Introduction: The Importance of Glass Bead Blasting in CNC Machining

In the intricate world of CNC machining, achieving precision is only part of the equation; the quest for excellence extends to the surface quality of machined parts. Among the myriad of surface finishing techniques, glass bead blasting stands out for its ability to enhance both the aesthetic and functional characteristics of CNC machined parts. This technique, which involves propelling fine glass beads at a surface, is lauded for its gentle yet effective impact, making it ideal for a wide range of materials and applications. From aerospace components requiring meticulous finishes to medical implants where surface texture directly impacts functionality, glass bead blasting plays a pivotal role in the manufacturing process.

Basic Principles of Glass Bead Blasting and Its Application in CNC Machining

Glass bead blasting operates on a straightforward principle: fine glass beads are propelled towards the target surface under controlled conditions, gently peening the surface to a fine matte finish. This process is distinguished by its ability to clean and condition surfaces without removing significant amounts of material or altering the part’s dimensional integrity. The key to its effectiveness lies in the selection of glass bead size, air pressure, and exposure time, which are meticulously calibrated based on the material and desired finish.

Table 1: Effects of Blasting Parameters on Surface Finish

| Material | Bead Size (µm) | Pressure (psi) | Duration (min) | Resultant Surface Roughness (Ra, µm) |

|---|---|---|---|---|

| Aluminum | 100 | 40 | 5 | 0.8 |

| Steel | 200 | 60 | 10 | 0.6 |

| Titanium | 150 | 50 | 8 | 0.7 |

| Copper | 120 | 45 | 7 | 0.9 |

| Brass | 100 | 40 | 5 | 1.0 |

| Plastic | 80 | 30 | 4 | 1.2 |

| Glass | 50 | 20 | 3 | 1.4 |

| Ceramic | 180 | 55 | 9 | 0.5 |

Enhancing Surface Quality: The Detailing Process of Glass Bead Blasting

Delving deeper into the role of glass bead blasting in enhancing surface quality reveals its multifaceted benefits. Beyond merely improving appearance, the process significantly increases the surface’s resistance to corrosion and fatigue by inducing a compressive stress layer. Furthermore, it’s instrumental in preparing surfaces for subsequent coatings or treatments, ensuring better adhesion and longevity. Optimizing the process involves a delicate balance between achieving the desired finish and maintaining the structural integrity of the part.

