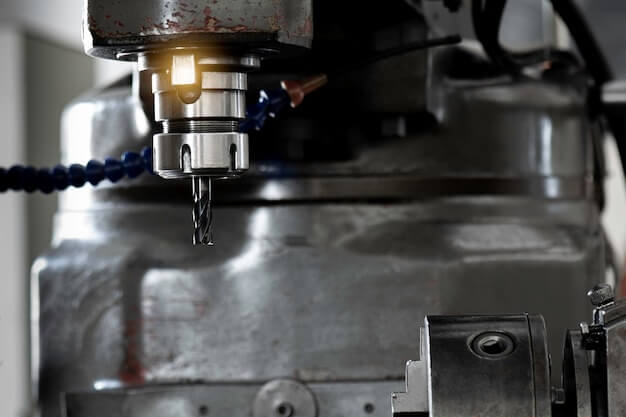

Bead blasting is a critical process used in Computer Numerical Control (CNC) machining to create high-precision parts. It provides an aesthetic finish and removes surface flaws, enhancing the functionality of components. Like many aspects of the broader manufacturing sector, bead blasting underscores the crucial role efficiency plays in product development. Today we will delve further into this procedure, how it operates alongside CNC techniques, its applications, and benefits for contemporary industrial production.

Bead blasting involves forcefully propelling a stream of abrasive bead materials against a component surface under high pressure. The technique is essential in cleaning, finishing, or peening surfaces within varied industries including automotive, aviation, fabrication, and more. Accomplished through either manual or automated systems, there are several types of machines and variations of bead material that can be used depending on the desired finished quality.

Integration with CNC machining processes has only increased the efficiency and precision of bead blasting. By programming instructions into the CNC, manufacturers can control exact speed, pressure, and coating consistency, benefiting from impressive accuracy levels unrivaled by human capabilities alone. This translates not only into greater uniformity in finishes but also significant time and cost savings.

While bead blasting isn’t a product itself, it’s integral to producing numerous items requiring smooth, clean finishes free from burrs or imperfections. For instance, stainless steel parts commonly found in the food processing or medical sphere receive their spotless, shiny appearance due to proper bead blasting. Likewise, premium car parts yield enhanced durability and performance due to the improved bonding characteristics resulting from effective bead blasting.

To execute bead blasting in a CNC machine set up accurately, firstly, drawings and specifications define necessary dimensions and features of the piece along the path where force should be applied. Then, feed rate – the speed at which the cutting tool engages the workpiece – and other variables like the pressure and temperature, need to be set. All these guidelines are then programmed into a CNC machine that applies them with meticulous precision.

Integrated bead blasting has several advantages in CNC machining:

• Surface Cleaning: Bead blasting effectively eliminates surface contaminants like rust or old paint from the workpiece, preparing it for subsequent treatments.

• Finishing: It helps achieve varying degrees of surface finishes – from matte to glossy – enhancing aesthetic appeal.

• Enhancing Bonding Capabilities: Through creating a ‘rough’ surface texture, bead blasting promotes better adhesion when coatings or paints are applied subsequently.

• Improving Durability: Stress relief provided by bead blasting increases overall component longevity and performance.

Finally, safety considerations and environmental responsibilities must not be overlooked while performing bead blasting within any setting. Appropriate measures should be taken to prevent eye injuries, respiratory issues, and skin irritation, which can result from exposure to fast-traveling abrasive materials. Moreover, recycling beads and other resources whenever possible helps minimize waste generation.

In summary, bead blasting is an indispensable procedure within the manufacturing sector, particularly when utilized in conjunction with computer-controlled accuracy offered by CNC machining. Guaranteeing enhanced visual appearance and improved functionality of products, this technique continues to revolutionize procedures within industries dependent on smooth finishing and exactness.

Other Articles You Might Enjoy

- Exploring Bead Blasting in CNC Machining(torsion snap joint Uriah)

Bead blasting is an essential process within the broader umbrella of CNC (computer numerical control) Machining. Understanding its role and functions can provide a unique perspective on manufacturing and production,…

- Precision CNC Machining Services for Aerospace: Specializing in Aluminum

Introduction to Precision CNC Machining Services in Aerospace Precision CNC (Computer Numerical Control) machining is a modern manufacturing technique that uses computer-controlled machine tools to create intricate parts with extreme…

- Challenges and Solutions in CNC Machining of Hardened Steels for Tool and Die Making

Introduction to CNC Machining and the Challenges of Hardened Steels CNC machining is a crucial process in tool and die making, heavily relied upon for its versatility and precision-driven manufacturing…