In the realm of manufacturing and fabrication, efficient and effective finishing methods can make all the difference. One such process that has been gaining traction is bead blasting—an integral part of Computer Numerical Control (CNC) machining. This article seeks to delve into the specifics of this technique, its applications, benefits, and procedures involved in carrying it out.

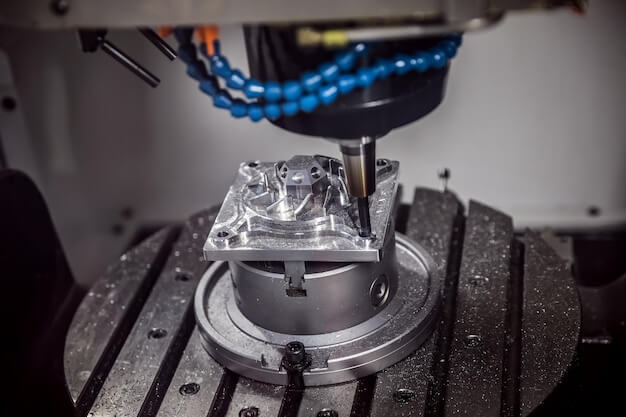

Bead blasting is a surface treatment method primarily used in CNC machining to create a smooth or rough texture on metal parts. It involves the use of high-pressure stream of abrasive materials onto the components, resulting in an evenly coarse finish, ready for coating or further processing. These materials often include tiny spherical beads made from glass, ceramic, or even stainless steel. The choice of bead material depends largely on the application requirements and nature of the substrate being treated.

For companies seeking better control over their products’ final appearance without sacrificing the precision offered by CNC machining, bead blasting serves as an excellent solution. Its diverse capabilities range from eradicating traces of old paint to preparing surfaces for painting; from removing corrosion and tarnish to enhancing the aesthetic appeal of manufactured parts.

Contrary to popular misconceptions, bead blasting isn’t exclusive to getting rid of unwanted residue on components. This technique holds immense potential when employed to alter surfaces’ microscopic properties – such as hardness, elasticity, plasticity – beyond mere aesthetics. Moreover, it aids remarkably in promoting adhesion between coated layers by increasing the component’s overall surface area.

Now, moving towards the question—how exactly is bead blasting carried out? Let’s dive deeper into the procedure.

The first step involves placing the items needing treatment inside a blast cabinet. Then, the beads are introduced at high velocities through nozzles directed at these items. Pressurized air or centrifugal force propels the beads, which subsequently strike against the objects producing sought-after effects. It’s vital to ensure the beads are uniformly distributed over the entire product surface for maintaining consistency.

While the process might seem straightforward, several factors come into play that dictate the outcome quality—most importantly, bead size and blasting pressure. Smaller beads – while capable of producing smoother finishes – also require longer blasting durations than their larger counterparts. Higher pressures will lead to a more rugged or textured finish than lower ones–knowledge of these helps in manipulating the result as desired.

A ensuring safety aspect worth mentioning – due care must be taken during bead blasting. Workers should wear protective clothing and masks to safeguard themselves from airborne particles emitted during the operation. Additionally, using air extraction and filtration systems in the workspace goes a long way in enhancing workers’ safety.

Bead blasting holds an edge amongst various other finishing processes owing to its capacity to cater to a broad spectrum of applications. When combined with CNC machining—the unrivaled precision it delivers is unmatched by traditional manual processing methods. Moreover, it is cost-effective, doesn’t harm the environment, and requires lesser time compared to other techniques—an impetus for its rising popularity amongst manufacturers around the globe.

In conclusion, bead blasting underpins the integrity of the finished products made through CNC machining, refining their appearance, functionality, and lifespan. By understanding the workings of this valuable technique and leveraging it appropriately, manufacturers can transform raw components into refined end-products. In the ever-evolving manufacturing landscape fraught with stiff competition, mastering such intricate processes can indeed become the key to success.

Other Articles You Might Enjoy

- High-Precision CNC Machining for Custom Optical Lenses

Introduction to CNC Machining and its Significance in Custom Optical Lenses CNC - Computer Numerical Control machining, is a highly precise process employed for the production of complex parts with…

- Exploring Bead Blasting in CNC Machining(weld line Wanda)

Bead blasting is an essential component of computer numerical control (CNC) machining. It involves the use of tiny beads under high pressure to smooth out surfaces, deburr parts, remove surface…

- Innovative CNC Machining for Advanced Spacecraft Components

Introduction: CNC Machining and its role in Spacecraft Components Computer Numerical Control (CNC) machining has, over the years, proven to be one of the most integral pillars within manufacturing industries.…

Afrikaans

Afrikaans Albanian

Albanian Amharic

Amharic Arabic

Arabic Armenian

Armenian Azerbaijani

Azerbaijani Basque

Basque Belarusian

Belarusian Bengali

Bengali Bosnian

Bosnian Bulgarian

Bulgarian Catalan

Catalan Cebuano

Cebuano Chichewa

Chichewa Chinese (Simplified)

Chinese (Simplified) Chinese (Traditional)

Chinese (Traditional) Corsican

Corsican Croatian

Croatian Czech

Czech Danish

Danish Dutch

Dutch English

English Esperanto

Esperanto Estonian

Estonian Filipino

Filipino Finnish

Finnish French

French Frisian

Frisian Galician

Galician Georgian

Georgian German

German Greek

Greek Gujarati

Gujarati Haitian Creole

Haitian Creole Hausa

Hausa Hawaiian

Hawaiian Hebrew

Hebrew Hindi

Hindi Hmong

Hmong Hungarian

Hungarian Icelandic

Icelandic Igbo

Igbo Indonesian

Indonesian Irish

Irish Italian

Italian Japanese

Japanese Javanese

Javanese Kannada

Kannada Kazakh

Kazakh Khmer

Khmer Korean

Korean Kurdish (Kurmanji)

Kurdish (Kurmanji) Kyrgyz

Kyrgyz Lao

Lao Latin

Latin Latvian

Latvian Lithuanian

Lithuanian Luxembourgish

Luxembourgish Macedonian

Macedonian Malagasy

Malagasy Malay

Malay Malayalam

Malayalam Maltese

Maltese Maori

Maori Marathi

Marathi Mongolian

Mongolian Myanmar (Burmese)

Myanmar (Burmese) Nepali

Nepali Norwegian

Norwegian Pashto

Pashto Persian

Persian Polish

Polish Portuguese

Portuguese Punjabi

Punjabi Romanian

Romanian Russian

Russian Samoan

Samoan Scottish Gaelic

Scottish Gaelic Serbian

Serbian Sesotho

Sesotho Shona

Shona Sindhi

Sindhi Sinhala

Sinhala Slovak

Slovak Slovenian

Slovenian Somali

Somali Spanish

Spanish Sundanese

Sundanese Swahili

Swahili Swedish

Swedish Tajik

Tajik Tamil

Tamil Telugu

Telugu Thai

Thai Turkish

Turkish Ukrainian

Ukrainian Urdu

Urdu Uzbek

Uzbek Vietnamese

Vietnamese Welsh

Welsh Xhosa

Xhosa Yiddish

Yiddish Yoruba

Yoruba Zulu

Zulu