Bead blasting is a process often used in CNC (Computer Numeric Control) machining to provide finished components with an aesthetically pleasing, uniform texture. As technology continues to advance, precision and quality become even more crucial; bead blasting serves as a practical solution for achieving these goals.

The process of bead blasting in CNC machining involves shooting small glass beads at a surface using high pressure without damaging the surface itself. It’s often compared to sandblasting but provides a smoother finish due to the roundness of the beads rather than rough, irregular sand particles.

This technique is employed primarily in industries where high precision matters, such as aerospace, automotive, electronics, and medical manufacturing. But how exactly is this method performed within the CNC machining process? Let’s delve deep into the world of bead blasting to uncover its secrets.

Preparing for Bead Blasting

Before anything else, it’s important that the component or material to be bead blasted is thoroughly cleaned. The removal of oils, grime, and any coating effectively enables the bead blasting approach to have better adhesion to the material, resulting in a more accurate finish.

Subsequently, the operator will select the appropriate type and size of glass beads apt for the application. Smaller beads offer a finer finish with lower metal removal, while larger beads are typically used when heavy-duty cleaning is required on tougher surfaces.

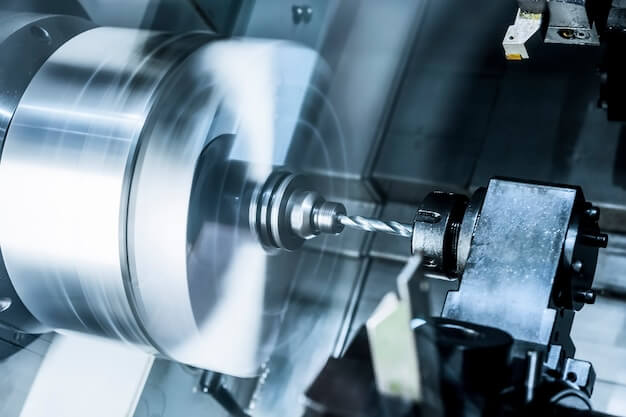

Implementing Bead Blasting in CNC Machining

CNC controlled bead blasting machines offer significant advantages over manual operations. The level of control allows for precise targeting of areas to be treated, with consistency in terms of bead distribution and air pressure. This results in an identical outcome across multiple workpieces – an element critical in many manufacturing applications.

During this process, the use of CNC facilitates commanded movements wherein pressurised streams of bead-mixture target specific sections of the part based on predefined calculations. By integrating the bead blasting process into the CNC machining workflow, manufacturers can significantly enhance aesthetics while increasing resistance to corrosion and other forms of common wear and tear.

Benefits of Bead Blasting

Using bead blasting in CNC endeavours has notable advantages including boosting surface hardness, enhancing fatigue resistance, improving bonding for coatings or paints, and providing a sterile surface for medical applications.

Industries such as aerospace and automotive also value bead blasting due to its capacity to remove burrs from machined parts without disturbing dimensional tolerances, a crucial attribute when manufacturing components that must fit together with exceptional precision.

Bringing it Together

Overall, when integrated properly within the larger context of a CNC machining operation, bead blasting becomes an integral part of high-precision, high-quality component production. Its contribution cannot be overstated, particularly when one considers the comprehensive scope of industries requiring these exacting standards – from the tiniest circuit board elements to massive aircraft engines.

The world of CNC continues to evolve mediating newer practices. As advancements proceed, methods like bead blasting will only become more relevant, helping to set the benchmark for excellence in multiple industrial sectors. Remember, precise processes provide perfect products!

Other Articles You Might Enjoy

- Unlocking the Potential of Bead Blasting in CNC Machining(bending sheet metal Vita)

CNC machining, an acronym for Computer Numerical Control machining, refers to a manufacturing process mainly used in industries involving complex cutting tasks. This sophisticated method utilizes computerized controls and machine…

- Affordable CNC Machining: Quick Turnaround for Prototype Steel Parts

Introduction: The Role of CNC Machining in Manufacturing Steel Parts CNC (Computer Numerical Control) machining is a pivotal factor in manufacturing steel parts, providing significant benefits ranging from precision to…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…