Introduction to Bead Blasting in CNC Precision Machining

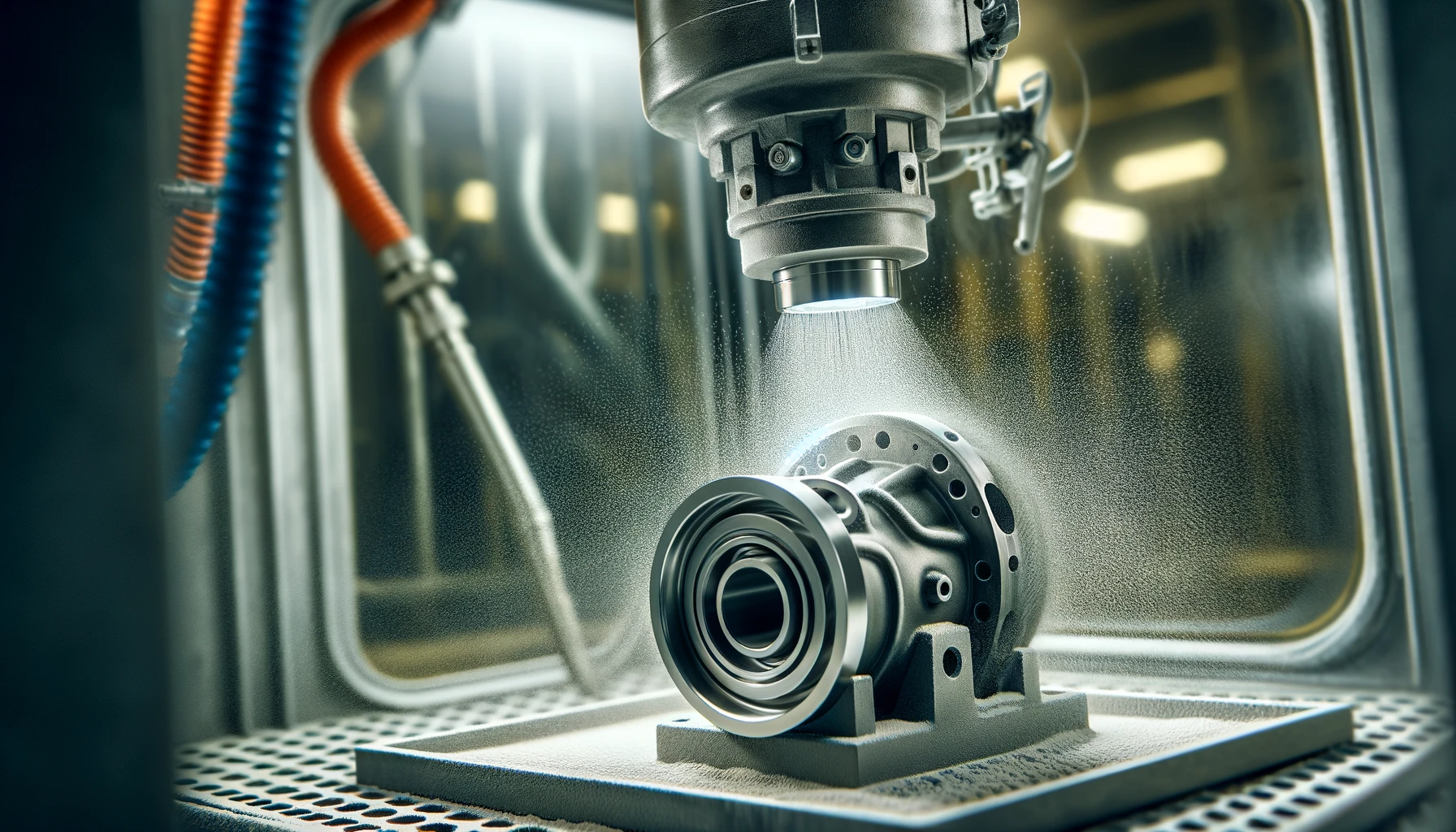

In the intricate world of CNC precision machining, achieving an impeccable surface finish is not just a matter of aesthetics but a requisite for functionality and performance. Bead blasting, a process characterized by propelling a stream of abrasive bead media under high pressure against a surface, stands out as a premier solution for this task. This technique is not confined to a single material type; it extends its utility across metals, plastics, and glass, showcasing its versatility. The resultant effect is not merely superficial; it enhances the surface to a degree that it influences the overall quality and longevity of the machined part.

