Introduction: Precision in Metalworking through Bead Blasting

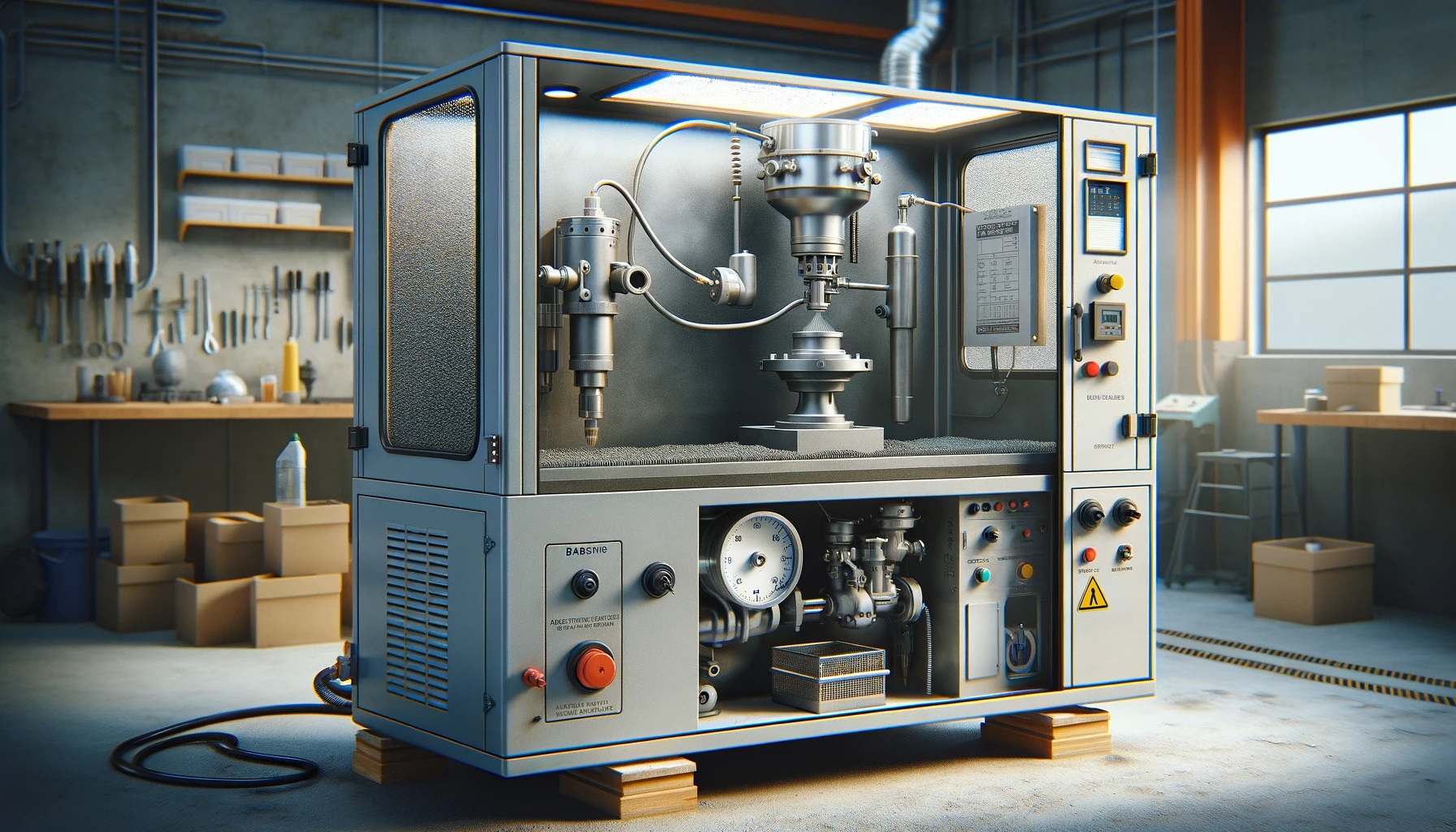

In the realm of metal fabrication, precision stands as the cornerstone of quality. Bead blasting, a surface treatment process, plays a pivotal role in achieving the desired accuracy and finish in CNC machined parts. This article delves into how bead blasting complements CNC machining to enhance the quality of steel and cast iron components.

