Introduction to CNC Machining and Copper’s Role

Computer Numeric Control (CNC) machining is a modern manufacturing technique used in various industries around the world. It employs computer-driven machinery to perform precise cutting, shaping, or drilling processes on robust materials like copper. The beauty of CNC Machining lies in its ability to produce complex geometries with high levels of accuracy; an attribute previously unachievable with manual operations.

Copper, one of the most efficient electrical conductors, has gained favor in CNC machining due to its unique properties. Its good thermal conductivity, corrosion resistance, and excellent machinability make it an ideal candidate for creating intricate designs with tight tolerances in industries such as electronics, automotive, aerospace, and others. Here are some features:

- Machinability: Copper can be easily formed into different shapes offering flexibility during the design phase.

- Conductivity: This metal conducts electricity and heat extremely well, benefitting electronic components.

- Corrosion Resistance: The longevity of copper parts increases due to their inherent resistance to rusting.

Understanding the Properties of Copper

Copper, being one of the most useful metallurgical elements within our world, finds itself in high demand due to its notable properties such as superior thermal conductivity, robust corrosion resistance, and outstanding force-bearing potency. This unique combination makes copper an excellent choice for various applications across different sectors.

- Thermal Conductivity: This is a critical feature that illustrates how well a material can conduct heat. For instance, copper’s impressive thermal conductivity is why we find it commonly used in cookware – it heats up fast and distributes heat evenly.

- Corrosion Resistance: This property defines how well a substance can withstand damage caused by oxidation or other chemical reactions with environmental elements. An everyday example where this attribute comes to play would be copper piping used in plumbing, having remarkable durability even under constant exposure to water.

- Force-bearing Potency: Known technically as tensile strength, this refers to how much stress a material can endure before failing or breaking. Consider the use of copper wire in electrical appliances, bearing significant loads without compromising its performance or structure.

In essence, these diverse advantageous attributes make copper not just versatile but invaluable as well, positioning it as an essential component in myriad applications ranging from construction and energy sector to telecommunications and beyond.

The Role of CNC Machining in Unlocking Copper’s Potential

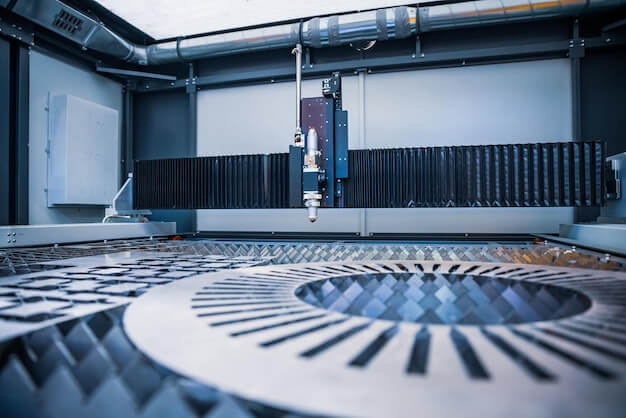

CNC machining, a fabrication process dominated by computerized controls and automated machine tools, plays an integral part in revealing copper’s potential within the manufacturing industry. The precision this technique offers enables tight control on complex geometries, advancing the usability of copper significantly.

For instance, in the electronics sector, the accurate and detailed parts produced with CNC machinery cater to the vital need for conductivity and heat dissipation – prerequisites that copper conveniently meets. This phenomenon is further amplified when these features are imposed judiciously using advanced CNC technology.

- Computer-controlled cutting: Exact incisions are made according to 3D models created in software programs. Applied rigorously on copper, it helps design intricate yet precise structures adept at enhancing device performance.

- Less Material Wastage: Owing to pre-defined tool paths & movements executed by computer commands, material wastage plummets substantially. Therefore, optimizing cost utilization of expensive raw materials like copper.

- Rapid Prototypes: High-speed milling generates prototypes quickly. Consequently, incorporating changes in electronic designs becomes comfortably feasible.

