Introduction to Precision CNC Machining Services in Aerospace

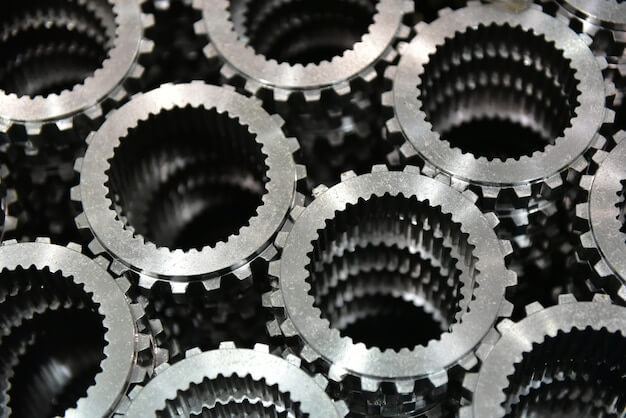

Precision CNC (Computer Numerical Control) machining is a modern manufacturing technique that uses computer-controlled machine tools to create intricate parts with extreme accuracy. It’s an essential service in the aerospace industry – an industry where precision, quality and reliability are of utmost importance. Airplanes, rockets, and satellites, they all heavily rely on precisely machined components for efficient functionality and safety.

CNC machining plays a pivotal role across various stages in the aerospace sector, from creating prototypes and tooling to full-scale production of complex parts like engine casings or wing spars. Specializing in aluminum, one of the most commonly used materials in this industry due to its lightweight and corrosion-resistant properties, CNC machining services offer both time efficiency and cost-effectiveness without compromising on part integrity or performance.

- Prototyping: The quick turnaround times offered by CNC machining make it ideal for creating high-quality prototypes required during the design phase of AeroSpace products.

- Full-Scale Production: CNC machining provides unrivaled dimensional accuracy and consistency which is crucial for mass-producing high-volume aerospace parts.

- Aluminum Parts: CNC machines can easily handle Aluminum, offering excellent finish and maintaining the structural integrity necessary for aerospace applications.

Precision CNC Machining Services for Aerospace: Understanding the Basics

CNC, or Computer Numerical Control, machining services refer to a process employed in manufacturing where pre-programmed computer software dictates movement of machinery and tools. The process allows total control and automation over a range of complex machinery, from lathes to mills, which can function perfectly without human intervention.

To understand how a CNC machine operates, consider an example of carving an aluminum block into a specific shape. The desired 3-dimensional design is first created using compatible software. This design is then converted into numerical coordinates representing particular points on the metal block. These coordinates make up a set of instructions that guide the CNC machine’s movements with extreme precision— down to fractions of a millimeter— ensuring perfect replication of the original design every time.

- Designing: Conversion of the blueprint into a digital design using CAD (Computer-Aided Design) software.

- Numerical Coordinates: Turning the digital design into a series of exact numerical coordinates.

- Machining: Using these coordinates as commands, guiding the CNC machine to accurately carve out the design from the aluminum block.

Given its accuracy, flexibility, and versatility, it’s no surprise that industries such as aerospace rely heavily on CNC technology for producing intricate components.

Specialization in Aluminum

Aerospace manufacturing predominantly utilizes aluminum due to its unique properties that fulfill the industry-specific demands. The light-weight nature of aluminum significantly reduces the overall weight of aerospace structures, enhancing fuel efficiency while maintaining structural integrity during flight conditions.

Beyond the weight advantage, aluminum exhibits distinct characteristics making it ideal for aerospace applications. Some noteworthy features include:

- High strength-to-weight ratio: Aircraft parts necessitate materials that are strong enough to withstand pressures yet light enough to maintain maneuverability and fuel efficiency.

- Tolerance to extreme temperatures: Spacecraft encounter vast temperature variations; hence a material with high thermal conductivity like aluminum is preferred.

- Natural corrosion resistance: This characteristic prolongs the lifespan of aircraft components exposed to harsh climatic conditions or corrosive substances.

- Ease of machinability: Aluminum’s malleability makes it easier to shape via precision CNC machining processes than other metals, reducing production times and costs.