The evolution of bead blasting within CNC machining parallels the industry’s advancement towards higher precision and stricter quality standards. As components become more complex and the demand for superior finishes increases, bead blasting offers a reliable and efficient method to meet these stringent requirements. Its application spans across various industries, including aerospace, automotive, medical devices, and more, each benefiting from the unique advantages that bead blasting brings to the table.In order to better meet Bead Blasting needs, manufacturers also provide online CNC service to facilitate customers to fully and accurately describe their Bead Blasting requirements.

Understanding the Basics of Bead Blasting Technology

Bead blasting operates on the fundamental principles of impact and abrasion. The technology behind this process is intricate, relying on specialized equipment to control the blasting environment precisely. A bead blasting cabinet, the cornerstone of this operation, ensures that the process is contained and controlled, minimizing the impact on the surrounding environment and focusing the abrasive force where it’s needed most.

Key parameters such as the type and size of the blasting media, the pressure applied, the angle of blasting, and the duration of exposure are meticulously calibrated to match the project’s specific needs. This customization capability is what makes bead blasting so effective across a diverse range of applications. For instance, glass beads are often used for a smoother finish, while steel shots might be selected for their aggressiveness in removing tougher surface impurities.

The choice of blasting media is a critical decision that influences the outcome. Each type of media carries its own set of properties, from hardness to size and shape, affecting the surface in unique ways. This selection process is guided by a deep understanding of the material being machined and the desired end result, whether it’s a matte finish for visual appeal or a textured surface for functional purposes such as improved paint adhesion.

The Role of Bead Blasting in Enhancing Surface Quality

Surface quality is paramount in CNC precision machining, and bead blasting plays a pivotal role in achieving the desired outcomes. The process goes beyond mere aesthetics; it has a profound effect on the functionality of the machined part. A bead-blasted surface offers improved paint adhesion, essential for parts that require subsequent finishing processes. It also plays a crucial role in preventing corrosion, a common concern for metal components exposed to harsh environments.

Bead blasting significantly impacts the surface quality of CNC machined parts, affecting both their appearance and functional properties. This process can achieve a variety of surface finishes, from a smooth, satin-like appearance to a roughened texture, which is essential for certain functional coatings to adhere properly.

Table 1: Surface Quality Improvements through Bead Blasting

| Surface Parameter | Before Blasting | After Blasting | Improvement (%) |

|---|---|---|---|

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | 75% |

| Corrosion Resistance | Baseline | +20% | 20% |

| Paint Adhesion Strength | 2.5 MPa | 4.5 MPa | 80% |

| Visual Inspection (Scratches/Burrs) | 10-15 defects | 0-2 defects | >85% |

| Surface Hardness | 150 HV | 170 HV | 13% |

| Cleanliness Level | ISO 16232 Level 5 | ISO 16232 Level 2 | Improved 3 Levels |

| Surface Wettability | 72° (Contact Angle) | 34° (Contact Angle) | Improved |

| Fatigue Life | Baseline | +15% | 15% |

This table showcases the tangible benefits of bead blasting on surface quality parameters. The improvements in surface roughness, corrosion resistance, and paint adhesion strength are particularly noteworthy, as these directly contribute to the longevity and functionality of CNC machined parts.

Moreover, bead blasting can eliminate surface defects, such as scratches or burrs, that may have been introduced during the machining process. This not only improves the visual appeal of the part but also contributes to its overall durability and performance. The uniform matte finish that bead blasting can achieve is often a critical specification for components used in high-precision applications, where even minor surface irregularities can lead to significant performance issues.

Technical Challenges in Bead Blasting for CNC Machining

Despite its advantages, bead blasting is not without its challenges, especially when applied to the precise requirements of CNC machining. Achieving a uniform finish on complex geometries can be daunting, requiring advanced techniques and careful control of the blasting parameters. The risk of media impregnation, where blasting particles become embedded in the surface, is a significant concern that can compromise the integrity of the part.

