Bead blasting is an outstanding technique used extensively in most industries that demand a high-quality finish, encompassing those as diverse as auto manufacturing to aerospace. This article aims to shed light on bead blasting and its application especially within CNC (Computer Numerical Control) machining.

Firstly, it’s crucial to understand what bead blasting entails. It’s oftentimes conflated with sandblasting but, although they share similarities, they’re fundamentally different processes. Bead blasting involves propelling tiny beads made from materials such as glass, ceramic or steel at a high velocity towards a surface. The primary goal behind this process is to clean, deburr, enhance appearance by producing uniform surfaces, remove rust, or prepare metal surfaces for other operations.

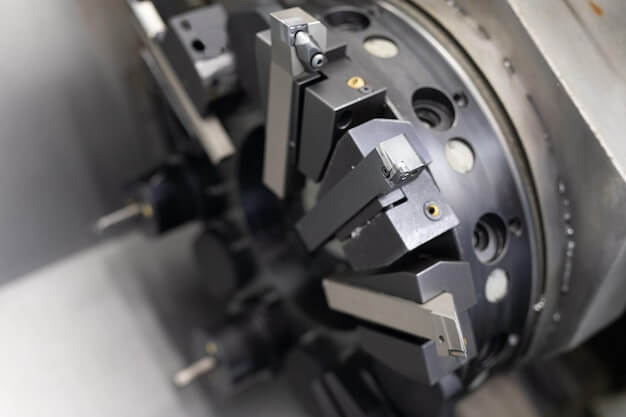

In the grander scheme, bead blasting forms part of the finishing techniques utilized in the realms of CNC machining. As a computer-controlled process that enables manufacturers to produce components from varying types of material bars accurately and quickly, CNC machining stands as a vital aspect of numerous industries.

Given CNC machining’s aptitude for precision, bead blasting comes into play when these machined parts need improvement in terms of texture and aesthetic appeal. Pieces fashioned using CNC machining range from simple items like screws and bolts to ingenious complex designs found in robotics and aviation. However, despite their complexity or simplicity, all these products go through various forms of finishing processes, with bead blasting being one prime example.

The importance of bead blasting can be seen most significantly in industries requiring superlative finishes, where not merely functionality matters but also aesthetics. Utilizing this technique helps boost component life span, adds resistance against corrosion, aids paint adhesion, and brings out the sheen desired in most end-products.

To conduct bead blasting in the CNC machining industry, specialized equipment is mandatory. Comprising mainly of three elements, which are the blasting cabinet, air compressor, and blasting media (beads), this kit aids essential operations. A CNC machined part is positioned within the secure environment of the blasting cabinet where beads are projected onto the piece with significant force using the air compressor.

The type of bead utilized in the process depends on several aspects. Glass beads proceedings attain a smooth finish without altering dimensions, fitting when precision ranks paramount. Steel shots or grits serve well for aggressive cleaning or etching if an added roughness is favored; finally, ceramic beads derive premium resilience and performance especially crucial for industrial applications that demand exceptional durability.

Bead blasting might appear to be simply about propelling tiny elements at high speed toward a surface; however, it involves more than the eye can see—a finite understanding of the material being worked upon, precise control over the technique, equipment proficiency, and broad awareness of safety protocols. These skills tend to accumulate with experience and expertise facilitating one to acquire accurate knowledge regarding choosing a specific kind of blast medium, pressure settings, moving patterns, and optimum stand-off distance to accomplish desired outcomes successfully.

In sum, bead blasting serves as a critical cusp between the creation and finalization phases in the manufacturing industry—more so within CNC machining. It offers components not just a visual appeal but also longevity and improved functionality. Hence, despite often going unnoticed by end users, experts understand its huge significance that plays a silent yet vital role in making products better address their purposes and last their maximum potential duration. Integrating bead blasting into any production line surely manifests technical craftsmanship balanced with a touch of artistic aesthetics—not mere companions, but rather two sides of the very same coin.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(cnc machining services china Nicole)

Bead blasting is a process used extensively in the world of computer numerical control (CNC) machining. A standard part of many businesses, bead blasting enriches various products that we use…

- Tool Steel in CNC Machining: D2 vs. A2 - A Comparison of Durability and Performance

CNC Machining and the Importance of Tool Steel Computer Numerical Control, commonly referred to as CNC machining, is a high-precision manufacturing process where pre-programmed computer software dictates the movement of…

- Unraveling Bead Blasting Process in CNC Machining(cnc machining china Sid)

Bead blasting is a significant process within the realm of Computer Numerical Control (CNC) machining, providing numerous industries with quality finishes for various types of products. From aircraft parts to…