By harnessing such cutting-edge capabilities, CNC machining champions boosting production efficiency, amplifying track-and-trace systems, and improving product quality substantially when dealing with copper as the baseline resource.

Advanced Techniques in Copper CNC Machining:

- Free-machining coppers have high machinability and are commonly used in CNC machining and rapid prototyping processes.

- They are suitable for electrical systems and welding torch tips due to their excellent conductivity and corrosion resistance.

Impacts/Benefits of CNC Machining with Copper

The potential of copper can be greatly unlocked with the implementation of advanced Computer Numeric Control (CNC) machining. This potent combination introduces unprecedented improvements in product quality, cost efficiency and material conservation. Incorporation of CNC technology on copper improves precision while reducing component variation, hence delivering end products that surpass conventional standards in their execution and application.

- Improved Product Quality-CNC controlled machines provide a higher degree of accuracy than manual operations, resulting in more intricately detailed parts created from copper that wouldn’t have been possible using traditional methods.

- Reduced Costs- With automated, high-speed processes, CNC machinery attenuates manufacturing time, thereby cutting down production costs considerably. Widespread implementation across industries has proven to be financially rewarding by improving profitability margins.

- Elimination of Waste- Advanced CNC techniques optimized for copper machining minimize scrap generation due to precise operational control, aiding both economies and environmental sustainability.

This outcome comes to light in numerous real life applications; for instance, in the automotive industry, where superiorly crafted copper components made via sophisticated CNC machines enable efficient and reliable engine performance. Likewise, within electronics, impeccably machined copper connectors and wires significantly enhance device functionality and longevity, simultaneously demonstrating the tangible impacts of this progressively symbiotic relationship between copper and advanced CNC machining technologies.

Future Perspectives: CNC Machining and Copper

In the future, advanced CNC machining promises to further harness the potential of copper in various industries. Innovations are expected to drive efficiency and precision in manufacturing workflows without necessitating complex technical knowledge. This could include the development of more efficient toolpaths for reduced waste or innovations in software algorithms that optimize cutting parameters specifically for copper. Advancements might also involve improved cooling methods during machining operations, given copper’s high heat conductivity, leading to enhanced quality and longevity of finished products.

The key components driving these advances may include:

- Newly developed software algorithms for optimized machining specific to copper

- Advancements in toolpath efficiencies resulting in minimal waste material

- Innovations in cooling systems designed to work with copper’s unique properties

With these advancements, we can expect not only increased productivity but also sustainable manufacturing processes due to smarter utilization of resources.

Conclusion

In summarizing the key points discussed in this article, it’s apparent that copper and advanced CNC machining are pivotal forces transforming various industries. The utilization of these two elements facilitates efficiency, precision, and overall productivity in multiple sectors ranging from automotive to electronics. For instance, by enabling manufacturers to accurately craft complex shapes with minimal waste, CNC machinery has enhanced cost-effectiveness while guaranteeing quality excellence—an evident revolution propelled by its combined usage with robust materials like copper.

It should be noted that exploring further into copper’s potential via advanced CNC machining is not only a transformative journey but also an inevitable necessity for anyone venturing deep into manufacturing and related fields.

- Copper: Noted for its excellent electrical conductivity and resilience against corrosion,

- Advanced CNC machining: Celebrated for its high-precision output, ability to repeat processes exactly, and reducing manual labor.

These technical marvels have opened up new possibilities for innovation and efficiency in production which merit persistent exploration. Unlocking the potential of combinations like these could likely hold the keys to future advancements in the field.

Other Articles You Might Enjoy

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…

- Precision CNC Machining for Advanced Industrial Sensors

Precision CNC Machining and its Importance in Advanced Industrial Sensors The world of advanced industrial sensors heavily relies on the precision that Computer Numeric Controlled (CNC) machining offers. CNC machining…

- Demystifying the Process of Bead Blasting in CNC Machining(g code cnc Elsa)

Bead blasting is an integral part of Computer Numerical Control (CNC) machining, essential for achieving high-standard finishes on metal surfaces. In this article, we'll delve deep into understanding the fundamental…