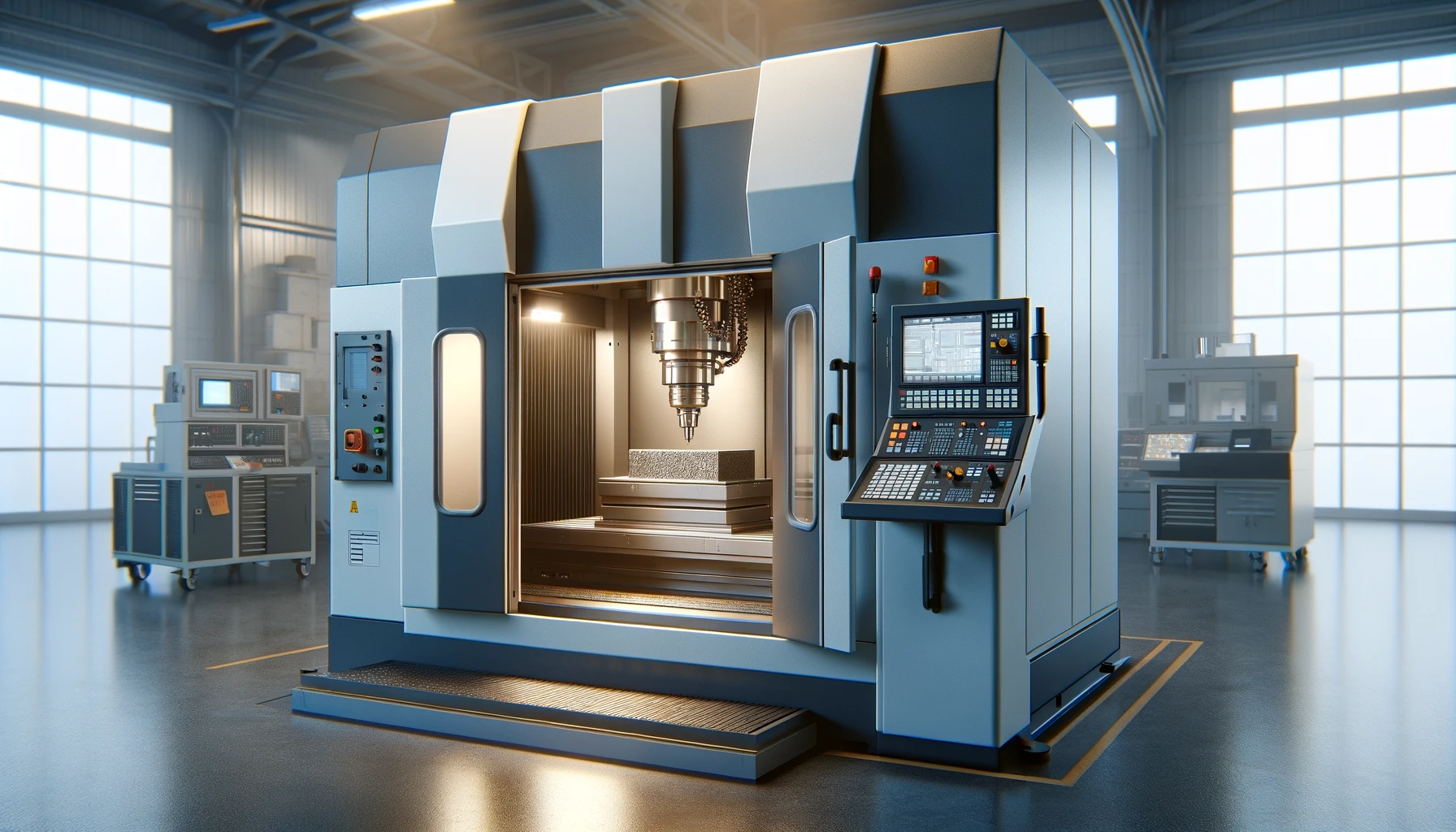

The integration of CNC (Computer Numerical Control) milling and Bead Blasting in modern manufacturing heralds a new era of precision and aesthetic excellence. CNC milling, known for its precise cutting capabilities, when combined with the surface finishing prowess of Bead Blasting, results in products that are not only functionally superior but also visually appealing.

Understanding CNC Milling Machining

CNC milling is a subtractive manufacturing process where computer-controlled tools remove material from a workpiece to create complex shapes with high precision. This process is vital in industries requiring intricate designs and tight tolerances, such as aerospace, automotive, and medical devices.

Advanced Capabilities:

- Multi-axis Machining: Allows for the production of complex shapes and fine details.

- High-Speed Machining: Increases production efficiency without compromising precision.

Table 1: Comparison of CNC Milling Capabilities by Axis Configuration

| Axis Configuration | Capabilities | Typical Applications | Material Compatibility | Production Volume | Precision Level |

|---|---|---|---|---|---|

| 3-Axis | Basic cuts, simple geometries | Flat parts, simple molds | Metals, plastics, composites | Low to medium | High |

| 4-Axis | Advanced geometries, rotational cutting | Complex parts, gears | Metals, plastics, composites | Medium | Very high |

| 5-Axis | Complex 3D shapes, intricate details | Aerospace components, medical implants | Metals, advanced composites | Low to high | Extremely high |

Exploring Bead Blasting

Bead Blasting is a surface finishing technique that involves propelling fine glass beads at a surface to achieve a uniform, matte finish. This process is crucial for preparing surfaces for further finishing or improving their aesthetic and mechanical properties.