Hence, these technical principles establish why Precision CNC Machining Services have specialized in aluminum for aerospace manufacturing.

Understanding Precision in CNC Machining:

- Material Selection: Choose the appropriate material for precision CNC machining based on its properties and suitability for the aerospace industry.

- Design Analysis: Conduct a thorough analysis of the design to ensure it aligns with the precision machining capabilities and meets the requirements for aerospace parts production.

- Programming: Utilize advanced computer programming to create precise toolpaths for the CNC machines, optimizing the machining process for precision aerospace components.

- Machining Execution: Implement the precision CNC machining process using state-of-the-art equipment to efficiently produce high-quality parts for aerospace applications.

- Quality Assurance: Perform rigorous quality checks to ensure the machined parts meet the highest standards and specifications.

- Service Provider: When seeking precision CNC machining services for aerospace, it is essential to partner with a reliable Precision Machining Service that offers expertise in CNC machining and proven capabilities in aerospace component production.

The Role of CNC Machining in the Aerospace Industry

Precision CNC machining plays a crucial role in the aerospace industry. It enables due to tight tolerances and high-performance production capabilities for creating complex yet lightweight components integral to aircraft structures and systems. Utilizing specialized Aluminium, CNC machining results in robust and heat-resistant parts that maintain integrity in extreme flight conditions.

For example, Airbus SAS, an international pioneer in the aerospace sector, relies heavily on precision CNC machining services for its highest-selling A320 family. Customized aluminum pieces such as brackets for window frames and various housing units are intricately machined to ensure passengers’ safety while optimizing fuel efficiency through reduced weight.

-

Application: Precision CNC machines deliver intricate designs with high accuracy for vitally important parts like engine components that require absolute precision.

-

Importance: Continuous advancement in technology demands evolving specifications and tolerances in airplane components which can be achieved only via these sophisticated CNC processes.

Benefits of Using CNC Machining Services in Aerospace Manufacturing

The implementation of Precision CNC machining services heralds key benefits for aerospace manufacturing, significantly impacting aspects such as time efficiency and cost reduction. For instance, usage of CNC machines enables intricate parts to be processed precisely and quickly, making production times shorter than those under traditional manual operations. As a result, this boosts the overall manufacturing speed, leading to faster delivery timelines and subsequent customer satisfaction.

Besides, the consistency offered by CNC machining translates to substantial cost savings. Unlike human workers who are susceptible to errors, CNC machines produce high-quality pieces with identical dimensions over repeated cycles. This precision limits wastage associated with faulty components and reworks. For example, a study conducted on aircraft manufacturers showed that adopting CNC technology saved them up to 35% of their total operating costs.

Moreover, the versatility of CNC machines allows for easy customization depending on design requirements or modifications. In one instance, a company specializing in satellite production was able to alter their blueprints swiftly during an upgrade operation, thanks to the adaptive features of their CNC software.

Conclusion

In summary, Precision CNC Machining Services plays a pivotal role in the growth and advancement of the aerospace sector. Through its efficacy in working with various materials, primarily aluminum, these services enable complex designs to be realized with utmost precision – contributing materially to the development of sophisticated aircraft and high-end space systems. Looking ahead, as technologies continue to evolve, one can expect CNC machining to become even more integral to aerospace manufacturing needs. The complexity of modern-day aviation demands detailed accuracy that only such advanced methods can provide. Hence, the future scope for CNC machining in aerospace is massive and brimming with possible advancements.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(torsion snap joint Uriah)

Bead blasting is an essential process within the broader umbrella of CNC (computer numerical control) Machining. Understanding its role and functions can provide a unique perspective on manufacturing and production,…

- Challenges and Solutions in CNC Machining of Hardened Steels for Tool and Die Making

Introduction to CNC Machining and the Challenges of Hardened Steels CNC machining is a crucial process in tool and die making, heavily relied upon for its versatility and precision-driven manufacturing…

- Ceramics in CNC Machining: Are They as Effective as Metals?

Introduction to CNC Machining and Ceramics CNC machining, or Computer Numerical Control machining involves the use of computers to control machine tools in the manufacturing process. This highly efficient method…