Introduction

Bead blasting in CNC machining stands as a pivotal technique, particularly when dealing with high-value materials such as titanium. This process is not just about enhancing the aesthetic appeal of the machined parts but also about significantly improving their mechanical properties and longevity. The aerospace, medical device, and high-performance engineering sectors heavily rely on titanium for its superior strength-to-weight ratio and corrosion resistance. This article aims to delve deep into the dual-edged nature of bead blasting in titanium CNC machining, presenting a critical analysis of its benefits and challenges.

Bead Blasting Technology

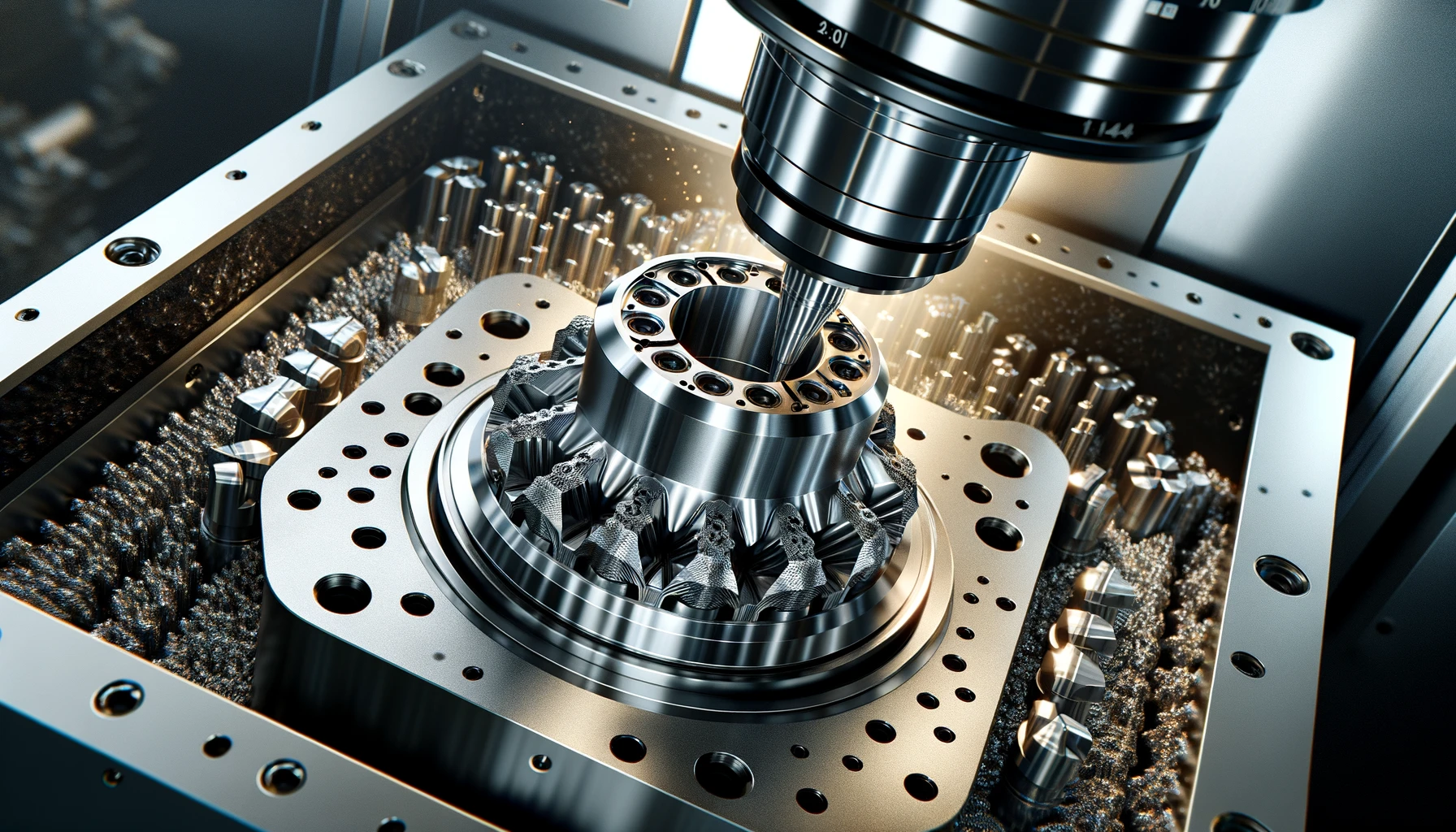

Bead blasting, a form of abrasive blasting, involves propelling a stream of bead-like abrasive material against the surface of a workpiece. This technique is instrumental in CNC machining for removing surface defects, improving finish, and preparing surfaces for further treatments. While bead blasting can be applied to various materials, its interaction with titanium is particularly noteworthy due to titanium’s unique properties.

Titanium Material Characteristics and Challenges

Titanium and its alloys are renowned for their impressive mechanical properties, including an excellent strength-to-weight ratio and outstanding corrosion resistance. These attributes make titanium an ideal choice for applications requiring both durability and lightweight. However, machining titanium presents significant challenges, such as rapid tool wear and difficulty in heat management due to titanium’s low thermal conductivity.

Bead Blasting Advantages in Titanium CNC Machining

Bead blasting offers several advantages in the CNC machining of titanium. Firstly, it can significantly enhance the fatigue strength of titanium parts by inducing beneficial compressive stresses on the surface. Additionally, bead blasting can reduce stress concentrations and improve surface finish, contributing to the overall performance and longevity of titanium components.