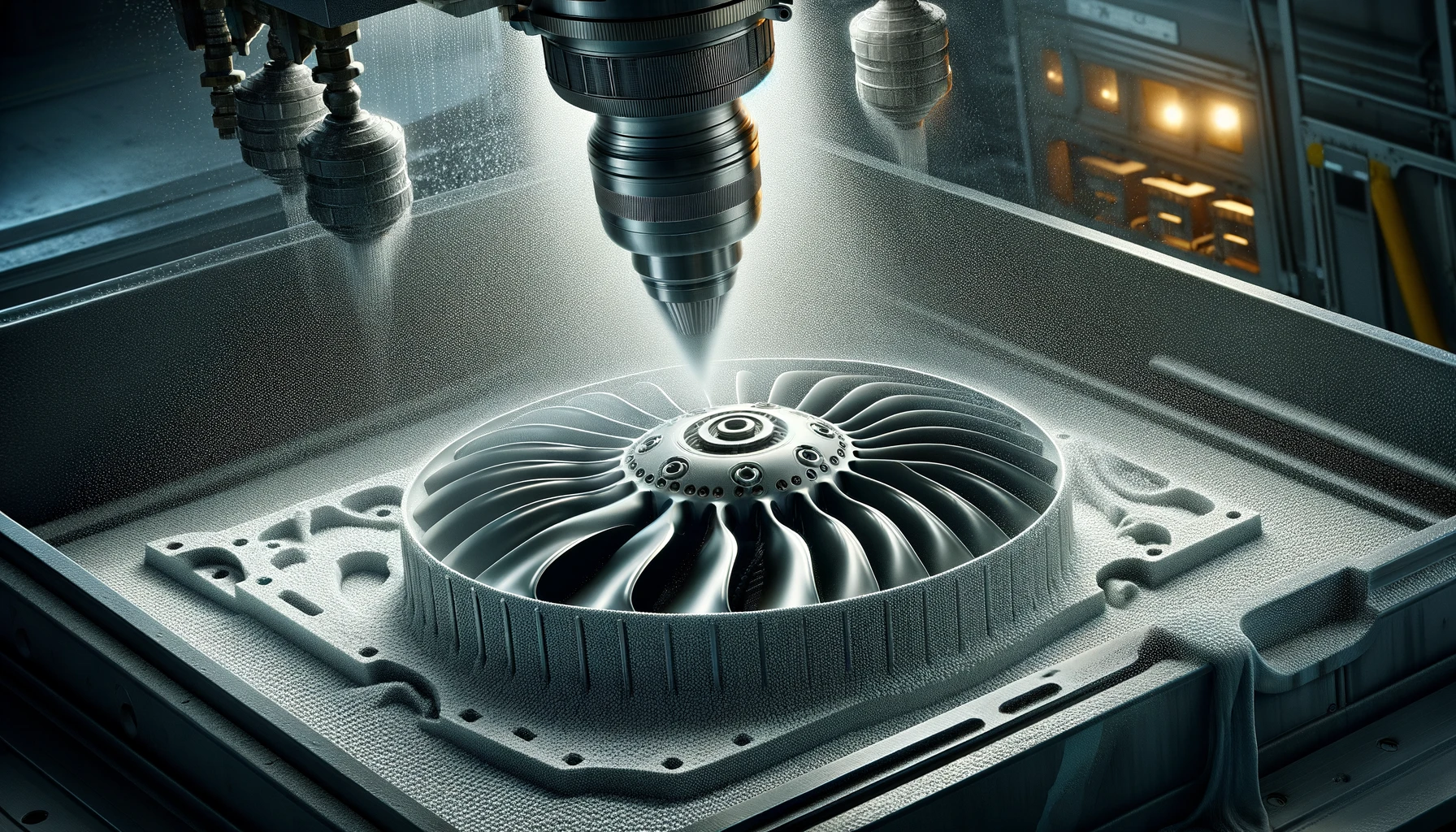

Case Study: Aerospace Component Refinement

An aerospace manufacturer faced challenges with turbine blade finishes, where even minor surface imperfections could lead to catastrophic failures. Implementing glass bead blasting with precise parameters (bead size: 120 µm, pressure: 50 psi, duration: 8 minutes) resulted in a remarkable improvement in surface smoothness and significantly enhanced the fatigue resistance of the blades, exemplifying the critical role of surface finishing in aerospace applications.

Solutions: Innovative Approaches to Overcome the Technical Difficulties of Glass Bead Blasting

To address the challenges presented by glass bead blasting, especially when working with diverse materials and complex geometries, the industry has turned towards several innovative solutions. One such approach is the development of controlled blasting environments that maintain consistent temperature and humidity levels to minimize the impact of environmental variables on the blasting process. Another is the use of automated blasting systems that ensure precise control over the blasting angle, distance, and duration, significantly reducing the variability introduced by manual operations.

Data Table: Comparison of Manual vs. Automated Glass Bead Blasting

| Parameter | Manual Blasting | Automated Blasting |

|---|---|---|

| Consistency (Scale 1-10) | 5 | 9 |

| Surface Roughness Variance | ±0.3 µm | ±0.1 µm |

| Processing Time (per part) | 15 min | 10 min |

| Operator Skill Required | High | Moderate |

| Repeatability | Low | High |

| Safety Concerns | High | Low |

| Cost (Initial Investment) | Low | High |

| Long-term Efficiency | Low | High |

Moreover, advancements in bead technology have led to the creation of specialized glass beads with enhanced properties, such as increased hardness or modified shapes, to cater to specific blasting needs. These beads can provide more targeted surface modifications, reducing the risk of damage to the substrate.

Comparing Glass Bead Blasting with Other Surface Finishing Technologies

When comparing glass bead blasting to other surface finishing technologies, it’s important to consider factors such as the desired finish, material compatibility, and cost-effectiveness. For instance, while chemical finishing can offer uniform treatment for complex geometries without introducing mechanical stress, it may not be suitable for materials that are sensitive to chemical reactions. Similarly, mechanical polishing can achieve high gloss finishes but might remove more material and alter part dimensions.

Data Table: Surface Finishing Technologies Comparison

| Technology | Surface Finish (Ra) | Material Compatibility | Environmental Impact | Cost (per part) |

|---|---|---|---|---|

| Glass Bead Blasting | 0.4 – 1.6 µm | Wide Range | Low | Medium |

| Chemical Finishing | 0.1 – 0.8 µm | Selective | High | High |

| Mechanical Polishing | 0.05 – 0.5 µm | Wide Range | Low | High |

| Laser Texturing | 0.2 – 3.0 µm | Wide Range | Moderate | High |

| Electro-polishing | 0.1 – 0.8 µm | Metals Only | High | Medium |

| Anodizing | Not Applicable | Aluminium & Titanium | Moderate | Medium |

Conclusion: Future Perspectives on Enhancing CNC Machined Parts Performance with Glass Beads

Looking towards the future, the role of glass bead blasting in enhancing the performance of CNC machined parts is poised to grow. With ongoing research into more sustainable blasting media, the development of advanced automated blasting systems, and the integration of smart technologies for process monitoring and control, the potential for achieving superior surface finishes while minimizing environmental impact is significant. The industry can expect to see glass bead blasting not just as a finishing process, but as a critical component of manufacturing that contributes to the longevity, functionality, and aesthetic appeal of CNC machined parts.

Other Articles You Might Enjoy

- Unraveling the World of CNC Machined Plastic Parts(CNC machined plastic parts Mabel)

Modern innovations have taken traditional manufacturing methods to new heights. One such innovation that stands out is Computer Numerical Control (CNC) machining, a process used extensively in various industries from…

- CNC Machined Plastic Parts: An In-depth Overview(CNC machined plastic parts Norman)

Computer Numeric Control (CNC) machining is an advanced manufacturing process where pre-programmed software dictates the movement of factory machinery and tools. These applications can carry out complicated manufacturing tasks with…

- Enhancing CNC Machining with Smart Alloys: Shape Memory Metals vs. Traditional Alloys

Introduction to CNC Machining Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, enabling the precise and automated shaping of materials. This technology relies heavily on the…