Introduction to CNC Machining in Steel Manufacturing

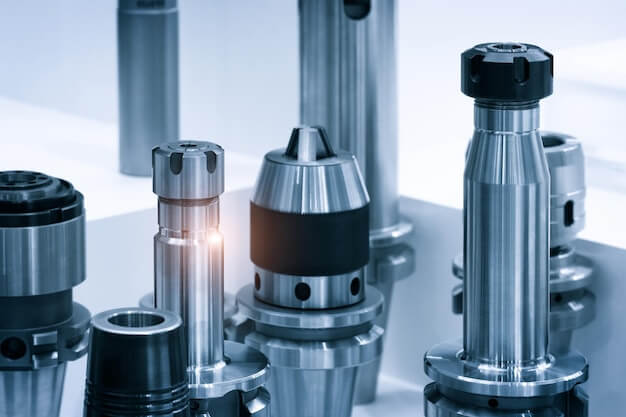

In the realm of manufacturing technology, Computer Numerical Control (CNC) machining occupies a pivotal position. Simplifying it, CNC machining is an automated process in which pre-programmed computer software dictates the movement of machinery and factory tools. This significantly eliminates the scope of manual handling, thereby enhancing precision, efficiency, and safety.

Emphasizing its significance to steel manufacturing, this advanced fabrication method plays a central role by ably transforming steel blocks into intricately fashioned parts and components. Efficient utilization of CNC machining technologies contributes to prolific levels of production with matchless accurateness devoid of material wastage:

- Greater Precision: Programmatic control enables precise calibration, resulting in faultless products.

- High Productivity: Automating complex tasks facilitates mass production without quality degradation.

- Versatility: It accommodates various materials, not just steel, making it adaptable for diverse industrial needs.

To put in context, one might consider large-scale productions like automobile or aerospace parts where stringent specifications coupled with high-volume demands make CNC machined steel indispensable.

Understanding Online CNC Machining Quotes:

- Material Selection: The choice of material for steel manufacturing significantly influences the online CNC machining quote, as different materials have varying machining requirements and costs.

- Complexity of Design: Intricate and complex designs may impact the online CNC machining quote for steel manufacturing, as they may require more advanced machining techniques and longer processing times.

- Tolerance and Surface Finish: Specific tolerance and surface finish requirements can affect the online CNC machining quote, as they may necessitate additional machining processes and meticulous attention to detail.

- Service Provider: When seeking fast estimates for steel manufacturing through CNC machining, it is essential to partner with a reliable online CNC service that offers expertise in steel manufacturing and accurate quoting.

Advantages of Utilizing CNC Machining Online Quote System

The efficiency and speed at which estimates can be obtained using a CNC machining online quote system offer significant advantages to businesses. The online platform facilitates instant access to quotes, thus accelerating the decision-making process for steel manufacturing projects. With an array of suppliers listed on one platform, it makes comparing prices, services and timelines a much more convenient task.

- Users are able to quickly gather multiple quotations from various suppliers in real-time without having to manually approach each supplier individually – this saves both time and resources.

- It eases the comparison among different vendors by offering a clear and concise overview of their offerings, helping businesses make informed decisions efficiently.

- The user-friendly nature of these online quoting systems eliminates potential miscommunications that could occur with traditional methods of obtaining quotes, ensuring a smooth transaction process.

Fast Estimates for Steel Manufacturing

In the realm of steel manufacturing, online CNC machining allows companies and individuals to receive fast estimates within a matter of hours or even minutes. The process begins with an initial submission through a portal on the manufacturer’s website. Here, one must provide detailed specifications concerning dimensions, materials, processing requirements, as well as delivery deadlines. Most platforms would usually require CAD files or 3D models to generate more accurate estimates.

The next phase is where common elements are taken into consideration in creating fast estimates. These include but are not limited to the type of material requested – in this case, steel, quantities needed, intricacies of part designs, production runs, and shipping preferences. Generally, manufacturers will conduct a thorough analysis based on these parameters before initiating the quote.

To shed some light on the progression of a quick estimate, consider the following illustration:

- You navigate to your preferred manufacturer’s website and locate their quotation portal.

- You upload necessary documents such as CAD files along with vital project details.

- The system processes the given information and factors in design complexity, material choice, quantity, and other correlated aspects.

- An outcome of these considerations is delivered swiftly in the form of a comprehensive yet understandable cost estimation- broken down by different areas like labor, materials, etc.

This simple step-by-step example articulates how streamlined and accessible estimating costs can be courtesy of a digital platform!

Resolving Common Issues with CNC Machining Online Quotes

In the process of acquiring an online quote for CNC machining, many users can encounter common challenges or pain points. A prominent issue users often face is difficulty in specifying particular details accurately which may result in inaccurate quotes. This occurs due to unfamiliarity with terminologies and measurements used within the realm of steel manufacturing.

To overcome these issues, practical solutions and tips are critical:

- Firstly, investing time in deeply understanding various aspects involved in CNC machining before asking for a quote. This covers everything from knowing key terms associated with the pricing model to having a clear idea about material specifications, tolerances etc.

- Secondly, using authentic and schematic diagrams while requesting the quote would eliminate confusion and misinterpretation of requirements.

- Thirdly, ensuring complete transparency by discussing upfront any possible modifications or amendments needed in design down the line – it not only helps avoid unpleasant surprises but also guarantees a more precise quote.

By addressing these commonly faced issues in CNC machining quotes, users can make sure that they get the most accurate estimate for their steel manufacturing needs.

Other Articles You Might Enjoy

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- CNC Machining Parts Factory: Specializing in High-Quality Steel

Introduction to CNC Machining and its Significance CNC (Computer Numerical Control) machining is a critical component in modern manufacturing, responsible for executing complex cuts and designs with absolute precision. This…