Opening: Exploring the Innovative Trends in China CNC Machining

The landscape of China’s manufacturing industry has been profoundly transformed by advancements in CNC (Computer Numerical Control) machining. As the backbone of modern manufacturing, CNC machining in China has not only enhanced operational efficiency but also elevated the quality standards of produced goods. In the forefront of these advancements are innovative trends like bead blasting and face milling, which have been pivotal in setting new benchmarks for precision and finish in manufacturing.

Bead blasting, a surface finishing technique, and face milling, a precise material removal process, have each played critical roles in this transformation. Their integration into CNC machining workflows signifies a leap towards more refined, efficient, and adaptable manufacturing processes. This synergy is not just reshaping the capabilities of CNC machining in China but also setting a precedent for global manufacturing practices.

Overview of Face Milling: Fundamentals and Applications

Face milling stands as a cornerstone technique in the realm of CNC machining, characterized by its ability to produce flat surfaces and intricate contours with high precision. This process involves the use of face milling cutters, which are equipped with multiple cutting edges that work simultaneously to remove material from the surface of the workpiece. The versatility of face milling allows it to be applied across a wide range of materials, from metals to plastics, making it indispensable in industries such as aerospace, automotive, and consumer electronics.

The application of face milling in the aerospace industry, for instance, underscores its precision and reliability. Components like turbine blades, which demand exacting standards for smoothness and dimensional accuracy, are routinely crafted using face milling techniques. The ability to achieve such high levels of precision not only ensures the performance of aerospace components but also significantly enhances their safety and longevity.

Case Study: A notable example is the collaboration between a leading Chinese CNC machining company and an aerospace manufacturer. The project involved the face milling of complex engine components, where the precision of the milled surfaces was critical to the components’ performance. The use of advanced face milling techniques resulted in a significant reduction in processing time and a marked improvement in component quality, setting a new standard for precision machining in the aerospace sector.

