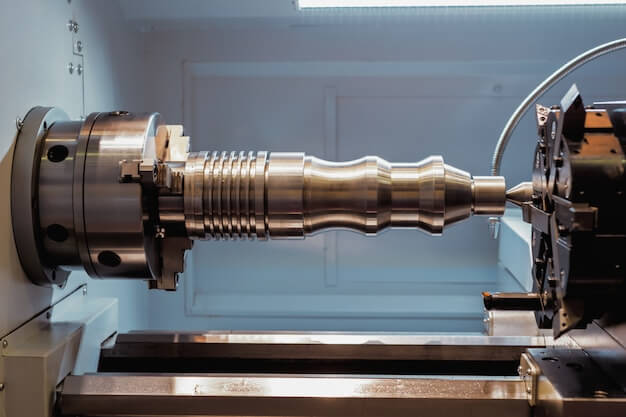

In the realm of Computer Numerical Control (CNC) machining – one of today’s hottest techniques for precision metal production – a couple of discussions are as old as time. One is the ongoing debate between using a Tig welder versus a Mig welder, and another surrounds the use of chamfers over fillets or vice versa during the fabrication process. These debates result from the inherent differences in these processes’ application efficiencies, costs, and result quality.

Welding Techniques: TIG Vs MIG

Tungsten Inert Gas (TIG) welding and Metal Inert Gas (MIG) welding are two dominant players in CNC machining and sheet metal fabrication. Both types have their advantages but differ significantly in operation.

TIG welding demands a high skill level offering stronger, higher-quality welds with no spatters to clean up. It deploys non-consumable tungsten electrode and an external gas supply protecting the welding area from atmospheric contamination which ensures clear-cut, tight finish on thin materials. However, it requires both hands, slows down production speed, may not work well on rusty metals and can be costly.

On the other hand, MIG welding uses a consumable wire fed through the welding gun acting as an electrode and filler material that might make it more suitable for thicker pieces and large-scale projects. Notably, its simplicity, versatility, quicker deposition rates and ability to handle different types of metals including aluminium boosts productivity. But they could leave behind slag requiring additional cleanup compared to TIG welding and should ideally be used indoors due to sensitivity to wind.

While both methods belong to the arc-welding category, they’re best suited for specific applications depending upon cost-effectiveness, job demands, material surfaces being welded, aesthetic requirements, and worker expertise available.

Chamfer Vs Fillet in Sheet Metal Fabrication

The world of sheet metal fabrication sees a lot of corners and edges, which are better off with an enhancement for safety, aesthetic, and functional reasons. This is where chamfers and fillets come into play.

A chamfering operation in CNC machining involves cutting away material to create an angled or bevelled edge between two surfaces on the workpiece. Chamfers are often used to facilitate part assembly, reducing sharpness and eliminating burrs from previous operations, preparing parts for welding applications and sometimes purely for aesthetics. However, they can make parts more structurally vulnerable to cracking at the vertices due to stress concentration.

As opposed to this, a fillet refers to rounding-off interior or exterior corners. Fillets not only enhance appearance but also strengthens angles against shock and cyclical loading by distributing stress along the rounded rather than focused edge thereby improving fatigue life.

Primarily, it comes down to design specifications, functionality requirements and production considerations whether one employs chamfers or fillets during the manufacturing process. It’s crucial to optimize these factors while maintaining cost effectiveness without compromising quality within necessary timeframes.

This dichotomous exploration has provided us with valuable insights into some of the core elements of CNC machining – TIG vs MIG and Chamfer vs Fillet. As always, both debates offer advantages and drawbacks depending on different scenarios. Like most aspects of engineering, the decisions depend heavily on specific application requirements and cost-benefit trade-offs.

If you’re embarking upon or working around CNC machining processes, be sure to familiarize yourself with each method’s intricacies and capabilities to choose what’s best suited for your project. Remember that excellence lies in attention to details.

Other Articles You Might Enjoy

- Prototype CNC Machining of Brass: Reliable and Affordable Services

Introduction to Prototype CNC Machining of Brass In the world of manufacturing, prototype CNC machining plays a crucial role. This technology-based process brings ideas into tangible reality by creating precise…

- Precision CNC Machining: Brass vs. Aluminum - Which Material Suits Your Project?

Precision CNC Machining: Overview and Material Selection CNC machining, an acronym for Computer Numerical Control machining, is a process in the manufacturing sector that involves the use of computers to…

- Custom CNC Machining Brass Components with Rapid Turnaround

Introduction to Custom CNC Machining Brass Components Custom Computer Numerical Control (CNC) machining is a precision manufacturing process employed in various industries. During this process, predetermined computer software dictates the…