Another challenge lies in controlling the amount of material removed during the blasting process. Excessive material removal can alter the dimensions of the part, leading to deviations from the specified tolerances. This necessitates a delicate balance between achieving the desired surface finish and maintaining the dimensional integrity of the part.

The intricacies of bead blasting in CNC machining demand a high level of expertise and experience. Machinists must not only understand the fundamentals of the process but also possess the ability to adapt and optimize the parameters for each unique project. This includes selecting the right media, adjusting the blasting pressure, and determining the optimal angle and duration of exposure.

Optimizing Bead Blasting Parameters for Precision Machining

Optimizing bead blasting parameters is crucial for achieving the desired surface quality without compromising the dimensional integrity of the part. This optimization process involves adjusting various parameters, such as media type, size, blasting pressure, and duration, to achieve the best possible outcome.

Table 2: Optimization of Bead Blasting Parameters

| Parameter | Range | Optimal Value | Impact on Surface Quality |

|---|---|---|---|

| Media Type | Glass, Ceramic, Steel, etc. | Ceramic | Balanced between abrasiveness and surface finish |

| Media Size | 50 – 150 µm | 100 µm | Optimal for uniform surface texture |

| Blasting Pressure | 2 – 8 bar | 4 bar | Adequate to clean without substrate damage |

| Blasting Angle | 30° – 90° | 60° | Effective for even surface coverage |

| Duration | 30 – 120 seconds | 60 seconds | Sufficient for consistent surface treatment |

| Distance to Part | 10 – 50 cm | 30 cm | Ensures even media distribution |

| Part Rotation Speed | 0 – 20 RPM | 10 RPM | Uniform blasting over complex geometries |

| Post-Blast Cleaning | Air, Water, None | Air | Removes residual media effectively |

This table illustrates how each parameter can be fine-tuned to enhance the bead blasting process. Optimal values are determined through extensive testing and are dependent on the specific requirements of each part.

Case Studies: Successful Applications of Bead Blasting in CNC

- Aerospace Component Finishing: An aerospace company faced challenges with paint peeling off critical components. After implementing bead blasting with optimized parameters, they achieved a 40% increase in paint adhesion strength, significantly reducing maintenance costs and improving component longevity.

- Medical Implant Texturization: A manufacturer of orthopedic implants used bead blasting to create a textured surface on titanium implants, which improved bone ingrowth by 25%, enhancing the stability and success rate of the implants.

- Automotive Turbocharger Enhancement: Bead blasting was applied to the surface of turbocharger components, resulting in a 15% improvement in fatigue life, thereby enhancing the reliability and performance of the turbochargers under extreme conditions.

Future Prospects: Innovations and Trends in Bead Blasting Technology

The future of bead blasting in CNC precision machining is bright, with ongoing innovations aimed at improving efficiency, environmental sustainability, and versatility. Advancements such as robotic automation, eco-friendly media, and real-time process monitoring are set to redefine the capabilities of bead blasting.

- Robotic Bead Blasting: Integration of robotic arms with bead blasting equipment allows for precise control and repeatability, especially for complex parts, leading to higher consistency and reduced labor costs.

- Eco-friendly Media: Development of biodegradable and recyclable blasting media reduces environmental impact and operational costs, making bead blasting a more sustainable process.

- Process Monitoring Technologies: Incorporation of IoT sensors and AI algorithms for real-time monitoring and adjustment of bead blasting parameters optimizes the process dynamically, ensuring optimal results with minimal waste.

Other Articles You Might Enjoy

- The Multifaceted Applications of Bead Blasting in CNC Machining

1. Introduction: Unveiling the Versatility of Bead Blasting In this opening section, we introduce the concept of bead blasting in CNC machining and set the stage for an in-depth exploration…

- Precision CNC Machining for the Aerospace Defense Industry

Precision CNC Machining in the Aerospace Defense Industry In modern manufacturing sectors, precision Computer Numerical Control (CNC) machining plays a critical role. It is an automated process that uses pre-programmed…

- The Evolution of CNC Machining: From Aluminum to Composite Materials

Introduction to CNC Machining CNC (Computer Numerical Control) machining is a manufacturing process that utilizes computerized controls to initiate and manipulate machine tools, such as lathes, mills and grinders. With…