Deciphering Bead Blasting: From Theory to Practice

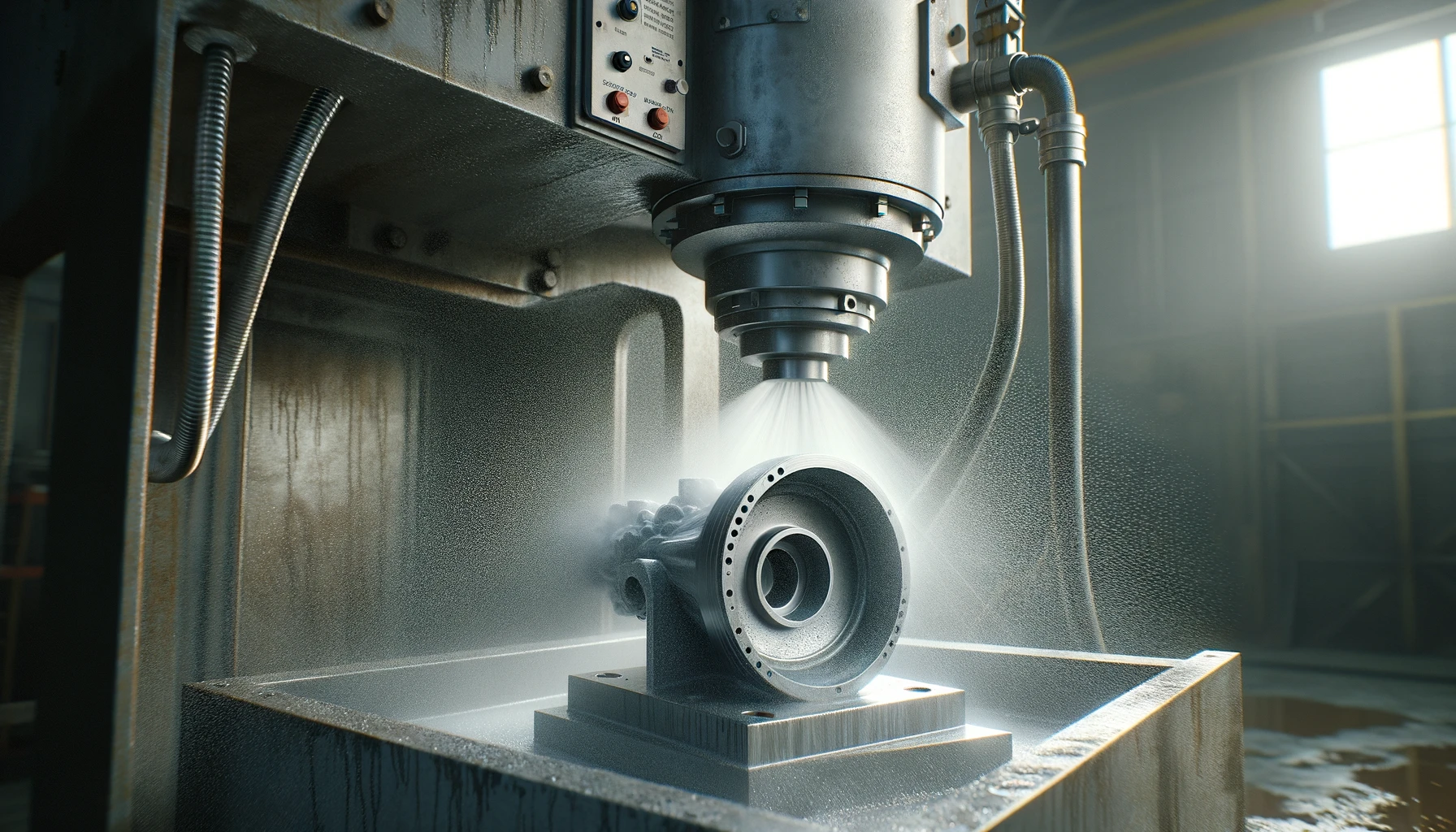

Bead blasting stands as a transformative surface finishing technique within the CNC machining process, utilizing fine glass beads or other media blasted at high velocity to clean or modify the surface of a workpiece. This method is renowned for its ability to remove surface imperfections and provide a uniform, matte finish without compromising the integrity of the workpiece. Its application spans across various sectors, including automotive, aerospace, and medical devices, where a high-quality finish is paramount.

The practicality of bead blasting lies in its versatility. It can be employed to prepare surfaces for painting or coating, remove rust and scale, or simply enhance aesthetic appeal. The process is particularly advantageous for intricate parts where precision and uniformity of the surface finish are crucial.

Data Table: A comparison of bead blasting with other surface finishing techniques:

| Technique | Finish Quality | Processing Time | Cost | Application Range |

|---|---|---|---|---|

| Bead Blasting | High | Medium | Moderate | Wide |

| Sand Blasting | Medium | Fast | Low | Limited |

| Electro-polishing | Very High | Slow | High | Metals Only |

| Powder Coating | High | Medium | Moderate | Metals & Plastics |

| Anodizing | High | Medium | High | Metals Only |

This table illustrates the nuanced differences between bead blasting and alternative methods, highlighting its balanced approach to quality, efficiency, and cost.

Challenges in Technological Integration: Difficulties of Combining Bead Blasting with Face Milling in CNC Machining

Integrating bead blasting and face milling into a cohesive CNC machining workflow presents a unique set of challenges. The primary difficulty lies in maintaining the integrity of the finely milled surfaces post-bead blasting, ensuring that the surface finish and dimensional accuracy are not compromised. Additionally, the transition between these two processes must be seamless to avoid bottlenecks in production, which requires precise coordination and control within the CNC machining environment.

Another challenge is the selection of appropriate parameters for both processes to match the specific requirements of each workpiece. This includes choosing the right type of beads for blasting and the optimal milling cutter geometry, which can vary widely depending on the material and the desired finish.

Data Table: Challenges and solutions in integrating bead blasting and face milling:

| Challenge | Impact | Solution |

|---|---|---|

| Maintaining surface integrity | Potential compromise of finish quality | Optimized process parameters & sequencing |

| Seamless process transition | Production bottlenecks | Advanced workflow management systems |

| Parameter selection for each process | Inconsistencies in final product quality | Comprehensive material and process testing |

This table encapsulates the critical considerations and strategic responses required to effectively combine bead blasting and face milling in a CNC machining context.

