Precision CNC Machining for High-Performance Electric Motors

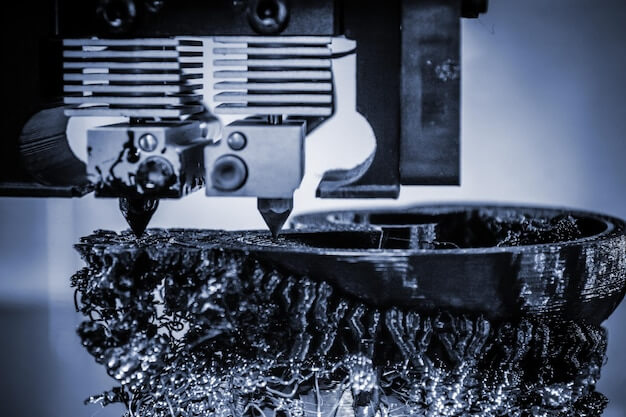

In the spectrum of diverse manufacturing methods, Precision CNC (Computer Numerical Control) machining stands as a vital process known for its accurate, consistent, and efficient operational nature. This specialized form of computer-directed machining has transformed sundry sectors within the industrial landscape, prominently marking its impact on motor production – specifically high-performance electric motors which continually demand precise and consistent components for optimal function.

The importance of precision machining in the manufacturing industry cannot be overstated. Its contributions to quality control, waste reduction, expedited production times, and overall product reliability have placed it at the echelon of the manufacturing paradigm. Moreover:

- It ensures parts are produced with incredible accuracy, true to exact specifications – thus eliminating room for human error or inconsistency from part to part.

- Substantially decreases raw material wastage through its precise cutting techniques.

- With automated functionality, it accelerates production rate without compromising quality.

Its pivotal role is further underscored when applied to the creation of high-performance electric motors, where every single component – from tiny rotors to casings – needs to meet strict tolerance levels and dimensional precision, enabling these motors to operate more efficiently and last longer. Therefore, Precision CNC machining stands essential not just within itself but also within the greater technological advancements we continue to pursue.

Understanding the Basics of High-Performance Electric Motors

High-performance electric motors are precision devices designed for efficiency and better output. These crucial mechanical components convert electrical energy into mechanical energy with excellent speed control, compactness, and high power-to-weight ratio.

The role of precision machining in their production cannot be emphasized enough, as it ensures that each part adheres to strict specifications for optimal performance. Machining processes such as turning, milling or drilling are used during manufacturing, all done with a high degree of accuracy thanks to cutting-edge Computer Numerical Control (CNC) technology.

In this line, Tesla Inc., an undisputed leader in the EV industry is a notable example of a company deploying advanced CNC techniques in motor production. Precision CNC machining allows them to achieve precise tolerances and ultra-smooth finishes on end products, facilitating greater efficiency and reliability of their world-renowned electric vehicles.

The Detailed Process of Precision CNC Machining in Electric Motor Production:

- Precision CNC machining plays a crucial role in the production of electric motors, ensuring the creation of intricate and high-quality components.

- To explore precision CNC machining for electric motor production, consider utilizing Precision Machining Service for reliable and efficient manufacturing solutions.

Benefits of Precision CNC Machining in Motor Manufacturing

When it comes to motor manufacturing, precision CNC machining offers several significant benefits that result in higher performance and efficiency. One such benefit is improved precision. Thanks to the computer-programmed control, every cut, drill or manual process can be executed with extreme accuracy, enhancing the engine’s overall efficiency by reducing energy loss and increasing torque strength.

- Improved consistency: With CNC machinery, each part perfectly matches its blueprint, ensuring there’s no variation between products. This high level of consistency leads to better stability and less wear and tear on motors.

- Durability: CNC machined parts are crafted from sturdy materials like steel and aluminum which are known for their long-lasting durability, leading in turn to longer engine lifespans.

- Better performance: By minimizing design flaws, achieving precise tolerances and allowing for tight assembly fits, precision machining contributes significantly to superior performance in electric motors.

In conclusion, precision CNC machining plays an indispensable role in motor manufacturing due to its extensive influence over not just the final product quality but also through contributing to efficiencies across the production process itself.

The Future of Motor Manufacturing with Precision CNC Machining

The future of motor manufacturing marches along the path of precision CNC machining, a technology that will inevitably shape and implement never-seen-before advancements in the field. With its capability to work diligently with unparalleled accuracy, CNC machinery is expected to redefine the efficiency and performance standards of high-performance electric motors. Several innovations are on the horizon that could dramatically alter how motors are manufactured.

- One potential advancement could be in the realm of artificial intelligence’d integration into CNC systems, which could revolutionize the rate and precision at which motors are produced.

- Digital Twin technology can provide real-time simulations of the manufacturing process, increasing precision and quality control.

- The advent of nanotechnology could spur on the creation of smaller, more efficient motors with highly compacted power densities.

In essence, new technologies fused with precision CNC machining will push the boundaries of what is feasible in producing high-performance, cost-effective, energy-efficient electric motors. As such, manufacturers who adapt swiftly to these cutting-edge tools will pave their way towards success in this rapidly evolving industrial landscape.

Conclusion: The Importance and Relevance of Precision CNC Machining for High-Performance Electric Motors

In conclusion, precision CNC machining plays a critical role in the manufacturing of high-performance electric motors. It allows for increased efficiency, accuracy, and repeatability through its automated process, reducing human error and increasing production speed. Aspects of an electric motor such as rotors, stators, and armatures can be precisely crafted with minimum wastage using this technology. Furthermore, it facilitates the creation of complex geometric shapes which are critical to the optimal performance of these motors.

- The ability of precision CNC machines to fabricate parts from a variety of materials also enhances their utility within this sector, supporting the development of innovative, eco-friendly, and powerful electric motors that drive diverse industries from automotive to aerospace.

- In addition, the versatility offered by these machines means they can be adapted for various sizes and types of electric motors, thereby enhancing their broad applicability.

Henceforth, the significance of precision CNC machining in producing superior quality high-performance electric motors cannot be underemphasized. Its role will continue to expand parallelly with advancements in electric motor technology and demands for enhanced efficiency and reliability.

Other Articles You Might Enjoy

- Unlocking New Possibilities in CNC Machined Titanium Medical Devices

Introduction to CNC Machined Titanium Medical Devices The prevalence of CNC machined titanium medical devices in the healthcare sector demonstrates their immense significance and usefulness. This technology furnishes an essential…

- CNC Aluminum Machining Services: Advanced Techniques for Perfect Parts

CNC Aluminum Machining Services In the current manufacturing landscape, CNC aluminum machining services play a pivotal role. CNC which simply translates to 'Computer Numerical Control', is an advanced technique used…

- Hastelloy vs. Stainless Steel in Chemical Processing Equipment: CNC Machining Perspectives?

Hastelloy vs. Stainless Steel in Chemical Processing Equipment: An Introduction In the realm of chemical processing equipment, two commonly used materials include Hastelloy and stainless steel. Hastelloy, a reputed superalloy…