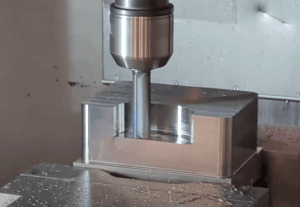

CNC machining, short for Computer Numerical Control machining, is a broad field encompassing various types of production methods such as milling, turning, drilling, and punching. Over the years, evolving technology has vastly improved this sector with two notable additions being the advent of MIG and TIG welding. Another component worth scrutinizing under the lens of CNC machining is sheet metal fabrication, which relies heavily on techniques like chamfering and filleting. In this article, we will deep dive into these concepts, highlighting their importance in CNC machining while contrasting them against each other.

Firstly, let’s tackle TIG versus MIG welding. Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) are both arc welding processes using inert gases for shielding from contamination but carry stark differences.

TIG welding entails the use of a non-consumable tungsten electrode to produce the weld. This method offers incredible control over both the weld and heat, resulting in high-quality, clean welds. However, the sophistication it demands can be quite challenging, making it suited for experienced professionals undertaking projects requiring precision.

On the contrary, MIG welding uses a continuously fed wire that also serves as an electrode. It’s simpler to learn, faster, and more efficient than TIG, making it ideal for larger projects not too preoccupied with aesthetically pleasing outcomes. The choice between TIG and MIG really boils down to the project’s requirements, outlining the need to contrast and compare before settling on a decision.

Secondly, within sheet metal fabrication – another crucial aspect of CNC machining – we encounter terms like ‘chamfer’ and ‘fillet’. These are methodologies employed to enhance workpiece aesthetics, decrease stress concentration or simplify the assembly process.

Chamfers are transitioning edges produced between two faces of a piece, often at 45-degree angles. Chamfering, in essence, makes the device safer to handle by eradicating potentially hazardous sharp edges and corners. In terms of assembly, chamfers make it easier to align parts, making them especially crucial in high-precision applications like engine components.

Fillet, on the other hand, is the process of smoothing an interior or exterior corner of a workpiece. Its specific usefulness lies in reducing stress concentration within the unit, ensuring long life and robust performance. Petticoat fillets are also favored for their aesthetic value as they enhance workpiece visual appeal.

The application of these CNC machining processes varies with each product being manufactured. However, whether it’s TIG welding, MIG welding, sheet metal fabrication, chamfering, or filleting, these processes all hinge on precision and accuracy.

In conclusion, understanding the nuances of TIG versus MIG welding and knowing when to choose between chamfering or filleting can ensure quality production outcome in CNC machining projects. Regardless of the approach you decide on, producing a superior end-product always requires insightful decision-making based on careful consideration of project requirements.

Other Articles You Might Enjoy

- Choosing the Right CNC Machining Shop: Factors to Consider

Choosing the Right CNC Machining Shop: An Introduction In today's advanced manufacturing environment, Computer Numerical Control (CNC) machining plays a significant role. CNC machining is a process utilized in the…

- Understanding CNC Machining: MIG vs. TIG Welding and more( cnc machining services china Julie)

Computer Numerical Control (CNC) machining has remarkably revolutionized the manufacturing industry by offering precise, efficient, and versatile solutions that cater to a range of products. Within this realm of production…

- Understanding CNC Machining: TIG vs. MIG Welding and More( g code cnc Hedy)

Computer Numerical Control (CNC) machining is a manufacturing process that uses pre-programmed computer software to control the movement of machinery, enabling precision in production tasks such as cutting, milling, drilling,…