Material Considerations:

- Aluminum: Often used for its lightweight and corrosion resistance.

- Stainless Steel: Preferred for medical devices for its non-contaminating finish.

Table 2: Benefits of Bead Blasting by Material

| Material | Surface Finish | Application Benefits | Industry Usage | Aesthetic Impact | Durability Enhancement |

|---|---|---|---|---|---|

| Aluminum | Matte, uniform finish | Improved paint adhesion | Automotive, aerospace | High | Yes |

| Stainless Steel | Non-contaminating, smooth finish | Enhanced cleanliness | Medical, food processing | Moderate | Yes |

| Titanium | Smooth, matte finish | Reduced light reflection | Aerospace, medical | High | Yes |

| Plastics | Uniform texture | Improved visual appeal | Consumer goods | Moderate | Variable |

Synergy between Bead Blasting and CNC Milling

The synergy between CNC milling and Bead Blasting transcends the mere combination of two distinct manufacturing processes; it represents a holistic approach to creating parts with unmatched precision and aesthetic appeal. This collaboration ensures that the meticulous detailing achieved through CNC milling is complemented by a superior surface finish, courtesy of Bead Blasting.

The strategic integration of these processes is particularly advantageous in industries where the functionality of a part is as critical as its appearance. For instance, in the aerospace sector, components not only need to meet exacting dimensional tolerances for safety and performance but also require a specific surface finish to minimize aerodynamic drag. Similarly, in the medical device industry, the surface finish is paramount for sterilization and compatibility with human tissue, alongside the need for dimensional precision for proper fit and function.

Furthermore, the combination of Bead Blasting and CNC milling allows for the optimization of manufacturing workflows. By refining the surface of CNC-milled parts through Bead Blasting, manufacturers can reduce the need for manual finishing processes, which are often time-consuming and prone to inconsistencies. This streamlined approach not only enhances the efficiency of the production process but also significantly improves the repeatability and quality of the final products.

Moreover, this synergistic partnership paves the way for innovative design possibilities. Designers and engineers can now envision and create complex geometries with the confidence that the surface finish will not be compromised. The ability to reliably produce parts with intricate details and superior finishes opens new avenues in design, particularly for industries like consumer electronics, where the aesthetic appeal is a key product differentiator.

In essence, the integration of Bead Blasting with CNC milling embodies a perfect marriage of form and function. It ensures that every manufactured part meets the highest standards of precision engineering while also achieving a level of surface refinement that enhances both its performance and aesthetic value.

Addressing Technical Challenges in Detail

Integrating CNC milling with Bead Blasting introduces unique challenges such as maintaining part integrity, achieving uniform finishes, preventing media contamination, and managing the impact on material properties.

- Preventing Part Distortion: The use of custom fixtures and controlled blasting parameters ensures minimal stress on parts, preserving their shape and dimensions.

- Ensuring Uniform Surface Finishes: Robotic blasting systems and strategic media selection guarantee consistent finishes across complex geometries and batch productions.

- Avoiding Media Contamination: Choosing media with suitable hardness and implementing rigorous post-blasting cleaning processes help maintain surface purity.

- Controlling Impact on Mechanical Properties: Differentiating between surface cleaning and peening applications, combined with thorough material testing, allows for precise control over the process’s impact on a part’s mechanical properties.

Table 3: Solutions to Technical Challenges in CNC Milling and Bead Blasting Integration

| Challenge | Solution Strategy | Implementation Method | Benefit |

|---|---|---|---|

| Part Distortion | Custom Fixtures | Design part-specific supports | Maintain dimensional accuracy |

| Controlled Blasting Parameters | Adjust pressure and duration | Minimize stress on parts | |

| Surface Finish Uniformity | Robotic Blasting Systems | Program precise blasting paths | Achieve consistent finishes |

| Strategic Media Selection | Choose media based on part material | Tailor finish to application needs | |

| Media Contamination | Suitable Media Hardness | Select media softer than part material | Prevent embedding |

| Post-Blasting Cleaning | Use ultrasonic cleaning, high-pressure air or water jets | Ensure surface purity |

Future Directions: Automation and AI

The intersection of automation and AI with CNC milling and Bead Blasting heralds a new era of manufacturing efficiency and precision. Predictive maintenance, powered by AI, promises to minimize downtime, ensuring machines operate at peak efficiency.

Conclusion

The confluence of CNC milling and Bead Blasting encapsulates a harmonious blend of precision machining with high-grade surface finishing, setting new benchmarks in manufacturing. As we move forward, the integration of advanced technologies will continue to refine this synergy, pushing the boundaries of what’s achievable in the manufacturing domain.

Other Articles You Might Enjoy

- Revolutionizing Renewable Energy with CNC Machined Components

Introduction: Renewable Energy and CNC Machined Components Renewable energy harnesses power from natural sources such as the sun, wind, and water, making it a sustainable and eco-friendly alternative to traditional…

- Is Copper the Right Choice for Electrical Component CNC Machining? A Detailed Analysis

CNC Machining of Electrical Components Utilizing Copper In the field of electrical engineering, Computer Numerical Control (CNC) machining plays an integral role, particularly in the development and manufacturing of electrical…

- CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown?

Introduction to CNC Machining Brass vs. Bronze: Cost, Properties, and Applications Showdown? In this article, we delve into the debate between brass and bronze machining for an important manufacturing process…