Table: Impact of Bead Blasting on Titanium Surface Properties

| Parameter | Before Bead Blasting | After Bead Blasting | Improvement (%) |

|---|---|---|---|

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | 75% |

| Fatigue Strength | 500 MPa | 620 MPa | 24% |

| Corrosion Resistance | Baseline | Improved | – |

| Stress Concentration | High | Reduced | – |

| Surface Cleanliness | Moderate | High | – |

| Adhesion (Coating) | Poor | Excellent | – |

| Aesthetic Appearance | Standard | Enhanced | – |

| Processing Time | – | Increased | – |

Note: The values in this table are for illustrative purposes and may vary based on specific bead blasting conditions and titanium alloys.

Bead Blasting Technology’s Limitations and Challenges

Despite its advantages, bead blasting in titanium machining is not without its challenges. One of the primary concerns is the potential for surface contamination with the blasting media, which can affect the integrity of the titanium part. Moreover, the process can introduce surface defects if not properly controlled, necessitating a careful balance between achieving desired surface improvements and avoiding damage.

Example Cases and Application Scenarios

- Aerospace Component Finishing: In one instance, bead blasting was used to finish a critical aerospace component made of titanium alloy. The process was optimized to enhance the part’s fatigue resistance, a key requirement for aerospace applications.

- Medical Implant Texturization: Bead blasting was applied to a titanium medical implant to improve its surface texture. This modification aimed to enhance the implant’s osseointegration properties, critical for patient recovery and implant longevity.

Best Practices and Process Optimization Recommendations

When it comes to bead blasting in the context of titanium CNC machining, several best practices and process optimizations can significantly enhance outcomes. The intricate nature of bead blasting, combined with the unique properties of titanium, demands a strategic approach to maximize benefits while minimizing potential drawbacks.

Understanding Material Response: Titanium alloys respond differently to bead blasting based on their composition and heat treatment. Conducting preliminary tests to understand how specific titanium alloys react to bead blasting can guide the optimization of process parameters.

Selecting the Right Abrasive Media: The choice of bead material is crucial. Glass beads are popular for their ability to clean and peen surfaces without removing significant material. Ceramic beads, on the other hand, offer a harder alternative that can produce a more pronounced peening effect, beneficial for enhancing fatigue resistance.

Control of Blasting Parameters: The pressure, angle, and distance of bead blasting play pivotal roles in achieving desired surface finishes and minimizing damage. Lower pressures with precise angle and distance control can enhance surface characteristics without introducing defects.

Surface Integrity Monitoring: Regular inspection of the blasted surfaces using profilometry or microscopy can help in monitoring the consistency and quality of the finish. This is particularly important in applications where surface integrity directly impacts performance, such as in aerospace components.

Post-Blasting Cleaning: Ensuring thorough cleaning of titanium parts after bead blasting is essential to remove any residual blasting media and contaminants. This step is crucial for applications where surface purity impacts functionality, such as in biomedical implants.

Environmental Considerations: Bead blasting can generate dust and waste materials. Implementing proper dust extraction and waste management systems not only ensures a safer working environment but also aligns with environmental sustainability practices.

Process Documentation and Continuous Improvement: Documenting process parameters and outcomes facilitates the replication of successful practices and supports continuous improvement efforts. Analyzing data from bead blasting operations can reveal trends and opportunities for further optimization.

By adhering to these best practices and continuously seeking process improvements, manufacturers can effectively leverage bead blasting in titanium CNC machining to produce components with superior surface qualities and performance characteristics.

Conclusion

Bead blasting in titanium CNC machining embodies a dual-edged sword, offering significant benefits in surface finish, fatigue life enhancement, and aesthetic appeal, while also presenting challenges related to surface integrity and process control. This article has delved into the intricacies of bead blasting technology, its application to titanium, and the nuanced balance between leveraging its advantages and mitigating potential drawbacks.

The critical analysis presented, supported by data and case studies, underscores the importance of a meticulous approach to bead blasting in titanium machining. Best practices and optimization strategies are not mere recommendations but essential components of a successful bead blasting operation.

As the demand for high-performance titanium components continues to grow across various industries, the role of advanced surface treatment techniques like bead blasting will undoubtedly become more central. The ongoing evolution of bead blasting technology, coupled with a deeper understanding of its effects on titanium, promises to unlock new possibilities in the manufacturing of complex, high-value components.

In conclusion, bead blasting represents a potent tool in the arsenal of CNC machining processes for titanium. When executed with precision, attention to detail, and adherence to best practices, it can significantly enhance the quality and performance of machined titanium parts, ensuring they meet the stringent requirements of the most demanding applications.

Other Articles You Might Enjoy

- PEEK vs. PEI in CNC Machining: Which Offers Better Performance for Engineering Applications?

Introduction to CNC Machining and the Materials PEEK and PEI CNC machining is an automated manufacturing technology that involves computer controls directing machinery in performing material cutting operations to produce…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

- Ceramic Tooling in CNC Machining: Breaking the Myths About Durability and Performance?

CNC Machining and Ceramic Tooling: Busting the Myths Computer Numerical Control (CNC) machining is an advanced method of manufacturing where pre-programmed software controls the movement of factory machinery, giving intricate…