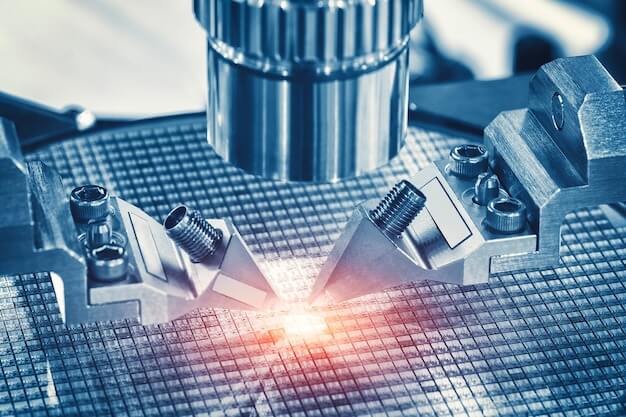

CNC, or Computer Numerical Control, is an efficient technologically advanced method in the manufacturing industry that has transformed many aspects of production. One specific application where CNC methodology truly shines is in CNC turning – an integral process involved in shaping various materials.

When we talk about CNC turning,it’s a subtractive machining processes where material is gradually removed from a workpiece until it attains its final design. The removal of the material occurs as the workpiece rotates on an axis amidst multiple cutting operations like drilling, grooving, threading, etc. Material types suitable for this technique extend across various domains, including metals such as steel and brass, along with plastics like ABS and nylon.

The beauty of CNC turning lies in the tight tolerances and excellent repeatability it offers while producing cylindrical parts.The controls programmed into the computer ensure very little variation between parts, ensuring consistency and high quality over long runs. With CNC turning, complex designs which might have been impossible to achieve manually can be easily realized,this makes it practical for creating intricate custom components cost-effectively.

In contrast, rivets – especially their various types – provide a different approach towards fabrication. Not primarily involving technology, they rely more on traditional methods but are no less significant within the broader context of manufacturing. Rivets have been used for hundreds of years to secure objects together, usually two metal sheets. They consist of a smooth cylindrical shaft with a head on one end, which upon installation flattens out enabling the fastened joint security.

There’s a wide array of types when you consider rivets. Some include solid (or round) rivets, semi-tubular rivet, blind rivets,and flush rivets. Each type comes with unique features tailor-fit for various situations.

Solid rivets, amongst the oldest of its kind, involve placing the tail through holes in the pieces being joined. We then hammer or otherwise deform the tail until it expands, approximately 1.5 times its original diameter, holding everything together – a process known as ‘upsetting’. These rivets provide strong, reliable joints and are widely used in aircraft structures.

Semi-tubular rivets, on the other hand, only partially extend through the items, making them ideal when working with softer materials like leather or fabric. They’re designed to create consistent, strong fastenings while reducing deformation risks.

Blind rivets have specially-designed features where you can install them from one side of the workpiece,a beneficial aspect in hard-to-reach places.Finally, flush rivets lie uniformly against the surface of the material they’re embedded into – perfect for applications where smoothness is critical, such as aerodynamics involving airframes.

In terms of production, manufacturing these rivets would require techniques like hot/cold forging, impact extrusion, CNC machining,and head forming. Though each method seems different, most would involve heating the base metal (if required), placing it under a die or mold specific to the desired shape, and applying extreme pressure until the metal forms into that shape—the efficiency differs based on what type of rivet we aim to produce.

Combining both CNC turning technology’s precision and the sturdy reliability brought about by different types of rivets offers an interesting avenue in various industries’ production plans.Conclusively, syncing up high-tech processes with traditional practices may well be key to innovative advances in manufacturing design and capability.

Other Articles You Might Enjoy

- Innovative CNC Machining for Custom Medical Instruments

Innovative CNC Machining for Custom Medical Instruments Computer Numeric Control (CNC) machining is an innovative automated process that utilizes computer software to control machine tools. The use of CNC machines…

- Aluminum Parts Machining: CNC Techniques for Precision and Efficiency

Introduction to Aluminum Parts Machining and CNC Techniques In the manufacturing industry, the machining of aluminum parts plays a crucial role for its effortless machinability which makes it an ideal…

- Tool Steel Grades in CNC Machining: Which One Should You Choose for Durability?

Introduction to Tool Steel in CNC Machining In the realm of CNC (Computer Numerical Control) machining, tool steel reigns supreme due to its exceptional durability and versatility. As a broad…