CNC (Computer Numerically Controlled) machining is a popular type of subtractive manufacturing technology. Among the various types available, CNC turning stands out due to its efficiency and versatility. On the other hand, rivets, a commonly used permanent mechanical fastener, come in numerous types as well. This article provides an overview of both subjects.

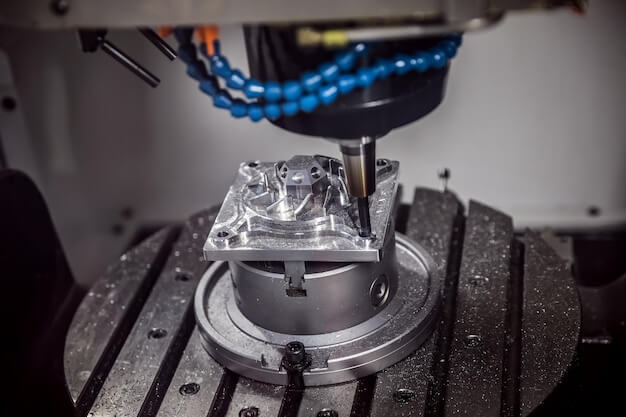

Firstly, let’s look at CNC turning which involves cutting material with a computer-controlled lathe. These machines are equipped with a rotating drive known as a chuck that holds a piece of material up against a tooling bit. The machine then rotates, or ‘turns’, while the cutting instrument maneuvers around it, slicing off chips of metal until the desired shape has been brought forth from the original blank.

CNC turning can be split into two base operations; outer diameter (OD) turning and Inner Diameter (ID) turning. Each operation serves a specific purpose, but both follow similar principles. The main difference lies in the directionality of the cutting action, either from outside-in during OD machinings or inside-out on ID work.

This exquisitely detailed carving capability makes CNC turning ideal for creating cylindrical parts like shafts, hubs, pulleys, wheels, even musical instruments. It is renowned for high precision — a key requirement in industries such as aerospace, automotive, medical manufacturing, and more.

Production using CNC turning typically follows a multi-step process starting with CAD modeling where engineers draft a 3D model of the end product. Then comes CAM programming, where software strategizes the required tool paths. Post-processing converts this strategy into G-code which is then sent to the CNC machine. After set-up, trial runs, and adjustments, optimal performance yields finished products.

Now onto rivets. Defined principally by characteristics like head style, body size, and materials used, rivet classifications broadly include blind rivets, solid rivets, semi-tubular rivets, and split rivets.

1. Blind Rivets: Easiest to install among the lot, blind rivets are so named because they can be installed from just one side of an assembly,”blind” to the opposite side.

2. Solid Rivets: Most robust in sturdy applications spanning bridges to aircraft, solid rivets have a smooth shaft and come in round-head, flat-head, or countersunk styles.

3. Semi-Tubular Rivets: Lighter yet strong, semi-tubular rivets feature a partially hollow body that reduces materials and costs while still offering stable attachment when set.

4. Split Rivets: With legs similar to tacks, but separating upon installation, split rivets create a secure bond in woodworking or leatherworking where head visibility is less of a concern.

Production methods for each type vary. For instance, blind rivets are produced by pushing the mandrel into the rivet shell then heat treating it for strength. In contrast, solid rivets go through processes such as heat treatment, cold-heading, and shank reduction before reaching their finished state.

In summary, CNC turning is a versatile manufacturing method providing precision and efficiency — ideal for producing parts with high complexity, while the various types of rivets cater efficiently to specific fastening requirements across broad industrial spectra. Both offer unique value propositions making them stalwarts within their respective domains.

Other Articles You Might Enjoy

- CNC Machining with Exotic Alloys: Are They a Game Changer for Your Production?

Introduction: CNC Machining and Exotic Alloys CNC (Computer Numerical Control) machining is a manufacturing process that employs pre-programmed computer software to dictate the movements of factory tools and machinery. It…

- Precision CNC Machining of Brass: Custom Solutions for Every Industry

Introduction: Understanding Precision CNC Machining of Brass The advent of Computer Numerical Control (CNC) technology has revolutionized the manufacturing industry, offering exceptional precision and efficiency. This method utilizes computer-programmed commands…

- Innovative CNC Machining for Custom Medical Instruments

Innovative CNC Machining for Custom Medical Instruments Computer Numeric Control (CNC) machining is an innovative automated process that utilizes computer software to control machine tools. The use of CNC machines…