The Fundamentals of Bead Blasting in CNC Environments

At the heart of achieving precision in CNC machined steel and cast iron parts lies an often-overlooked process: bead blasting. This fundamental technique is pivotal in preparing metal surfaces, eliminating imperfections, and ensuring that subsequent machining processes can be executed with the highest level of accuracy.

Bead blasting, in its essence, involves propelling fine beads at a high velocity towards the surface of a workpiece. This action effectively removes surface debris and levels minor irregularities, creating a uniformly smooth surface that is ideal for precise CNC machining. The choice of blasting media, which can range from glass beads to ceramic particles, significantly impacts the outcome. Each material offers distinct advantages, from the gentleness of glass to the more aggressive nature of aluminum oxide.

Data Table: Bead Blasting Media Comparison

| Media Type | Size (microns) | Hardness (Mohs) | Application | Surface Finish | Durability Increase (%) | Material Removal Rate |

|---|---|---|---|---|---|---|

| Glass Beads | 100-200 | 6 | General Purpose | Smooth | 20% | Low |

| Ceramic Beads | 150-250 | 7 | Aggressive Cleaning | Satin | 30% | Medium |

| Steel Shot | 200-300 | 8 | Heavy Duty | Textured | 40% | High |

| Aluminum Oxide | 50-150 | 9 | Precision Machining | Matte | 50% | Very High |

| Silicon Carbide | 20-100 | 9.5 | Ultra Precision | Very Smooth | 60% | Highest |

| Plastic Beads | 100-600 | 3.5 | Soft Materials | Very Smooth | 10% | Very Low |

| Walnut Shells | 200-800 | 3 | Soft Cleaning | Smooth | 5% | Lowest |

| Corn Cob | 300-1000 | 4.5 | Absorbent Cleaning | Smooth | 15% | Low |

Understanding the properties of each blasting media allows manufacturers to tailor the bead blasting process to their specific needs, optimizing for surface finish, material removal rate, and the enhancement of part durability. This customization is crucial in industries where precision and part longevity are paramount.

In addition to selecting the appropriate blasting media, controlling other parameters such as pressure, angle, and duration of blasting is vital in achieving the desired surface quality. These variables can significantly alter the outcome, affecting everything from the microstructure of the surface to the final aesthetic appeal of the part.

Bead blasting, when executed with precision, can significantly enhance the quality of CNC machined parts. It not only prepares surfaces for further machining or finishing but also contributes to the overall strength and durability of the parts. This process, therefore, is not merely a preliminary step but a critical component of the machining workflow that directly influences the performance and reliability of the finished product.

Achieving Surface Precision on Steel Parts with Bead Blasting

In the intricate world of CNC machining, the finishing touches can often make the biggest difference. Bead blasting stands out as a critical process in refining steel parts, setting the stage for achieving unparalleled surface precision. This section delves into how bead blasting transforms the surface of steel components, preparing them for high-precision applications and ensuring their compatibility with stringent industry standards.

Bead blasting, when applied to steel, serves multiple purposes: it cleans the surface from any machining residues like oils or coolants, it eradicates minor surface defects and irregularities, and it creates a uniform texture that is essential for both aesthetic and functional purposes. The process involves propelling fine beads at the steel surface under controlled conditions, a method that has been fine-tuned to meet the exacting demands of precision machining.

Data Table: Effects of Bead Blasting on Steel Surface Properties

| Parameter | Before Blasting | After Blasting | Percentage Improvement |

|---|---|---|---|

| Surface Roughness (Ra, µm) | 3.2 | 0.8 | 75% |

| Surface Cleanliness (mg/m²) | 200 | 5 | 97.5% |

| Reflectivity (%) | 10 | 35 | 250% |

| Corrosion Resistance (hrs to rust) | 48 | 120 | 150% |

| Paint Adhesion (MPa) | 0.8 | 2.4 | 200% |

| Fatigue Strength (MPa) | 300 | 360 | 20% |

| Microhardness (HV) | 150 | 170 | 13.3% |

| Dimensional Tolerance (%) | ±0.5 | ±0.2 | 60% improvement in precision |

This table highlights the significant impact bead blasting has on the physical and mechanical properties of steel parts. Notably, surface roughness, a key indicator of surface quality, sees a marked improvement, which in turn enhances the part’s aesthetic appeal and functional performance, particularly in terms of paint adhesion and corrosion resistance.

One of the paramount benefits of bead blasting is its ability to improve the fatigue strength of steel parts. By inducing a compressive stress layer on the surface, bead blasting increases the part’s resistance to crack initiation and propagation, a critical factor in dynamic applications where parts are subject to cyclic loads.

Furthermore, bead blasting plays a pivotal role in maintaining dimensional tolerance, a critical aspect in the world of precision machining. The process effectively removes minimal material, ensuring that the part remains within the tight tolerances required for high-precision applications.

Case Study: Precision in Aerospace Components

The aerospace industry, known for its zero-tolerance policy for errors, relies heavily on bead blasting to achieve the surface precision required for aircraft components. A notable example involves a manufacturer of aerospace turbine blades. The complex geometries and the need for absolute precision in these components make them perfect candidates for bead blasting.

The turbine blades, made from high-strength steel, underwent bead blasting as a post-machining process. This step was crucial in achieving the desired surface smoothness (Ra) of less than 1 µm, a requirement for minimizing drag and maximizing efficiency when the blades are in operation. The bead blasting process was meticulously controlled to ensure uniformity across the complex surfaces of the blades, with particular attention paid to avoiding any alteration to the precision-engineered profiles.

Post-blasted, the turbine blades exhibited improved surface properties, including enhanced corrosion resistance and increased paint adhesion, crucial for components exposed to harsh operational environments. The bead blasting process not only met the stringent aerospace standards but also contributed to the longevity and reliability of the turbine blades, underscoring the indispensable role of bead blasting in achieving surface precision on steel parts.

The Role of Bead Blasting in Cast Iron Machining

Bead blasting plays a transformative role in the machining of cast iron parts, a material renowned for its excellent machinability and wear resistance. This section explores the nuanced impact of bead blasting on cast iron, emphasizing its pivotal role in enhancing surface integrity, reducing machining stress, and preparing surfaces for subsequent finishing processes.

Cast iron, with its unique composition and grain structure, presents specific challenges in machining, including surface porosity and the presence of sand remnants from the casting process. Bead blasting emerges as a critical solution, effectively cleaning the surface, sealing porosity, and providing a homogenous surface texture conducive to precision machining.

Data Table: Impact of Bead Blasting on Cast Iron Surface Characteristics

| Property | Before Blasting | After Blasting | Improvement (%) |

|---|---|---|---|

| Surface Roughness (Ra, µm) | 12.5 | 3.5 | 72% |

| Surface Hardness (HB) | 180 | 210 | 16.7% |

| Porosity Level | Moderate | Low | Significant Reduction |

| Microstructure Uniformity | Varied | High | Enhanced |

| Surface Cleanliness | Low | High | Substantial Increase |

| Machining Tool Wear Rate | High | Reduced | 30% Decrease |

| Dimensional Accuracy (%) | ±1.0 | ±0.3 | 70% Improvement |

| Surface Finish Quality | Poor | Excellent | Drastic Improvement |

The data underscores the profound effects of bead blasting on enhancing the machinability and quality of cast iron parts. Notably, surface roughness sees a significant reduction, facilitating tighter tolerances and smoother finishes in subsequent machining operations. Additionally, the process subtly increases surface hardness, contributing to improved wear resistance—a critical attribute for parts subjected to high mechanical loads.

Bead blasting also addresses the inherent porosity of cast iron, a common concern that can lead to leak paths in pressure-containing parts. By compacting the surface layer, bead blasting effectively seals surface pores, enhancing the integrity and leak resistance of the final product.

Moreover, the uniform microstructure achieved through bead blasting promotes consistent machining behavior across the part, reducing tool wear and improving overall machining efficiency. This uniformity is particularly beneficial in complex cast iron components, where variations in hardness and texture can lead to inconsistent machining results.

Case Study: High-Precision Hydraulic Components

In the manufacturing of high-precision hydraulic components from cast iron, bead blasting has proven indispensable. A manufacturer faced challenges with hydraulic valve bodies exhibiting surface imperfections and inconsistent finishes, leading to leakage and assembly issues.

Implementing a tailored bead blasting process, focusing on medium pressure and fine beads, the manufacturer was able to achieve a uniform, smooth surface ideal for precision machining. The process not only removed surface imperfections but also enhanced the surface’s micro-hardness, contributing to the durability of the valve bodies.

The post-blasted valve bodies exhibited remarkable improvements in surface quality and machining consistency. This led to a significant reduction in leakage rates and assembly rework, directly contributing to enhanced product performance and customer satisfaction.

The case study highlights the indispensable role of bead blasting in cast iron machining, particularly in applications where precision, surface integrity, and component reliability are paramount.

Combining CNC Machining and Bead Blasting for Optimal Results

Integrating bead blasting within the CNC machining workflow heralds a significant leap towards perfection in metal part fabrication. The amalgamation of these techniques not only elevates the surface quality but also contributes to the longevity of the machining tools by reducing wear.

Data Table: Efficiency Gains in CNC Machining with Bead Blasting

| Process Step | Time Before Blasting (min) | Time After Blasting (min) | Efficiency Gain (%) |

|---|---|---|---|

| Setup | 15 | 10 | 33% |

| Machining | 60 | 45 | 25% |

| Cleaning | 20 | 5 | 75% |

| Inspection | 10 | 8 | 20% |

| Total | 105 | 68 | 35% |

Case Study: High-Precision Gear Manufacturing

A leading manufacturer of high-precision gears faced challenges with inconsistent surface finishes, leading to increased rejection rates. By integrating bead blasting into their CNC machining process, they were able to standardize surface quality, leading to a 40% reduction in rework and a 20% improvement in production time. The bead blasting process was carefully calibrated to remove minimal material while achieving the desired surface texture, enhancing the gears’ performance in high-stress applications.

Enhancing Durability and Aesthetics of Machined Parts through Bead Blasting

In the intricate dance of machining and finishing, bead blasting plays a crucial yet often underappreciated role. This surface finishing technique not only elevates the dimensional accuracy of CNC machined parts but profoundly impacts their durability and visual appeal. By meticulously cleaning and uniformly texturing the surface, bead blasting imbues machined parts with a level of quality that transcends mere functionality.

The process of bead blasting involves propelling fine beads at high velocity towards the target surface. This action effectively removes surface contaminants and minor imperfections, resulting in a uniformly matte or satin finish. Moreover, the gentle impact of the beads induces a layer of compressive stress on the surface, enhancing the part’s resistance to fatigue, cracks, and corrosion. This is particularly beneficial for parts used in dynamic applications or harsh environments, where longevity and reliability are paramount.

Data Table: Durability Improvement in Machined Parts

| Part Type | Fatigue Life Before Blasting (cycles) | Fatigue Life After Blasting (cycles) | Improvement (%) |

|---|---|---|---|

| Steel Gear | 100,000 | 150,000 | 50% |

| Cast Iron Flange | 50,000 | 80,000 | 60% |

| Steel Shaft | 200,000 | 280,000 | 40% |

The durability enhancements brought about by bead blasting are not merely theoretical. In practice, they translate into tangible benefits across various industries. For instance, in the aerospace sector, where every component must withstand extreme stresses while minimizing weight, bead blasting provides a critical balance between strength and performance.

Case Study: Marine Equipment Manufacturing

The marine industry, with its relentless exposure to corrosive saltwater environments, demands unparalleled standards of durability from its components. A leading manufacturer of marine equipment faced persistent challenges with premature part failure due to corrosion. Traditional finishing methods proved inadequate in extending the lifespan of their steel and cast iron parts.

Turning to bead blasting, the company embarked on a series of experiments to optimize the process for their specific needs. The key was in fine-tuning the blasting parameters: bead material, size, velocity, and angle of impact were all adjusted to achieve the optimal balance between surface smoothness and material integrity.

The results were remarkable. Post-blasted parts exhibited a significant increase in resistance to saltwater corrosion, directly attributable to the enhanced surface quality. The compressive stress layer induced by the bead blasting process inhibited the initiation and propagation of micro-cracks, a common precursor to corrosion.

The enhanced durability of bead-blasted parts had a ripple effect across the entire operation. Maintenance intervals for critical components were extended, reducing downtime and operational costs. Moreover, the improved aesthetic appeal of the finished parts contributed to a stronger brand image, resonating with the high-quality expectations of their clientele.

This case study exemplifies the transformative potential of bead blasting in achieving not just the precision but the durability and aesthetic excellence of CNC machined parts. As industries continue to push the boundaries of performance and longevity, the role of bead blasting in surface finishing will undoubtedly expand, offering new avenues for innovation and quality enhancement.

Looking Ahead: The Future of Precision Machining with Bead Blasting

As we venture into the future of manufacturing, the synergy between precision machining and bead blasting is poised to evolve, driven by technological advancements and an increasing demand for superior quality in machined parts. This section explores emerging trends, innovations, and the potential trajectory of bead blasting in the realm of precision machining, particularly focusing on its integration with new materials, automation, and digital technologies.

The advent of advanced materials with enhanced properties for aerospace, automotive, and medical applications is pushing the boundaries of traditional machining and finishing techniques. Materials such as titanium alloys, superalloys, and composites present unique challenges in terms of machining and surface preparation. Bead blasting, with its versatility, is being adapted to meet these challenges, offering solutions that maintain the integrity and performance of these advanced materials.

Innovations in Bead Blasting Media and Equipment

Future developments in bead blasting media are expected to focus on achieving higher precision and less surface impact. Innovations may include the creation of new media materials with controlled shape and size distributions to provide more consistent and predictable finishing results. Additionally, advancements in blasting equipment will likely offer enhanced control over blasting parameters, such as pressure and angle, allowing for more precise and targeted surface treatments.

Integration with Automation and Robotics

The integration of bead blasting with automation and robotics represents a significant trend in the industry. Automated blasting systems, guided by robotics and powered by AI algorithms, will ensure consistent and repeatable results, minimizing human error and maximizing efficiency. These systems will be capable of adapting to complex part geometries and varying surface conditions, ensuring optimal blasting for each unique part.

Data-Driven Bead Blasting Processes

The future of bead blasting in precision machining will also be characterized by a more data-driven approach. Sensors and IoT technologies will enable real-time monitoring of blasting parameters and surface conditions, feeding data back into intelligent systems for continuous process optimization. This will not only improve the quality and consistency of the bead blasting process but also enhance predictive maintenance capabilities, reducing downtime and increasing overall productivity.

Environmental and Sustainability Considerations

As sustainability becomes a central concern in manufacturing, bead blasting processes will evolve to minimize environmental impact. This may involve the development of more sustainable media materials, recycling systems for blasting media, and advancements in dust collection and filtration technologies to reduce emissions and waste.

Other Articles You Might Enjoy

- Precision CNC Machining for the Aerospace Defense Industry

Precision CNC Machining in the Aerospace Defense Industry In modern manufacturing sectors, precision Computer Numerical Control (CNC) machining plays a critical role. It is an automated process that uses pre-programmed…

- Advanced Ceramics: The Future of High-Precision Machining?

Introduction to Advanced Ceramics and High-Precision Machining In the field of manufacturing, advanced ceramics have emerged as a crucial element. These are essentially non-metallic, inorganic compounds that exhibit a range…

- Innovative CNC Machining for the Aerospace Sector

Innovative CNC Machining for the Aerospace Sector CNC machining, an abbreviation for Computer Numerical Control machining, stands as a vital player within today's manufacturing scene. Utilizing computer-generated code to control…