Optimizing the Machining Process: Strategies for Enhanced Efficiency and Quality

In the quest to optimize CNC machining processes, particularly when integrating advanced techniques like bead blasting and face milling, manufacturers are constantly exploring strategies that enhance efficiency and elevate product quality. One such strategy involves the implementation of smart manufacturing principles, leveraging IoT (Internet of Things) and AI (Artificial Intelligence) to achieve real-time monitoring and adaptive control of machining processes.

Automation plays a pivotal role in this optimization effort, allowing for seamless transitions between different machining stages and reducing manual intervention. This not only speeds up the production cycle but also minimizes the potential for human error, leading to consistently high-quality outputs.

Case Study: A leading automotive parts manufacturer in China adopted an integrated CNC machining system that combined bead blasting and face milling with automated loading and unloading mechanisms. This integration led to a 30% increase in production efficiency and a significant improvement in the surface quality of engine components, showcasing the tangible benefits of process optimization in a high-volume manufacturing environment.

Case Studies: Chinese CNC Machining Enterprises Successfully Applying Bead Blasting and Face Milling Techniques

The adoption of bead blasting and face milling in China’s CNC machining sector has led to numerous success stories, where companies have not only overcome technical challenges but also achieved remarkable improvements in product quality and manufacturing efficiency.

Case Study 1: A renowned Chinese medical device manufacturer implemented bead blasting in conjunction with face milling to produce surgical instruments. The precise control over the surface finish and material removal allowed for the production of instruments with enhanced durability and performance, meeting the rigorous standards of the medical industry.

Case Study 2: In the aerospace sector, a Chinese CNC machining facility specializing in aircraft components adopted face milling followed by bead blasting to achieve superior surface finishes. This process enhancement resulted in components that exhibited better fatigue resistance and adherence to tight tolerances, crucial for aerospace applications.

Data Table: Summary of key improvements from case studies:

| Company | Industry | Efficiency Improvement | Quality Metrics |

|---|---|---|---|

| Automotive Parts Manufacturer | Automotive | 30% increase | Surface finish uniformity |

| Medical Device Manufacturer | Medical | 20% faster production | Instrument durability |

| Aerospace Components Facility | Aerospace | 25% reduction in rework | Fatigue resistance, tolerances |

These case studies exemplify the strategic application of bead blasting and face milling in enhancing the capabilities and outcomes of CNC machining processes.

Looking Ahead: Pushing the Boundaries of Innovation in China CNC Machining

As China continues to assert its position as a global manufacturing powerhouse, the CNC machining sector stands at the cusp of further transformative changes. Innovations in material science, combined with advancements in digital manufacturing technologies, are poised to redefine what’s possible in CNC machining.

The integration of bead blasting and face milling techniques will continue to evolve, with future trends likely focusing on even greater precision, efficiency, and sustainability. The adoption of environmentally friendly materials and processes, along with the further automation and digitization of manufacturing workflows, will drive the next wave of innovation in this field.

The potential for AI-driven predictive maintenance and process optimization promises to further enhance the efficiency and reliability of CNC machining operations, ensuring that China’s manufacturing industry remains at the forefront of technological advancement and competitive excellence.

Other Articles You Might Enjoy

- Understanding Bead Blasting in CNC Machining(face milling Rex)

Bead blasting, an abrasive process used within various manufacturing industries, plays a critical role particularly with Computer Numerical Control (CNC) machining to create precise, smooth finished components. Whether it’s for…

- Rapid Prototyping with CNC Machining: High-Quality Stainless Steel Parts

Rapid Prototyping and CNC Machining: A Brief Overview Both Rapid Prototyping and Computer Numerically Controlled (CNC) Machining represent transformative technologies within the realm of manufacturing. Rapid Prototyping refers to techniques…

- Exploring the Limits of CNC Machining with Exotic Metal Alloys

Introduction: CNC Machining and Exotic Metal Alloys CNC machining involves the use of computers to control machine tools, enabling precision manufacturing. A critical aspect of this technology lies in material…