machining a suitable manufacturing process for the sector.

- Blog: Gain valuable insights into manufacturing processes by visiting the blog section on CNC machining.

- Case Studies: Learn successful stories to inspire your project by exploring the case studies related to CNC machining.

- Knowledge Base: Access whitepapers, design guides, materials, and finishing information in the knowledge base section.

- Surface Finishes: Explore different finishing options that enhance part appearance and functionality in the surface finishes section.

The Importance of Prototyping in Product Development

In the competitive world of product development, prototyping is a critical aspect. The relevance of prototypes can’t be overstated as they serve as tangible representations used for testing and refining design ideas before a final product is produced. With CNC machining services being implemented in prototype creation, it provides an efficient platform for rapid and repeatable production of intricate designs that were previously impossible or time-consuming.

- Validation: A functional prototype helps to verify if the proposed design works as expected or needs further adjustments.

- Cost-effective: Identifying and resolving design flaws at the early stages with the use of prototypes reduces potential costly mistakes during mass production.

- Faster Production: Leveraging advanced technologies like CNC machining accelerates the production cycle thereby aiding in quicker turnaround times.

CNC machining’s ability to deliver precise automated cuts on various materials including aluminum, benefits designers and engineers by offering reliable replication of parts for testing and validation – bringing us custom aluminum solutions from sketches to reality more efficiently than ever before.

Custom Aluminum Solutions via CNC Machining

In the world of manufacturing and production, custom aluminum solutions represent a fusion of precision engineering and flexibility. They intrinsically involve the use of CNC machining services – a technology enabling unprecedented levels of detail and consistency. Essentially, it is when Computer Numerical Control (CNC) technology is employed to shape aluminum into bespoke components designed for various industry applications.

To contextualize this concept, consider an automotive component being prototyped. The process begins with an Aluminium block set on the CNC setup; programmed algorithms then deploy tools that cut, mill, drill or turn the aluminium, producing accurate and repeatable parts(

Benefits of Using Custom Aluminum with CNC Machining

Custom aluminum, a preferred choice in CNC machining services, provides multiple advantages that make it one of the most efficient and practical options for producing high-precision parts. One crucial advantage of custom aluminum is its precision. The automated nature of CNC machining enables precise cuts every time, achieving dimensions and shapes impossible by other methods.

- Precision: This refers to the meticulous detail achievable when using custom aluminum, presenting opportunities for designs that were previously limited by manual processes.

- Efficiency: With CNC machines, you can continuously produce large volumes of parts with minimal supervision, dramatically increasing efficiency.

- Customization: As the name suggests, custom aluminum allows for a wide variety of part types and sizes – catering to specific needs beyond traditional manufacturing capabilities.

CNC machining also offers two vital benefits — cost and time savings. In terms of cost-efficiency, utilizing this method reduces labor costs as fewer workers are required compared to manual processing. On top of that, thanks to the high-speed and consistent performance of CNC machines, work gets done faster without compromising quality, saving valuable time. Consequently, both shorter production times and decreased labor costs fundamentally contribute to overall savings — making custom aluminum CNC machining an incredibly productive solution for a wide range of applications.

Considerations When Choosing Prototype CNC Machining Services

When choosing a provider for prototype CNC machining services, there are several important considerations to keep in mind. Paramount among these is the company’s reputation within the industry. Look for service providers renowned for exceptional quality and customer satisfaction. An ideal CNC machining partner should also boast considerable experience within the field. A track record of engagement with diverse projects over time indicates a depth of understanding that novice firms may lack.

- Capability: Ensure that the CNC machine shop has the necessary equipment and technical know-how to deliver your specific project requirements.

- Quality Assurance: Assess their commitment to quality by checking if they adhere to regulatory standards and have provisions for inspections and testing.

- Lead Time: Consider the provider’s turnaround time given the speed at which prototyping needs to be done to stay competitive.

These key factors, alongside price points and additional offered services like assembly or packaging, should guide you in selecting a competent and reliable prototype CNC machine service provider.

Other Articles You Might Enjoy

- Understanding Bead Blasting in CNC Machining(face milling Rex)

Bead blasting, an abrasive process used within various manufacturing industries, plays a critical role particularly with Computer Numerical Control (CNC) machining to create precise, smooth finished components. Whether it’s for…

- Rapid Prototyping with CNC Machining: High-Quality Stainless Steel Parts

Rapid Prototyping and CNC Machining: A Brief Overview Both Rapid Prototyping and Computer Numerically Controlled (CNC) Machining represent transformative technologies within the realm of manufacturing. Rapid Prototyping refers to techniques…

- Exploring the Limits of CNC Machining with Exotic Metal Alloys

Introduction: CNC Machining and Exotic Metal Alloys CNC machining involves the use of computers to control machine tools, enabling precision manufacturing. A critical aspect of this technology lies in material…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu